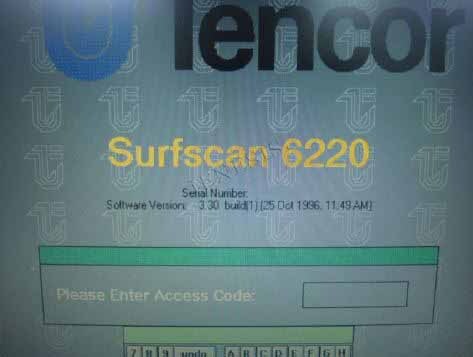

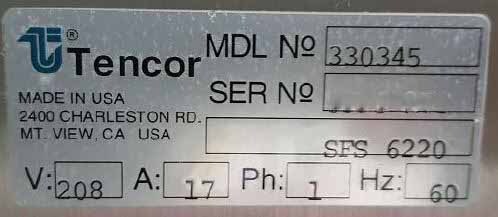

Used KLA / TENCOR 6220 Surfscan #9174323 for sale

URL successfully copied!

Tap to zoom

ID: 9174323

Defect inspection system, 4"-8"

Laser hours: 2,184

PSL Sizing

Automatic wafer handler

Sensitivity:

Most surfaces: 0.20μm @ 95%

Polished surfaces: 0.10μm @ 95%

Detects sub-micron particles on bare silicon

Capture rate: 0.12μm defect sensitivity on bare silicon

Repeatability:

Less than 1.0% at 1 standard deviation

Mean count: > 500

Diameter latex spheres on bare silicon: 0.204

Contamination:

Less than 0.005 particles / cm > 0.15 μm

Haze sensitivity: 0.02 ppm

Defect map & Histogram:

Zoom illumination source

Argon-ion laser: 30 mW

Wavelength: 488 nm

2D Signal integration: 50μm Spatial resolution

Non-contaminating robotic handler

Random access: Sender / Receiver unit.

KLA / TENCOR 6220 Surfscan is a fully programmable wafer testing and metrology equipment with a variety of photometric, atomic force microscope (AFM), topographical and spectrometry capabilities. It is ideal for use in nano-fabrication, process control, and research and development of advanced semiconductor materials. Its ability to integrate with other metrology systems makes it a great choice for product and process development. KLA 6220 Surfscan's high-density optical detection system captures images and maps of defect sites, then automatically classifies and measures them. It contains multi-modal scanning modes for film inspection, mapping across a filmset in three dimensions and across single film surfaces. This allows for wafer mapping and series of defect analysis to occur easily. TENCOR 6220 Surfscan was designed for maximum versatility and accuracy. It uses a variety of lasers to provide precise measurements of defects on the wafer surface. Its imaging unit, based on probabilistic algorithms, can distinguish between defect features, such as pits, marks, and scratches. It can also examine roughness both on the vertical and horizontal surfaces of the wafer with extreme accuracy. 6220 Surfscan also includes reliable metrology systems that allow for precise measurements of film thickness and material properties, such as reflectance and index of refraction. Its optical, AFM, and spectrometry systems work together to give accurate measurements of chemical composition, layer thickness, and crystal growth orientation to help ensure process control. KLA / TENCOR 6220 Surfscan comes with a variety of interface options, including chemical detection and electrical measurements. It also has robust software to simplify the process of aligning wafers and capturing images. As a result, the machine can be used by researchers and engineers to develop and test new materials, processes, and technologies. In conclusion, KLA 6220 Surfscan is an advanced and versatile wafer testing and metrology tool that can measure and examine defects with precision. With its multi-modal scanning capabilities and reliable measurements, it is a great choice for product and process development for advanced semiconductor materials.

There are no reviews yet