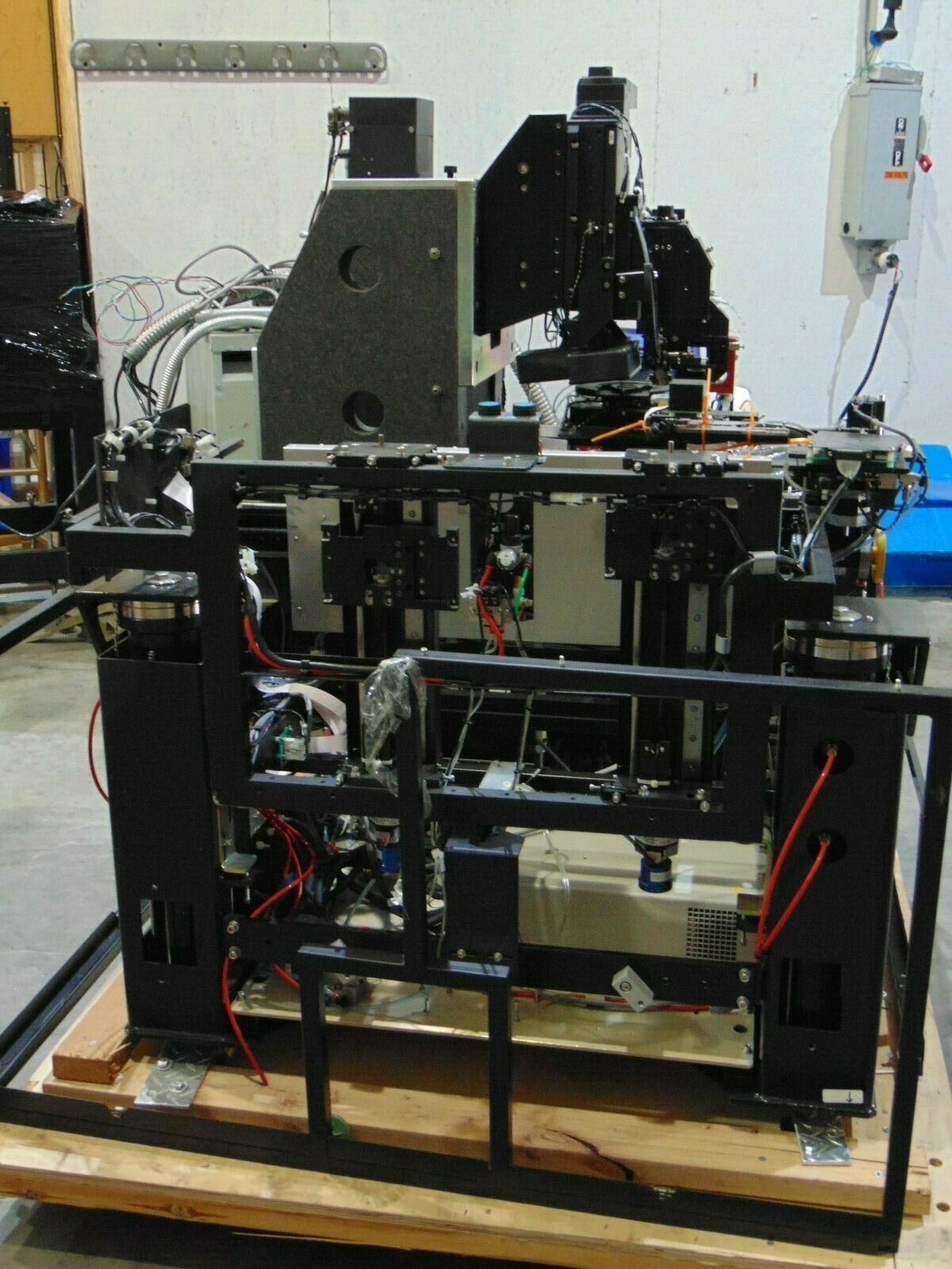

Used KLA / TENCOR 5100 #9300311 for sale

URL successfully copied!

