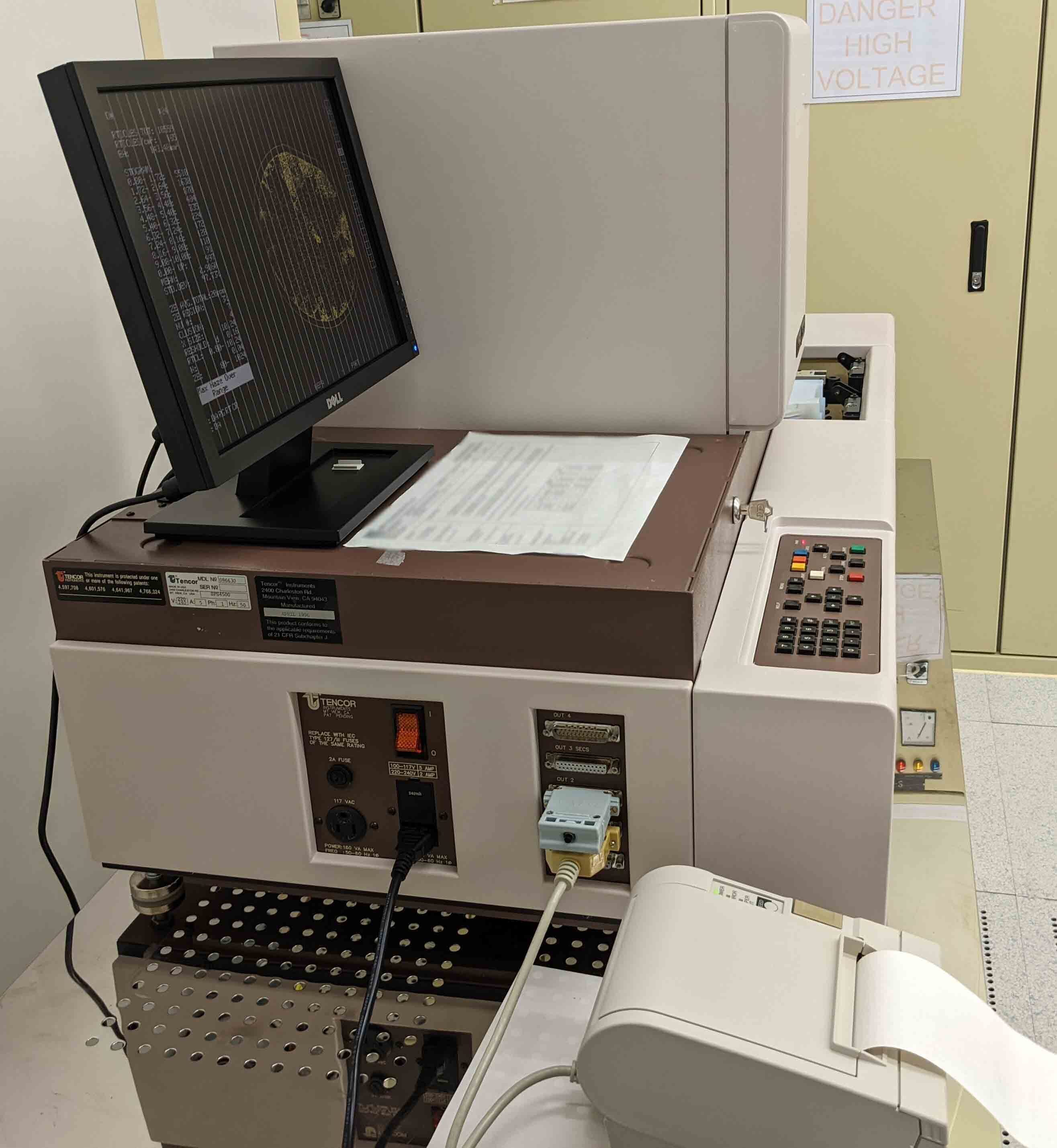

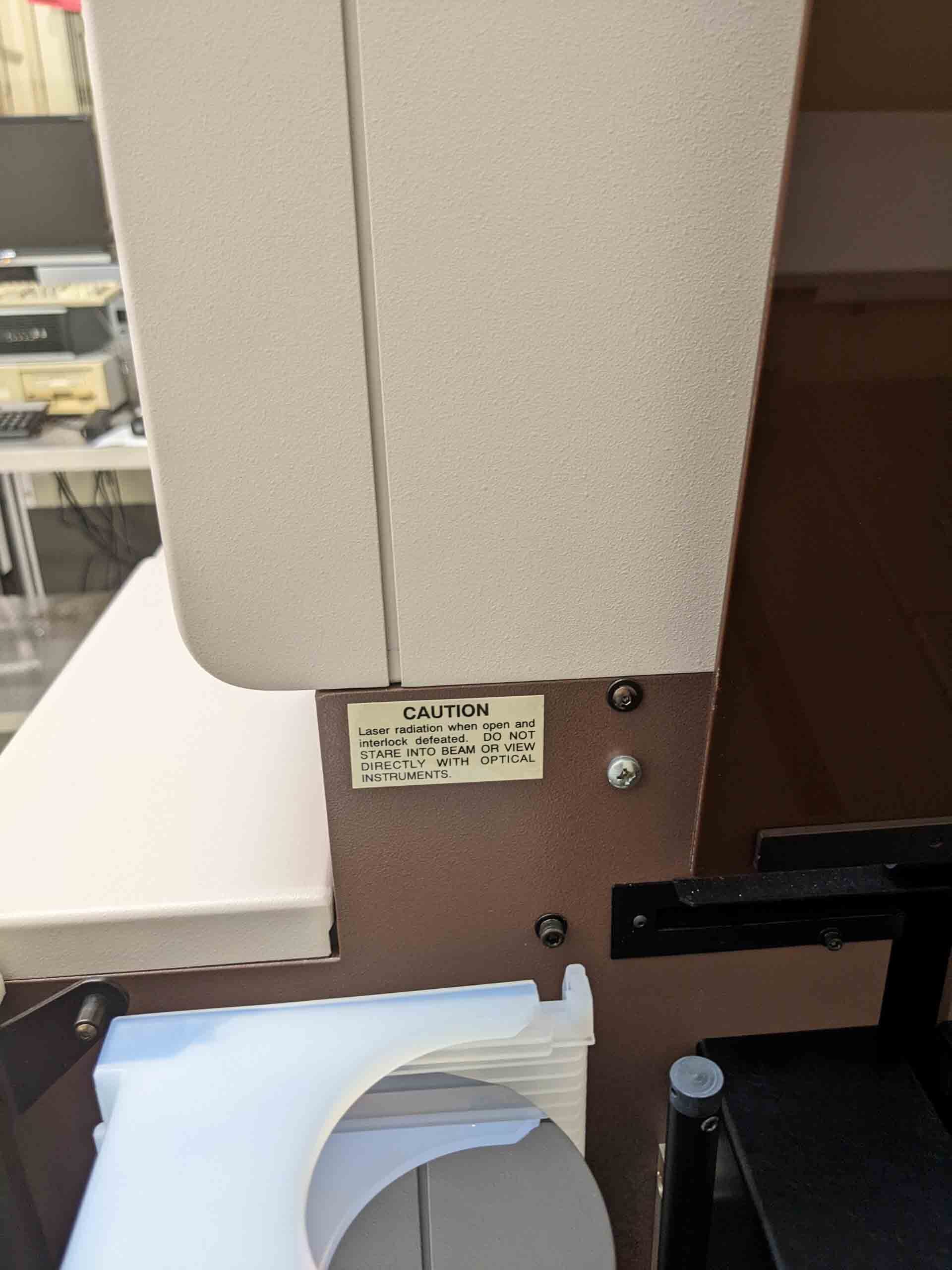

