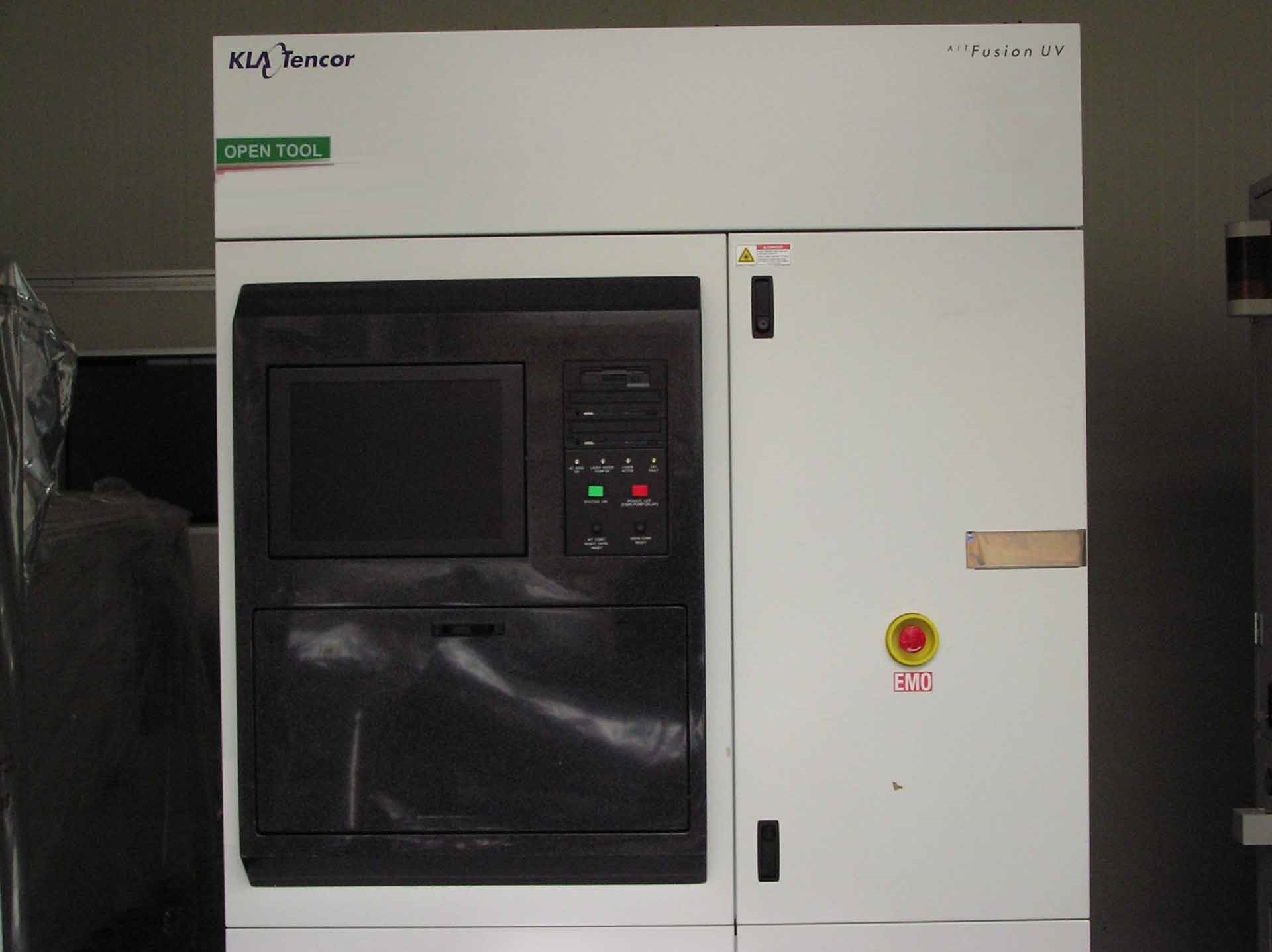

Used KLA / TENCOR AIT UV #9211161 for sale

URL successfully copied!

