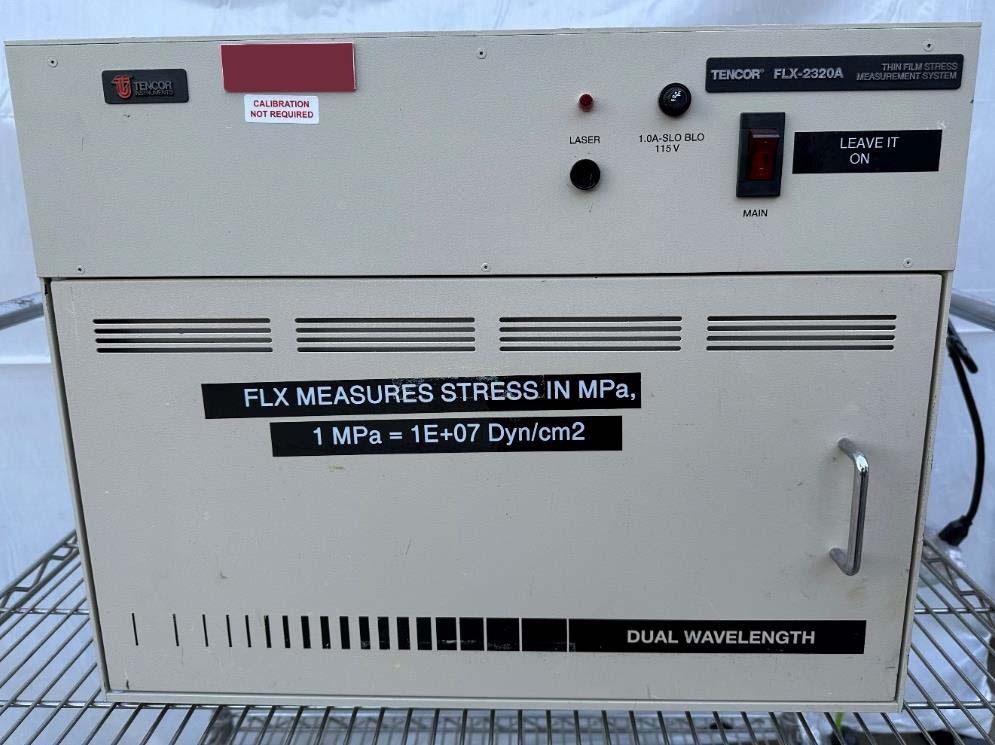

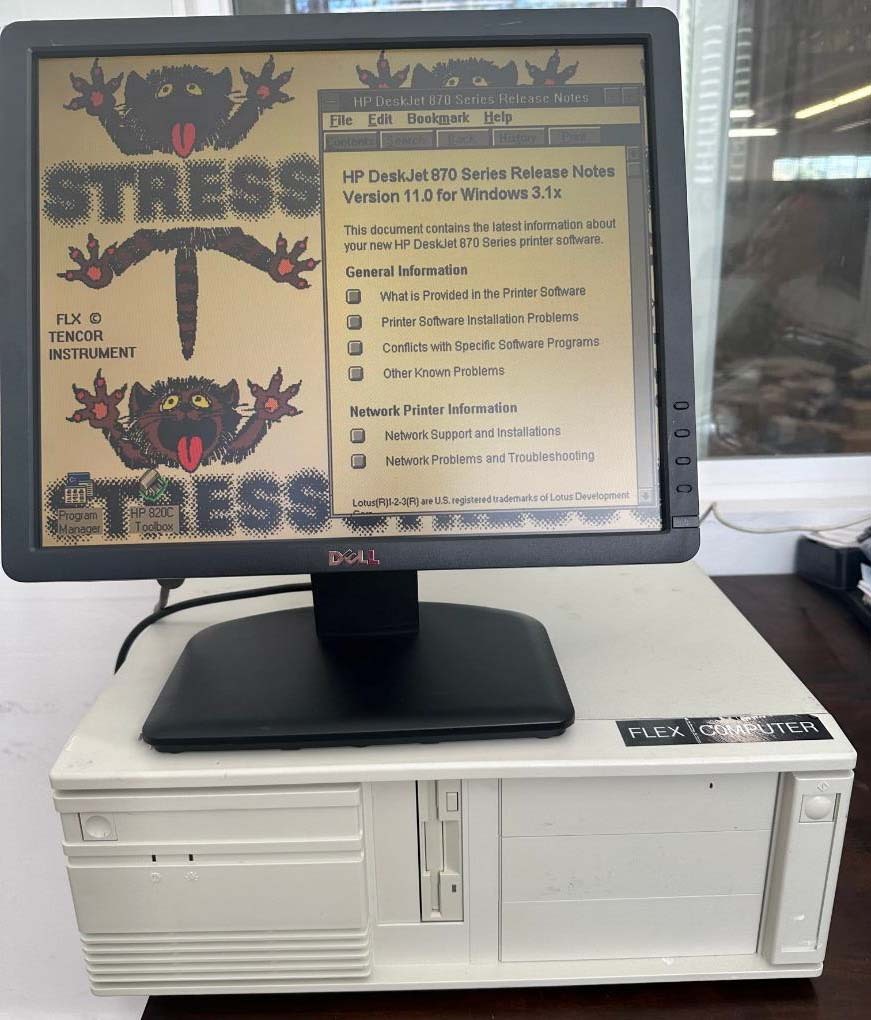

