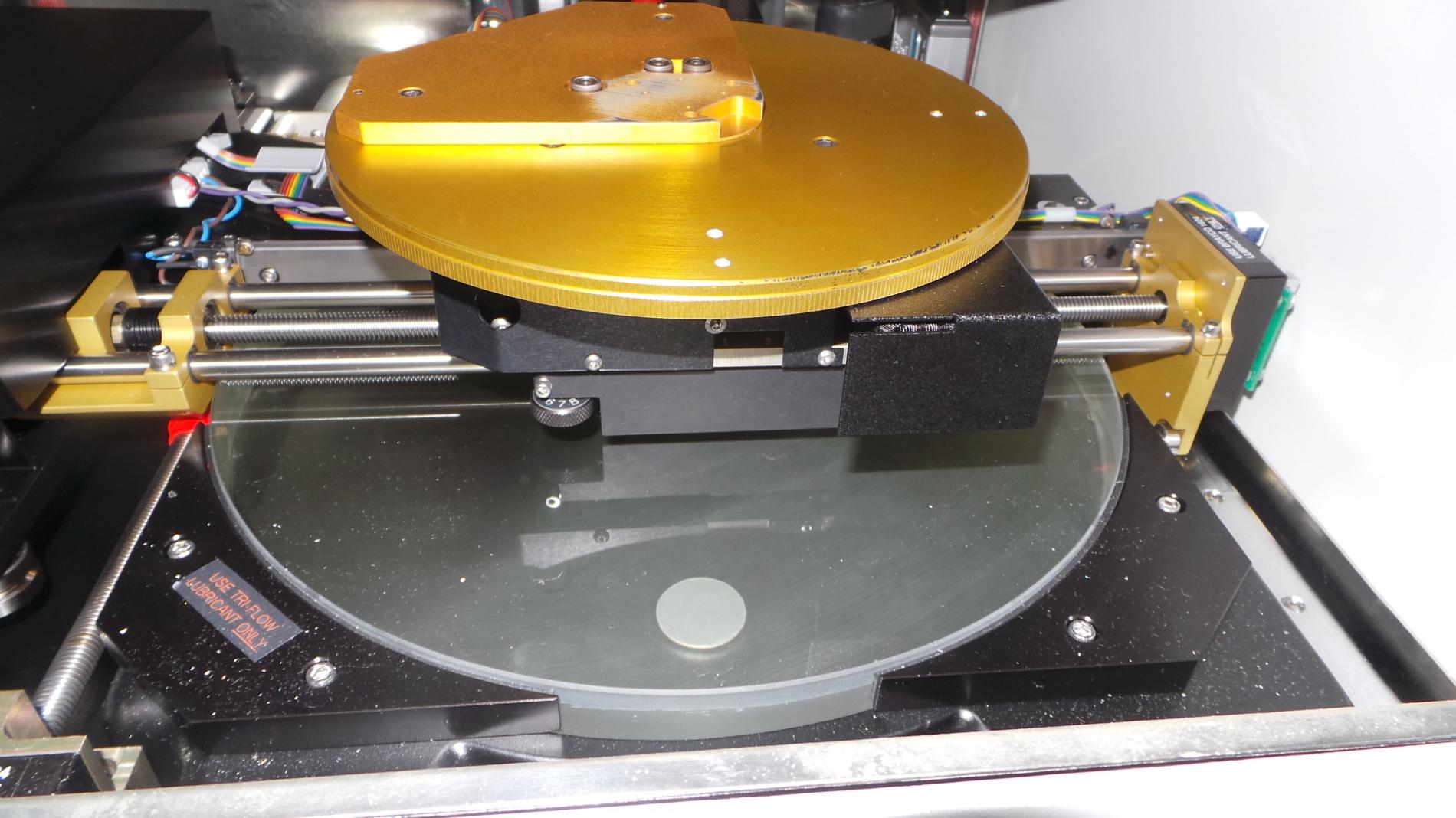

Used KLA / TENCOR P16+ #9130068 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9130068

Wafer Size: 2"-6"

Vintage: 2010

Surface Profiler, 2"-6"

