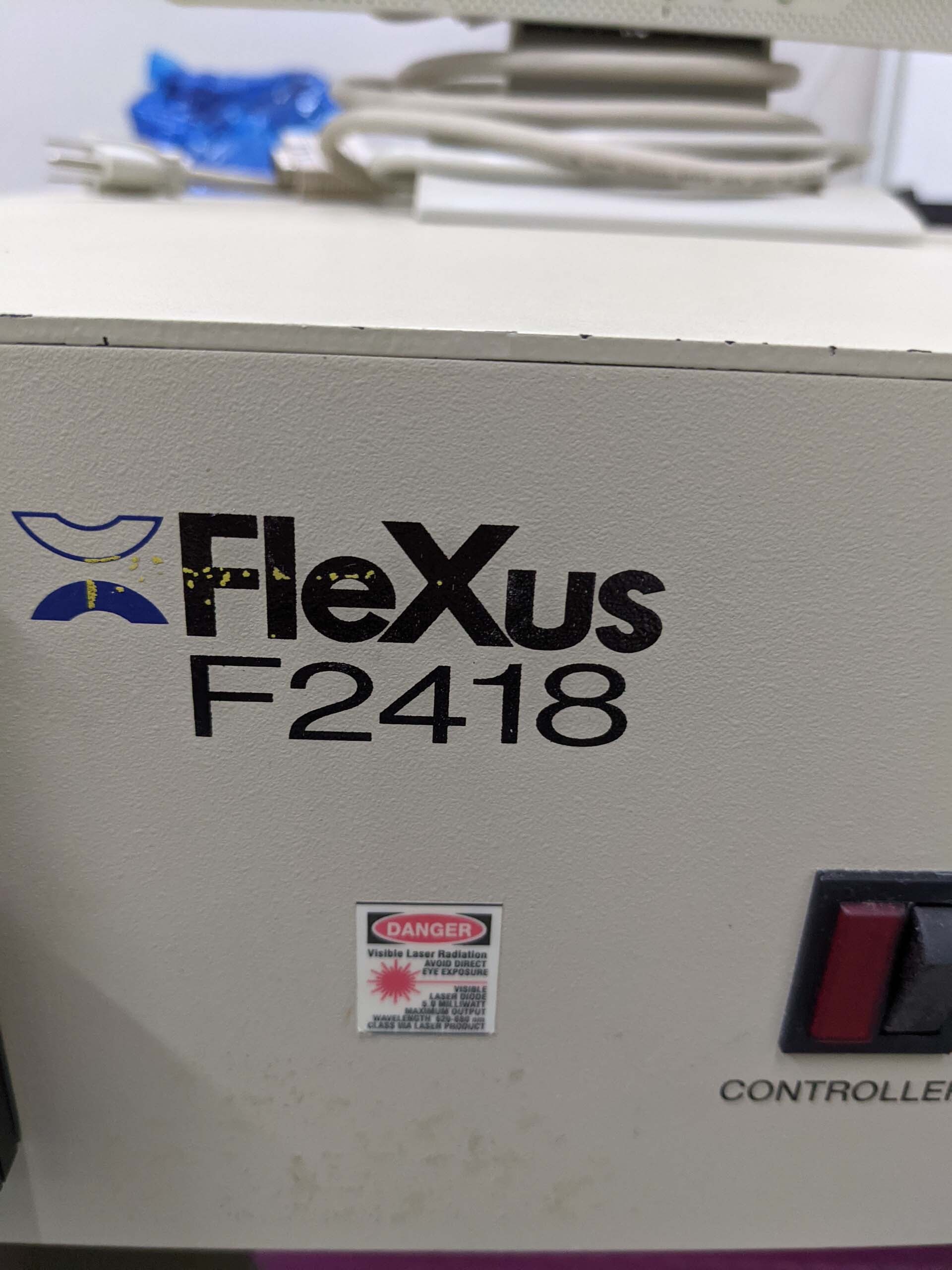

Used KLA / TENCOR Flexus F2418 #9375031 for sale

URL successfully copied!

