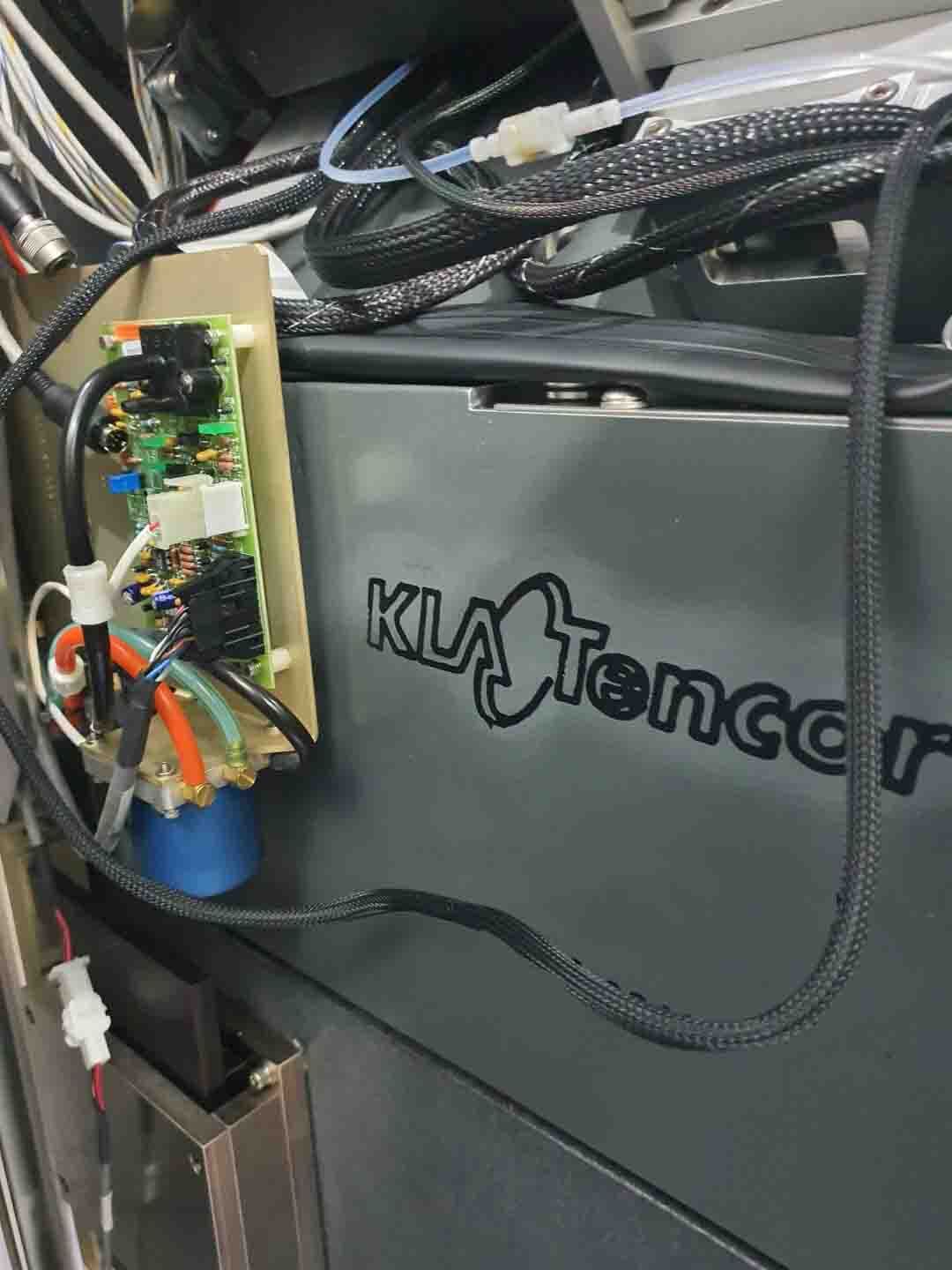

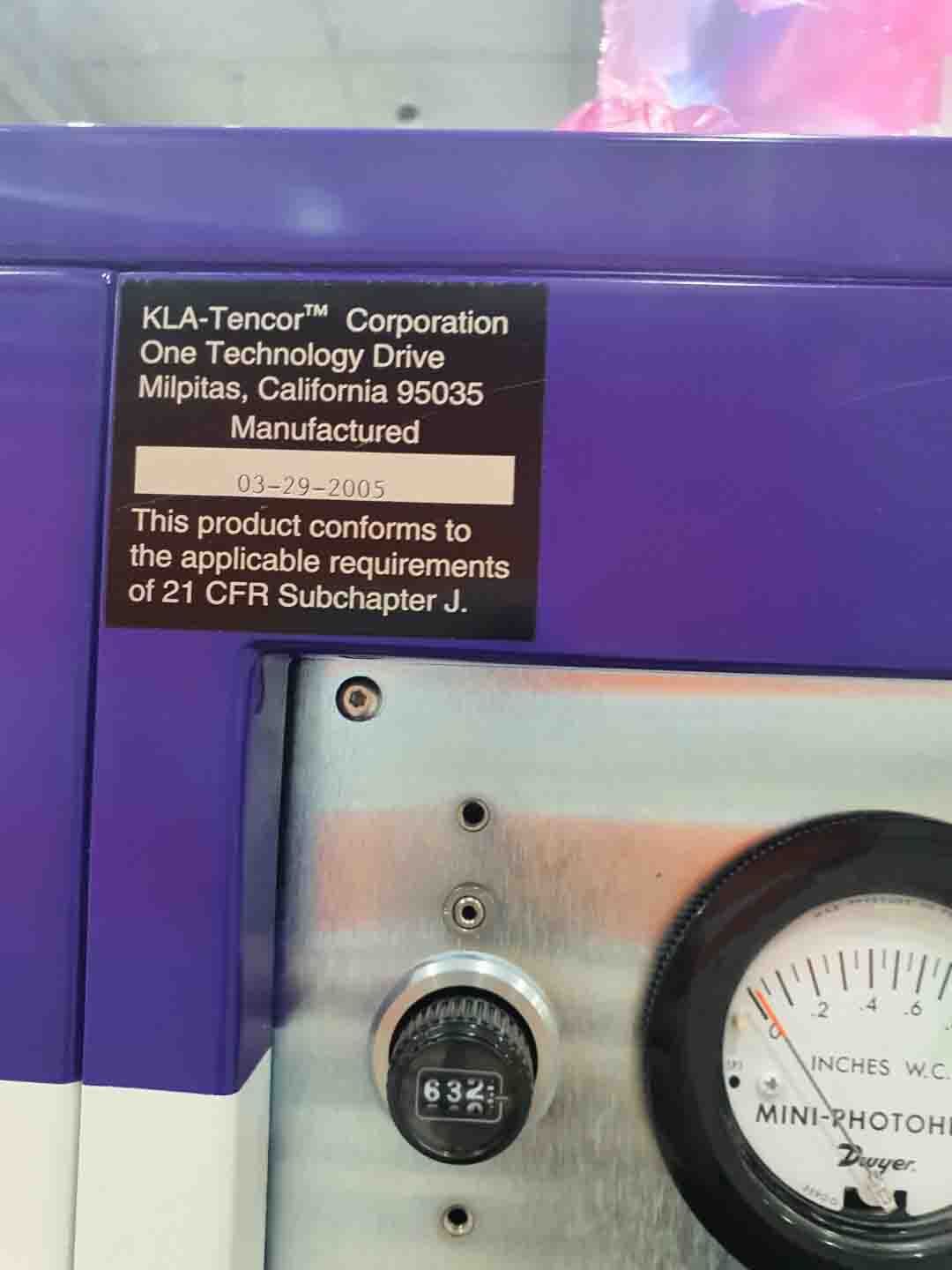

Used KLA / TENCOR Puma 9000 #293607038 for sale

URL successfully copied!

