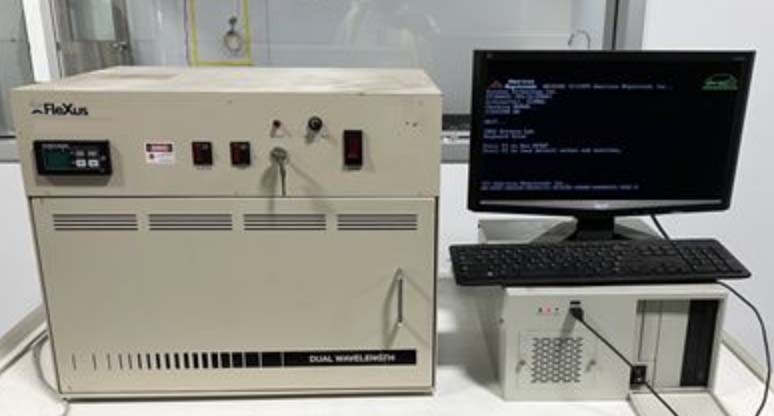

Used KLA / TENCOR FLX-2320 #293662213 for sale

URL successfully copied!

Tap to zoom

ID: 293662213

Wafer Size: 8"

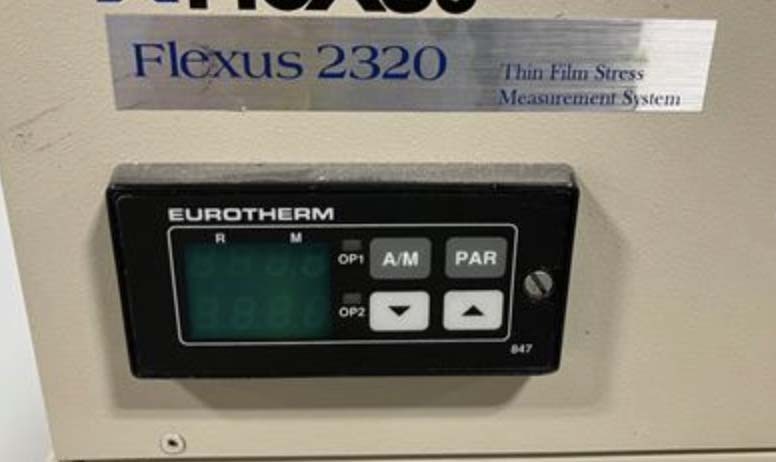

Thin film stress measurement system, 8"

Chuck size, 8"

Temperature range: 500°C

Manual wafer load

Printer

Monitor

Wafer locator

Power supply: 230 V, Single phase, 50/60 Hz, 30 A.

KLA / TENCOR FLX-2320 is a wafer testing and metrology equipment that has been designed to provide manufacturers with improved performance and throughput, and reduced metrology cycle time. The system features a wide range of capabilities which are intended to efficiently monitor and ensure the uniformity of the production of next-generation integrated circuits. For testing and metrology, KLA FLX-2320 employs an X-Ray Diffraction (XRD) module, an Energy Dispersive Spectroscopy (EDS) module, a high-speed area profiling module, and a full-field On-Line Topography (OT) module. These modules are capable of precisely measuring the properties of substrates used in semiconductor fabrication, allowing for improved fabrication process control and the detection of subtle defects at the surface and sub-surface level. The X-Ray Diffraction (XRD) module of the unit is used to accurately measure the stress and strain of substrates. This is done by collecting diffracted X-ray data, that is analyzed using pattern matching algorithms. The Energy Dispersive Spectroscopy (EDS) module measures the elemental composition of the surfaces of substrates by analyzing the X-ray energies emitted from the sample. This ensures the uniformity of the composition across the substrate surface, as well as the overall quality of the sample. The high-speed area profiling module allows for accurate dimensional measurements of features on substrates. This is done by utilizing lasers to measure the shape, size, and location of features on a substrate. The full-field On-Line Topography (OT) module scans an entire substrate and produces a full-field image of the surface in less than 5 minutes. This enables quick detection of patternu variances and defects over the entire substrate of a part. TENCOR FLX 2320 features a highly automated machine with automated sample-handling capabilities, advanced metrology software, and a touchscreen user interface. This automation reduces guesswork while eliminating the need for manual interventions, increasing productivity and accuracy. The tool also has an in-line cleaning station that allows for the continuous removal of debris and dust particles from the sample before metrology takes place. To summarize, KLA / TENCOR FLX 2320 is a wafer testing and metrology asset designed to provide manufacturers with improved performance and throughput, and reduced metrology cycle time. This model utilizes a wide range of capabilities including X-Ray Diffraction (XRD), Energy Dispersive Spectroscopy (EDS), high-speed area profiling, and full-field On-Line Topography (OT) modules. The automated equipment and advanced metrology software enable the efficient and accurate detection of defects on substrates, allowing manufacturers to quickly ensure the uniformity of their production process.

There are no reviews yet