Maximum scan length: 80 mm or 200 mm

Laterial resolution1: X = 25 nm, Y = 1 µm

Microhead 5 SR: Vertical range 327 µm

Stylus force 1-50 mg

13 µm, resolution <0.01A

64 µm, resolution <0.04A

327 µm, resolution < 0.20A

Microhead 5 LF: Vertical range 130 µm

Stylus force 0.05-50 mg

6.5 µm, resolution < 0.01 A

26 µm, resolution < 0.02 A

130 µm, resolution < 0.10 A

Microhead 5 XR: Vertical range 1000 pm

Stylus force 0.5 - 50 mg

13 µm, resolution < 0.01 A

130 µm, resolution < 0.08 A

1000 µm, resolution < 0.60 A

Vertical linearity2: ± 0.5% above 2000 A

10 A below 2000 A

Repeatability: 7.5 A or 0.1% (1 s),whichever is greater

Reproducibility: 15.0 A or 0.25% (1 s), whichever is greater

Scan speed3: 2 µm/sec to 25 mm/sec

Sampling rate: 5, 10, 20, 50, 100, 200, 500, 1000 Hz

Stylus control: Electromagnetic force compensation

Stylus: 4 different radii for long-scan

applications—2.0 µm, 5.0 µm,

12.5 µm, 25 µm (coarse). Submicron

radius (0.1 - 0.8 µm) for micro

surface analysis (fine)

Dual view optics (field of view):

Side view: 1750 x 1750 µm

Top view: 1400 by 1040 µm or optional 900 by 650 µm

Camera: Optional digital color camera

Relative humidity : 30 - 40% (non-condensing) recommended

Temperature : 16°-25° C, rate of change ≤2° C/h

Electrical : 90 - 110 V, 50 - 60 Hz

110 - 130V, 50-60 Hz

208 - 260V, 50 - 60 Hz

Power requirements: 430 VA

Vacuum : 500 mm Hg @ 27 liters/min

Floor vibration : ≤250 µ inch/s (6 4 pm/s) RMS, 1-100 Hz

Audio noise : ≤80 dB (C weighting scale)

Laminar airflow : ≤100 ft/min (30 m/min) down blowing recommended

Microprocessor: Pentium®4 2.8 GHz or greater

Operating system : Windows® XP-based operating system

RAM : 1 GB or greater

Disk storage : 80 GB or greater

Removable storage : 3.5 inch, 1.4 MB floppy disk drive DVD/CDRW

Monitor: 17-inch flat panel LCD

Network : PCI ethernet card

2010 vintage.

KLA / TENCOR P16+ is a wafer testing and metrology equipment designed for leading-edge semiconductor processes. It is the flagship product of KLA family, providing industry-leading performance for particle testing, process control and wafer surface metrology. KLA P 16+ supports multiple wafer configurations, including 12-inch and 8-inch wafers, as well as supporting 3-Dimensional Non-Contacting (3D-NC) Inspection and Optical 3D Profiling (3DOP) applications. The system offers advanced test capabilities for all types of wafer topographies, such as TSV, Cu pillar and eTOX. It is designed to deliver accurate measurements across substrate topography, 3D features, and other critical parameters, even for advanced test requirements. TENCOR P-16+ unit offers both Non-Contact and Contact testing capabilities. It incorporates innovative, advanced architectures and patented technologies that reduce the time of wafer testing and full data collection processes. These technologies enable the machine to compare test results efficiently with established standards based on the desired criteria or pre-defined limits. The tool can also detect defects using advanced algorithm-based automatic defect detection functions. TENCOR P 16+ features an intuitive, user-friendly interface for easy data management and visual presentation of results. It also comes with a range of unique software tools for improved efficiency and productivity, including DataTrends tools, Digital Manufacturing Toolbox and image analytics. The comprehensive toolbox, combined with an array of features available through web-enabled interfaces, enable the asset to quickly analyze, visualize, and report results, making it an ideal choice for production. In addition, the model supports industry-leading metrology capabilities, delivering high accuracy and repeatability. It combines advanced algorithms with high-speed scanning to produce ultra-smooth surfaces on a variety of substrate material. It also supports multiple metrology applications for a range of applications, from advanced process control to yield analysis. TENCOR P16+ provides manufacturers with an efficient, cost-effective tool to measure, analyze, and inspect devices. It delivers top-of-the-line performance, with intelligence-based automation capabilities, a comprehensive toolset, and advanced wafer testing and metrology capabilities. The equipment is an ideal choice for high volume production environments, and provides the flexibility and accuracy needed to ensure yield and cycle times.

There are no reviews yet