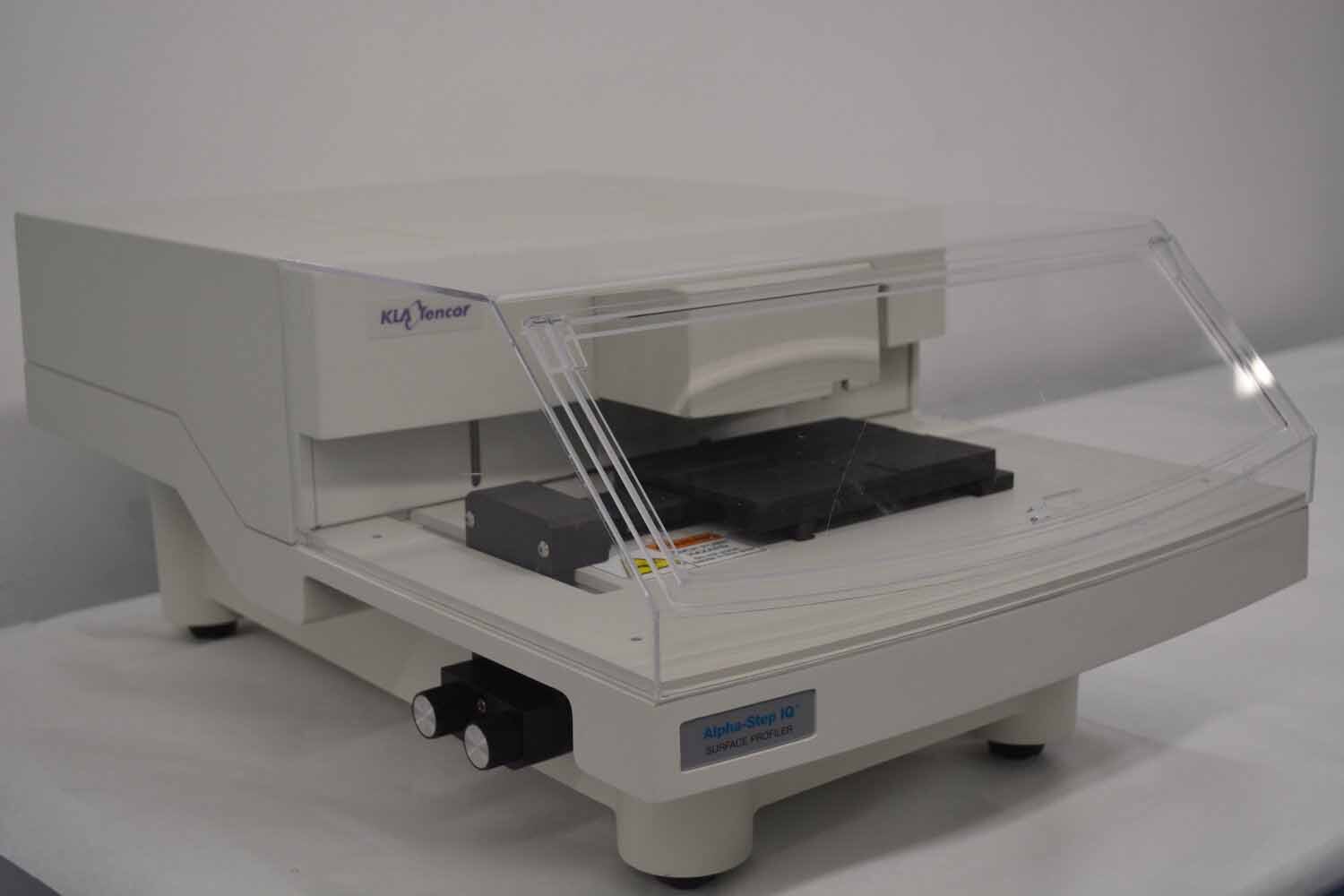

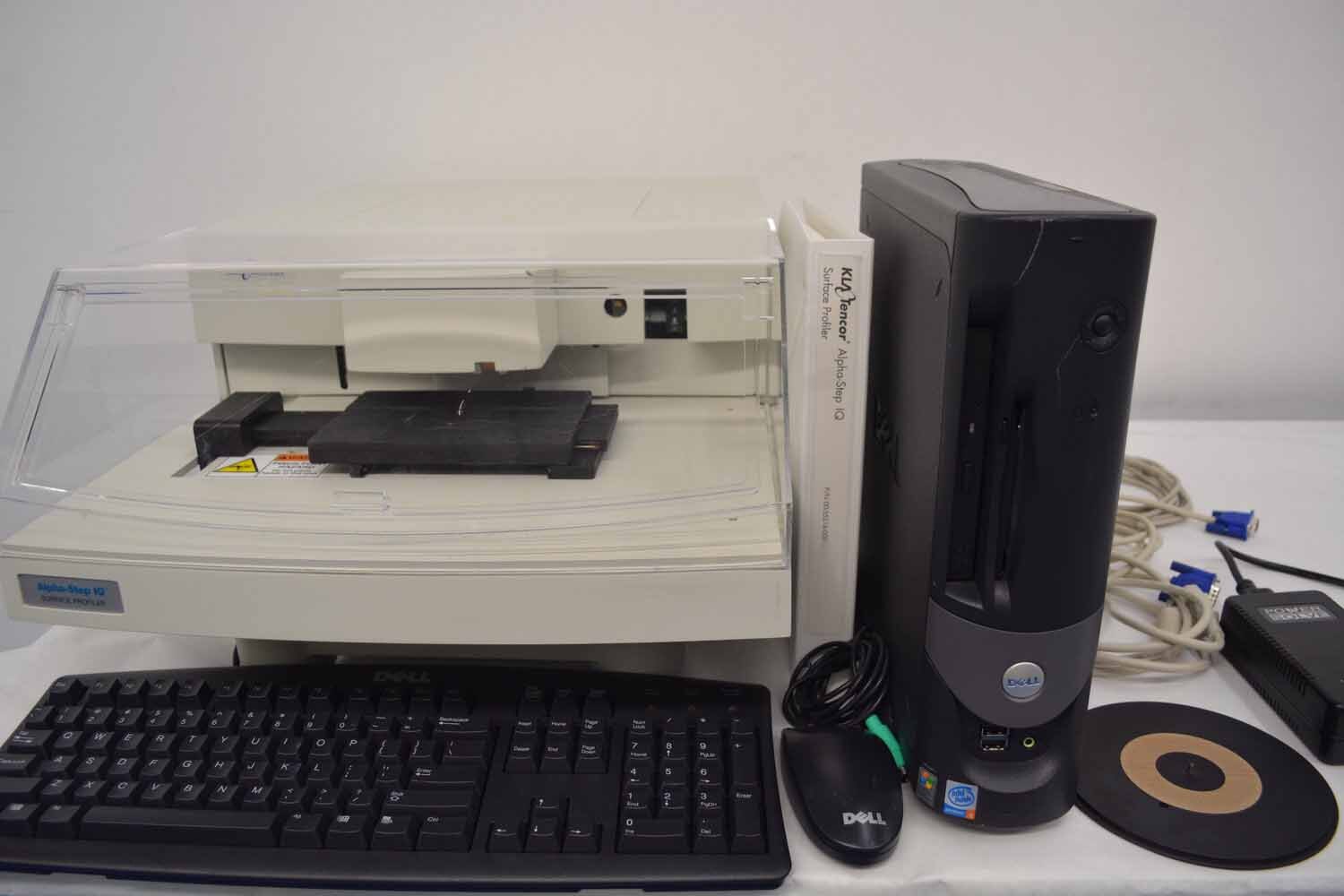

Used KLA / TENCOR Alpha Step IQ #9229842 for sale

URL successfully copied!

Tap to zoom

KLA / TENCOR Alpha Step IQ is an advanced wafer testing and metrology equipment designed for advanced process control of semiconductor nanolithography. It features a number of powerful features which ensure that the levels of quality required for modern semiconductor manufacturing process are met. KLA Alpha Step IQ is an imaging-based system, allowing users to create images of a complete wafer surface with nanometer resolution. It utilizes high NA (numerical aperture) optics, facilitated by specialized beam delivery and imaging accessories, to inspect both the top and bottom surfaces of the wafer. The unit can detect a wide variety of features, from submicron features to larger trenches and other structures. The scan head is moved by an X-Y servo-controlled motor stage, which provides the user with an impressive ability to measure and analyze features on a variety of wafer geometries. The machine is able to measure a large number of key metrics related to the wafer surface, including aspect ratio, critical dimension, line width roughness, sidewall angles, and more. These data points may then be graphically displayed via the user interface, or used to create a 3D map of the wafer surface. Advanced analytics are also available, which can detect sub-micron variations in heights, angles, and other features. A number of additional features make TENCOR ALPHASTEP IQ a truly powerful wafer testing and metrology tool. Imaging capabilities may be enhanced with post-process options, including map-based analysis and auto-focus. Additionally, image data can be captured and stored for post-analysis. The asset also includes automated wafer alignment features for improved accuracy. Overall, KLA ALPHASTEP IQ is a highly advanced wafer testing and metrology model that is ideal for process control and semiconductor nanolithography. It offers a powerful combination of imaging and analytical features, making it capable of detecting a wide range of features on a variety of wafer geometries. Furthermore, its automated alignment capabilities and post-processing options add an extra layer of accuracy and accuracy of analysis.

There are no reviews yet