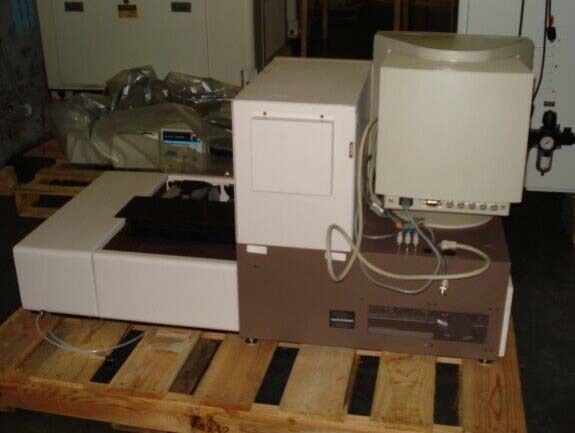

Used KLA / TENCOR 4500 SURFSCAN #9411440 for sale

URL successfully copied!

Tap to zoom

ID: 9411440

Wafer Size: 2"-6"

Wafer inspection system, 2"-6"

High angle optics

Non-patterned surface inspection system

Surface polisher: 0.025 %

Submicron sensitivity: Detects 0.2 micron particles

Surface haze sensitivity: Detects 0.4 PPM

Scattering cross-section: < 0.5 micron² per 50 passes

High scattering surface:

Metals

Polysilicon

CVD Films.

KLA 4500 is a state-of-the-art wafer testing and metrology equipment that offers superior process control, measurement accuracy and repeatability. The 4500 provides a comprehensive solution for evaluating and measuring critical surfaces on today's advanced technology substrates, while also providing advanced defect-detection capabilities to ensure a high-level of quality control on wafer production lines. The 4500 combines a suite of process control options, including scanning electron microscope (SEM) metrology, optical image analysis, review editing and advanced defect inspection for the semiconductor industry, with sample-specific software that enables automated wafer inspection and measurement from sample to sample. The 4500 is designed to provide quick and accurate analysis of critical layers on a substrate, including those on advanced patterned wafers; intricate 3D nano-scale structures; mask layers such as gate and trim; and special film stacks. It achieves this through high resolution imaging and specialized algorithms that can detect and map even the smallest of defects to within ±1 nm. Through its fast, automated analysis capability, the system allows manufacturers to quickly pinpoint and resolve problems, while also providing a comprehensive evaluation of their product. The 4500 includes a variety of features which enable it to provide fast, accurate results. These include: high resolution imaging capabilities that permit detailed visualization of overall surface topography; multiple signal processors that analyze the scanning electron microscope (SEM) images; and complex data algorithms that are used to compare the imaging results against the sample to measure defects or determine other characteristics of the wafer. Additionally, the 4500 includes a patented MDMVA (mandrel-shaped defect measurement and visualization algorithm) feature which is used to quickly detect, classify and quantify defects that are otherwise hard to measure. The 4500 also offers a wealth of other benefits to manufactures, including improved yields and shorter cycle times. This is enabled by the automated wafer testing and metrology unit's data analytics which can be used to optimize processes and parameters. With this machine, manufacturers are able to quickly analyze process trends, maximize throughput and ensure highest quality substrates. All in all, TENCOR 4500 is a reliable and cost-effective solution for wafer testing and metrology. It provides superior speed, accuracy and repeatability for measuring critical surfaces on today's advanced technology substrates. In addition, the tool offers a wide range of features and flexibility that enable manufacturers to get the most out of their wafer testing and metrology operations.

There are no reviews yet