Tap to zoom

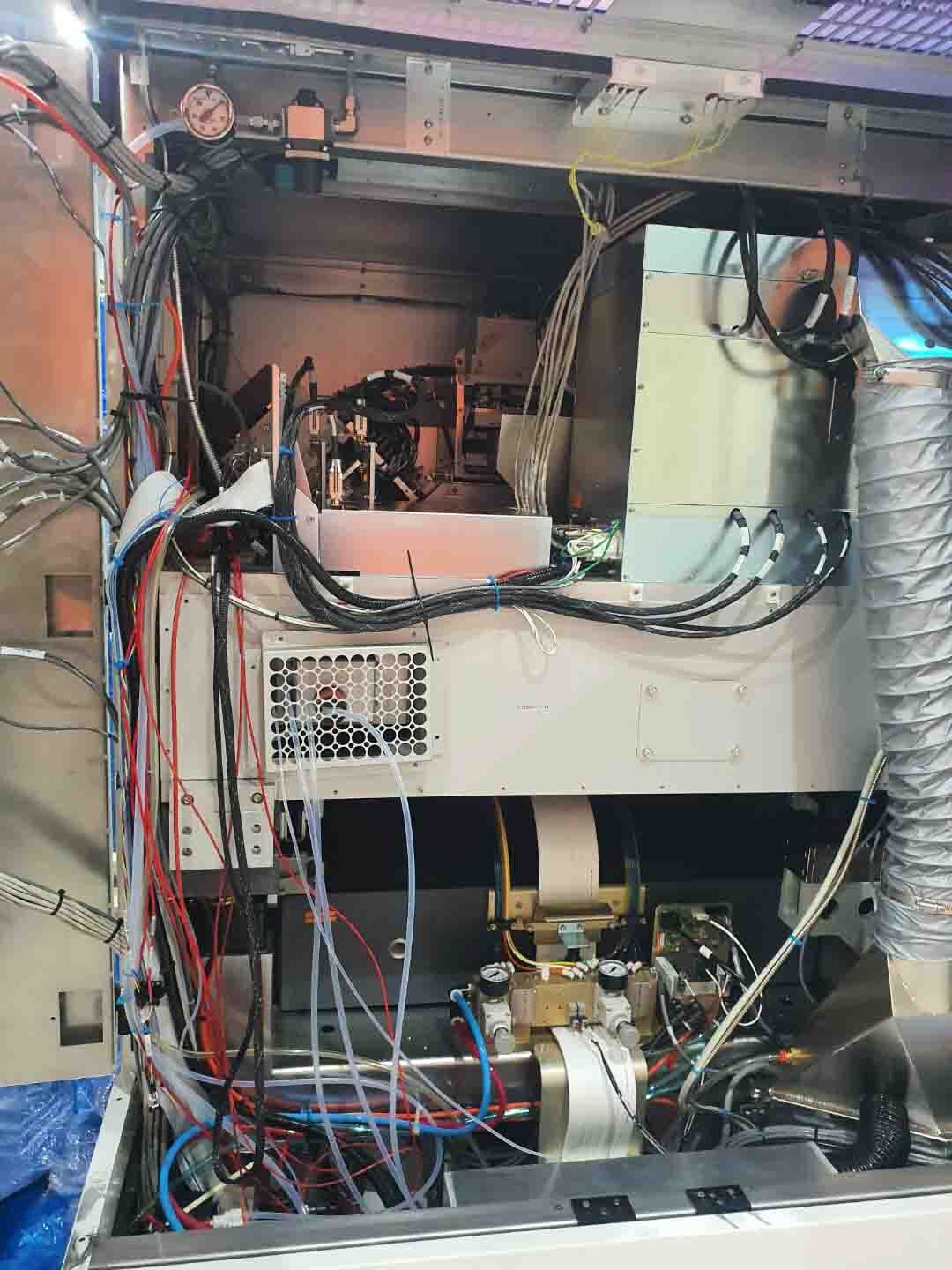

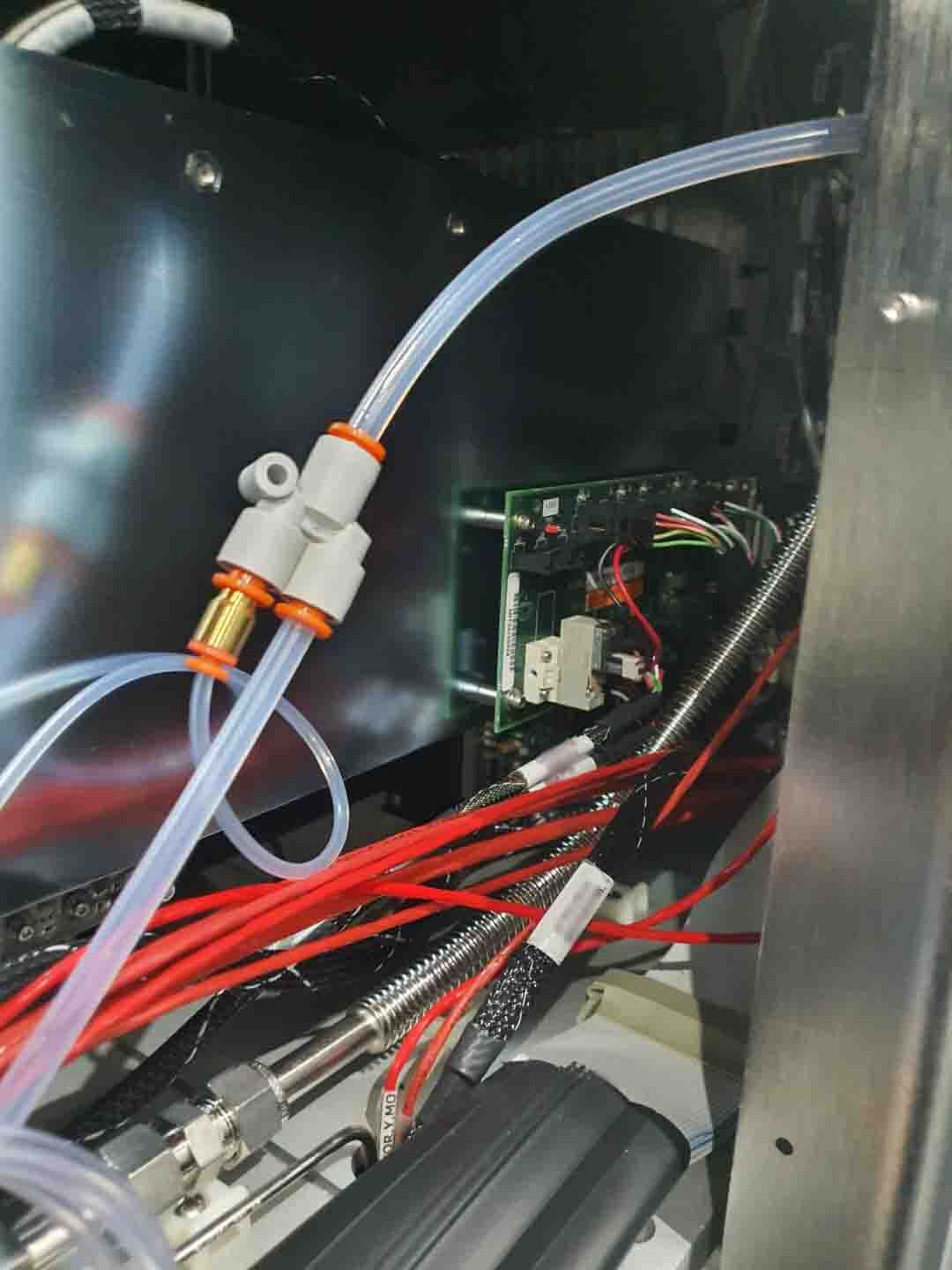

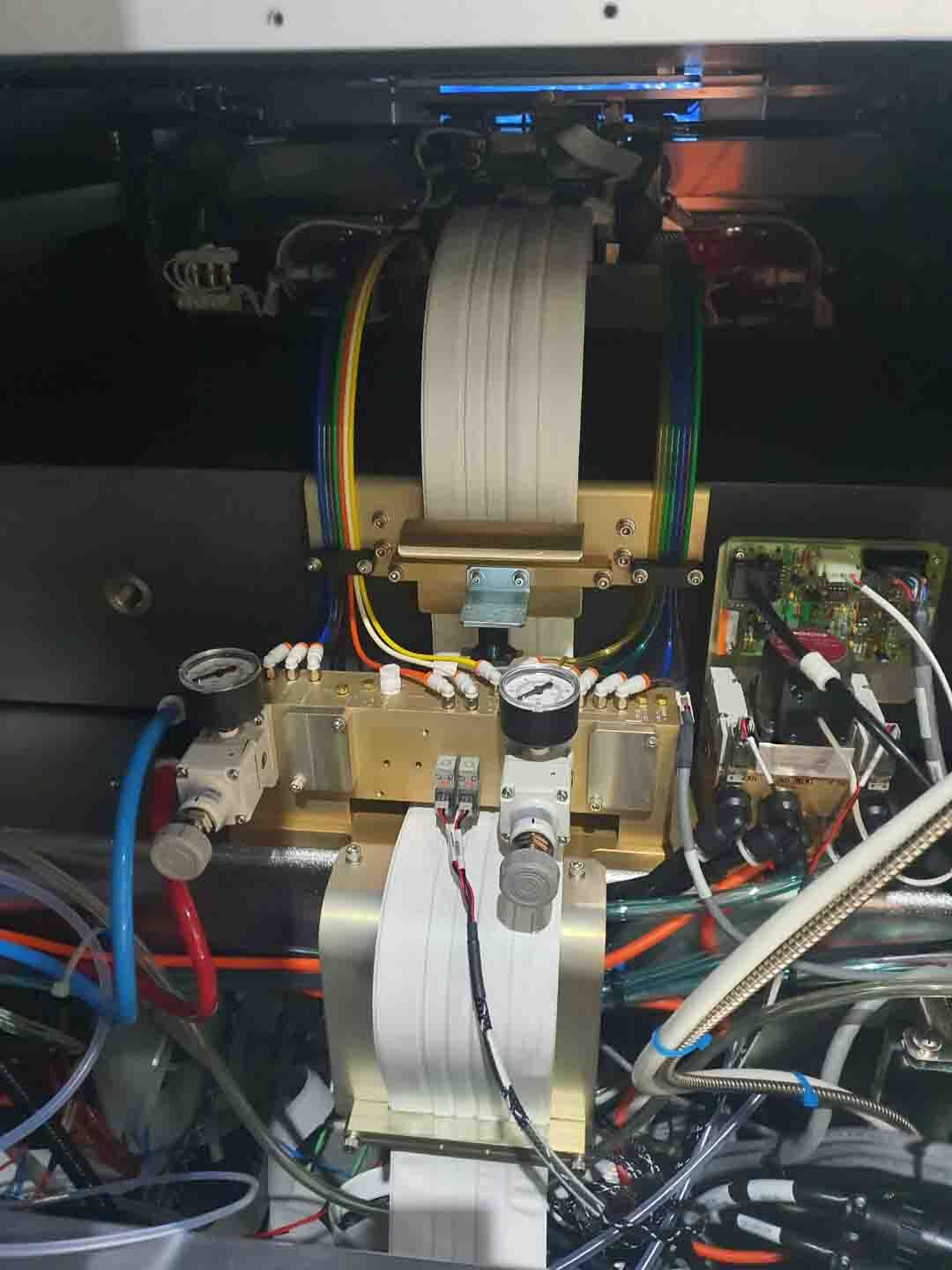

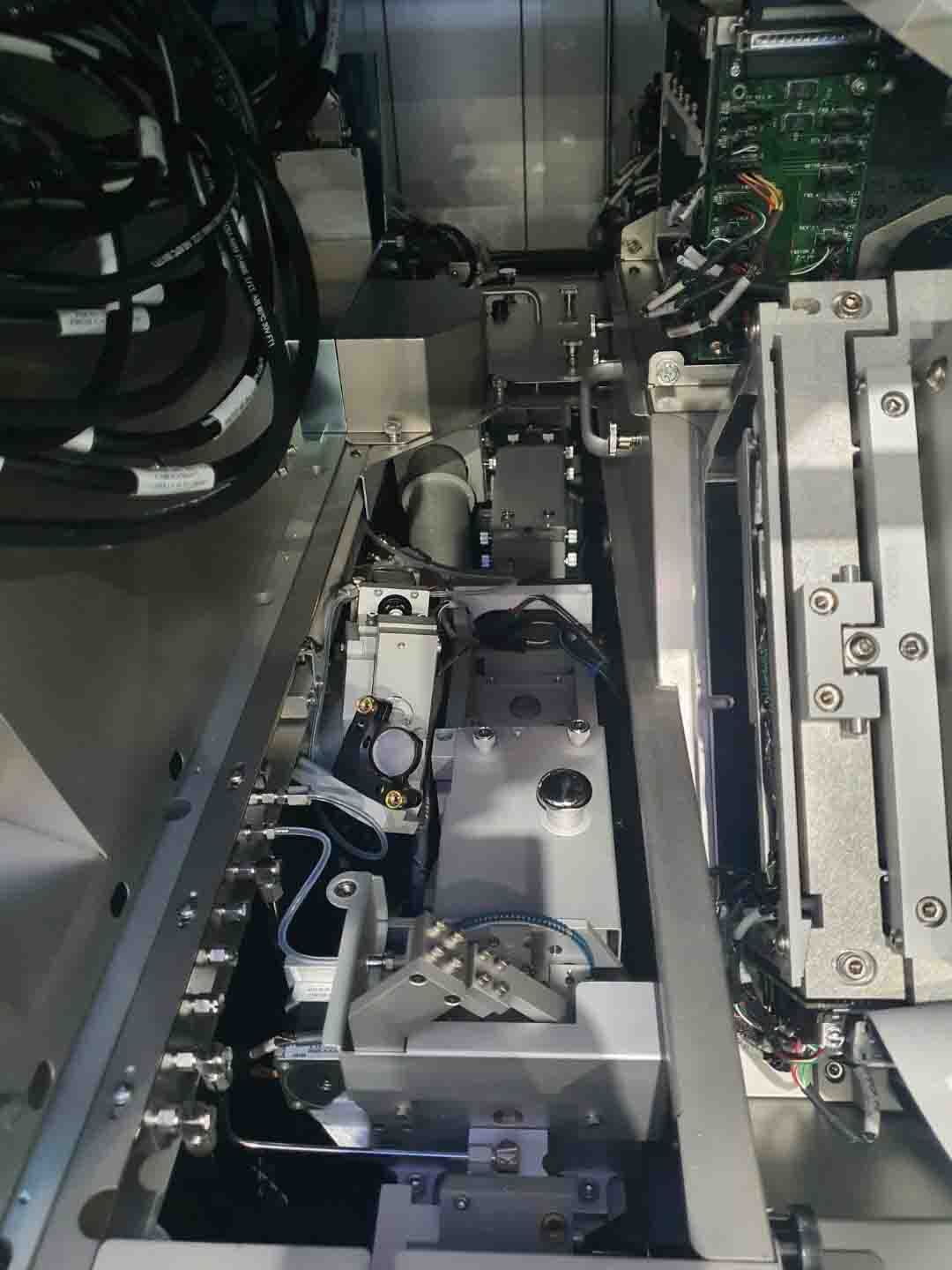

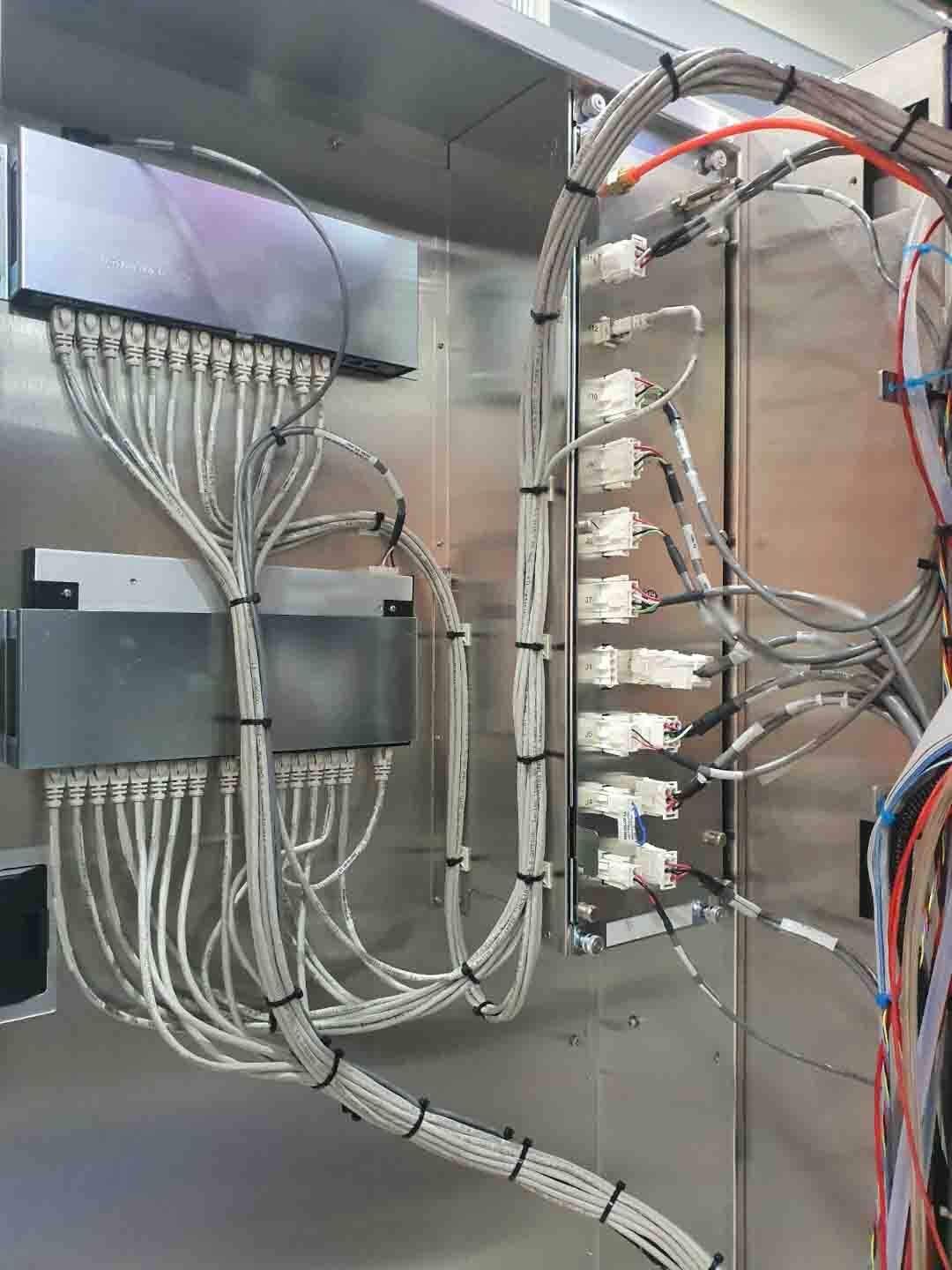

KLA / TENCOR Puma 9000 is an automated wafer testing and metrology equipment developed by KLA. This system has been designed to provide a comprehensive range of semiconductor engineering solutions through the implementation of advanced level measurement