Tap to zoom

ID: 9211161

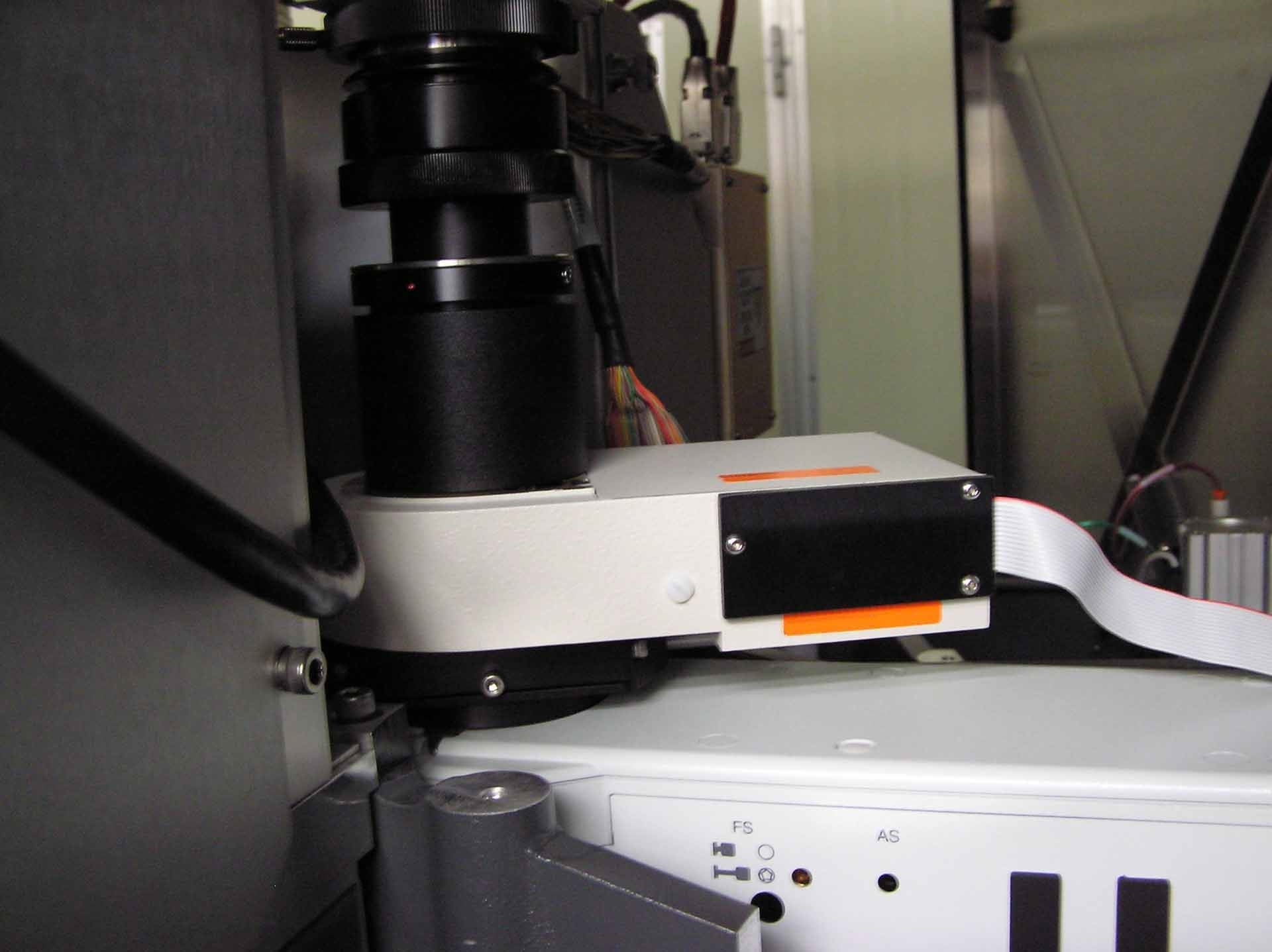

Wafer inspection system

Assy pillar AIT-UV

Raid array: (3) Hard disks

