Used KLA / TENCOR Candela CS10 #9186184 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9186184

Vintage: 2012

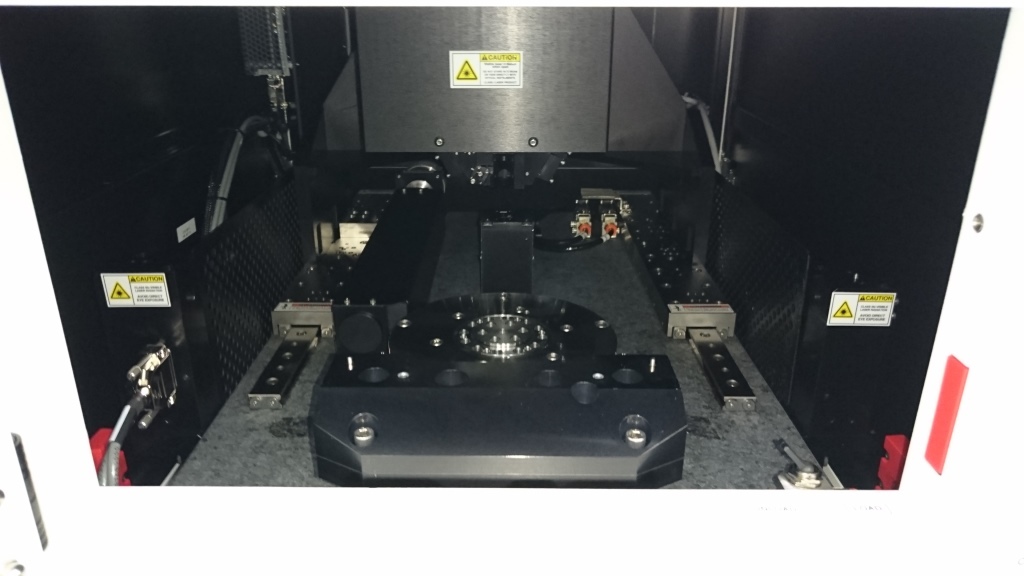

Optical surface analyzer

Dual-laser optical X-Beam technology

(2) Laser paths / (4) Independent wafer surface detection techniques

Particle sensitivity on polished silicon wafers: <0.08 Micron

Exceptional sensitivity to micro scratches:

Automatic wafer surface inspection

Defect detection / Classification: 2"-12" Transparent and opaque wafers

Kit, 6"

Software version: 6.8

2012 vintage.

KLA / TENCOR Candela CS10 wafer testing and metrology equipment utilizes advanced imaging and metrology technology to inspect wafers before they are used for electronic device fabrication. This system utilizes 5-axis articulating stages to support full wafer inspection with confined loading and unloading areas. The CS10 has a novel horizontal beam path, which reduces an operator's footprint while also providing enhanced view fields to enhance global defect detection. Its advanced optics unit utilizes step scan capabilities to scan specially refractive flat specimens with unsurpassed focus and resolution. It also features 3k x 2k image capture resolution and advanced Image Upscaling technology that ensures even sharper images. The CS10 is configured with the latest in imaging and metrology technology, offering multiple sensor and analysis configurations in a single instrument. It is calibrated and capable of measuring a broad range of signal levels from 0.1nm to 80um and evaluating a variety of materials of various thickness, e.g. high-aspect-ratio device structures and thinned wafers. The CS10 is compatible with various process chemistries and an extensive library of automated measurement algorithms. It features material-adaptive technologies to address various wafer types, as well as wafer shapes and sizes ranging from 200 to 800 millimeter. The CS10 offers extensive options for wafer probing from non-contact optical measurements to contact and non-contact probes, such as Acoustic Micro Imagers, Eddy Current, Laser Displacement Mapping, and Defect Metrology. It is integrated with a metrology tool suite for defect metrology and semiconductor process control analysis. The CS10 is also flexible enough to be fitted in an existing production environment without any need for special cabling, and its advanced data management capabilities enable secure storage of customer data and tight machine security. It is reliable and easy to use, with comprehensive operator training and technical support available. Overall, KLA CANDELA CS-10 is a reliable and versatile wafer testing and metrology tool that provides the latest imaging and metrology technology to ensure high quality and accurate inspection of various wafer types and sizes. It is a valuable solution for electronic device manufacturers that require fast and precise defect detection in a cost-effective manner.

There are no reviews yet