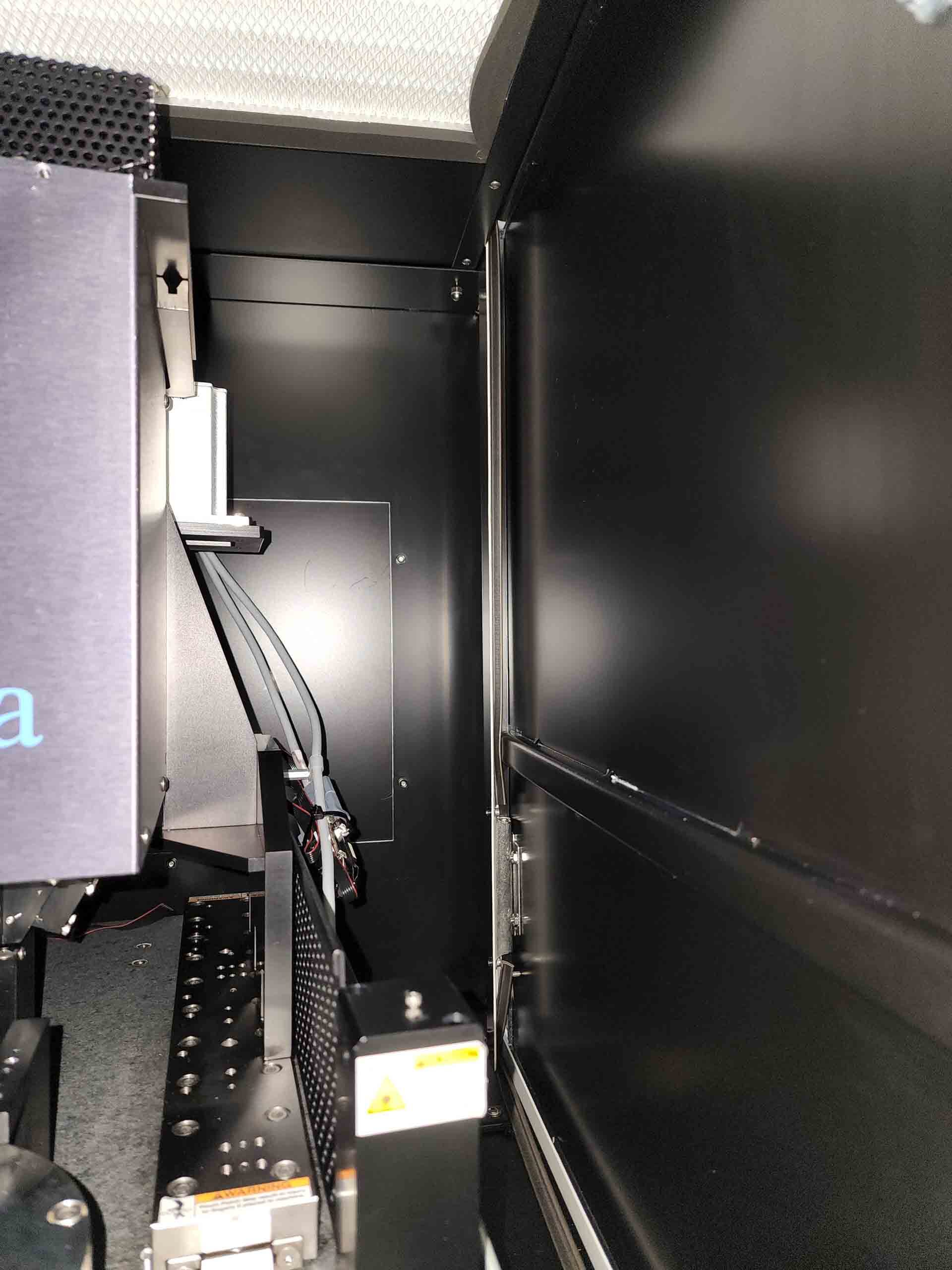

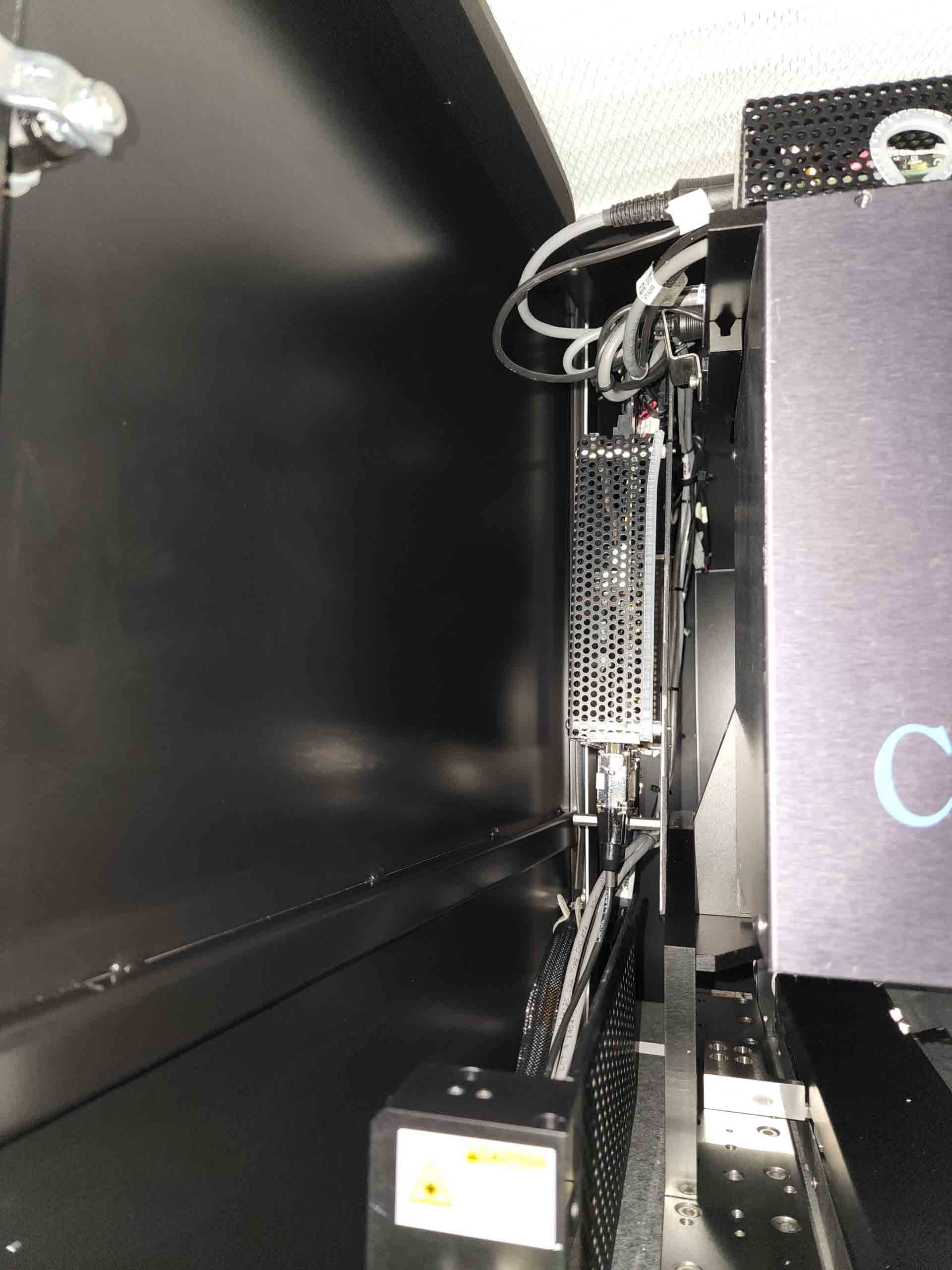

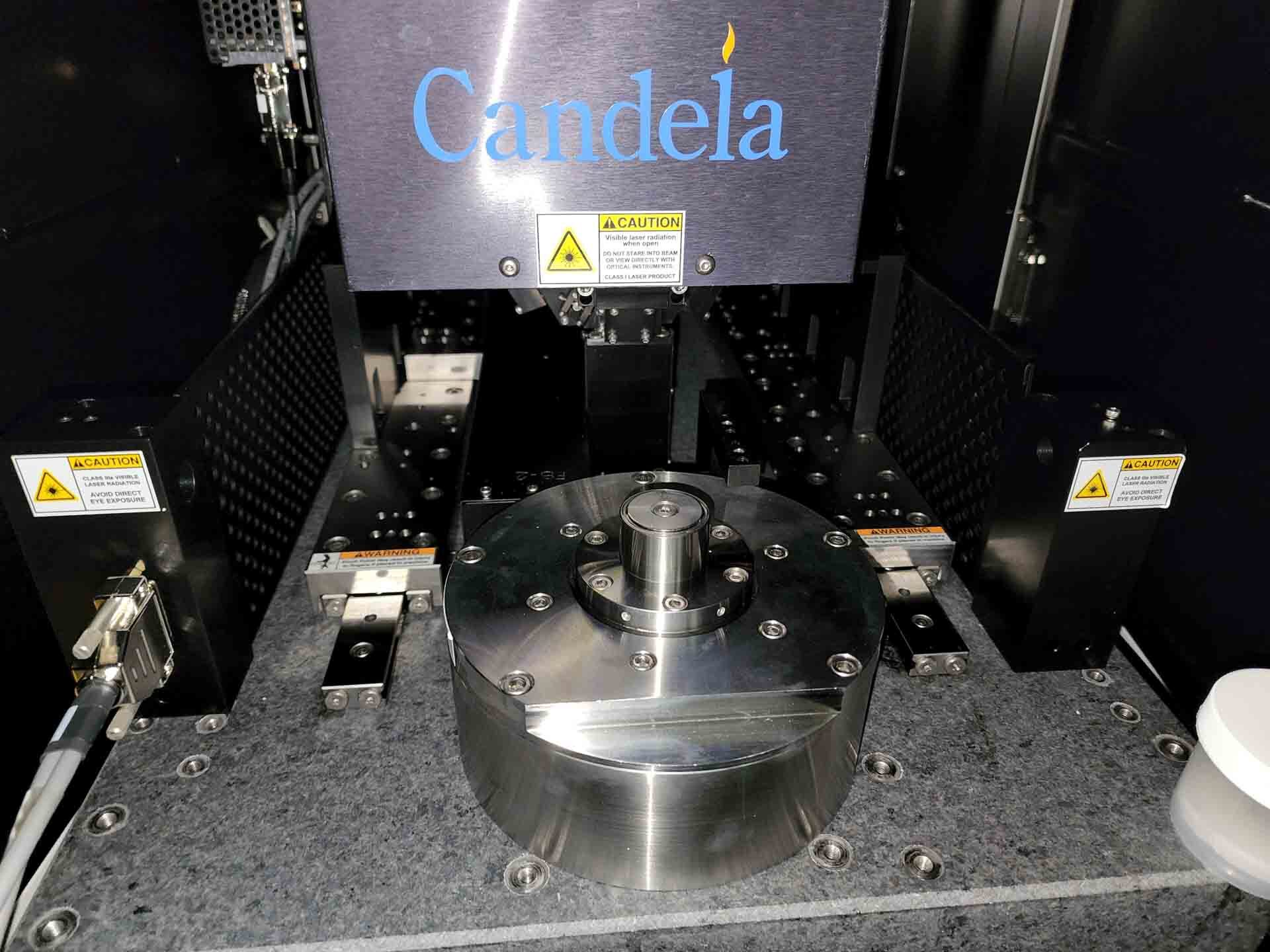

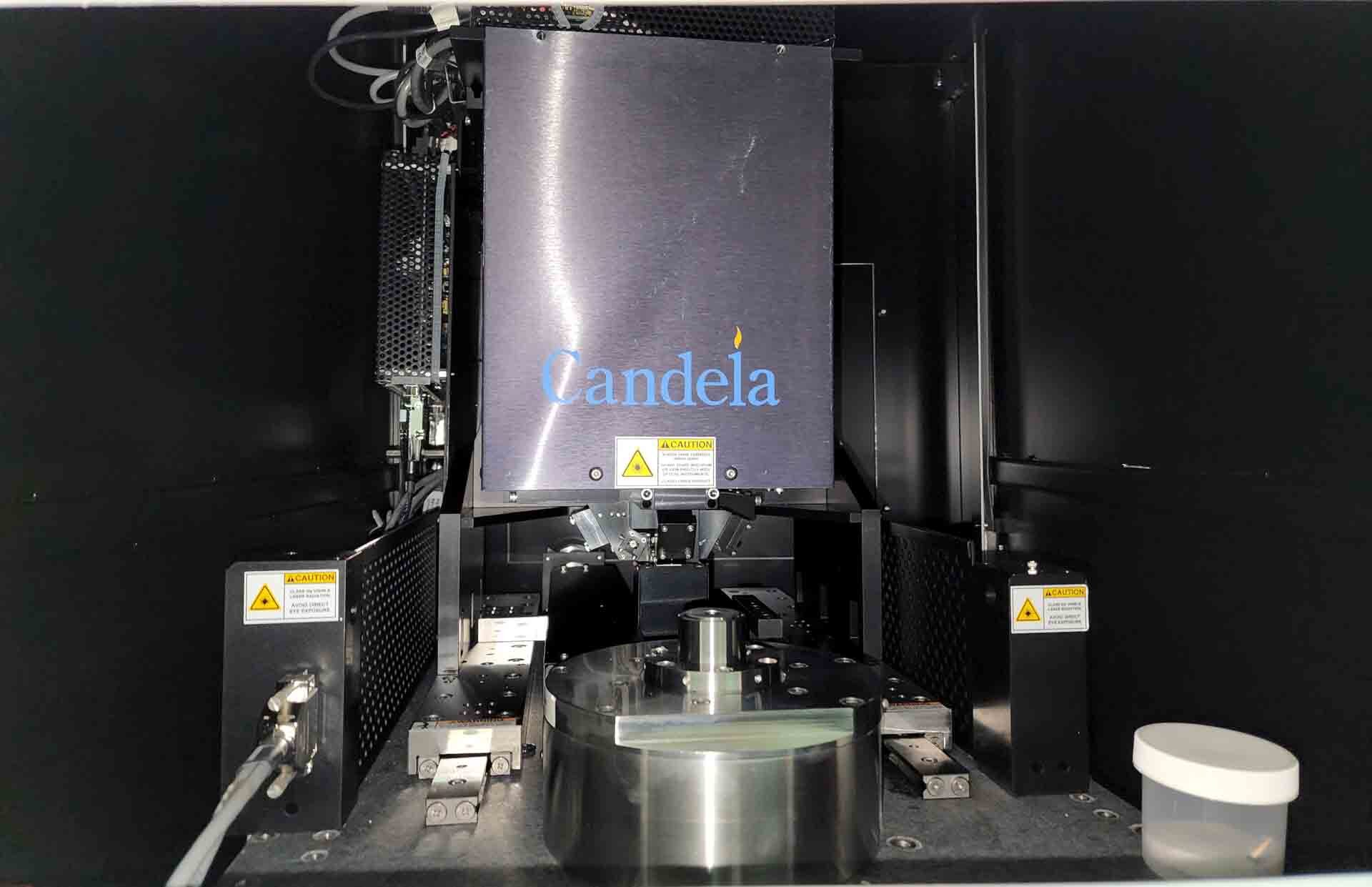

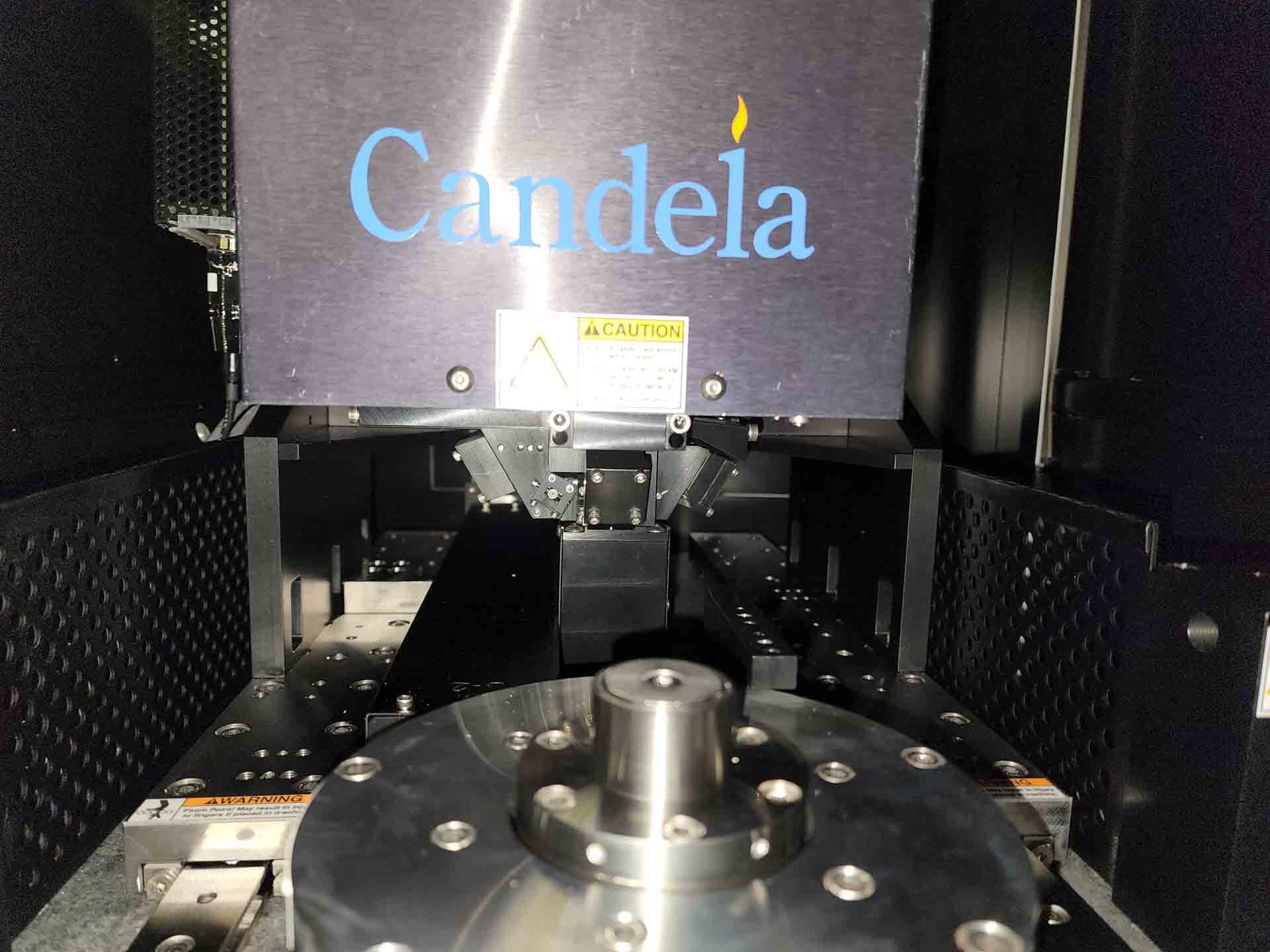

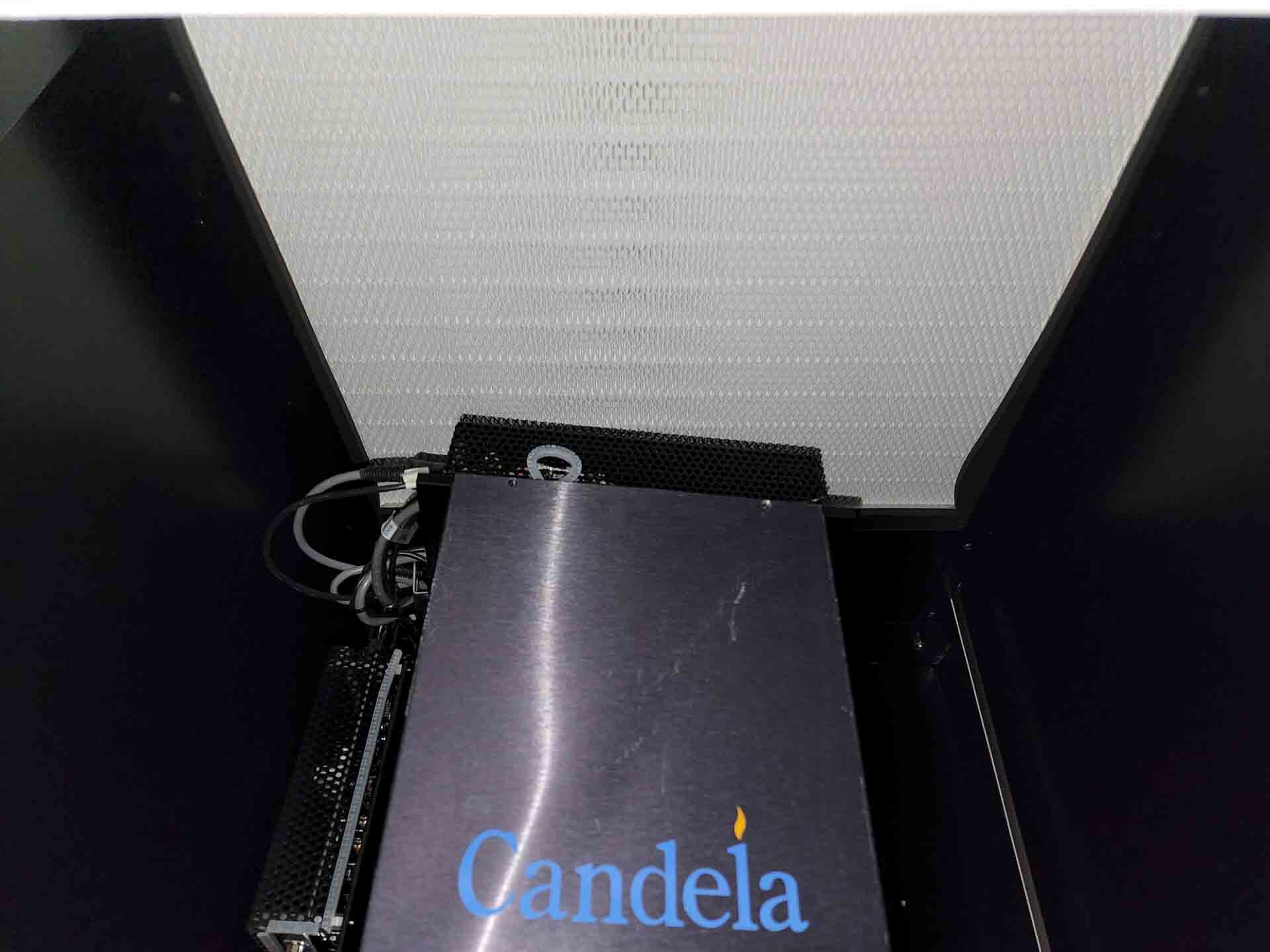

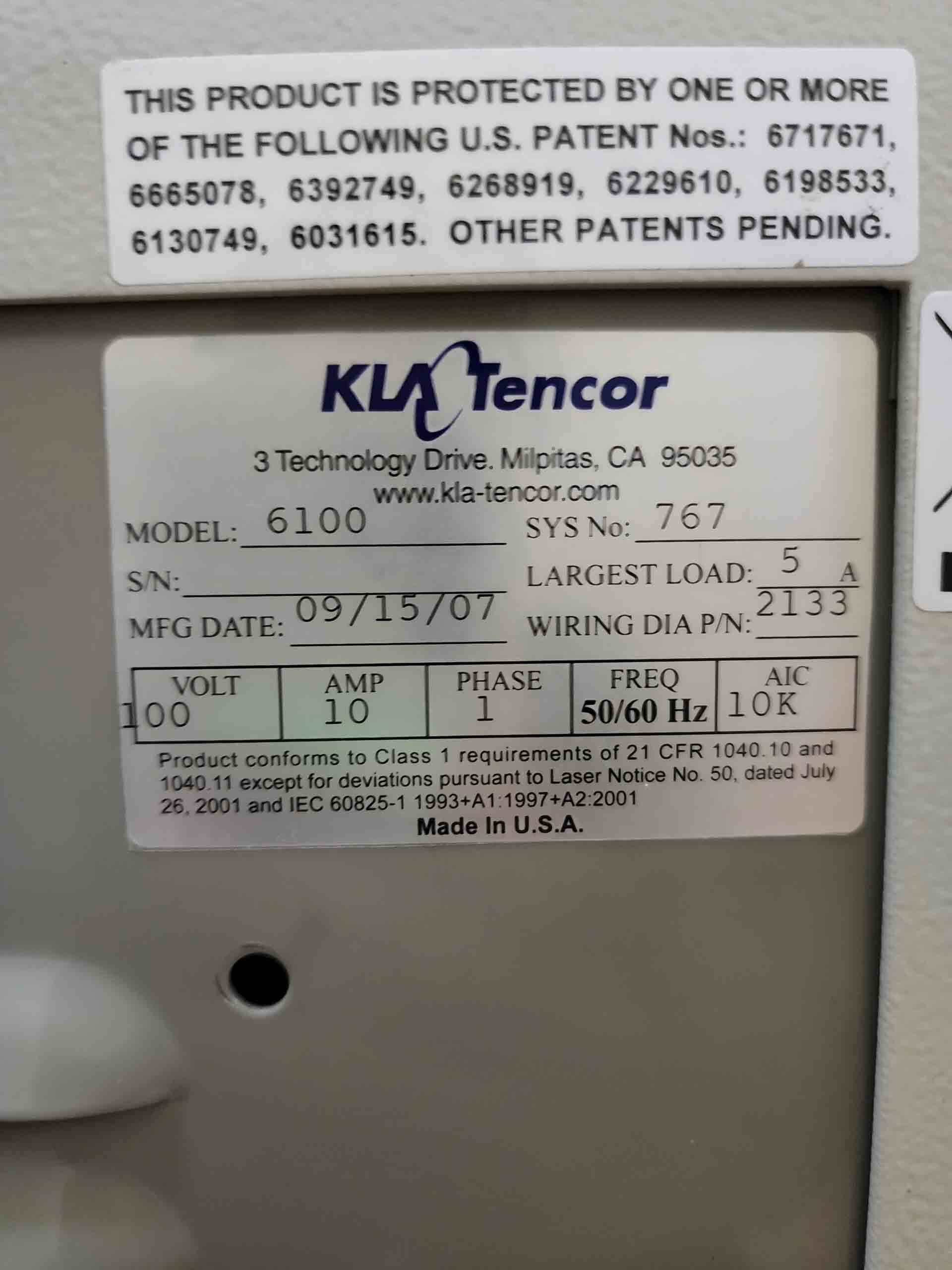

Used KLA / TENCOR Candela 6100 #293597435 for sale

URL successfully copied!

Tap to zoom

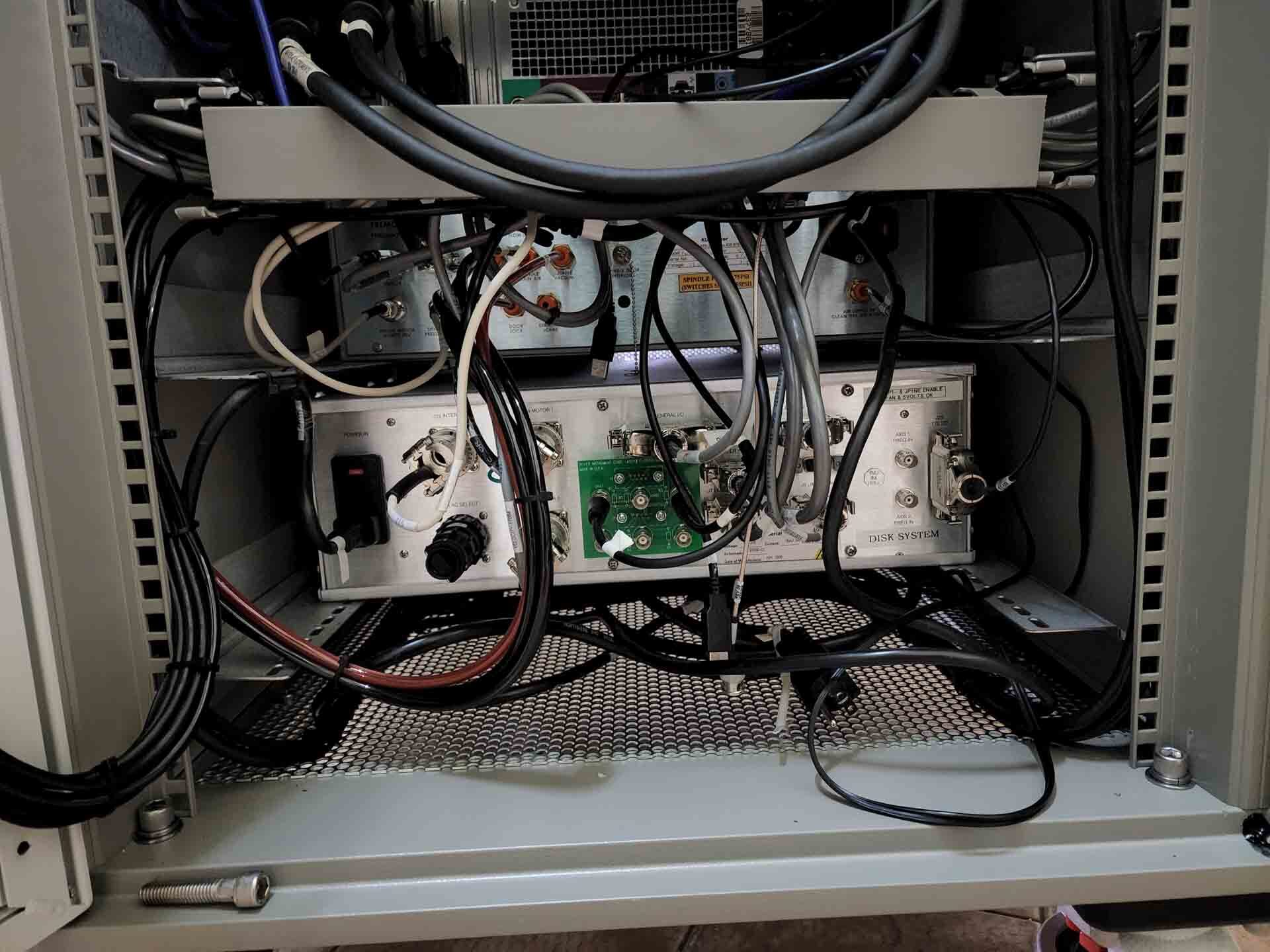

