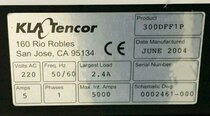

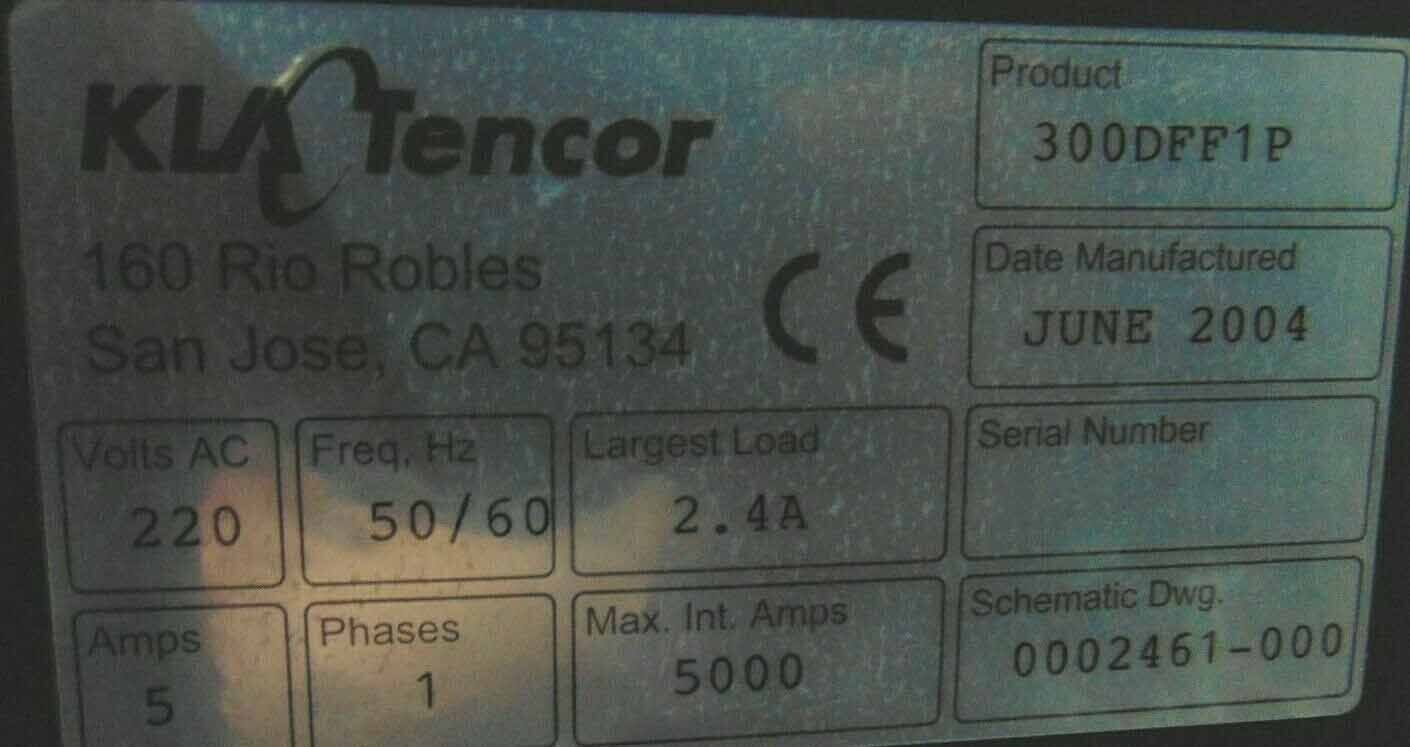

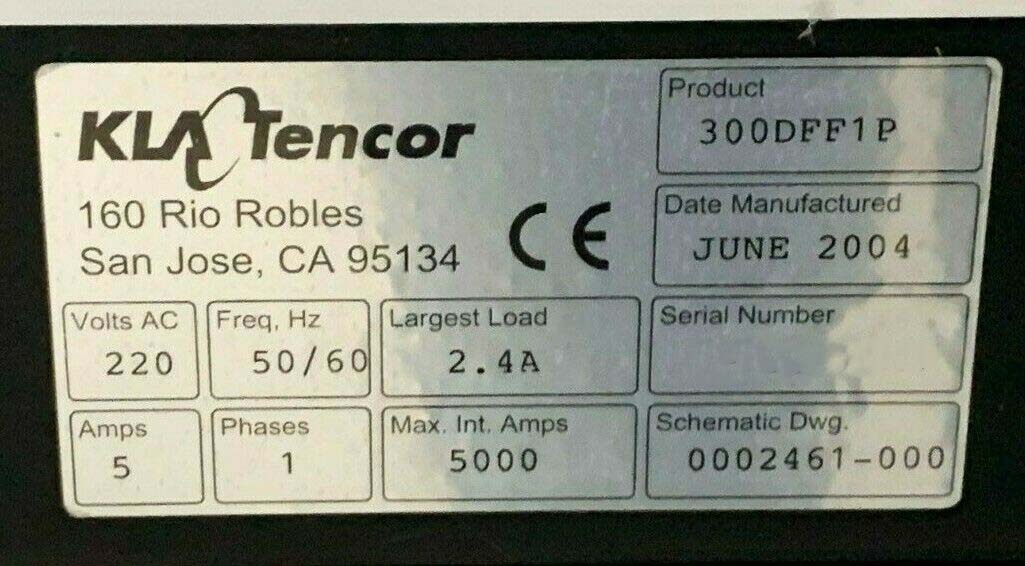

Used KLA / TENCOR 300DFF1P #9283029 for sale

URL successfully copied!

Tap to zoom

ID: 9283029

Wafer Size: 12"