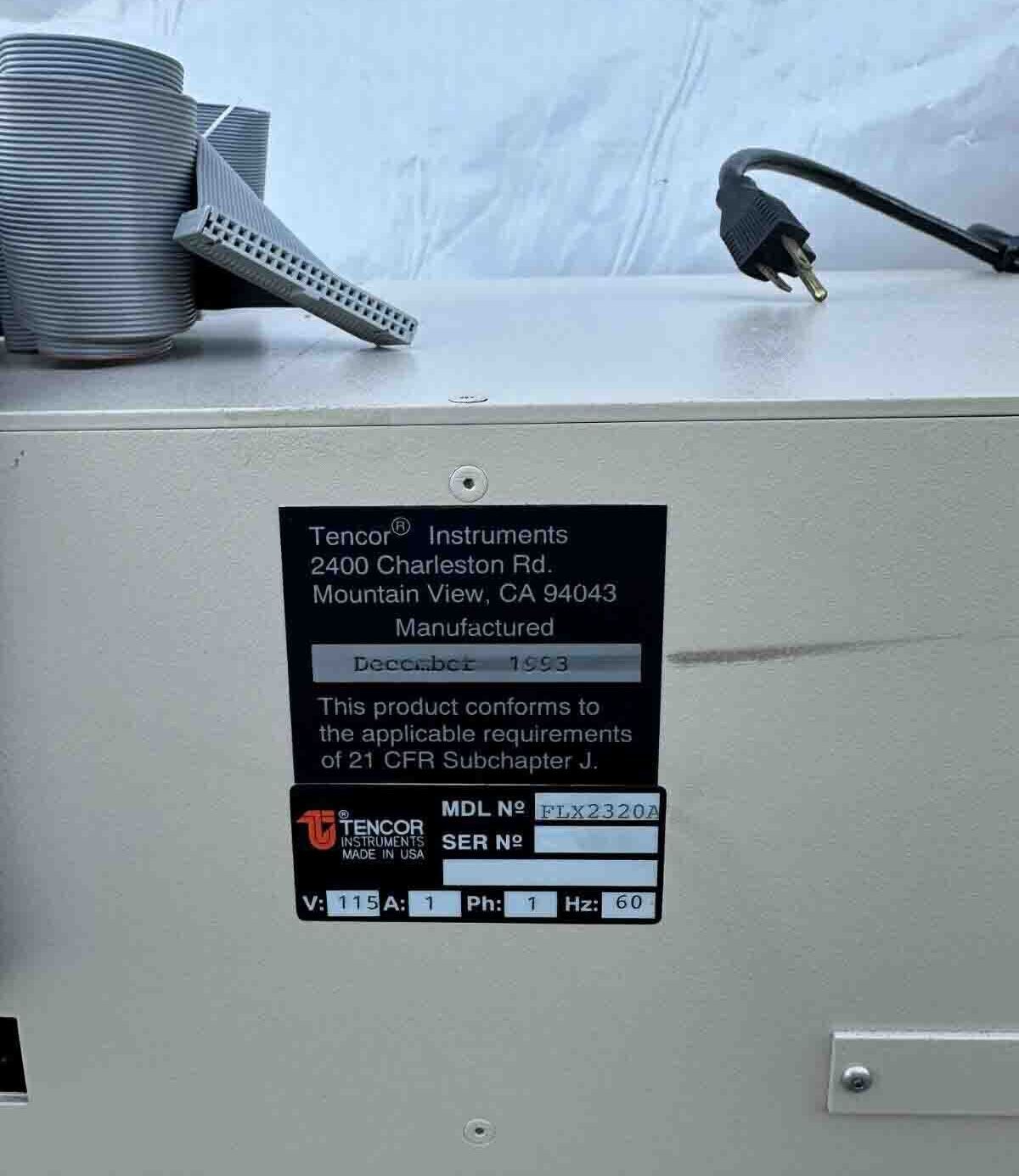

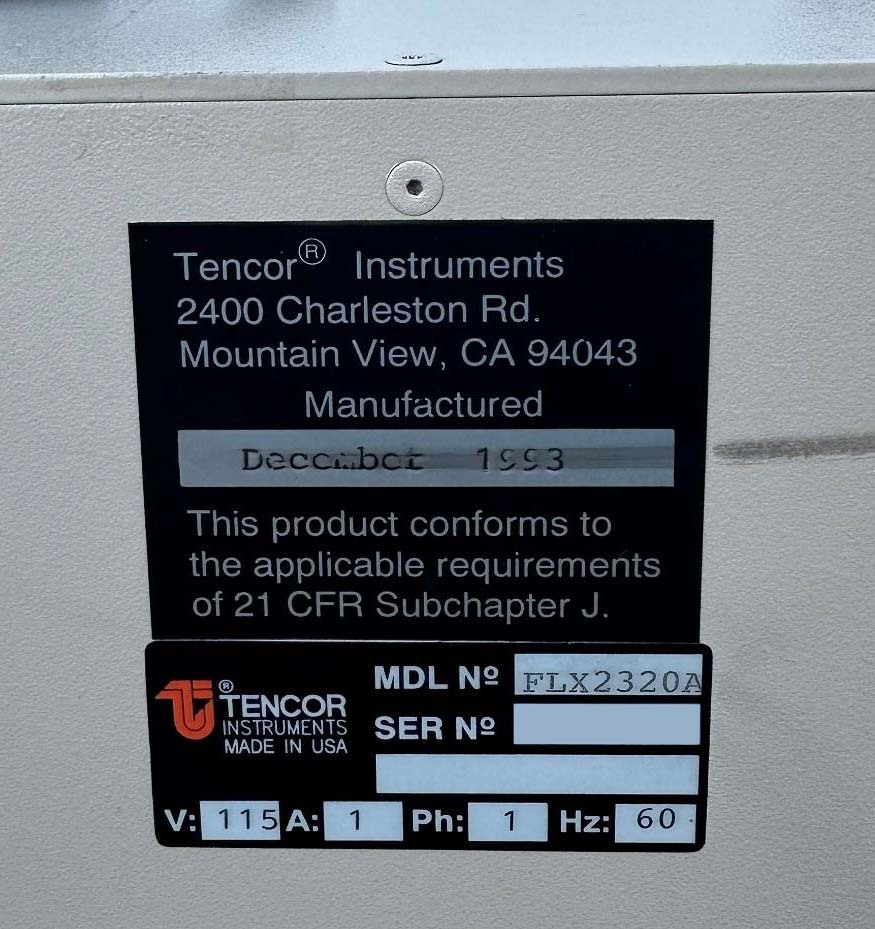

Used KLA / TENCOR FLX-2320A #293645945 for sale

URL successfully copied!

