Used KLA / TENCOR P15 #9004295 for sale

URL successfully copied!

Tap to zoom

ID: 9004295

Wafer Size: 4"-8"

Vintage: 2005

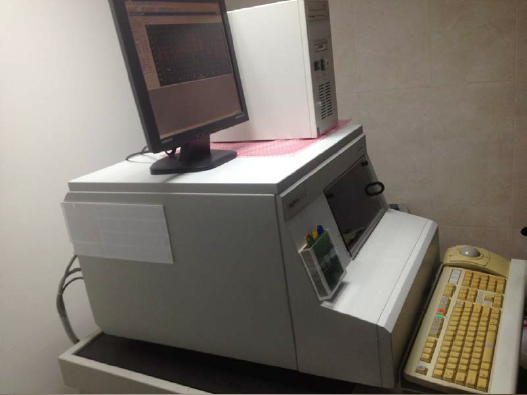

Wafer surface inspection system, 4"-8"

P/N: 00151-000

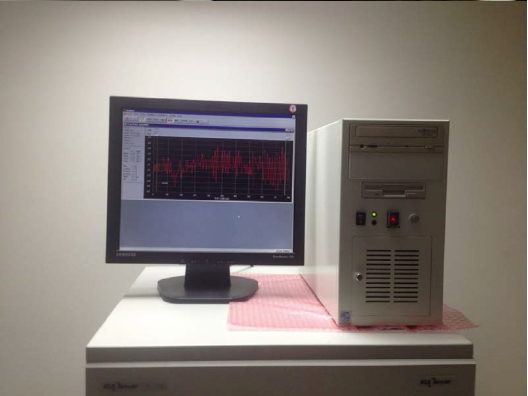

PC Configuration:

CPU: Pentium III-C 650 MHz processor

Memory: 128M

20 GB HDD

1.4MB 3.5” Floppy disk drive

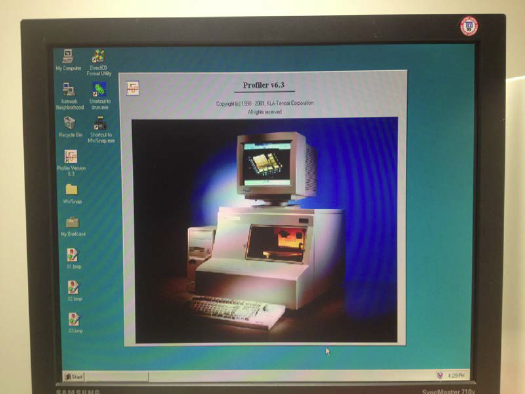

OS: Windows NT 4.0

Application software: Version 6.3

Performance requirement:

Vertical range: 0-300 um

Stylus force: 1-50 mg

Constant stylus force control

Dual view optics (sideview: 95-410x, topview: 115-465x)

Black and white camera

Stylus: 2.0 um radius

2005 vintage.

KLA / TENCOR P15 is a wafer testing and metrology equipment designed specifically for the efficient wafer testing and monitoring of the fabrication process of various semiconductor products. It is a multi-sensor system that can be used for metrology applications, such as cross-sectional analysis, form & surface analysis, as well as for testing workflows. This unit offers a broad range of technologies, from optical microscopes, white light interferometry, and stylus measurements to electrical testing, thermoelectric testing, and acoustic microscopy. KLA P-15 machine features a combination of advanced imaging, image processing, and analysis technologies. The tool can detect physical characteristics of wafers, such as topography, uniformity, and electrical resistance. It also provides a wide range of characterization parameters, including die size, pitch, shape, and flatness. TENCOR P 15 asset comes with a host of automated features that make it easier for semiconductor processes to be optimally monitored during fabrication. By utilizing this model to monitor wafers at strategic points in their manufacturing, fabricators can make early corrective actions when required. The equipment also features a real-time system for tracking and adjusting wafer parameters to ensure a consistent product. The unit provides robust data acquisition, image processing, and analysis tools for developing complex wafer fabrication inspection. It is able to capture electronic images from the microscope and process data into reports or CAD images, or run a customized algorithm to evaluate the particle count, etch rates, edge quality, and yield. This machine is equipped with edge-detection algorithms and algorithms to separate the small particles from the larger defect signals. It can perform high speed and accuracy testing, delivering a precise and comprehensive characterization of wafers. KLA / TENCOR P 15 has a wide range of energy sources, including atomic force microscopy (AFM), photolithography, and plasma etching. The data acquisition tool supports various image and characterization modes and provides outputs in standard formats. It can even integrate with other testing equipment to complement the process control. In conclusion, KLA P 15 is an advanced wafer testing and monitoring asset designed for efficient and effective fabrication monitoring. Its robust and comprehensive features offer comprehensive characterization and feedback systems for improved visibility into a production line. This model is extremely useful in minimizing defects during manufacturing, improving yield, and reducing costs and lead time.

There are no reviews yet