Tap to zoom

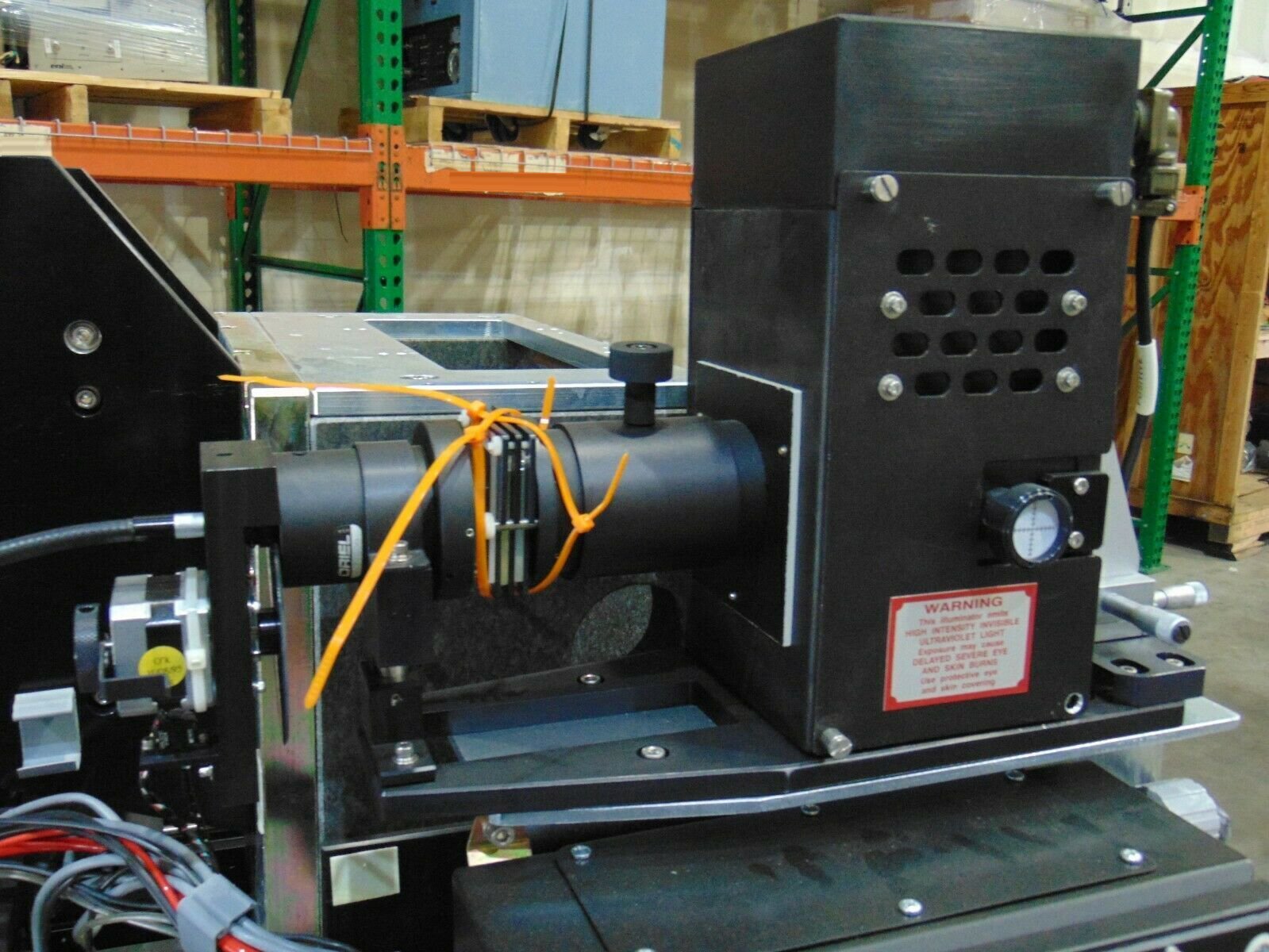

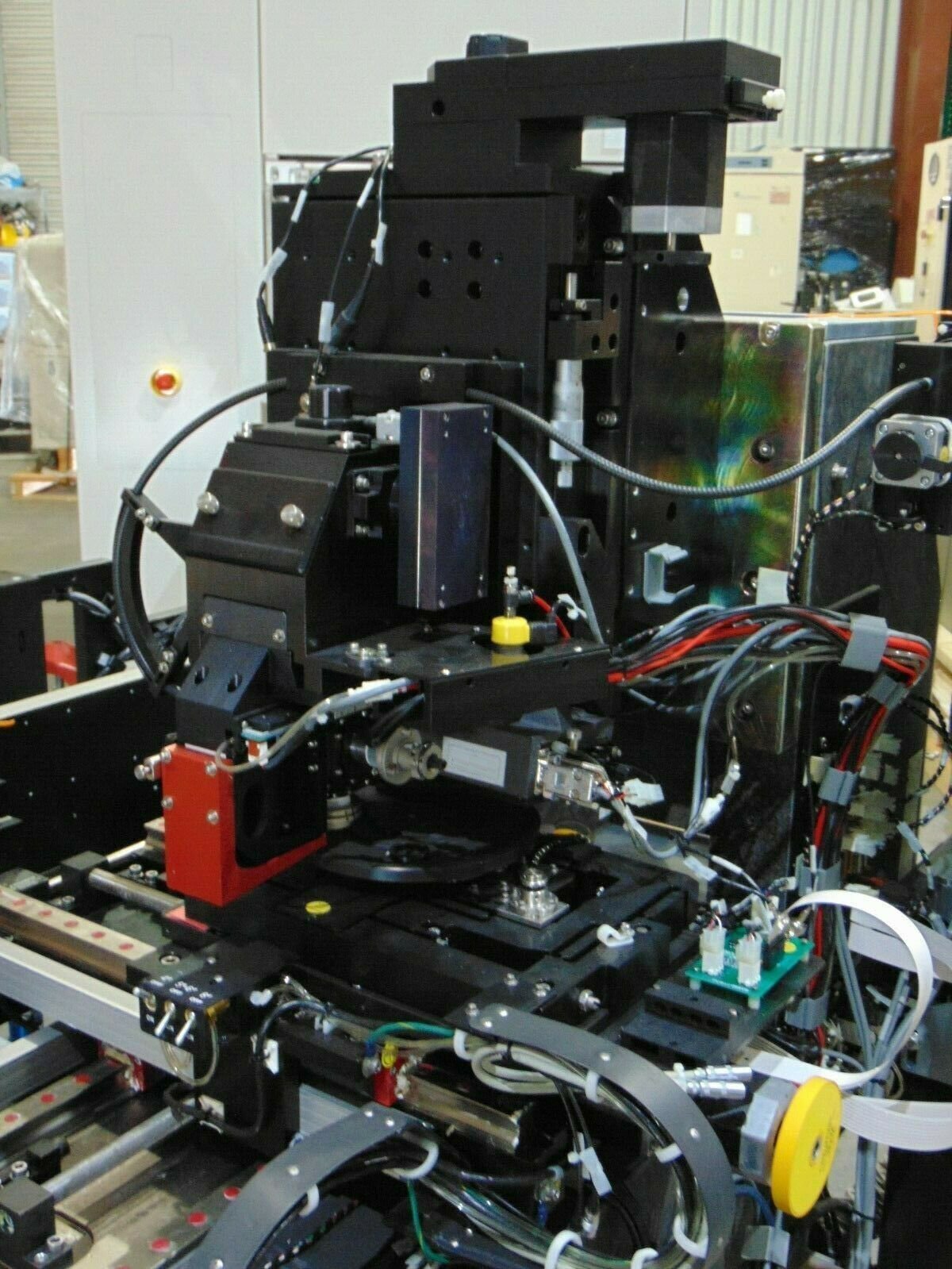

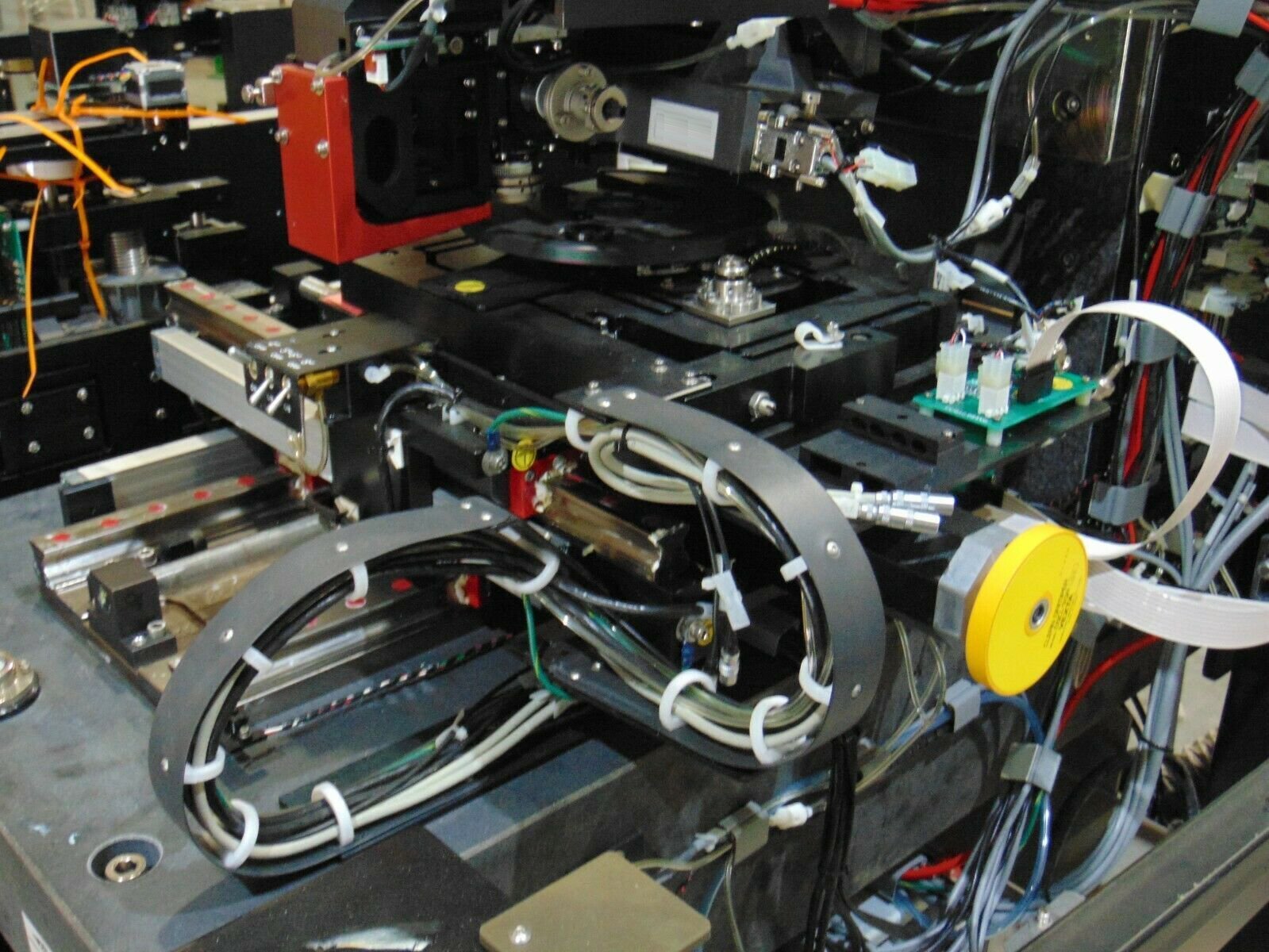

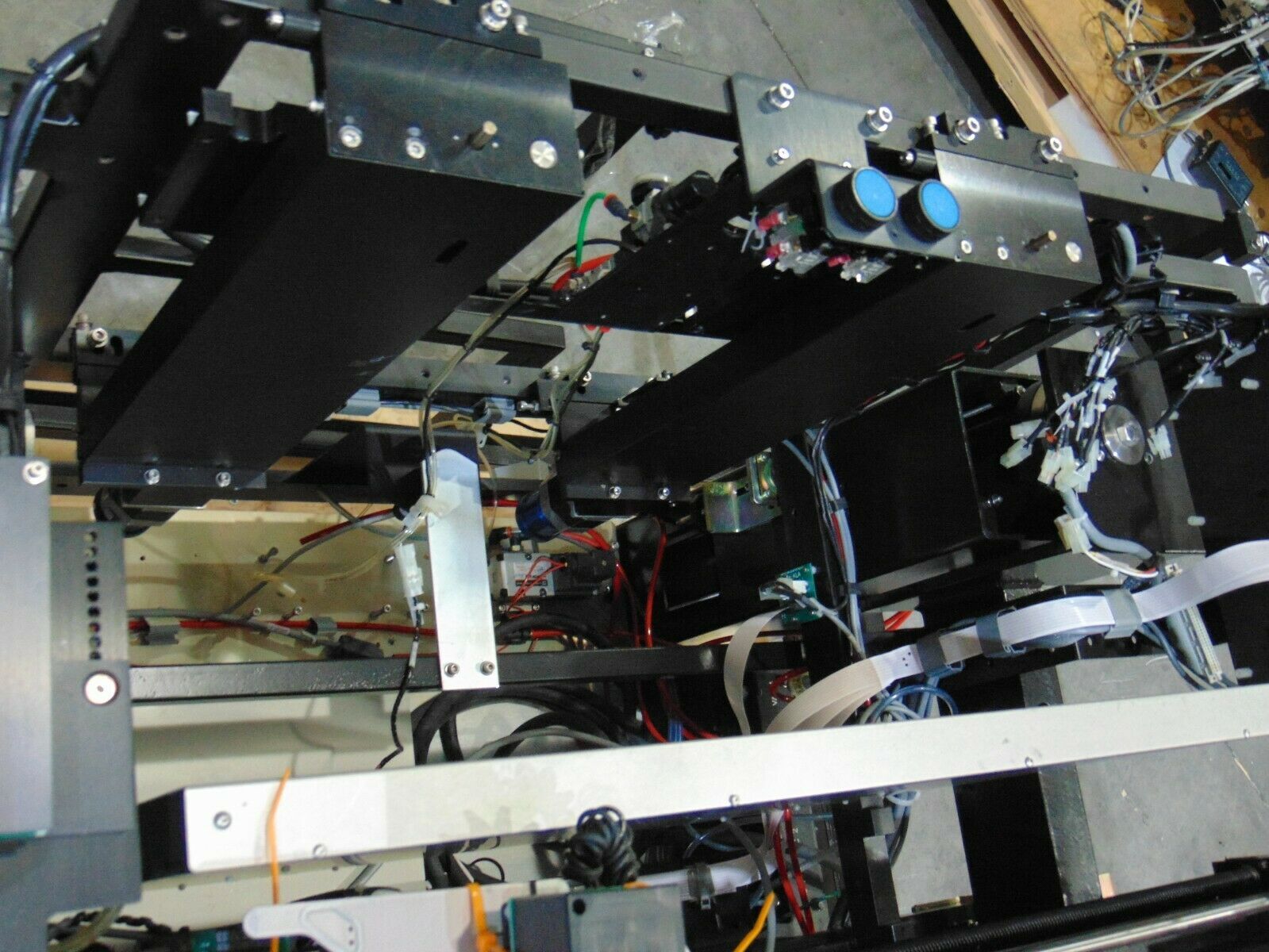

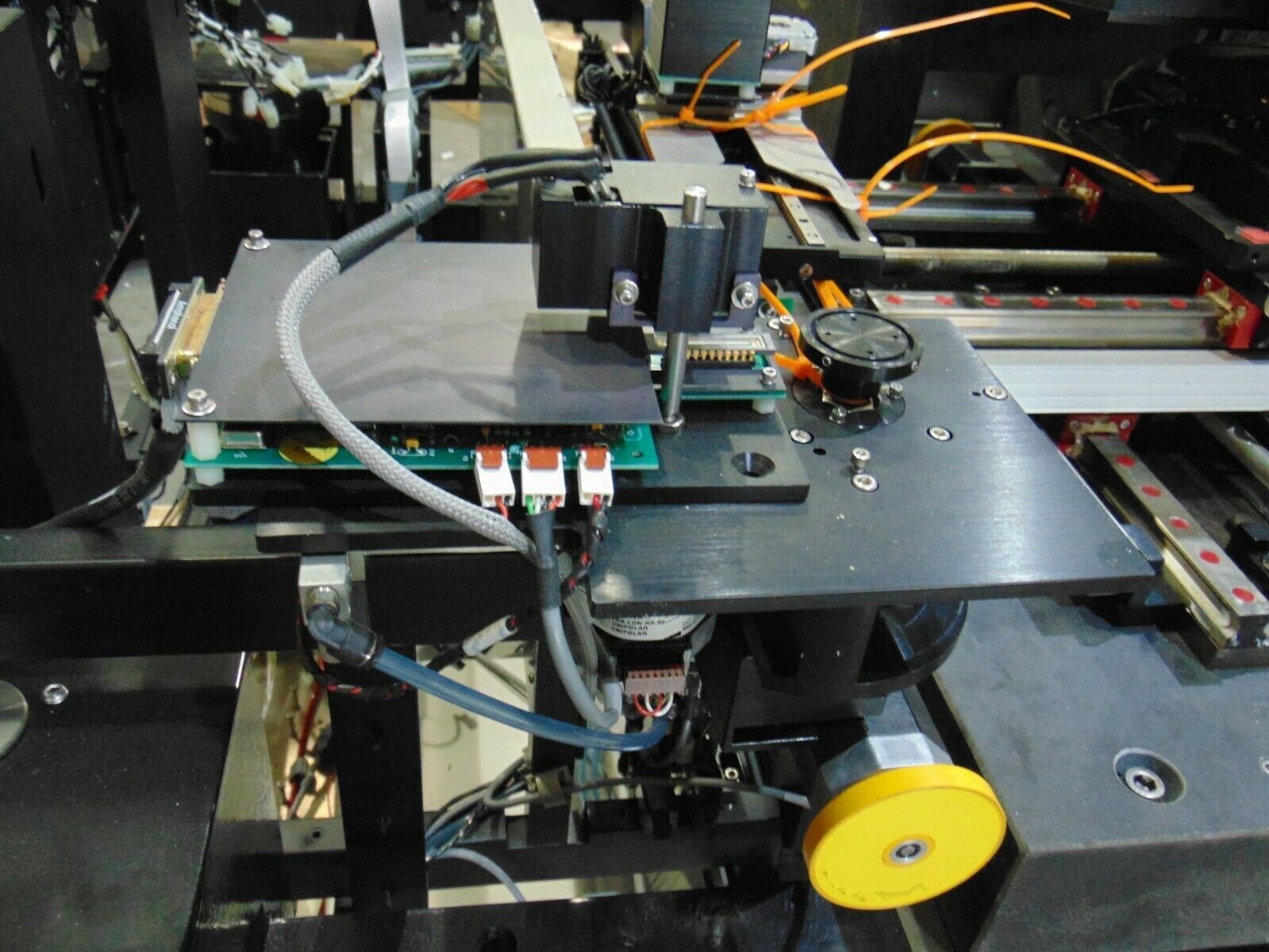

KLA / TENCOR 5100 wafer testing and metrology equipment is a state-of-the-art tool designed to ensure that semiconductor wafers are of the highest quality. The system is composed of three components: an imaging unit, a pattern recognition machine, and a packaging tool. The imaging asset is arguably the most important component, as it is responsible for providing a quality image of the wafer. Laser interferometers and microscopes capture the image and relay it to powerful optical encoders, which provide an exact measurement of the wafer's dimensions. The imaging model is also equipped with an advanced light source, which dramatically improves the accuracy and resolution of the imaging equipment. The pattern recognition system is responsible for recognizing and analyzing imperfections in the wafer. This algorithm uses neural networks to ensure that distorted shapes are accurately identified and pinpointed. The unit can be used to recognize crack defects, slope defects, and even particles as small as 25nm. Finally, the packaging machine is responsible for packaging the wafer safely to ensure that no further damage is done to the wafer. The tool is equipped with a variety of sensors that monitor the packaging process. This ensures that the wafer is safe and secure throughout the shipping process. In conclusion, KLA 5100 wafer testing and metrology asset is an invaluable tool for ensuring that wafers are of the highest quality possible. The imaging model, pattern recognition equipment, and packaging system all work together to ensure that wafer defects are accurately identified and addressed. This ensures that semiconductor wafers are safe and reliable, which is essential for the success of any semiconductor project.

There are no reviews yet