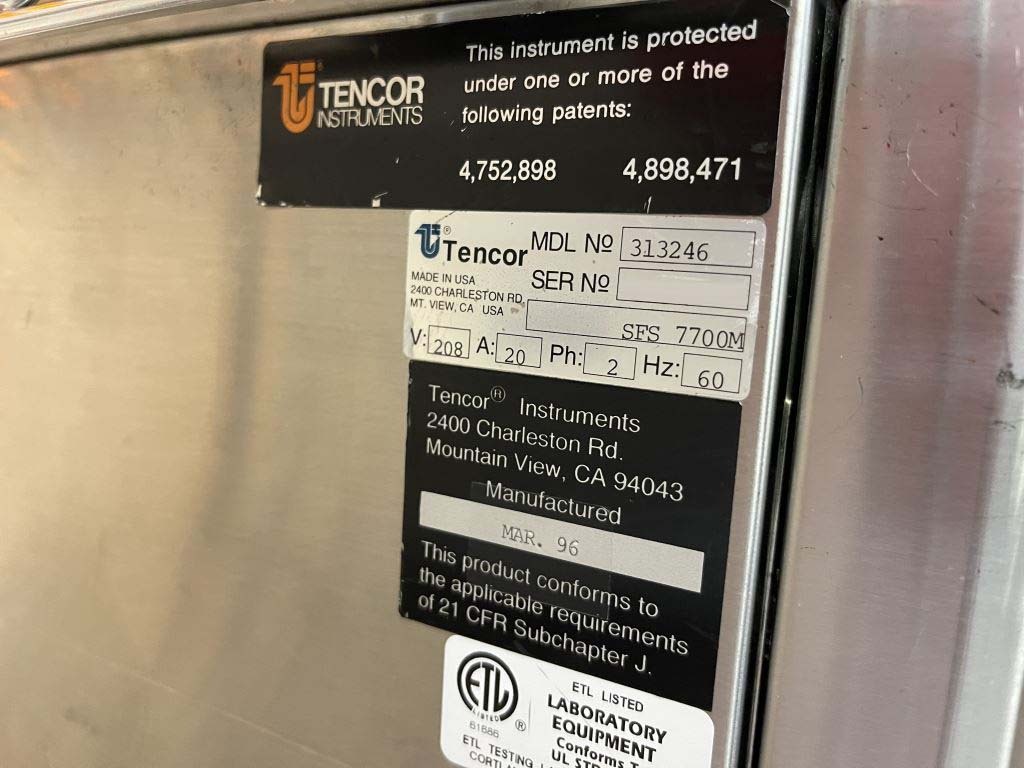

Used KLA / TENCOR 7700M Surfscan #293627334 for sale

URL successfully copied!