and analysis technologies. The unit is capable of providing real-time analysis and inspection, as well as process control, to ensure the best wafer yields and optimal manufacturing conditions. The machine features high-resolution imaging for wafer inspection and metrology, along with advanced pattern recognition software for defect detection. This allows for full control of the process, from initial die-strip alignment to optical performance evaluation of the final product. It also provides an efficient means of producing data to be used for yield-improvement purposes. KLA Puma 9000 offers a combination of best-in-class speed and accuracy, with optimized operation time and throughput. This tool is capable of inspecting up to 25 wafers per hour with a resolution down to 1 micron. It is equipped with a high-throughput, non-contact stage that enables automated measurement and analysis of multiple locations across the wafer in a single scan. The imaging capabilities of the asset can capture wafer features as small as 0.3 microns across. TENCOR Puma 9000 is integrated with host process control systems, enabling data collection and analysis at the module, tool, and model level. This allows for process optimization on the fly, enabling suppliers to increase throughput and react quickly to process changes. Additionally, the equipment is compatible with a range of recipes, ensuring transfer of fit-for-purpose defect detection and process control algorithms. Overall, Puma 9000 is a high-performance, integrated wafer testing and metrology solution. It allows for automated inspection and metrology of wafers in combination with recipe-based process control. This system offers improved control of processes and yields, allowing for fast and reliable metrology and defect identification, leading to greater accuracy and repeatability of results.

There are no reviews yet