Tap to zoom

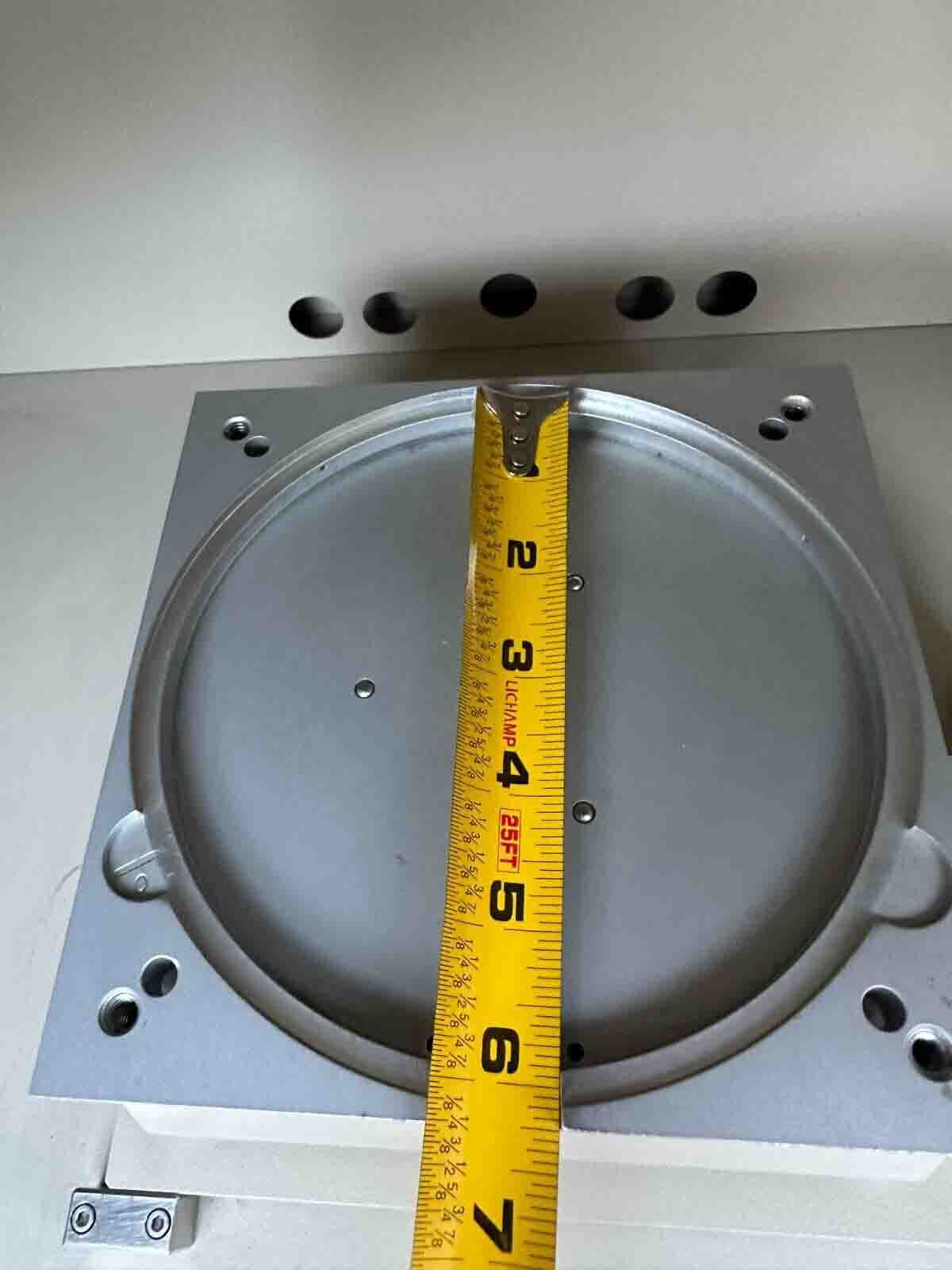

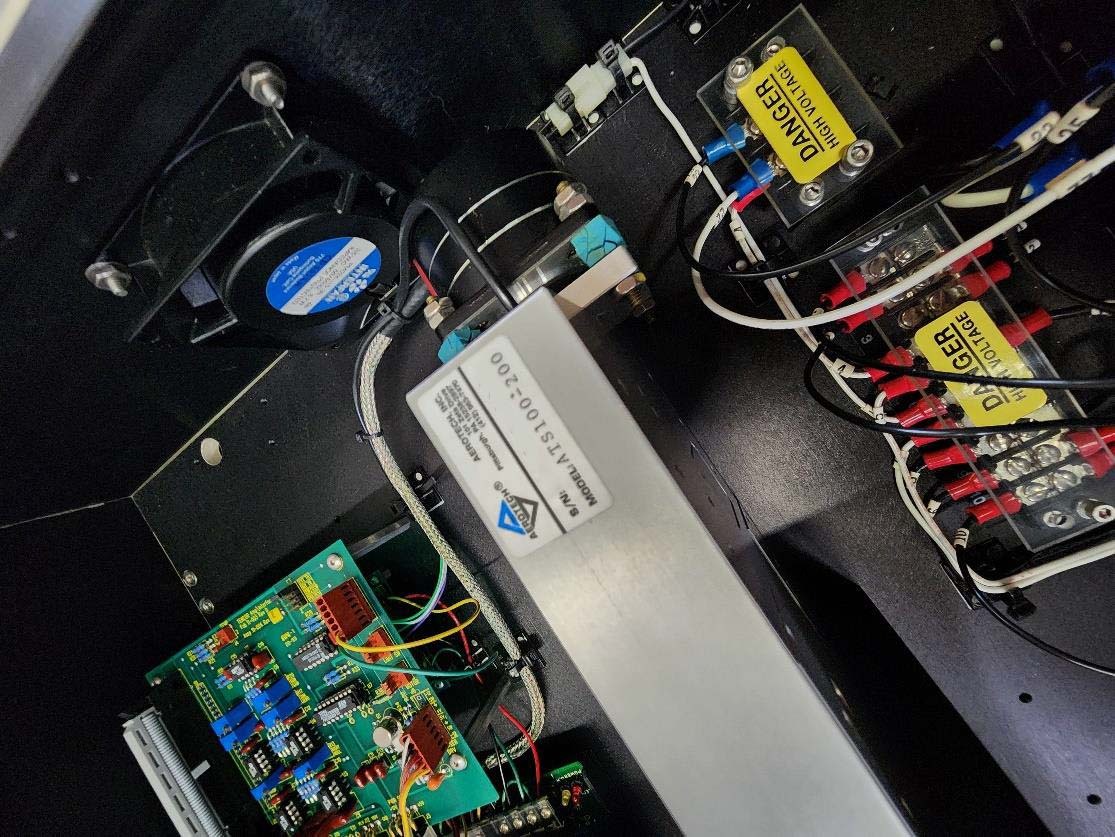

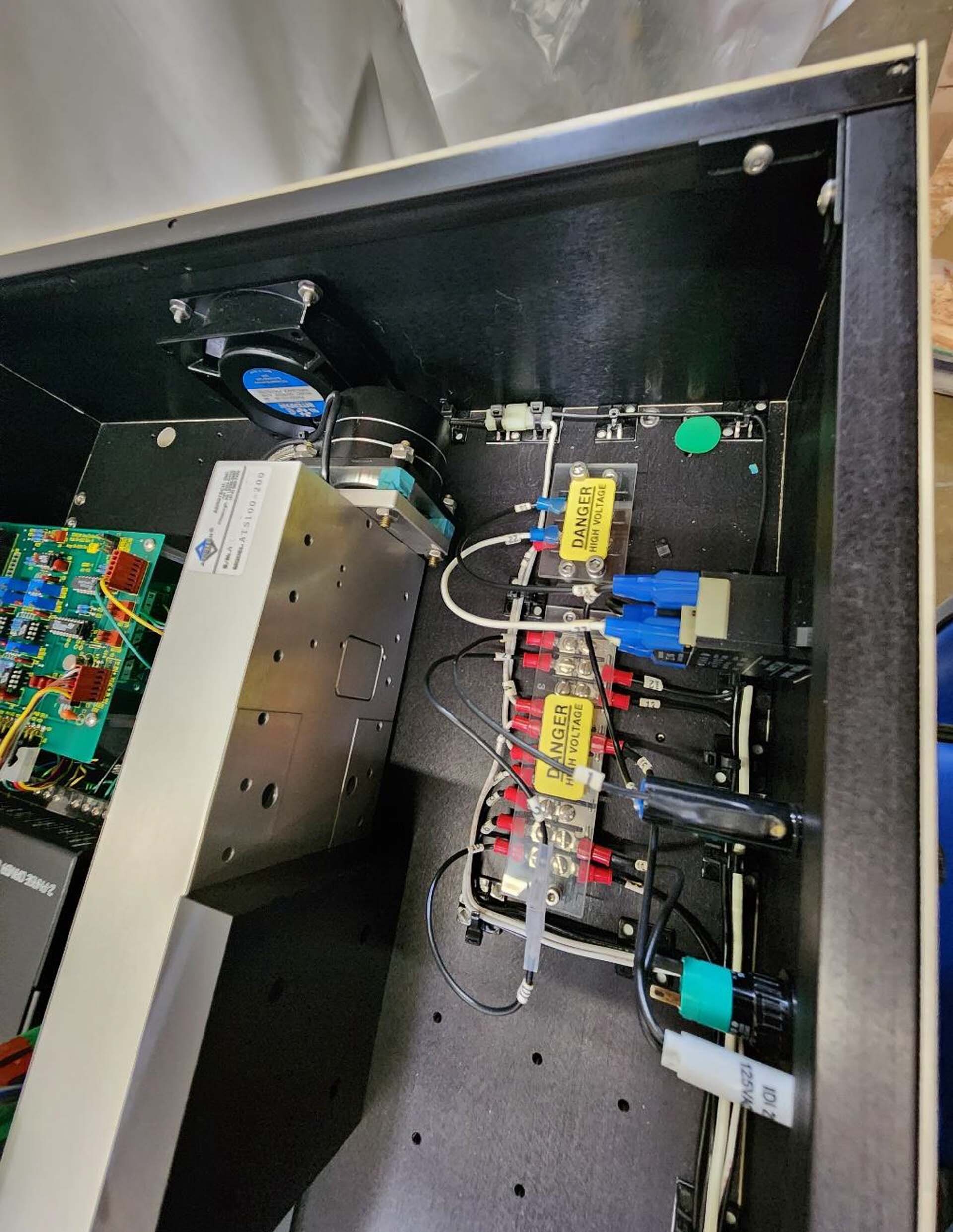

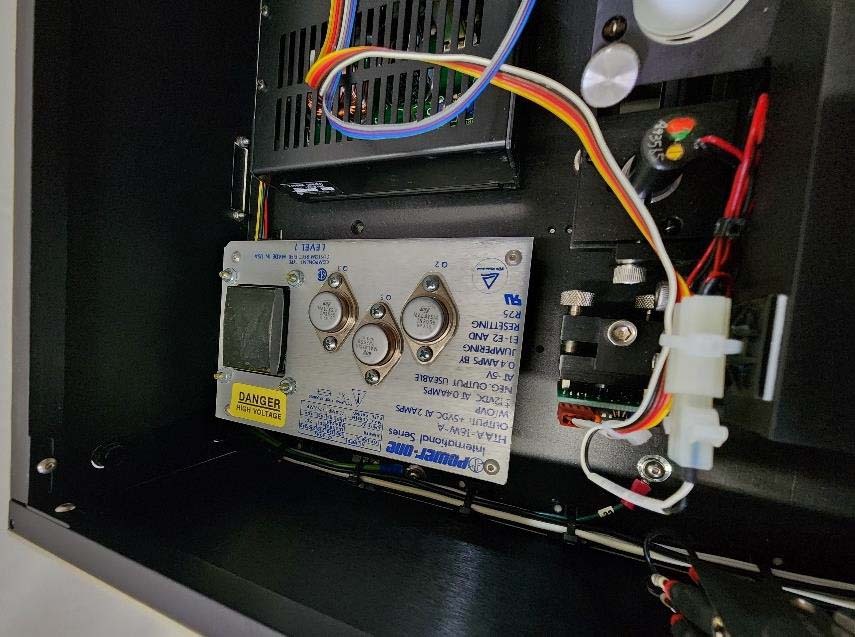

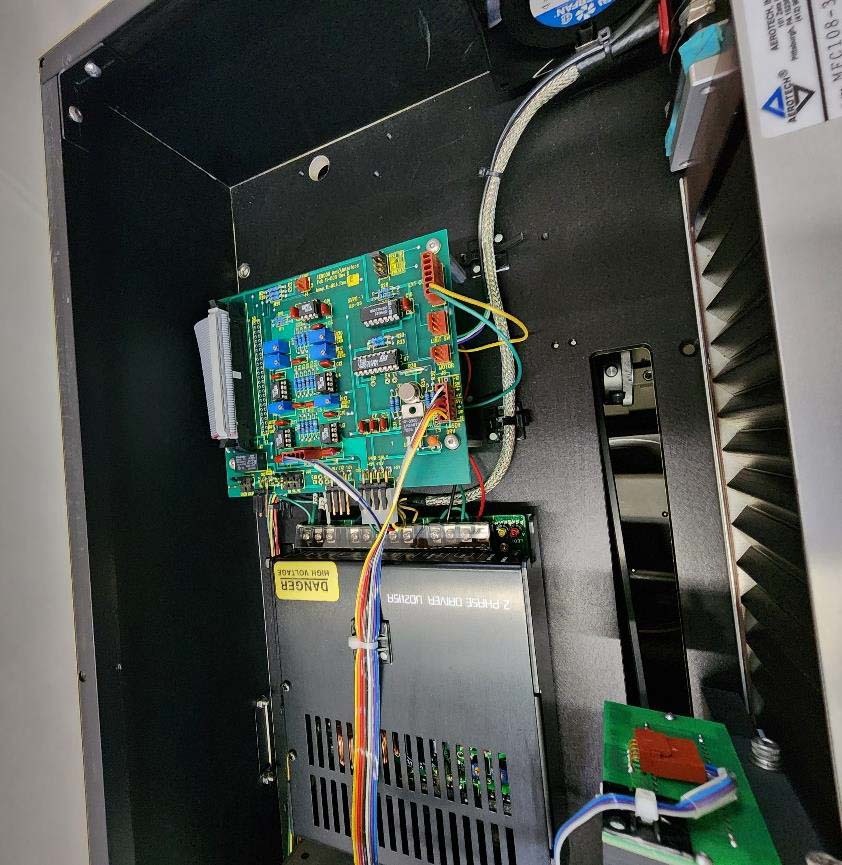

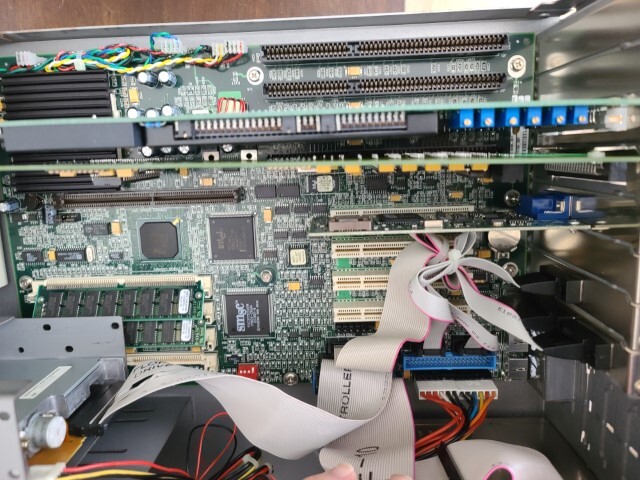

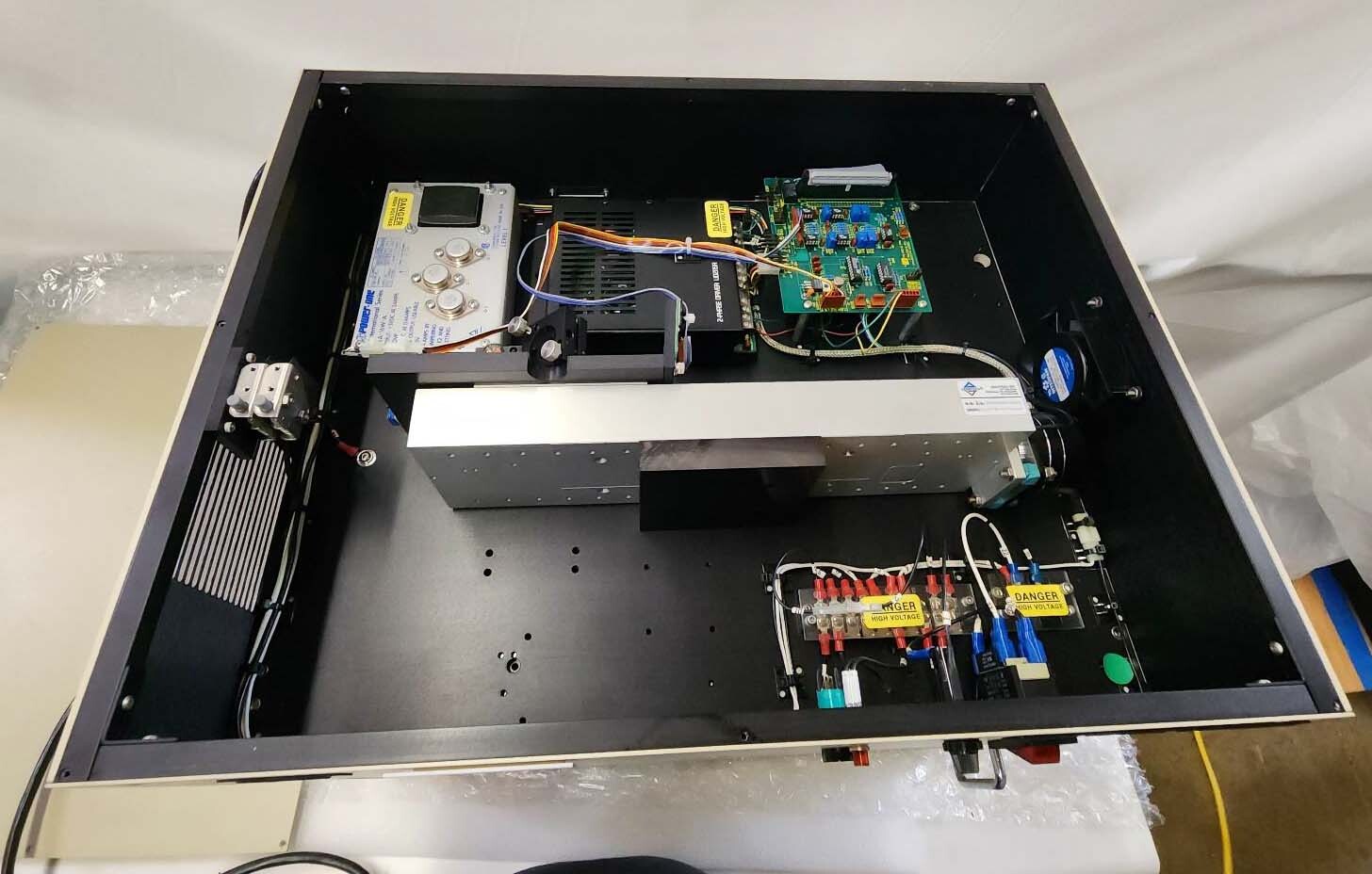

KLA / TENCOR FLX-2320A is a specialized wafer testing and metrology equipment designed for the analysis and characterization of semiconductor thin films and surfaces. The system includes a Dielectric Measurement Unit (DMS) which monitors the dielectric properties of deposited thin films, a Optical profiler (OP) which