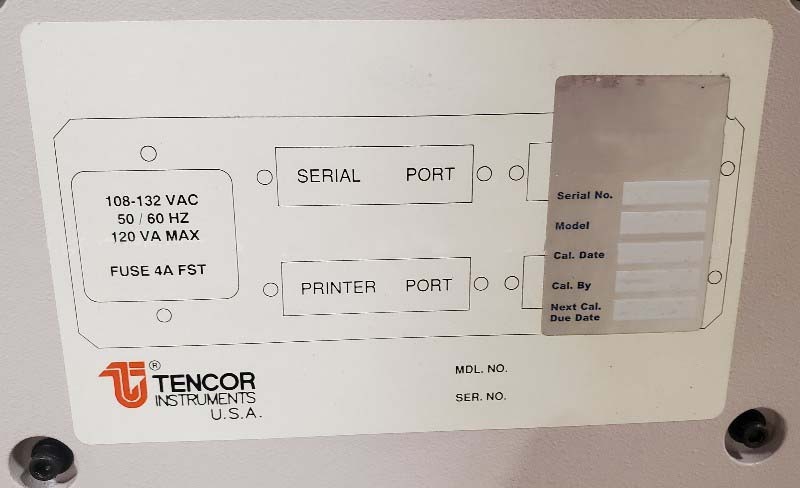

Used KLA / TENCOR P2H #9408171 for sale

URL successfully copied!

Tap to zoom

KLA / TENCOR P2H is a leading wafer testing and metrology equipment specially designed to improve yield and production throughput in the semiconductor industry. It utilizes a three-dimensional automated visual inspection process to detect potential fabrication issues on a substrate surface. This allows for rapid detection and correction of defects on the current wafer, as well as trends on the overall production. KLA P-2H system's automated microscope imaging unit can image and measure the profile of structures and defects on a wafer. By capturing detailed information on the structures and defects, wafer engineers can quickly detect, analyze and report on any anomalies. The machine also allows engineers to view multiple inspection images of the same wafer by allowing integration with other available software that can provide a single source of data. It also offers various custom analysis tools, as well as interactive graphical displays and reports. The automated measurement software for TENCOR P 2H tool is designed to rapidly measure and analyze its images. Its automatic image processing asset learns and adjusts to changes in the wafer's substrate, reducing inspection time and improving accuracy. The operating software also offers a range of defect detection options, including Template Matching, Hot Pixel Matching, Spatial Dimension Setting and Background Estimation. This range of options allows for accurate detection and classification of subtle defects. P 2H model also provides data-driven testing and analytics that measure and track the quality of the processor's fabrication. With these advanced capabilities, the equipment can identify process improvements, measure yield drops and reduce waste generated by process flow and design. Additionally, it includes data connectivity, which allows sharing of wafer test data and other production numbers with other systems in a factory. Overall, KLA P2H is a comprehensive wafer testing and metrology system which offers a high level of performance, accuracy and reliability. Its automated three-dimensional inspection process and comprehensive range of features provide manufacturers with the capabilities to improve quality, reduce costs and increase production throughput.

There are no reviews yet