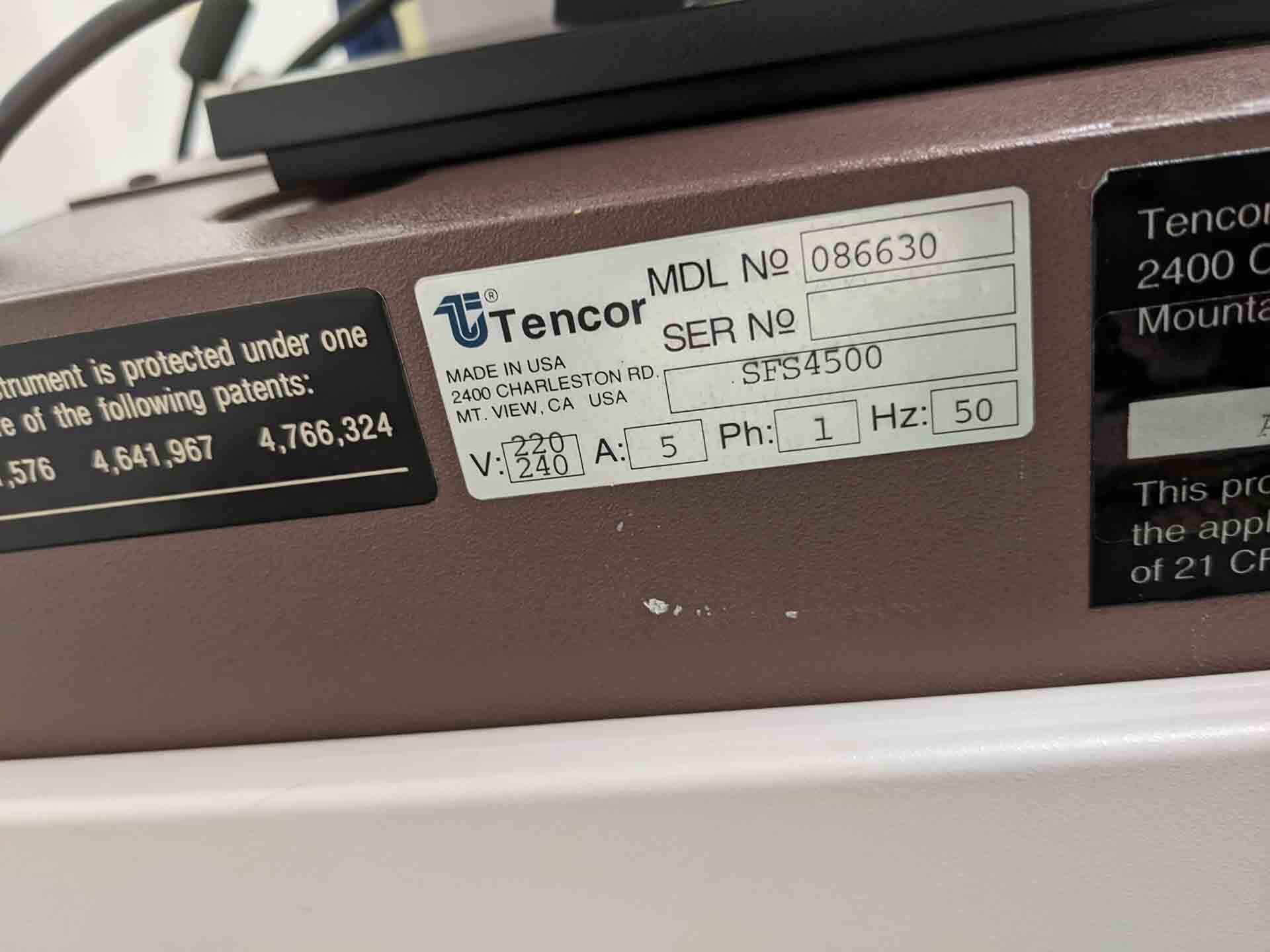

Used KLA / TENCOR 4500 SURFSCAN #293626873 for sale

URL successfully copied!

Tap to zoom

ID: 293626873

Wafer Size: 6"