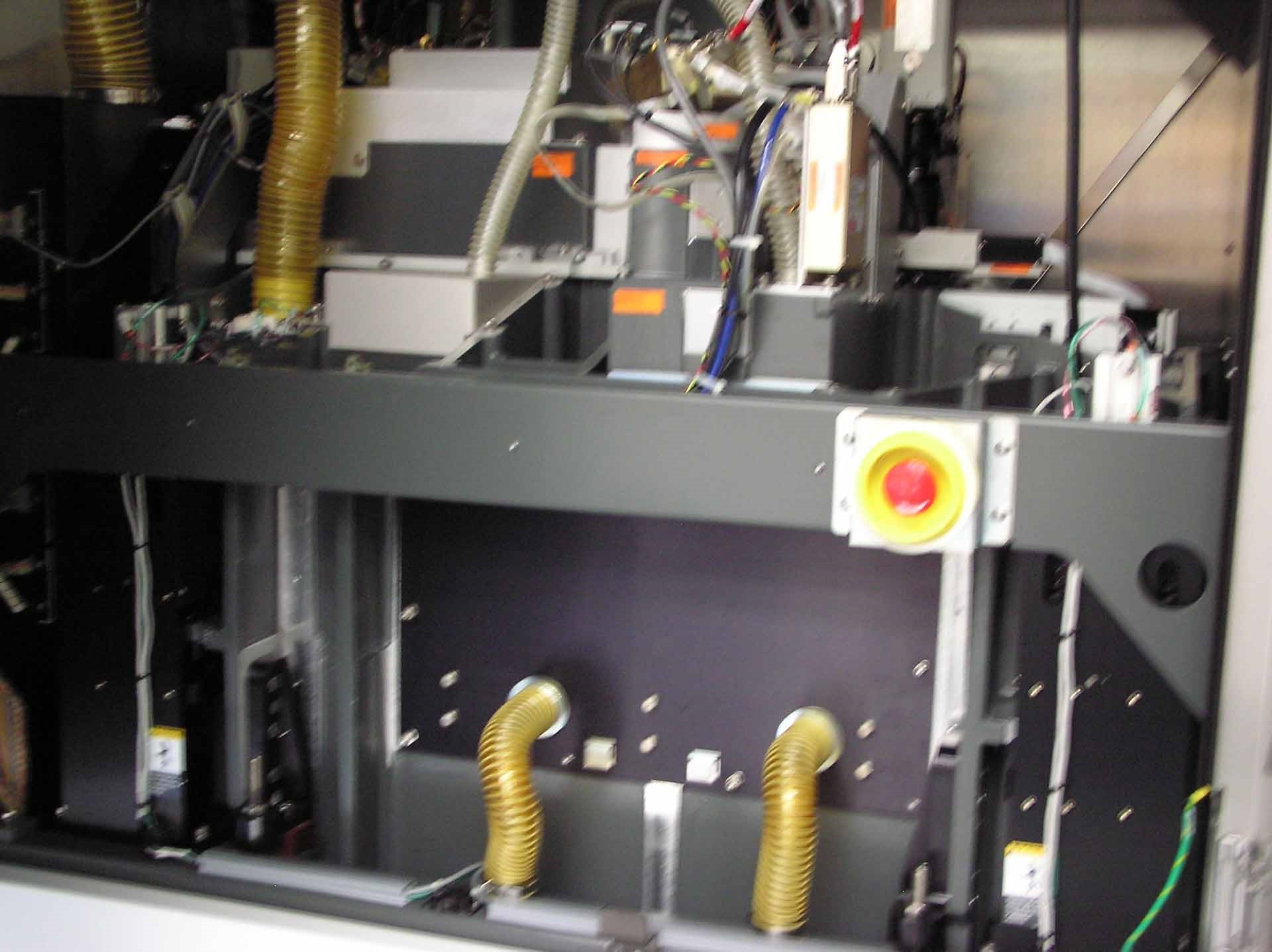

Robot type: BROOKS / PRI AUTOMATION ATM207-2-S-CE

Controller type: PRI ESC-212B

Setup disk P/N: 524140

PO Configuration:

AIT-Fusion UV final assy group

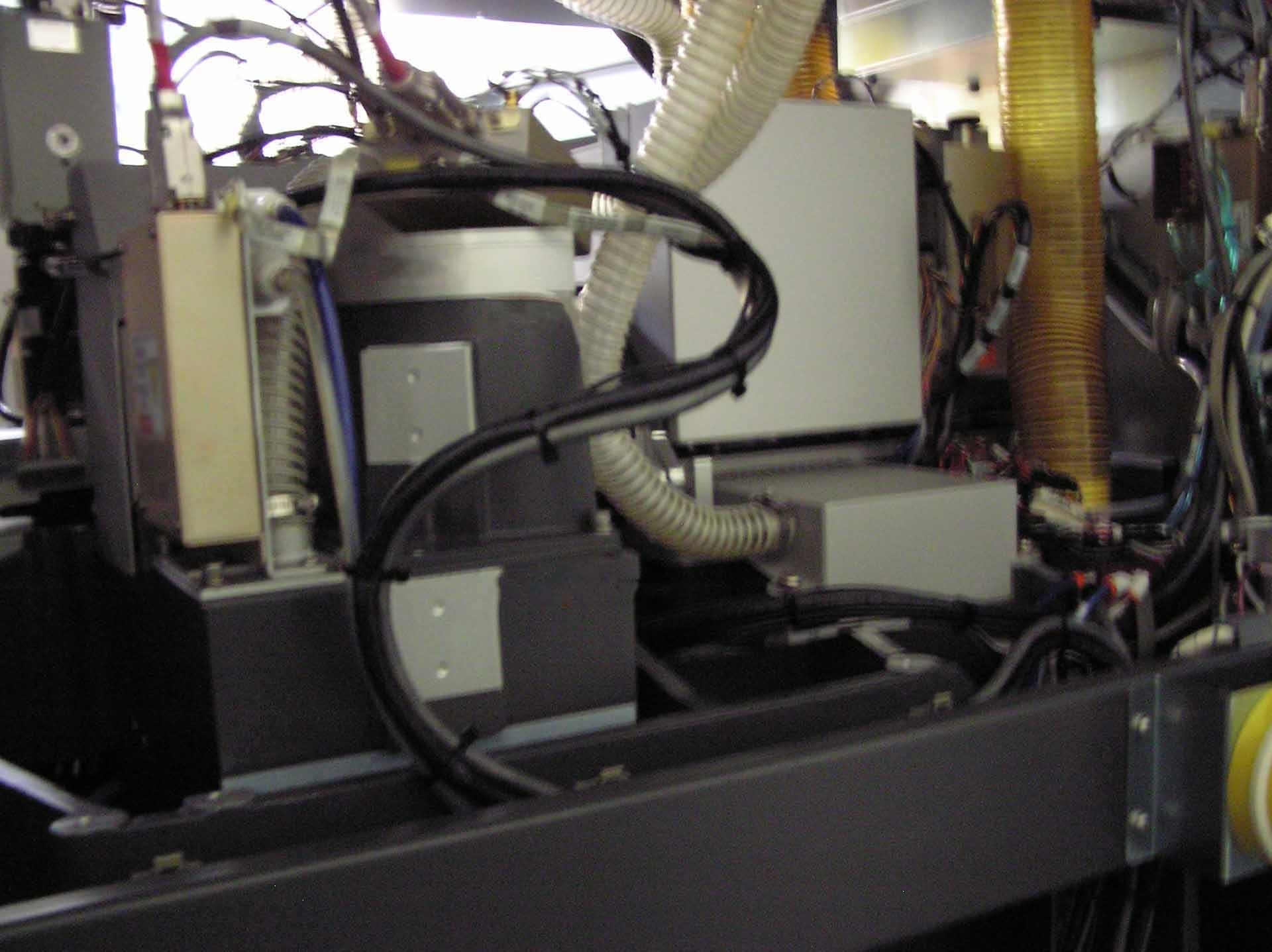

Advanced collection optics configuration with UV illumination

Adaptive mode

Technology:

Multi-spot optics: 2.2um,3.5 um and 5.0um Spot sizes

Automatic coordinate registration and alignment

Region based multi-threshold capability (RBMT)