Vintage: 2004

Handler, 12", parts machine

EFEM Loader assembly

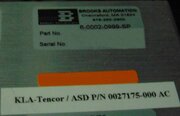

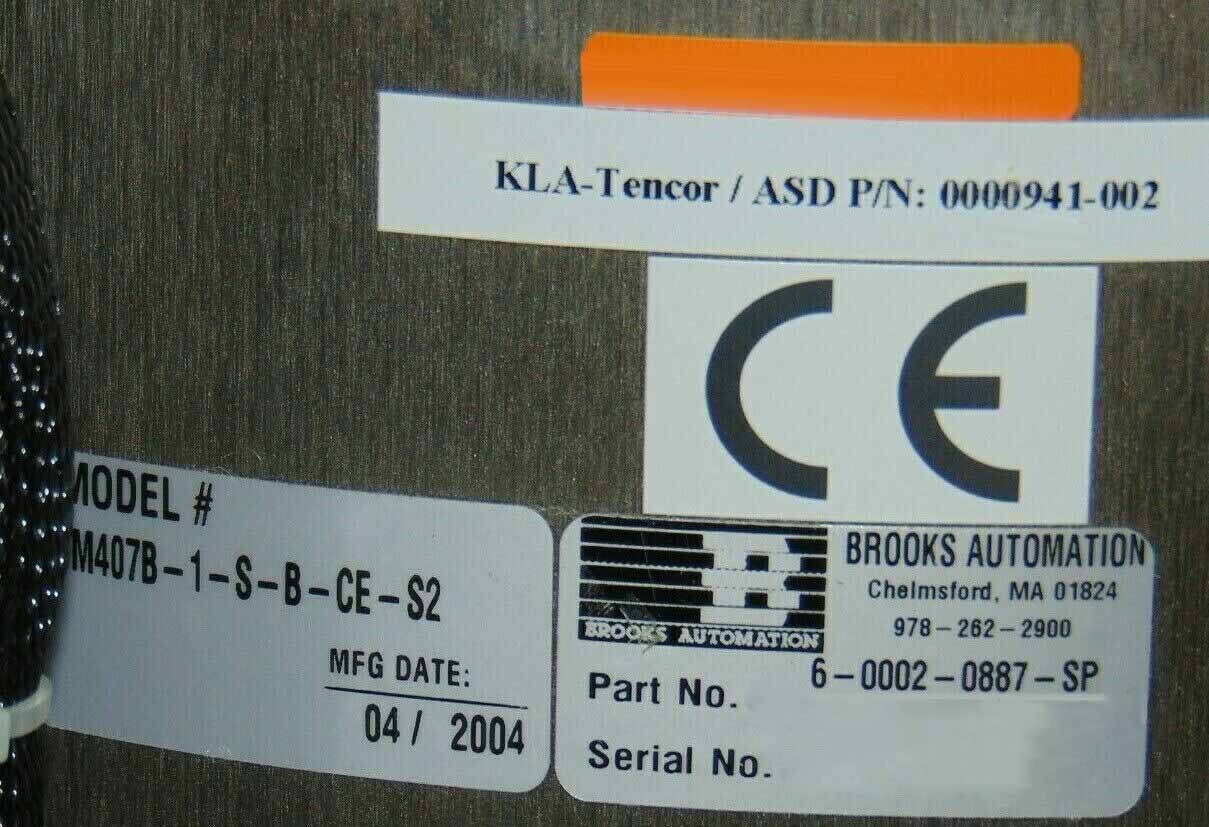

BROOKS / ABM407B-1-S-B-CE-S2 / 6-0002-0887-SP Robot for KLA / TENCOR 0000941-002

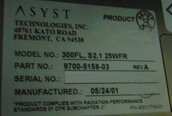

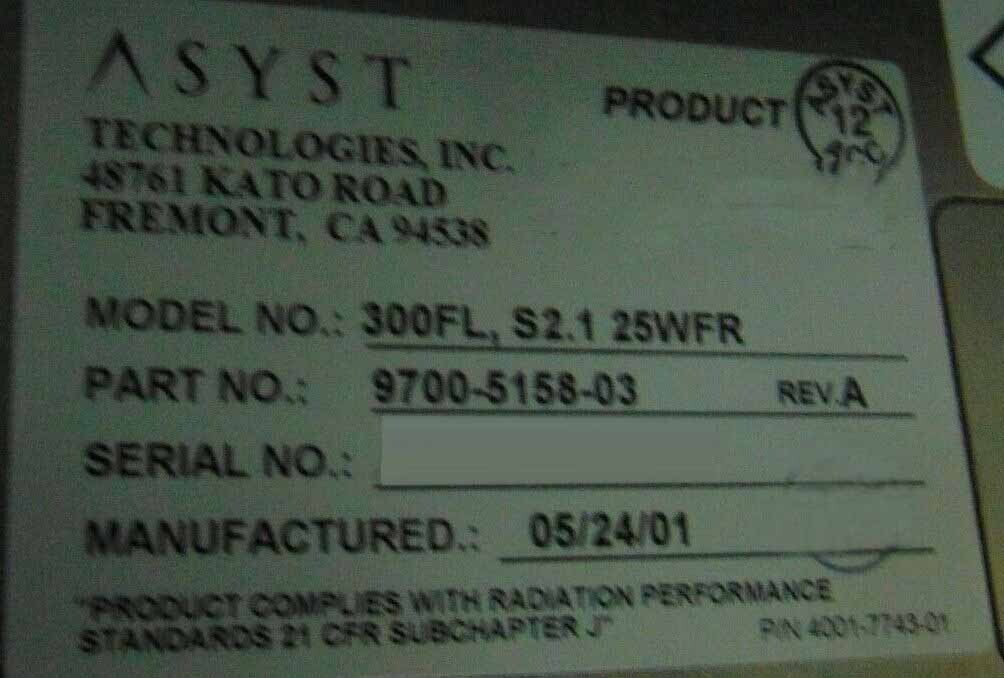

ASYST / 300FL / S2.1 / 25WFR / 9700-5158-03 Load port

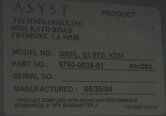

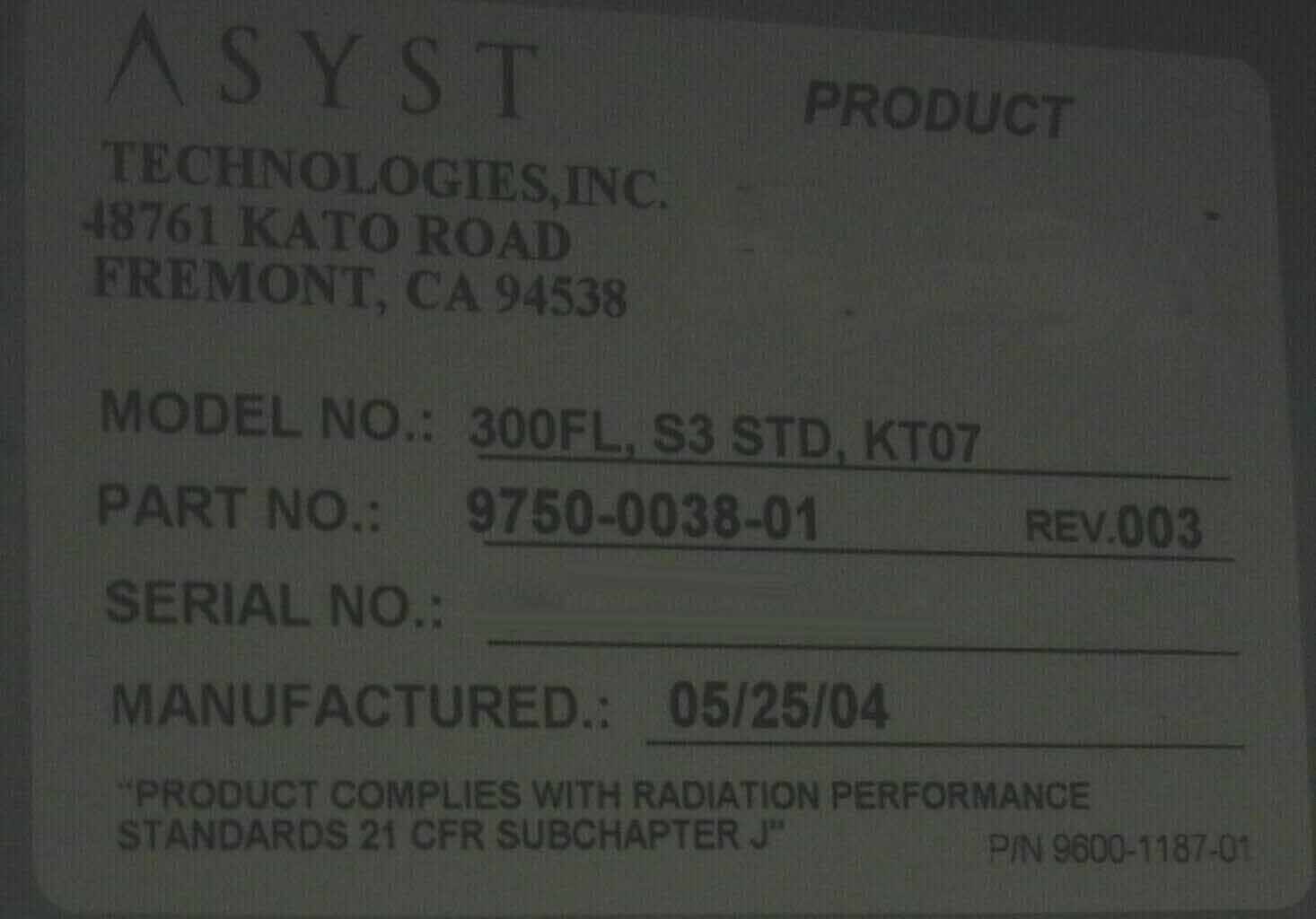

ASYST / 300FL / S3 STD / KT07 / 9750-0038-01 Load port

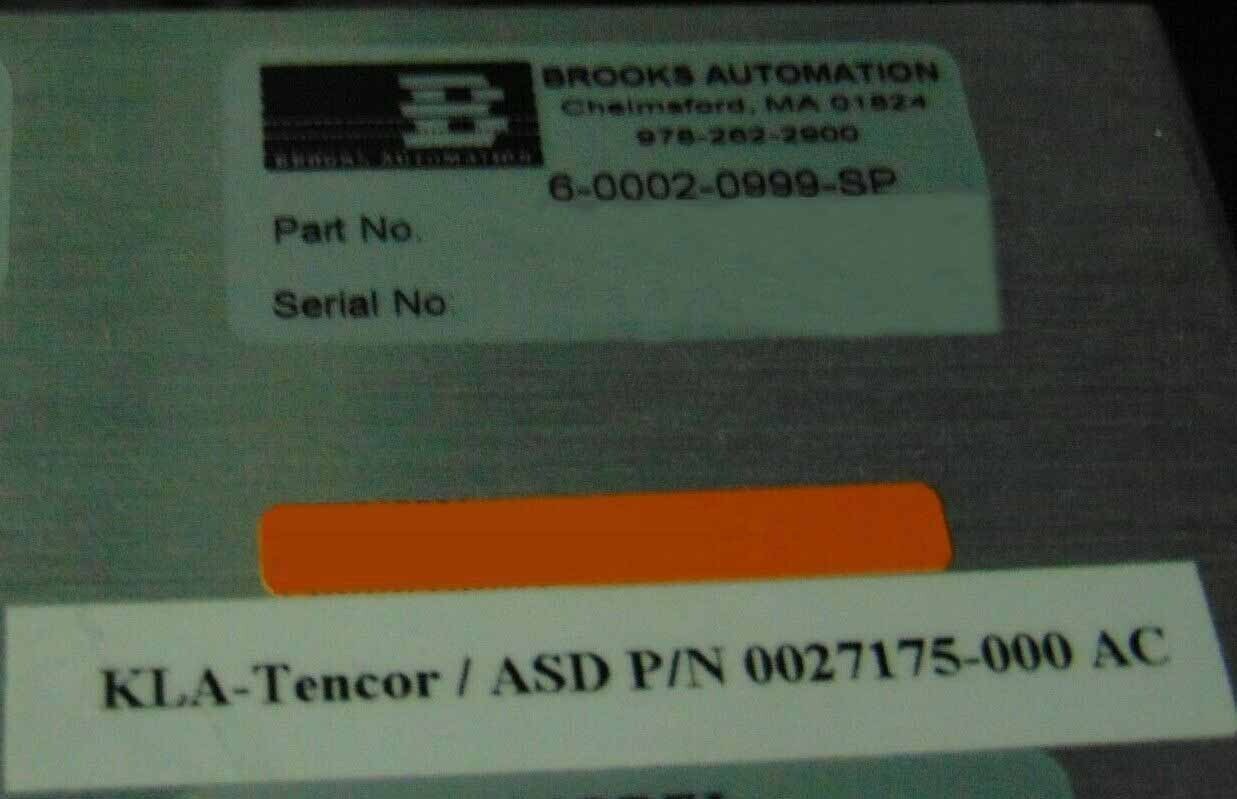

BROOKS / - / 6-0002-0999-SP / Robot rail for KLA / TENCOR 0027175-000 AC

Removed parts:

Robot

Power distribution box

Pre-aligner

Robot controller

Handling:

Scuffing

Scratching

2004 vintage.

KLA / TENCOR 300DFF1P equipment is a dedicated wafer testing and metrology platform that provides comprehensive measurements, analytics, and