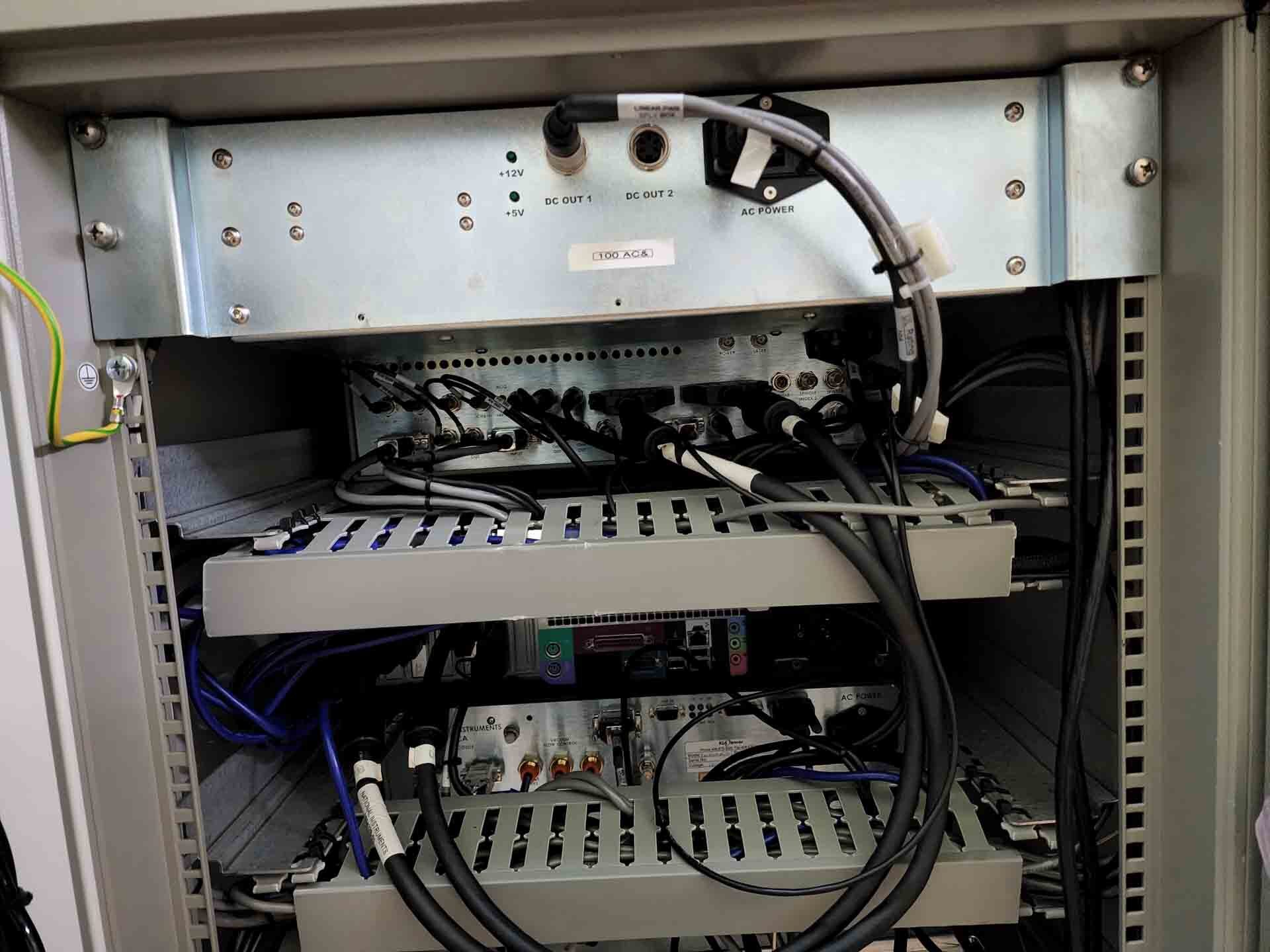

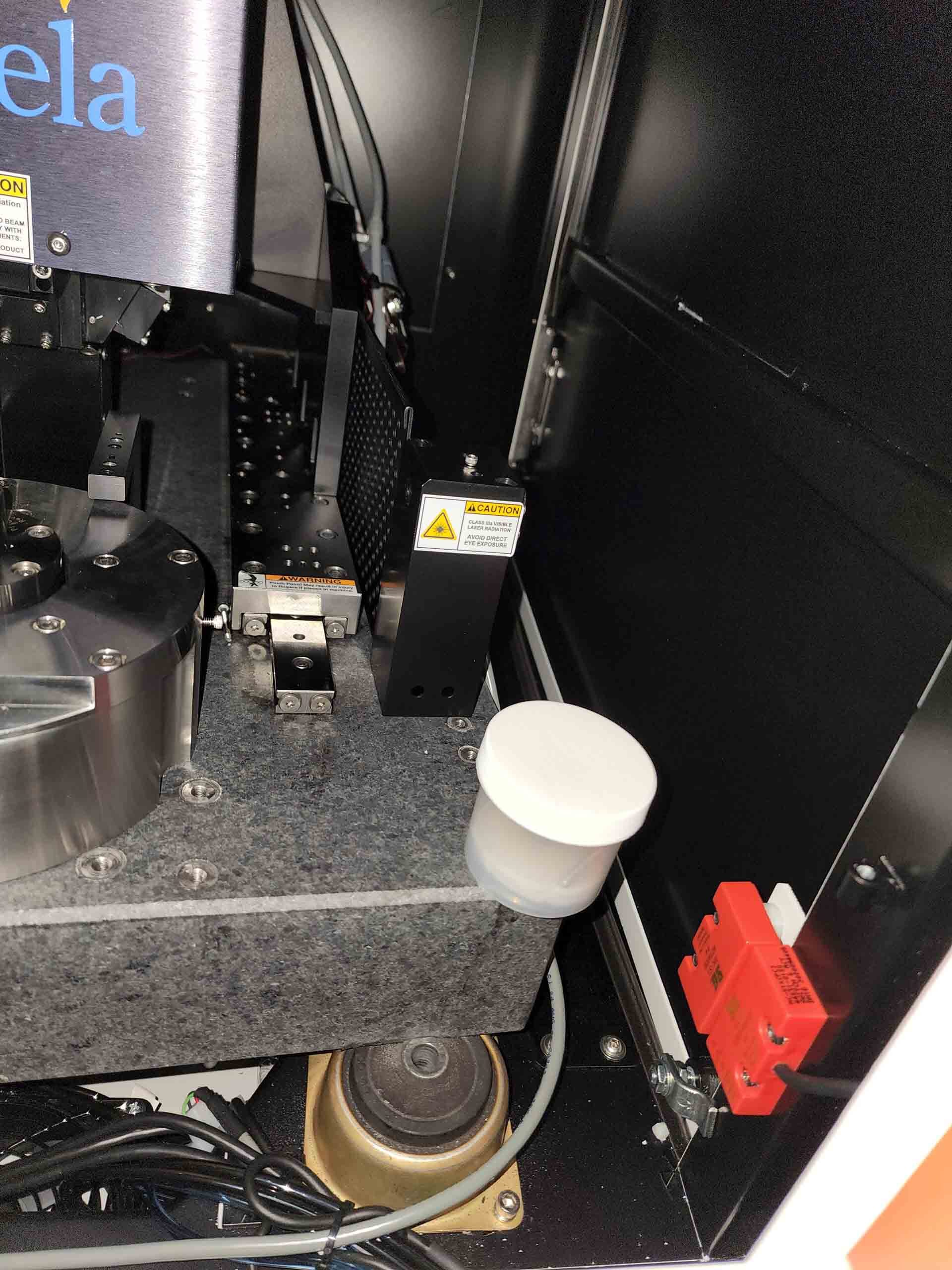

KLA / TENCOR Candela 6100 wafer testing and metrology equipment is a tool used in the semiconductor fabrication process to measure the electrical characteristics of integrated circuits. It provides an automated, high-throughput wafer testing and metrology process, offering reduced total cycle time and