Core technology Package

AIT Standard detection algorithms

Advanced detection algorithms

HLAT

Channel merge

Run time alignment

iADC and RTC Real time classification systems

Run time sampled image acquisition

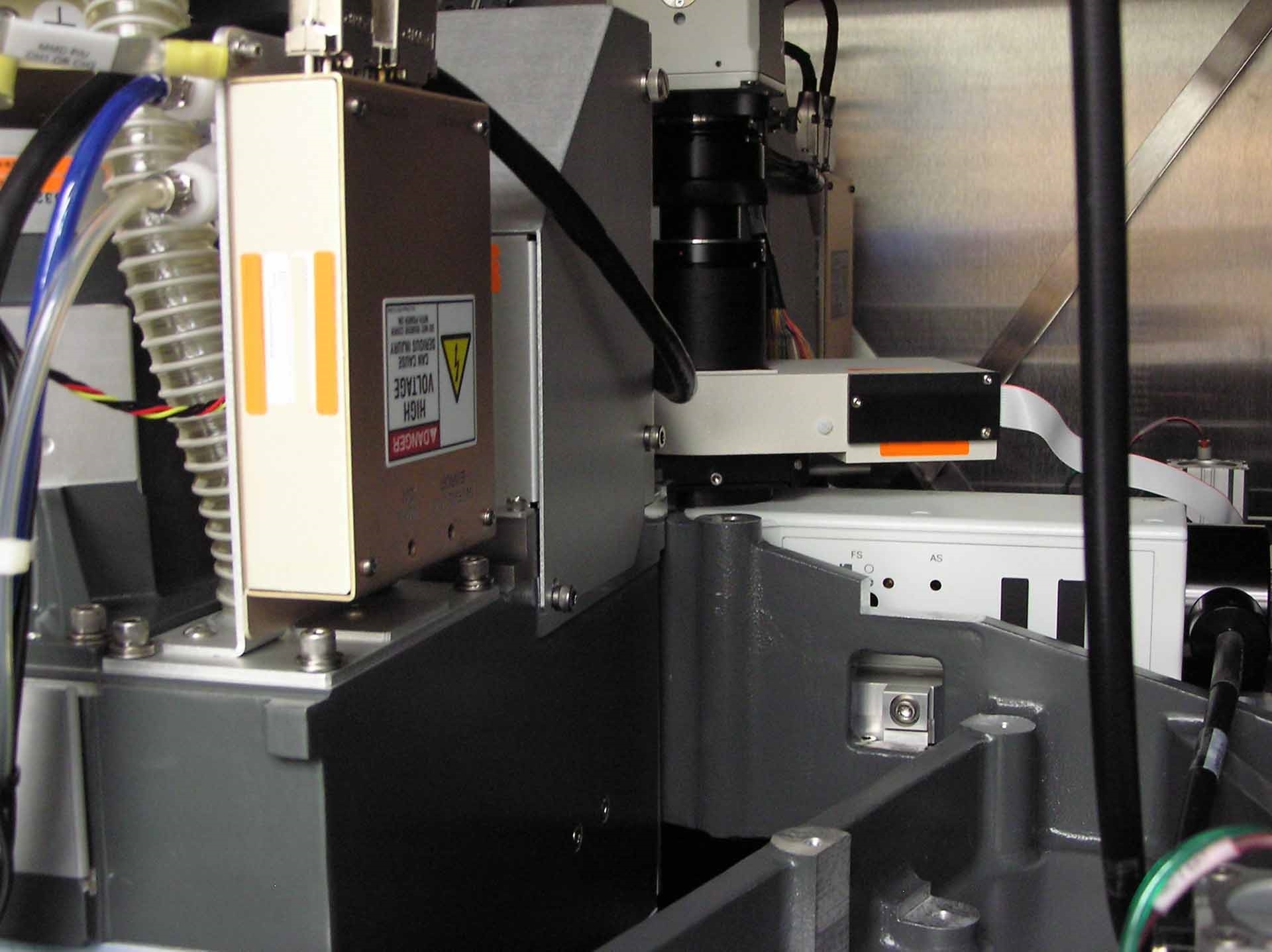

Internal optical review microscope:

Includes:

(5) Microscope review objectives: 5x, 10x, 50x, 100x, 150x

Bright field and dark field review modes

Autofocus capability

Integrated ULPA filter package

High resolution color flat panel display

Supports LAN connectivity over 10/100

Base-T and BNC (10 Base-2) connectors

Operations / Reference manual

KLARF File output

External panels, cleanroom white

HSMS Interface

Signal tower

(4) Colors: RYGB, standard mount 8"

Real time classification (RTC) package

Options:

Art dual open handler, 8"

iADC Option

Power supply: 208V, 3-Phase WYE

Short circuit load: 65kVA @ 208V

Full load: 75A

Operating system: Windows NT 4.0 file and printer connections (Supports).

KLA / TENCOR AIT UV is a state-of-the-art wafer testing and metrology equipment designed for providing the best-in-class precision and repeatability of wafer test results. It utilizes advanced optics and Illumination Technology to deliver precise Optical Characterization for wafer metrology. The system is designed to measure a variety of wafer metrics, such as die thickness, spherical radius and mean surface roughness. KLA AIT UV is able to measure both planar and cylindrical wafer surfaces, and can handle test samples with large surface areas up to 12 inches. What makes this unit unique is its ability to combine high accuracy with ultra-precision. It is equipped wih dual-sided wafer chuck station that eliminates the need for manual wafer switching. It also features two optical sensors and a high-resolution camera that ensure precision results both quickly and efficiently. The machine's advanced hardware also allows for advanced data analysis techniques, such as curve fitting and parametric surface fitting. TENCOR AIT-UV is also expandable with up to four Ultra-High speed Motion Modules, making it ideal for larger-scale analysis of data from either single wafers or batch data acquisitions. In addition to its advanced optical and Illumination Technology, AIT UV also features an intelligent automation architecture which simplifies wafer testing and allows for unified data set exchange for increased test coverage. It is fully integrated with KLA standard data acquisition software, making it easy to access and analyze the tool's test results. The asset is also equipped with advanced monitoring tools and status LEDs that allow for quick and easy troubleshooting and automated log generation. KLA / TENCOR AIT-UV is a top-of-the-line wafer testing and metrology model that offers users the best in both accuracy and repeatability. It combines fully automated wafer testing with advanced metrology software to deliver flawless results, maximizing wafer yield and minimizing costs due to rework. The equipment's expandability also allows for testing and analysis of larger samples and data sets. In a nutshell, AIT-UV is designed to ensure optimum wafer test performance.

There are no reviews yet