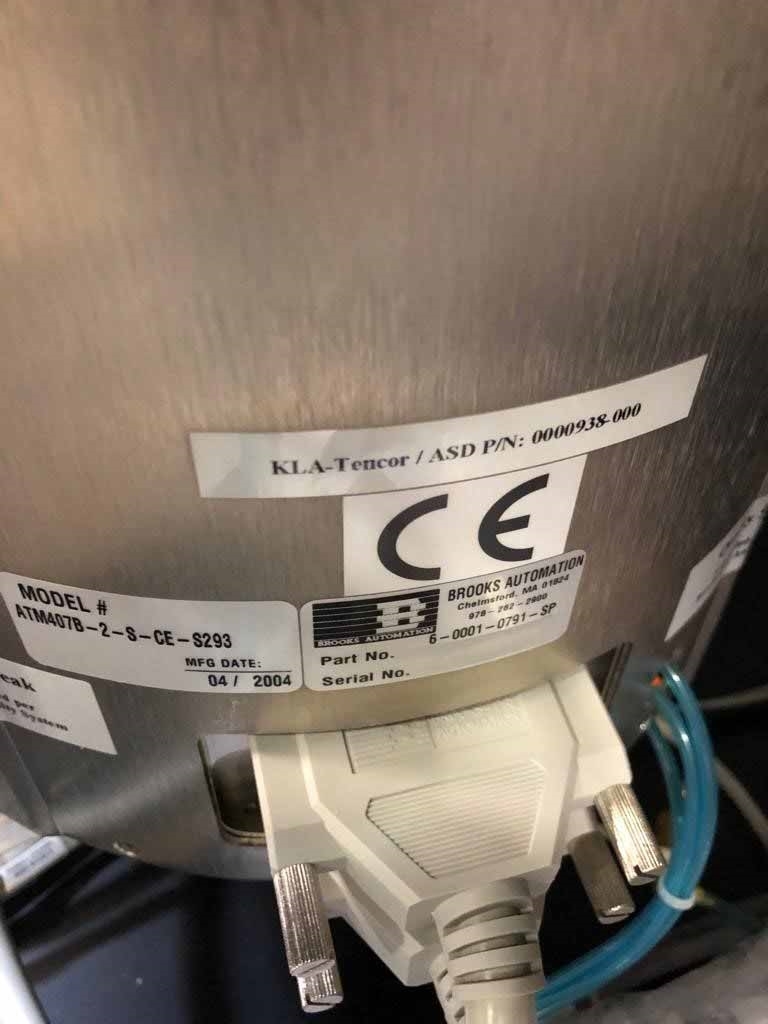

Used KLA / TENCOR AIT #9256108 for sale

URL successfully copied!

Tap to zoom

KLA / TENCOR AIT is a wafer testing and metrology equipment, integrating test and inspection technologies for high-productivity semiconductor wafer analysis. The system is designed to enable industry-leading test speeds and precision space measurements for both 2D and 3D architectures. KLA AIT combines sophisticated applications and functions, providing automated alignment, test detection, defect recognition and classification, high-precision metrology, and correlation analysis on a single platform. The wafer testing unit is comprised of a single module that combines several important features such as off-line calibration, high-speed and large-field-of-view scanning, reliable auto-alignment, statistical process control, wafer-to-wafer correlation, and in-situ testing. The machine is capable of handling large-size wafers up to 300 mm in diameter, with superior defect detection accuracy for an improved yield. Its advanced test technology provides both high-throughput defect inspections and simultaneous multi-sensor measurements. TENCOR AIT tool features an intuitive graphical user interface for easy operation and has powerful hardware for reliable and robust test performance. The asset makes use of a high-precision optical-alignment model for shorter exposure times and automated alignment of wafers across different sensing technologies. This feature ensures consistent accuracy and repeatable measurements for all test configurations. Moreover, the equipment is designed to have a flexible grouping for simultaneous measurement of multiple samples, enabling faster test throughput. It also features intelligent defect management solutions, enhanced camera systems, algorithms for better correlation, and advanced wafer mapping capabilities. AIT is capable of detecting and classifying even the most subtle defects, helping customers optimize their wafer fabrication processes and drive yield improvement. The system is an integral part of advanced fab operations, delivering consistent in-process wafer measurements and test results for every application. In addition, the software suite offers powerful data analysis capabilities, providing real-time visualization of the test results. This allows customers to easily troubleshoot process problems and improve the overall process performance.

There are no reviews yet