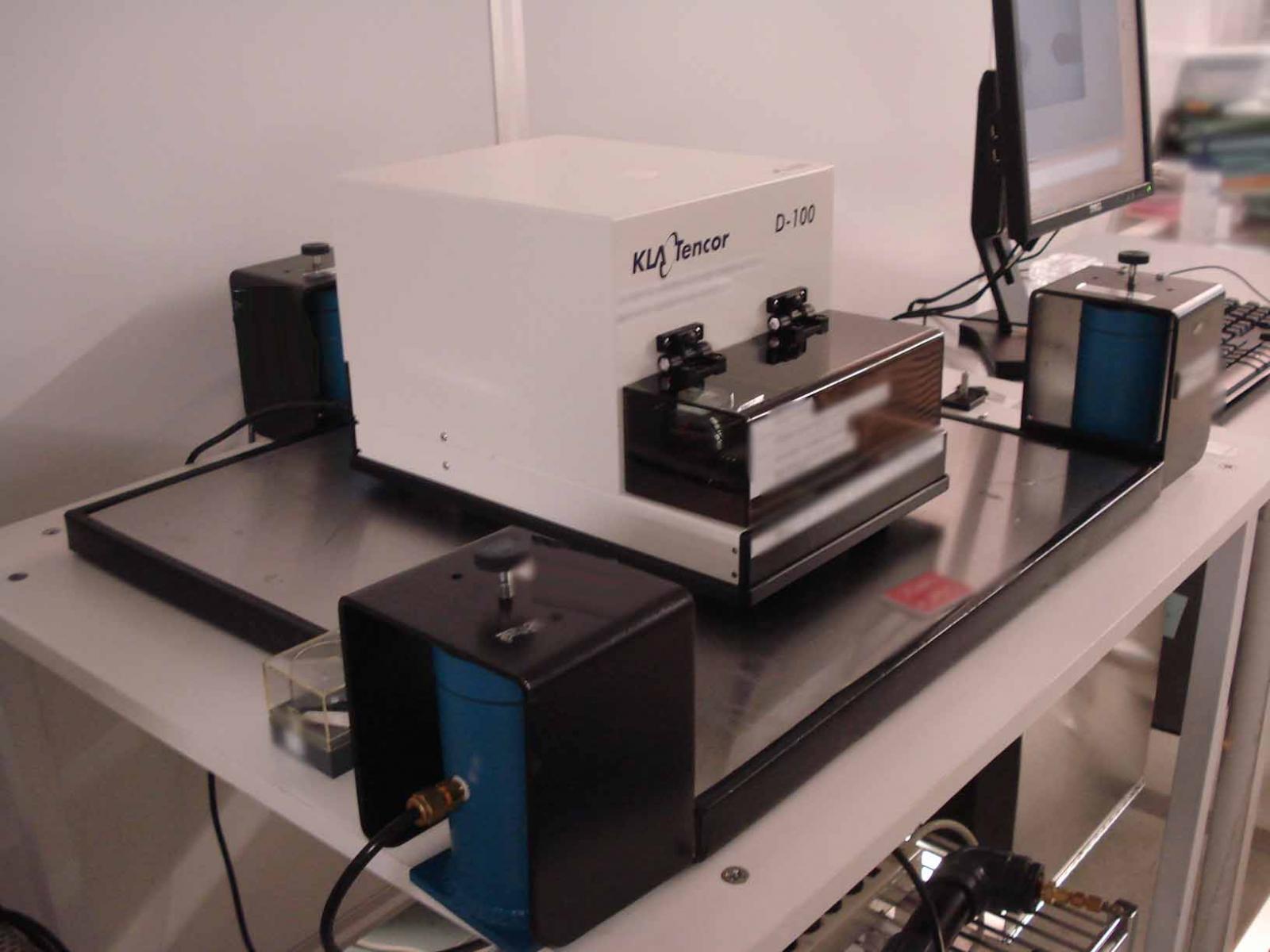

Used KLA / TENCOR D-100 #9183316 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

KLA / TENCOR D-100 wafer testing and metrology equipment is a highly advanced technology designed to achieve rapid, accurate, and precise analysis of bare and device substrates on a wafer level. This technology utilizes multiple scanning probes, high-resolution stitching, and parallel processing that work together to accurately gather data and analyze wafer topography. KLA D-100 is a scan system that utilizes advanced scanning probes and stellar stitching to accurately capture measurements of the wafer topography. Working together, two probes—a dual-arc laser confocal and a dynamic aperiodic scanning optical microscopy (ASOM) probe—scan the substrate from two different heights to capture the deepest and most accurate data of the wafer topography. This data is then stitched together (or merged) to deliver detailed, high-resolution images of the wafer surface. The images generated by the stitching software enable users to view detailed, three-dimensional contours of the wafer topography. The unit also features a variety of measurement and metrology processes. These measurements are attained using a combination of coherence scanning interferometry (CSI), critical dimension non-uniformity (CDU), and etch gap measurement (EGM) technologies. CSI utilizes a single laser beam that interferes collectively with multiple reflected laser beams from the wafer to accurately measure wafer topography at a nanometer scale. CDU captures multiple images from different fields-of-view and creates correlation maps of line widths and other critical dimensions for analysis. EGM uses critical dimension optical scanning microscopy (CDOSM) to gather data for wafer etch gap measurements. TENCOR D-100 also includes advanced tools for image processing. In-machine image processing allows users to accurately analyze data quickly and generate up to three distinct types of images. These images are used for determining line widths, spacing, critical dimensions, overlay, focus, defect detection, and other things. The tool also contains edge detection tools, phase image correlation, particle count, and other imaging capabilities. In addition, D-100 wafer testing and metrology asset is designed for model-level automation capabilities. The equipment features integrated interfaces and central processing units, which enable users to easily connect to their existing IC test systems. These interfaces enable users to quickly and accurately perform measurements and create large amounts of data points for precise multi-site analyses and production lot tracking. KLA / TENCOR D-100 is also equipped with modern security features, such as encryption and authentication algorithms. Furthermore, the system includes a built-in client-server solution, which allows users to securely access metrology data from any remote location. All in all, KLA D-100 wafer testing and metrology unit is a revolutionary solution that helps users achieve precise and reliable measurements of wafer topographies. With its advanced scanning and metrology processes, integrated automation, and secure access capabilities, TENCOR D-100 enables manufacturers to reduce costs, optimize throughputs, and improve yields.

There are no reviews yet