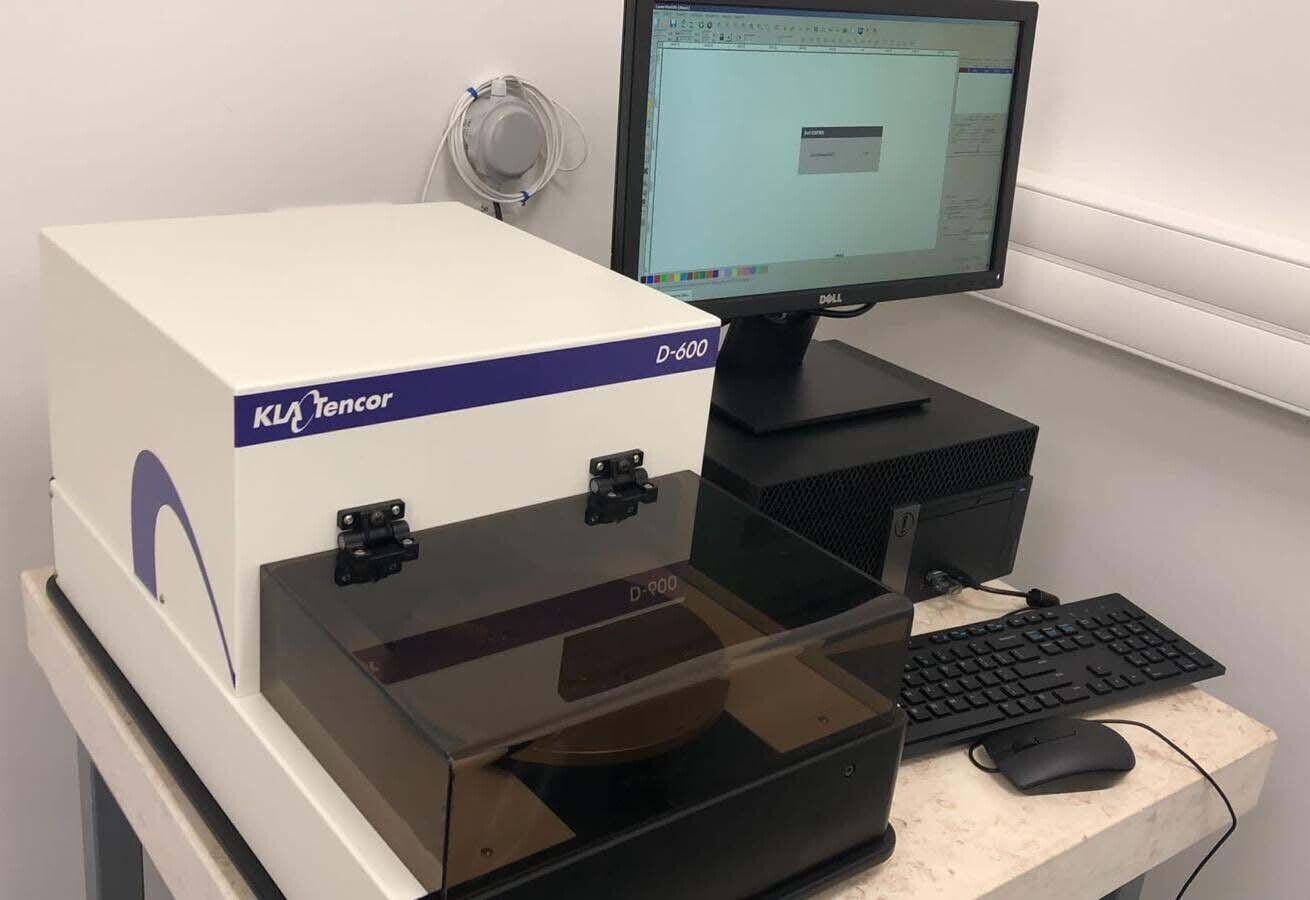

Used KLA / TENCOR D-600 #9411226 for sale

URL successfully copied!

Tap to zoom

ID: 9411226

Wafer Size: 8"

Vintage: 2018

Profiler, 8"

Stage type: Motorized

Vacuum chuck

X and Y Range of motion: 150 and 178 mm

Theta stage: 360°

Maximum scan length: 55 mm

Scanning speed: 10 - 400 μm/sec

Sample thickness: 30 mm

Measurement specifications:

Step height repeatability: 5.0 A or 0.1%

Vertical range: 1,200 μm

Vertical resolution: 0.38 A

Stylus force: 0.03 – 15 mg

Sampling rate: 2,000 Hz

Maximum points per scan: 120,000

Lateral resolution: 100 nm

Side view FoV: 3760 x 3120 μm

Camera: 5 MP Color

Zoom: 4x Digital

Radius:

Standard: 2 - 50 μm

Submicron: 0.2 μm

High aspect ratio: 0.2 - 2 μm

Angle

Standard: 60°

Submicron: > 90°

High aspect ratio: 20 - 45°

Processor: 3.40 GHz Dual core

RAM: 2 GB

Hard drive: 250 GB

USB and ethernet

Operating system: Windows 7

Monitor, 19"

Facilities:

Electrical: 90-260 V, 50/60 Hz

Power: 150 mA

Vacuum: 500 mm Hg (27 Liters/min)

2018 vintage.

KLA / TENCOR D-600 is a state-of-the-art wafer metrology equipment designed to measure material properties, electrical properties, and wafer geometry of advanced wafer substrates and materials. The system can be configured to fit various process needs and utilizes advanced imaging, defect inspection, and analytical algorithms to perform highly accurate and repeatable inspections. The unit is built on a modular imaging platform and is composed of 6 main components which include an imaging station, a vision machine, a sample handling interface, a metrology station, a thermal control tool, and a diagnostic and control unit. The imaging station utilizes high resolution imaging techniques, such as optical scattering, fluorescence and Raman spectroscopy, to provide detailed analysis of the wafer material. The vision asset captures images in real time and can measure features on the wafer as small as one micron in size. The sample handling interface allows for samples to be automatically loaded and unloaded from the model. The metrology station measures characteristics such as thickness, flatness, surface roughness, contamination and reflectivity. The equipment is also able to detect electrical properties and analyze potential defects. This data is then analyzed to provide information about the wafer's properties. The thermal control system keeps the wafer at an optimal temperature to ensure an accurate measurement. Finally, the diagnostic and control unit provides the operator with an interface to configure unit parameters, view inspection results, and modify experiment parameters. It also allows the machine to be operated remotely and can interface with other systems in the lab. By incorporating the latest technologies and designs, KLA D-600 is able to perform a variety of wafer metrology applications quickly and accurately.

There are no reviews yet