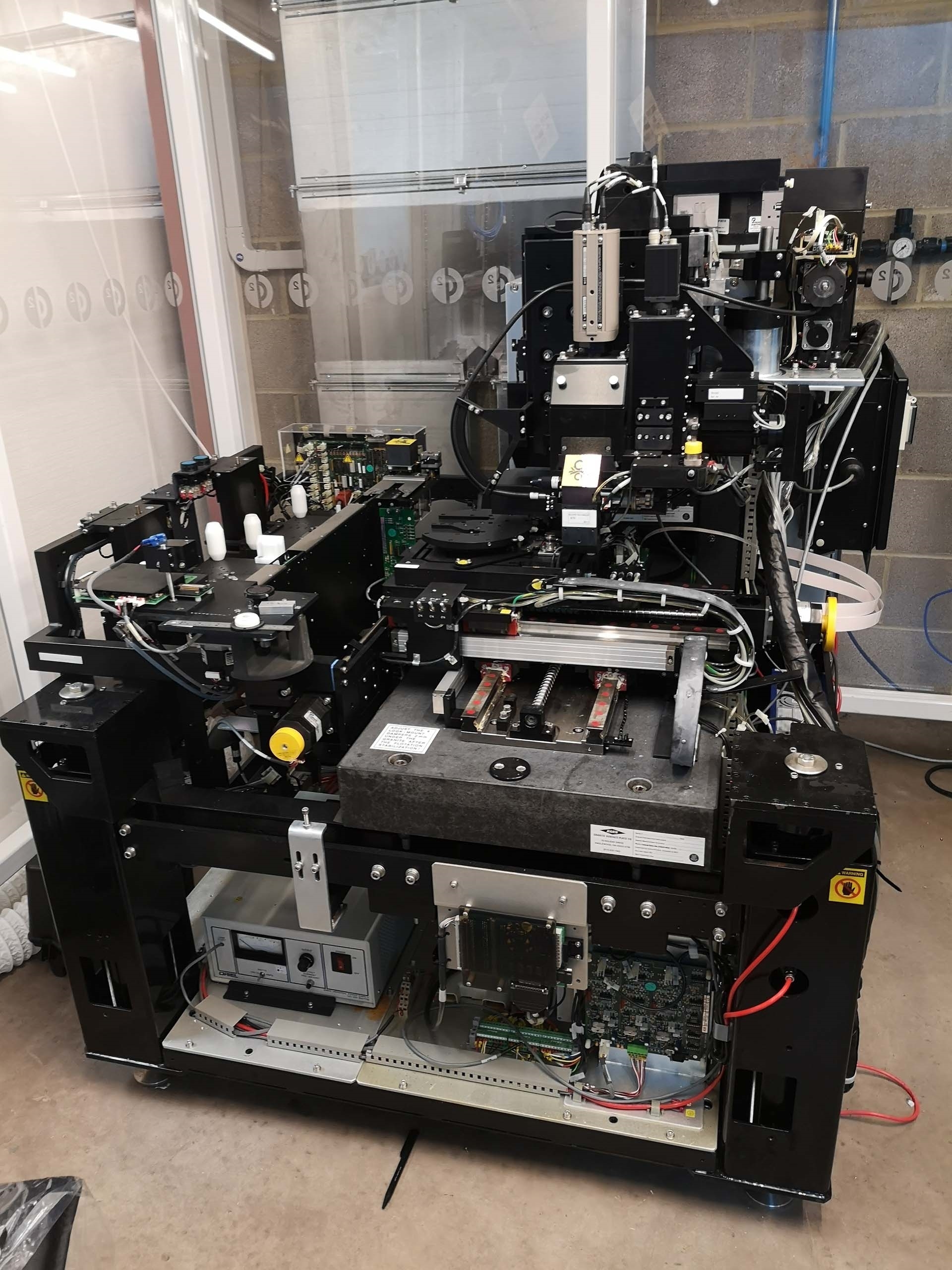

Used KLA / TENCOR 5200XP #9157118 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9157118

Overlay measurement system

Does not include monitor

Thermal printer damaged.

KLA / TENCOR 5200XP is a wafer testing and metrology equipment designed to provide precision and accuracy in semiconductor manufacturing processes. It is an advanced wafer inspection tool designed to detect and measure defects on a wafer surface. The system is equipped with a high resolution digital camera and a large-scale automated vision unit (AVS) to analyze images of test wafers and acquire detailed metrology data with a nominal resolution of 0.1 microns. KLA 5200XP employs a number of techniques to analyze wafers, including light scattering imaging (LSI), reflected energy imaging (REI), and optical brightness imaging (OBI). These techniques allow for the detection of small defects in areas of the wafer that are difficult to access even with high resolution microscopes. The machine also supports contact imaging, a technique used to measure extremely small variation in the height of the contacts on the wafer surface. TENCOR 5200 XP also uses a range of automated wafer testing and analysis tools, such as defect and tolerance analysis and optical parameter analysis. These tools allow for complete evaluation of wafer surface defects, ensuring that potential hazards to proper functioning of the device are identified before the fabrication process. As an automated tool, TENCOR 5200XP can reduce the human labor required to manage the inspection process and maintain a high level of accuracy. It features a closed-loop manufacturing capability, which can control the operation of other systems in the facility. Additionally, 5200XP can be used to measure and store wafer test and metrology data, enabling more accurate assessment of current process parameters. In summary, 5200 XP is a versatile wafer testing and metrology asset designed to provide accurate, high resolution analysis of wafer surfaces. It features a range of automated testing and metrology tools to detect and measure defects, enabling greater control of the fabrication process. The model also includes advanced vision technology and closed-loop manufacturing capabilities to reduce labor and maximize accuracy.

There are no reviews yet