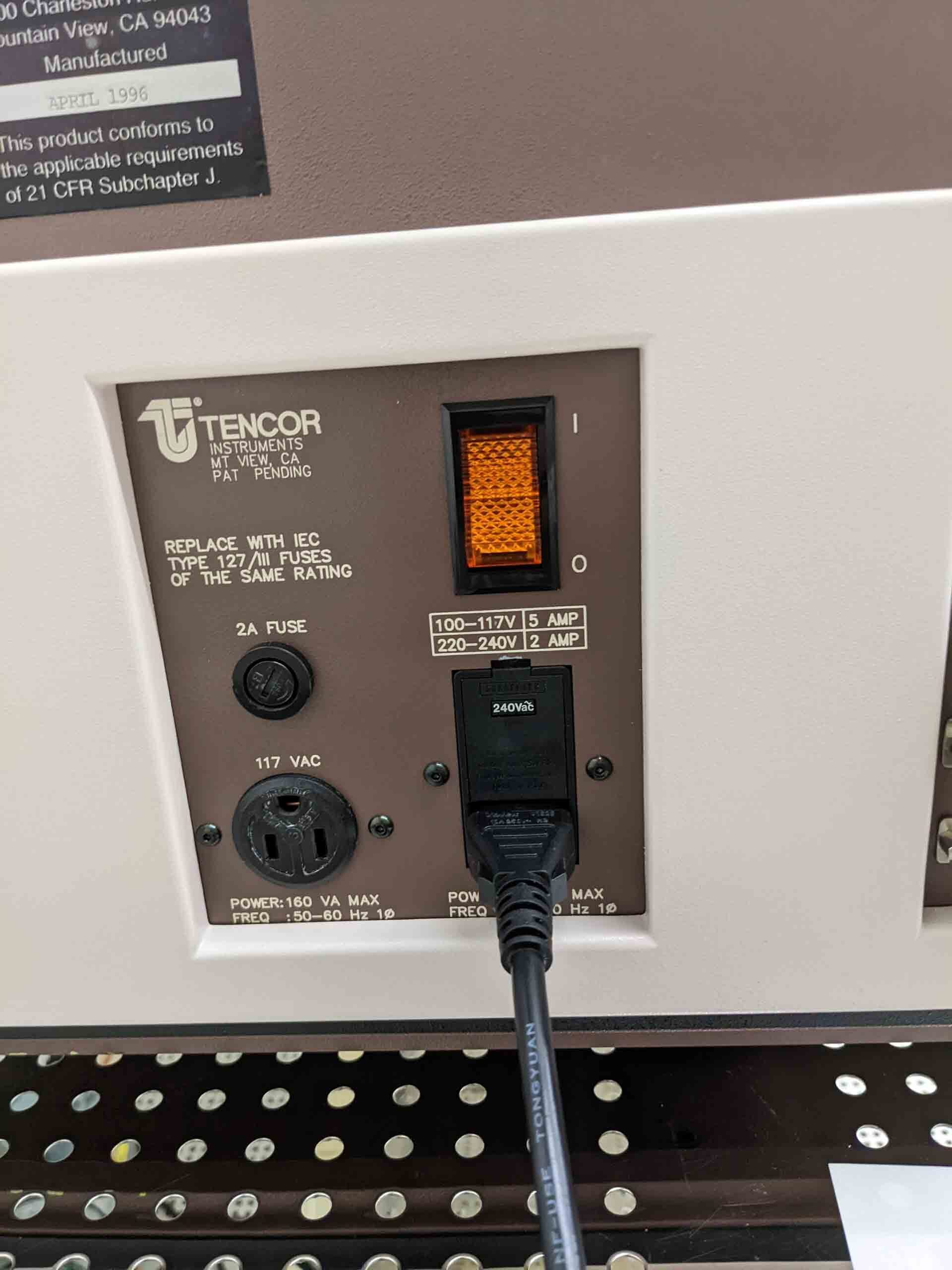

Vintage: 1996