measures critical dimensions and surface topography, a Layer Monitoring Machine (LMS) which evaluates layer thickness, and a Full Wafer Analysis Tool (FWA) which measures full wafer data across wafer map distributions. KLA FLX 2320 A consists of a 3-axis XYZ stage and a load lock chamber with a robotic wafer transfer asset. The model is designed to accurately measure wafer diameters from 8" to 12" in a quick and accurate manner. The stage offers a range of motion in the X and Y axes, allowing for accurate scanning of the sample and yielding both surface height data and critical dimension parameters. The measuring area has a scan field of up to 70mm x 70mm and can also be used for imaging and analysis of defects, as well as for overall pattern recognition. The DMS equipment of TENCOR FLX-2320-A measures thin film thickness and deposited layers on a wafer, monitoring the size and shape of conductors and insulators. The metrology solution offers the versatility to test new materials and optimize processing parameters, providing exceptional dielectric accuracy and repeatability. The OP system of FLX-2320-A enables accurate and fast measurements of the topography and profile of thin-film structures. The measurements include height, width, and average roughness parameters of features ranging in size from several microns to nanometers. The unit's built-in automation capabilities eliminate manual adjustment of parameters, offering a convenient and highly accurate method for measuring wafer surface topography. The LMS ensures the accurate measurement of wafer layer thickness at every point on the device. The machine's pitch-to-pitch operators automatically adjust lateral resolution and pitch, allowing for fast and repeatable measurements with an increased level of accuracy. The FWA of FLX 2320 A builds on the technology of the OP and LMS, using a unique combination of high-end optics and sensors to measure an entire wafer in a single scan. This comprehensive metrology solution delivers wafer map data inclusive of global parameters such as step height, surface roughness, temperature, and layer thickness. In sum, KLA FLX-2320-A combines the latest in imaging, metrology and wafer testing technology to offer a sophisticated and comprehensive wafer characterization solution. With its variety of features and capabilities, this tool is the ideal choice for applications in automotive, data storage, and other semiconductor industries.

There are no reviews yet