improvement in testing speed and accuracy. The main components of the system are: On-wafer measurement head, Measurement Electronics POD (MEP), Carrier-based Measurement Unit (CMS) and third-party automation uppers. The on-wafer measurement head is the part of the machine that physically interacts with the wafers in order to measure the electrical characteristics. This includes probes that are held in place during the measurement process, ensuring that the wafer is properly positioned for the tests to be applied. The Measurement Electronics POD is the main piece of equipment that operates in a controlled environment, gathering, filtering and analyzing data from the on-wafer measurement head. The Carrier-based Measurement Machine, meanwhile, integrates measurement and testing results from multiple wafers during the same cycle, providing data comparison and analysis that helps manufacturers optimize their process. Finally, the third-party automation uppers, such as Semiconductor Accelerator, allow manufacturers to integrate KLA Candela 6100 into the overall production process to maximize efficiency. The tool is designed to deliver outstanding testing speed and accuracy, with features such as advanced timing measurements, active noise cancellation, ultra-low voltage control, low current characterization, advanced geometrical analysis and high-speed comparisons. It is also optimized for increased device testing, including radiofrequency and digital devices. This makes it an ideal tool for identifying and ensuring yield and process control in semiconductor fabrication and chip production. TENCOR Candela 6100 is a versatile and scalable asset, ideal for a wide range of wafer sizes and technologies. Its built-in capacity for automated testing and continuous data acquisition reduces the number of re-test cycles and allows for faster product optimization. In addition, its modular structure increases reliability and scalability, acting as a platform for future technology requirements. In summary, Candela 6100 is a powerful wafer testing and metrology model designed to optimize the wafer manufacturing process. It offers high-speed, accurate measurements across a broad range of wafer sizes and technologies and is a reliable tool for increasing yield and process control. Its advanced features, high throughput, and scalability make it a reliable and valuable tool in semiconductor production.

There are no reviews yet