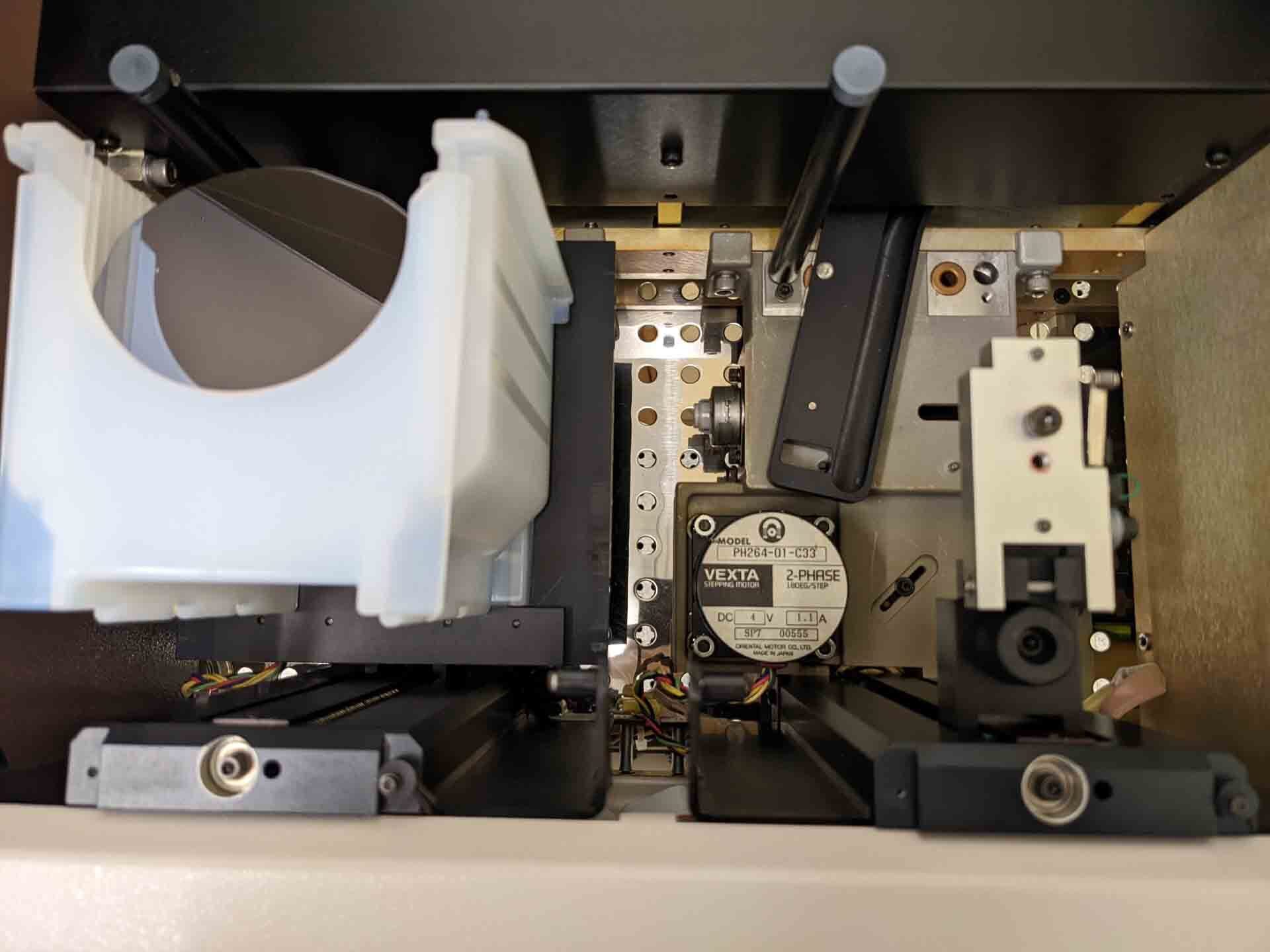

Wafer inspection system, 6"

1996 vintage.

