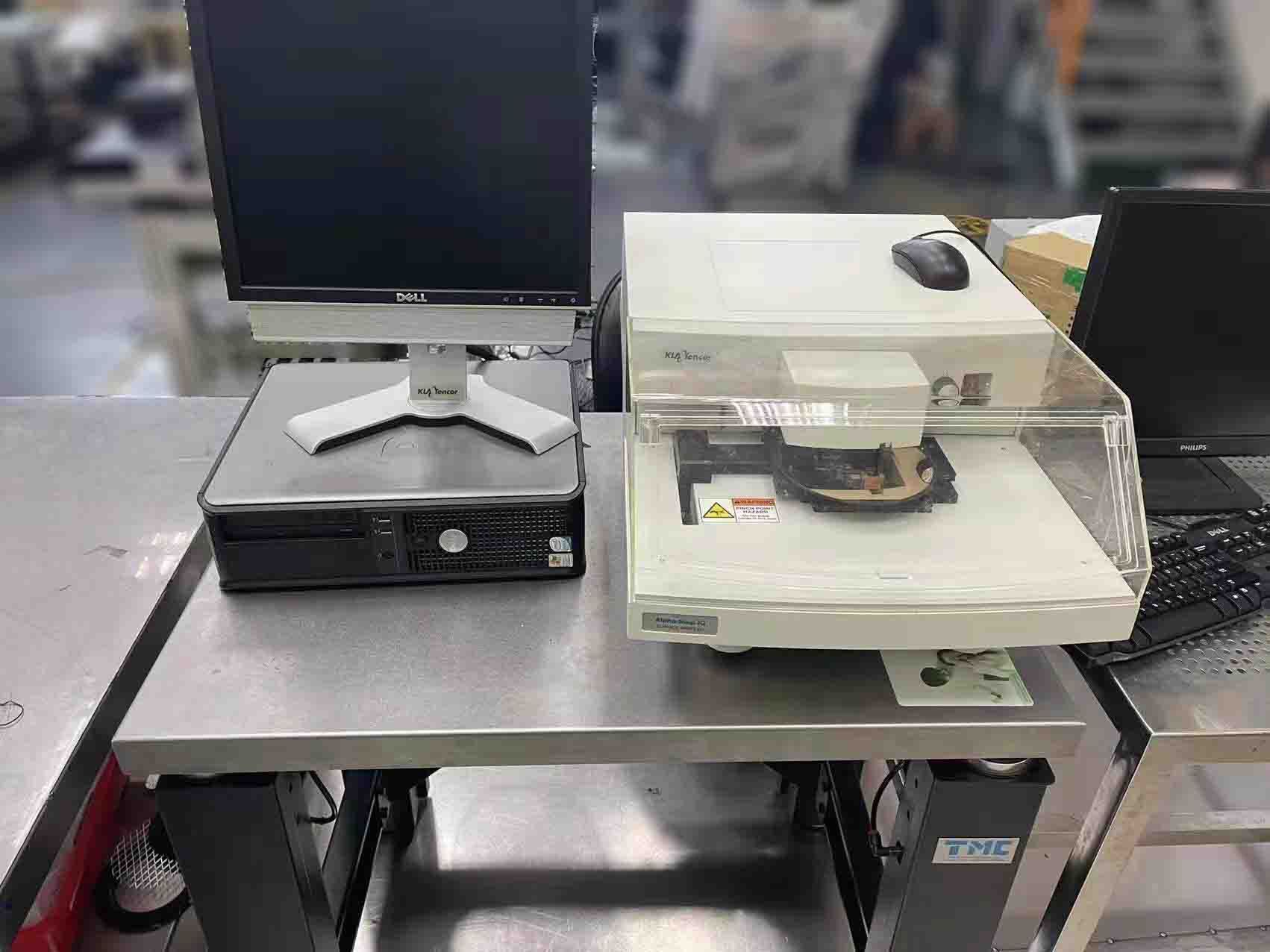

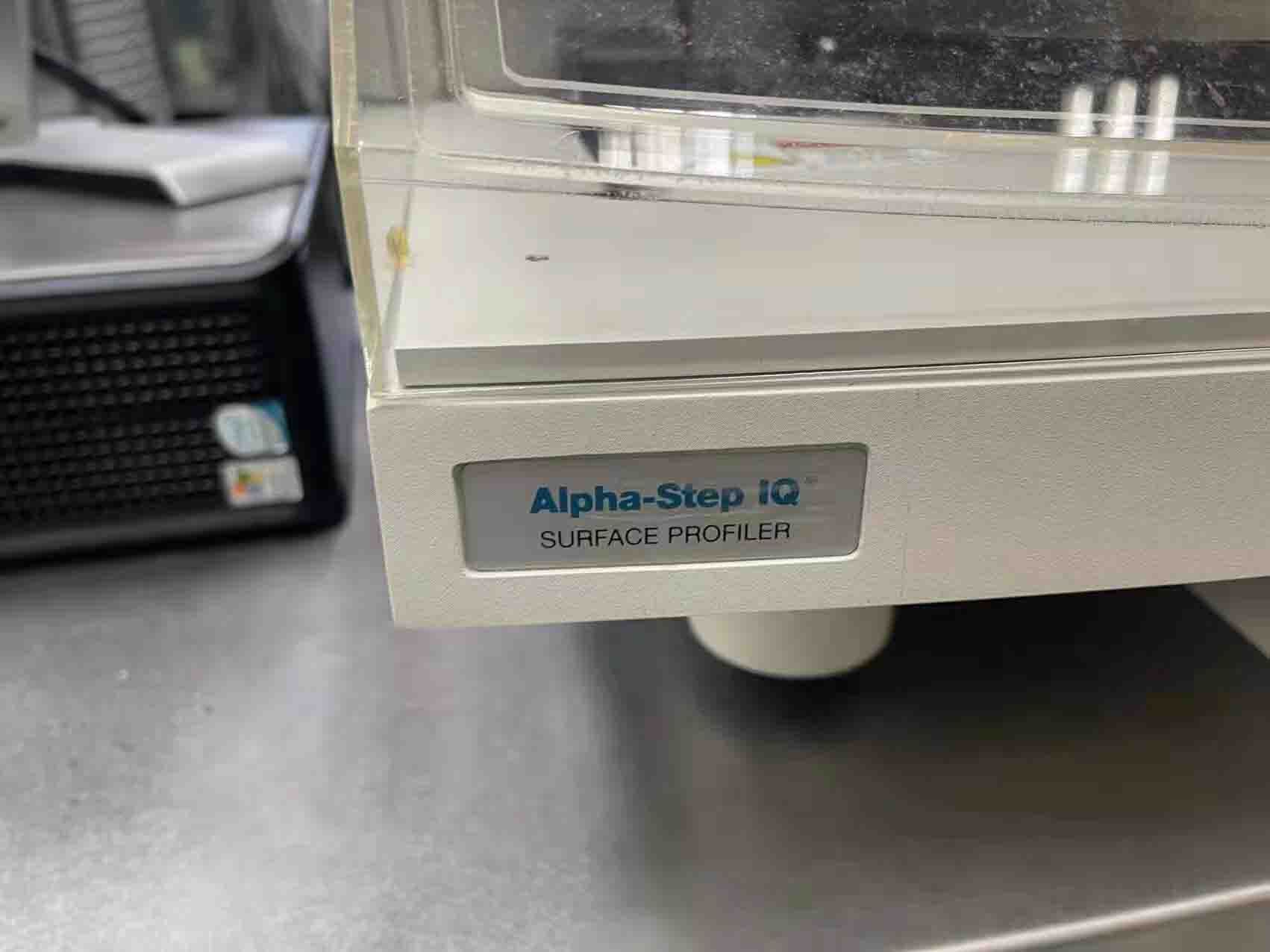

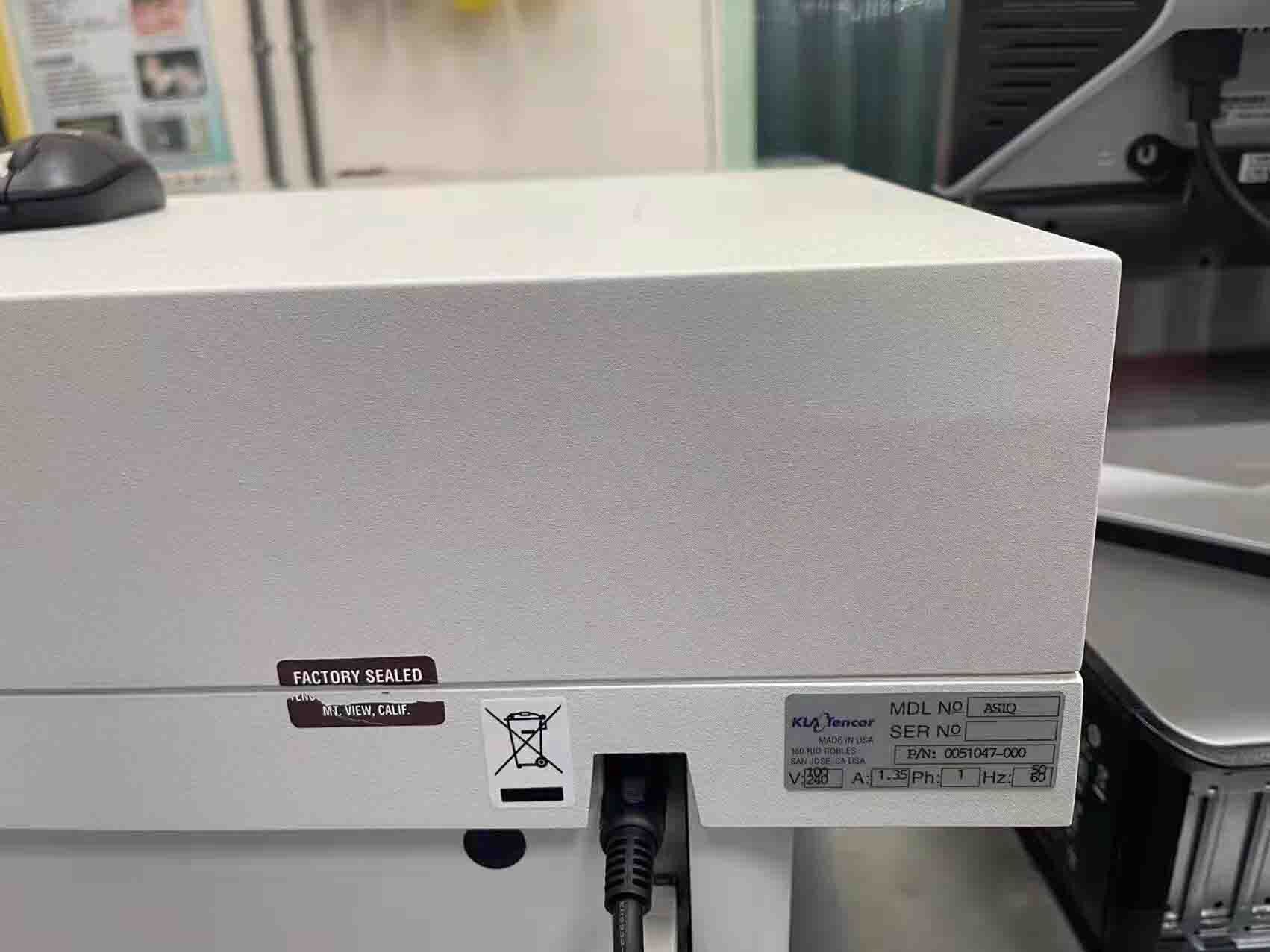

Used KLA / TENCOR Alpha Step IQ #293610543 for sale

URL successfully copied!

Tap to zoom

KLA / TENCOR Alpha Step IQ is a high throughput wafer testing and metrology equipment optimized to ensure efficient testing, process control and device characterization. The system offers advanced inspection capabilities while maintaining robust manufacturing capabilities by providing accurate, repeatable, and traceable measurements of a range of patterns. KLA Alpha Step IQ incorporates up to two independent process chambers and advanced software algorithms to enable fast and accurate measurements of device topography, such as critical dimensions and line/space widths. The unit offers fast and reliable inspection of a variety of process