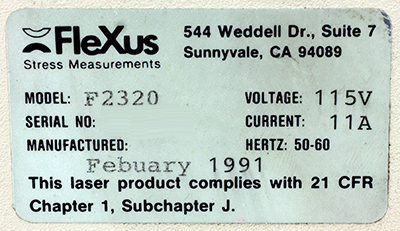

Used KLA / TENCOR Flexus 2320 #9031965 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9031965

Vintage: 1991

Dual Wavelength 500 deg C Scanning Thin Film Stress Measurement System, up to 6"

Accurately measures the stress of thin films at temperatures up to 500 deg C

Stress measurements performed at high temperatures provide a better understanding of film properties

Detects conditions that lead to reliability problems such as metal film and dielectric cracking, voiding and lifting, and hillock formation

Wafer topography can be displayed in both 2-D and 3-D

115V, 50/60 Hz, 11A

1991 vintage.

KLA / TENCOR Flexus 2320 is a wafer testing and metrology equipment designed for wafer-level process control and yield analysis. The system boasts a wide selection of advanced features which allow it to acquire, analyze and report on various results from wafer surfaces, as well as evaluate and adjust a broad range of important characteristics. KLA Flexus 2320 is equipped with 5-dimensional imaging capabilities, high-precision pixel-level measurements for uniformity and advanced overlay metrology. This advanced metrology unit provides volatile and non-volatile measurement capabilities including defect review, line pattern fidelity, line width, focus and overlay measurements. The machine's defect review tools allow for separation of particles, pinholes, scratches, pellicles and other defects from true defects and false alarm sources. TENCOR Flexus 2320 is also equipped with a range of image analysis and metrology functions which include proration, line angle, line width and defect metrology. This suite of software and hardware features is designed to enable specifications-driven process control, repeatable measurements and superior throughput. It is capable of detecting particles and voids on wafers without adversely affecting the wafer process. Using its advanced 5-dimensional imaging capabilities, Flexus 2320 can quickly acquire multiple parametric data for each wafer, enabling defect detection on multiple levels, including height, surface area, edge profile, lateral dimension, electron mobility, and capacitance. Any de-speckle noise or dust on wafers can also be identified and filtered out using its advanced imaging capabilities. In addition, KLA / TENCOR Flexus 2320 offers a range of options for process control. Its state-of-the-art analysis and reporting capabilities allow for real-time Sigma plots which can be used to validate process specifications. This tool can also generate 3D images of defects on wafers which allows for root-cause analysis of catastrophic failures. KLA Flexus 2320 can also detect the location of defects and flags them for review and/or inspection. TENCOR Flexus 2320 provides an extremely flexible, high-performance solution for wafer testing and metrology. Its advanced capabilities and powerful software and hardware features enable quick process validation, repeatable measurements, defect detection and process control. Its comprehensive metrology and imaging capabilities make it an unbeatable choice for high-precision, reliable wafer testing and metrology.

There are no reviews yet