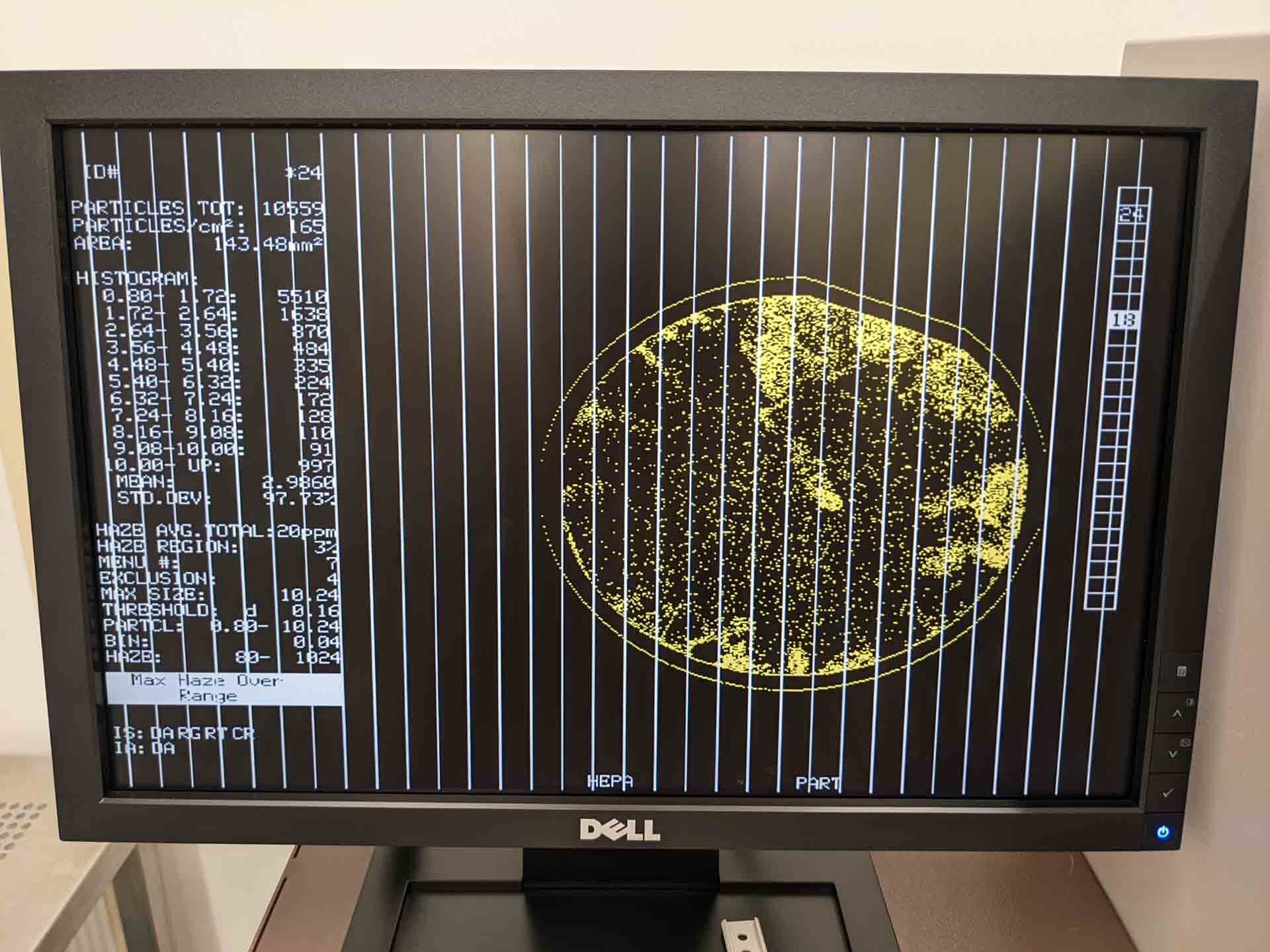

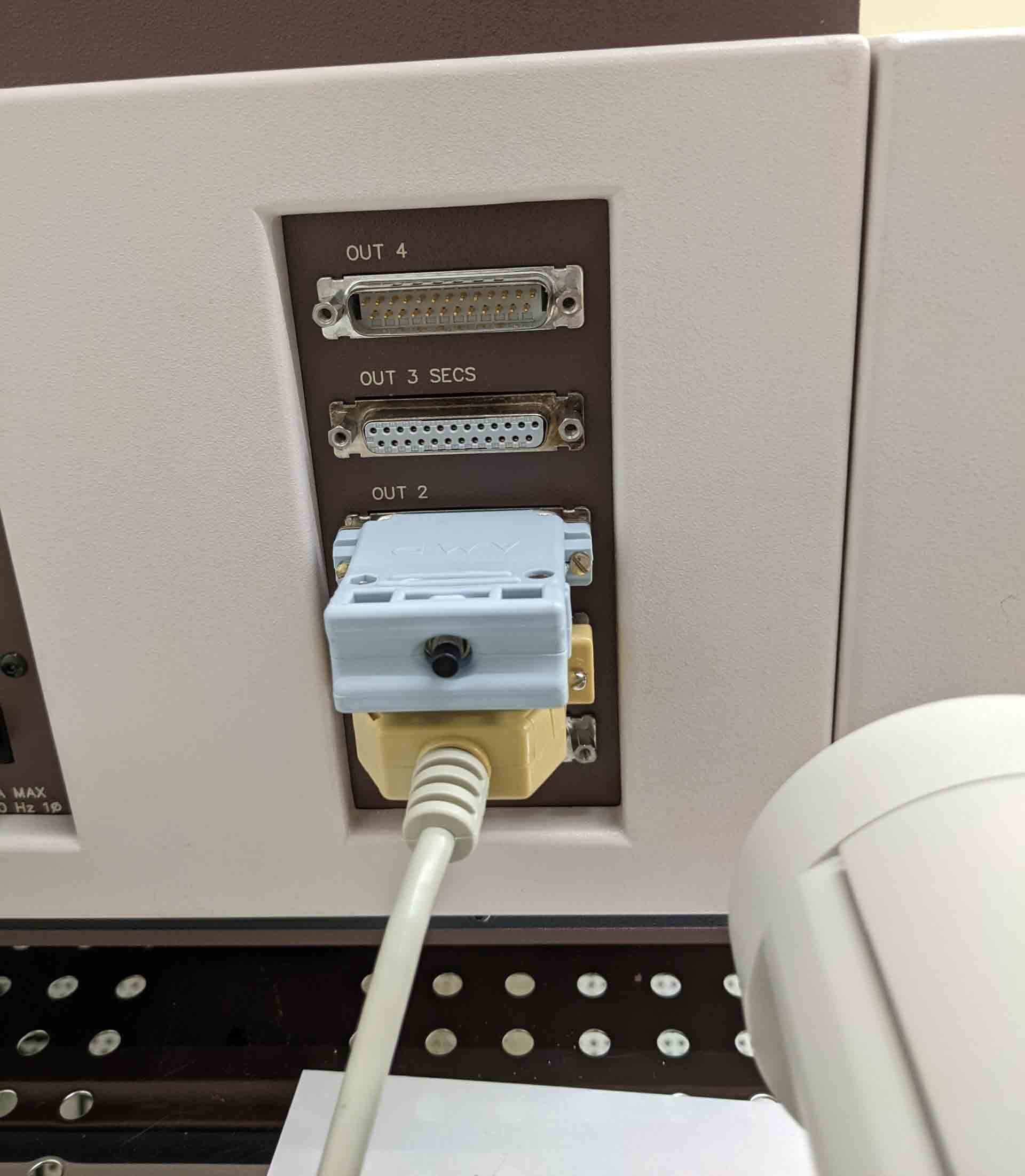

KLA / TENCOR 4500 SURFSCAN is an advanced wafer testing and metrology equipment that offers precise detection and analysis of microstructural features in integrated circuit (IC) wafers. The system uses 3D scanning technology to inspect wafers for a variety of parameters, such as electrical performance, circuit arm measurements, solderability, and more. This type of analysis allows manufacturers to quickly identify and resolve critical yield problems. KLA 4500 SURFSCAN unit contains powerful 3D scanning and analysis capabilities, making it a versatile solution for a variety of wafer testing applications. The machine is capable of scanning up to 300 wafers in extreme detail, with integrated optical inspection capabilities capable of measuring features down to hundreds or even thousands of nanometers. Additionally, the tool's high-speed scanning capability allows for rapid throughput and quick turnaround times for testing. The asset also provides high resolution imaging of wafers to identify electrical and optical defects, as well as other potential microstructural issues. An onboard software suite provides statistical analysis and reporting capabilities, which can be used to identify areas of improvement and corrective action. TENCOR 4500 SURFSCAN is designed for use in a variety of production environments, with a robust and reliable architecture that stands up to heavy use. The model is also equipped with a redundant power equipment and continuous cycle time monitoring to ensure the highest level of performance and reliability. Additionally, the system comes with a comprehensive suite of automated measurement algorithms, allowing for testing of critical parameters in a variety of device types. Overall, 4500 SURFSCAN is an advanced wafer testing and metrology unit that combines high-precision 3D scanning and advanced analysis capabilities. This combination enables rapid throughput and comprehensive analysis of a variety of device parameters and microstructural issues. With its robust and reliable architecture, the machine is well suited for use in high-volume production environments, making it an ideal platform for wafer testing and metrology.

There are no reviews yet