Tap to zoom

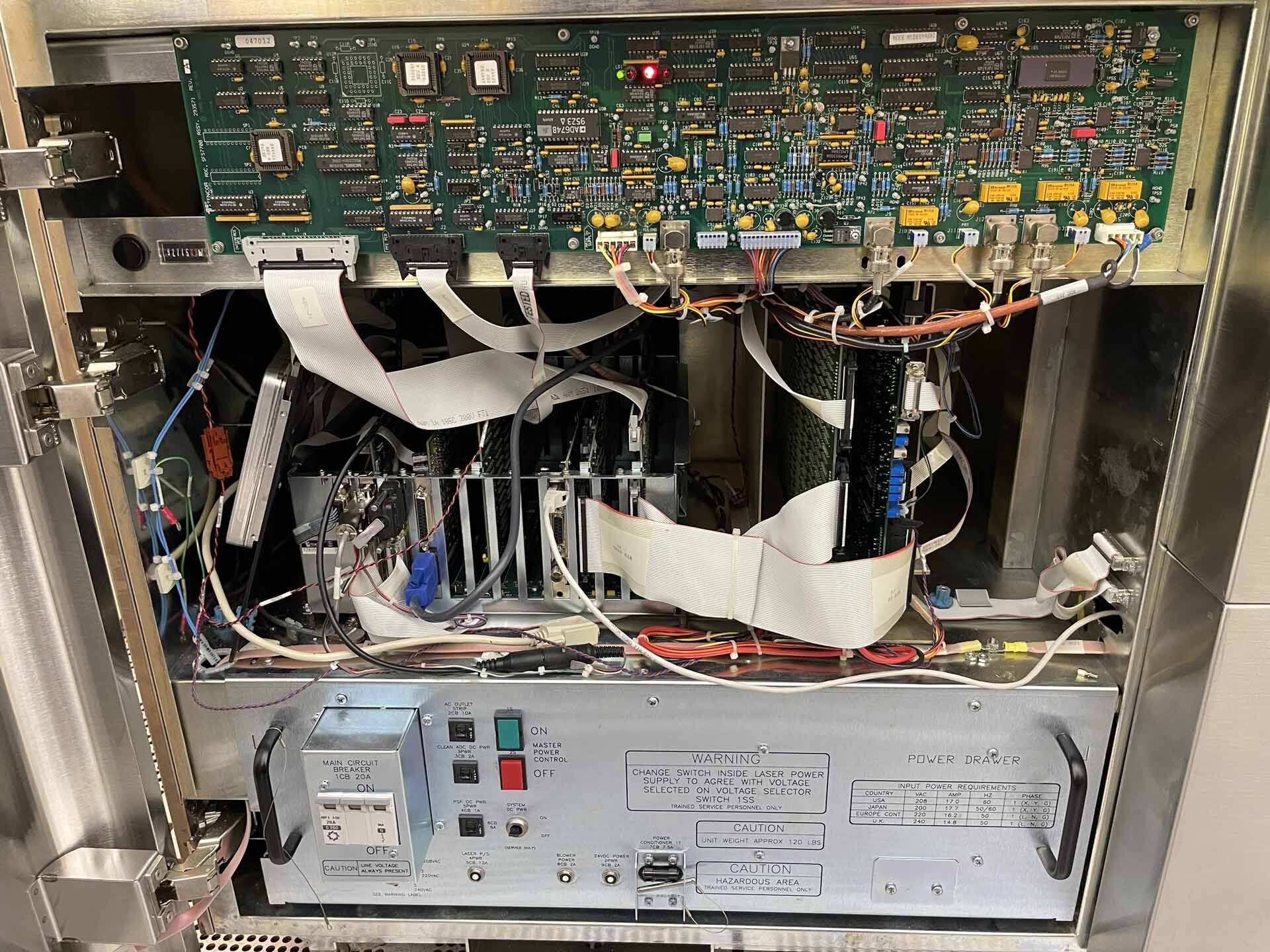

KLA / TENCOR 7700M Surfscan is a high-precision wafer testing and metrology equipment used for monitoring and controlling the quality of device manufacturing processes. This system allows for fast, accurate measurements of topography, profile, critical dimensions, and nanoscale features. KLA 7700M Surfscan utilizes a scanning electron microscope (SEM) to scan a step wedge, mask pattern, or wafer substrate. This scanning electron microscope comes with advanced features such as auto-focus, a high voltage supply, an x-ray detector, a secondary electron detector, and an advanced control software. The unit's advanced imaging capabilities are further complemented by its high-resolution zoom optics and its powerful analysis tools, including statistical feature extraction, defect classification, contamination analysis, yield management, 3D visualization, video measurements and more. Once the scanning electron microscope has completed the data-gathering process, TENCOR 7700M Surfscan machine allows users to analyze and evaluate the data, as well as take corrective action if necessary. This imaging and analysis data can assist in determining optimal etch rates, developing protocols for process improvements, predicting failure rates, and avoiding potential yield losses. 7700M Surfscan also offers an automated tool for prober interfacing, allowing for the obtaining of precise measurements, such as critical dimensions, topography, and roughness of fully-etched circuits. This asset also includes a high-performance camera and advanced optics for precise 3D scanning capabilities. By providing insight into the manufacturing process and integrated metrology capabilities, KLA / TENCOR 7700M Surfscan offers a powerful and reliable solution for monitoring, tracking, and controlling quality in the semiconductor industry. This model is designed to provide users with the most accurate and reliable analysis data possible, allowing them to maintain the highest possible quality standards and reduce the risk of costly rework, downtime, scrap and yield losses due to errors or inefficiencies.

There are no reviews yet