process monitoring with the highest precision and accuracy. The system enables process engineers to run comprehensive tests to detect and pinpoint critical process failures quickly, accurately, and efficiently. KLA 300 DFF1P unit features a wide range of advanced technologies, including dynamic reticle inspection, automated wafer metrology, inspection and cleaning, texture measurement, 3D metrology, CD SEM (Scanning Electron Microscopy) and drone-powered aerial metrology. The machine utilizes wide-area metrology for fast, powerful wafer analysis and measurements. This allows measurement of wafers on the same substrate and with the same parameter setting, enabling more accurate comparison and data analysis. This technology is used to analyze wafer tilts and rotations, identify particle distribution, determine the critical electrical characteristics of a wafer and perform metrology measurements including critical dimension (CD) and critical dimension uniformity (CDU). The tool features enhanced routing, automation, and other advanced programming features to facilitate efficient testing. Automation of routine tasks is accomplished through programmable protocol scripts that enable autonomous runs, with minimal manual intervention. The automated pattern recognition algorithms also allow for more thorough analysis of a wafer's critical electrical parameters to pinpoint process failure mechanisms quickly and accurately. TENCOR 300 DFF 1 P includes an image-based particle detection and cleaning asset combined with patented edge detection algorithms. This model ensures that defects and particles are accurately identified, isolated, and removed quickly and with minimal disruption of the process. The equipment features a multi-sensor architecture for texture measurement, enabling the analysis of grain size, orientation, and surface roughness. In addition, the system utilizes a highly sensitive 3D metrology unit for analyzing nanometrology that provides accurate information on the height distributions of features on the wafer. Resolution of the machine is high enough to detect changes in film thickness, line width, CD, and depth of any 3D structures such as trenches and vias. Finally, the tool also features aerial metrology with built-in automated drone technology for superior 3D data collection and analysis. Automated drone-based metrology asset enable enhanced wafer surface analysis with high accuracy and reliability. In addition, the model is also capable of running thorough electrical tests through current-voltage, capacitance, and inductance measurements. This allows for better control of parameters and process optimization.

There are no reviews yet