steps, including lithography, etch, and film deposition. Using advanced optical microscopy, TENCOR ALPHASTEP IQ can measure surface roughness, etch depths, CD uniformity, resist thickness, and line/space widths with greater accuracy and speed than conventional optical microscopes. Mirror diagnostics and imaging are used to ensure the highest fidelity measurements. TENCOR Alpha Step IQ incorporates chromeless metrology mode for unmatched repeatability and accuracy of critical dimensions, even on challenging chip design.. The advanced software algorithms applied to the inspection and profiling data helps maintain tight CD specifications. The machine also includes optical overlay measurement to ensure highly accurate process control. In addition to these features, KLA / TENCOR ALPHASTEP IQ provides advanced reporting capabilities, including a range of graphing and display options, to ensure a complete picture of the process's results. Through the use of statistical process control, the tool can identify individual process deviations and analyze the entire process, providing the means to quickly isolate, study, and respond to potential process issues. In conclusion, Alpha Step IQ is an advanced wafer testing and metrology asset that offers a highly efficient, accurate, and reliable method for wafer processing and device characterization. The model offers quick and accurate measurements of a range of patterns, from critical dimensions and line/space widths to surface roughness, etch depths, and resist thickness. The advanced software algorithms help maintain tight CD specifications and analysis of the entire process helps quickly identify and respond to potential process issues.

There are no reviews yet