Tap to zoom

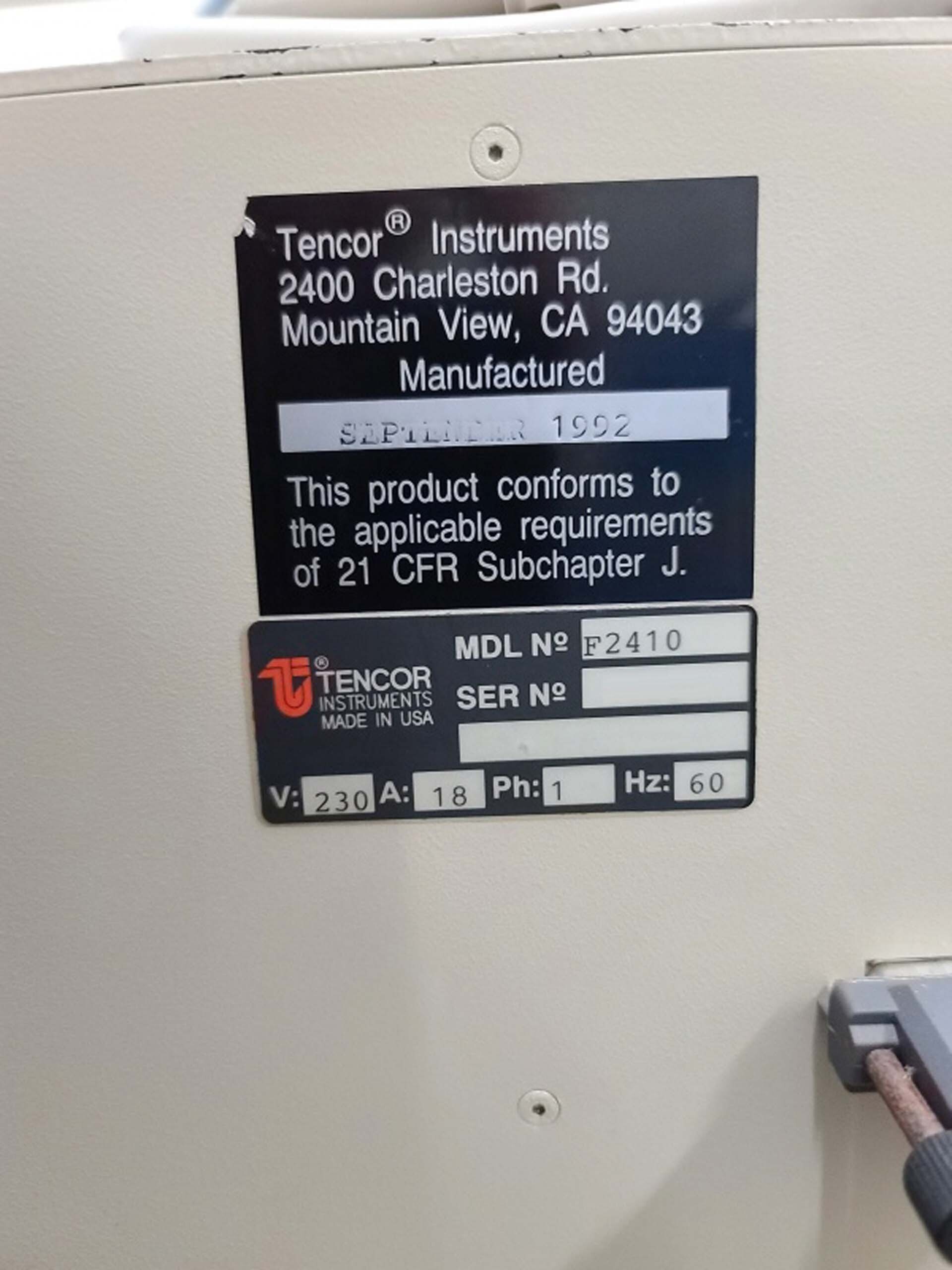

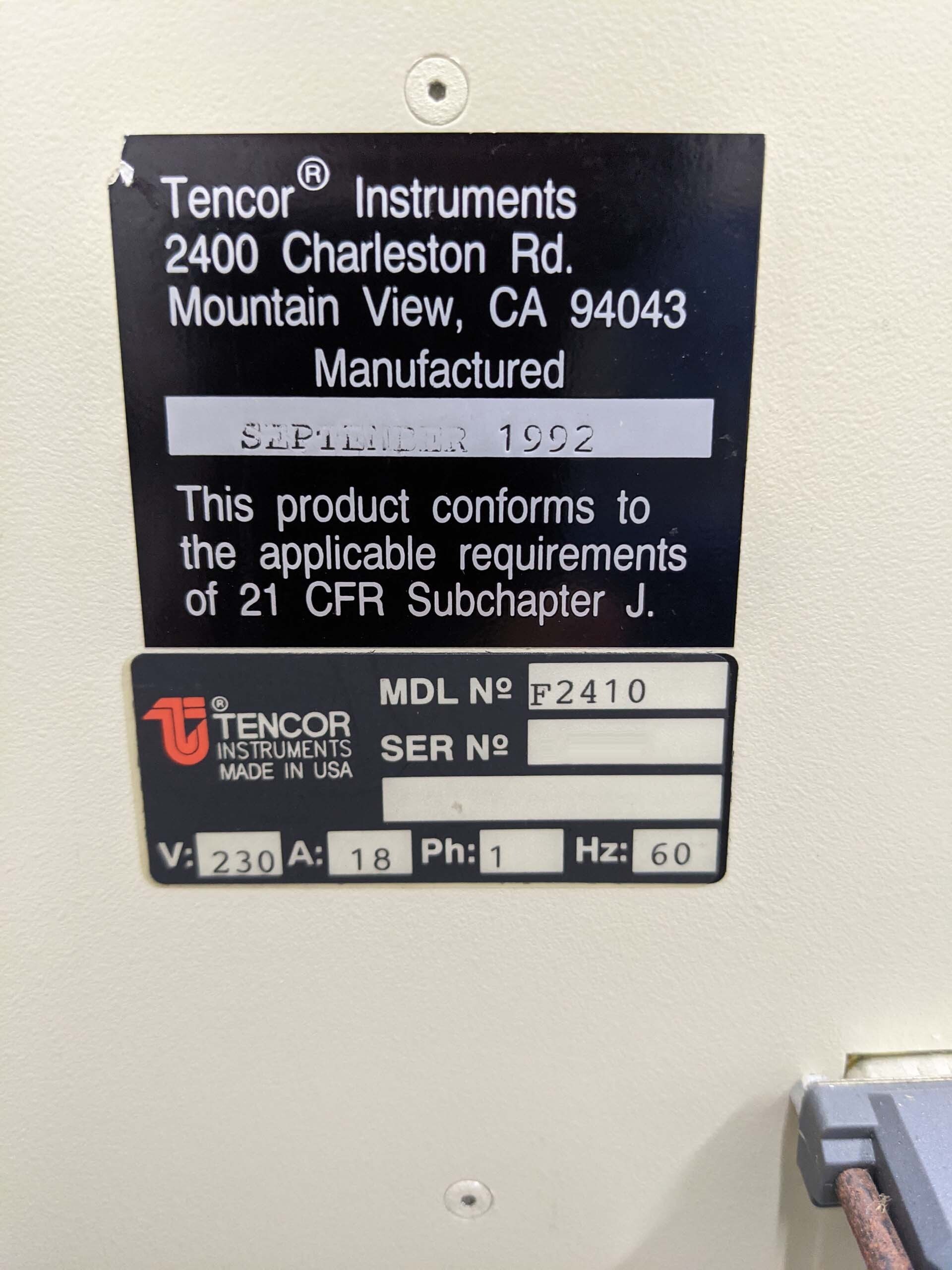

ID: 9375031

Vintage: 1992

System, parts machine

Wafer flatness gauge

Control PC missing

1992 vintage.

KLA / TENCOR Flexus F2418 is a wafer testing and metrology equipment used for a variety of applications including IC device characterization, die-level defect inspection, and wafer-level monitoring. It is capable of inspecting and measuring silicon wafers up to 200mm. KLA Flexus F2418 is designed to increase efficiency and accuracy in the manufacturing process. The system is optimized for parallel testing across multiple objectives, simultaneously scanning up to four dies at once. It uses both optical and e-beam imaging formats for defect inspection, and provides extremely fast, non-destructive inspection throughput for testing high-volume, low-value wafers. The F2418 has a modular design, allowing for customer customization and expansion, greater throughput from higher-volume on-the-fly wafer level measurement, and advanced inspection capability to detect smaller anomalies at high magnifications. It also includes multiple measurement channels, which is customizable to meet various measurement needs for faster, more accurate testing. TENCOR Flexus F2418 also has a higher resolution optics unit for defect detection and analysis. This includes variable-magnification optics, ranging from low (1X) to high (64X), enabling high-resolution imaging of small die sizes down to 8 microns. The probe positioner calculator ensures higher measurement accuracy and provides more precise alignment of the probe position needles and platens relative to the sample for more reliably accurate testing. The F2418 has advanced analytical capabilities, featuring an array of measurement programs that are optimized for wafer level measurements, progressive measurement cycles, determination of flatness, thick film determination and other marking and defect characterization needs. It also includes algorithms for image processing and data pattern matching designed to accurately and quickly detect miniscule defect abnormalities. The machine is also equipped with an integrated tool suite called the Metrology Toolbox, which offers a broad set of measurements to automate wafer level metrology. This tool is designed to simplify the steps needed to evaluate wafers over multiple device product lines, enabling shorter cycletimes and smarter decision making. Flexus F2418 is an advanced wafer testing and metrology asset designed to reduce cycle time and increase throughput for high-volume wafer-level measurements. With optimized optics, high-resolution imaging systems, and advanced analytical capabilities it is an ideal choice for integrated circuit device fabrication and other high-value manufacturing in the semiconductor industry.

There are no reviews yet