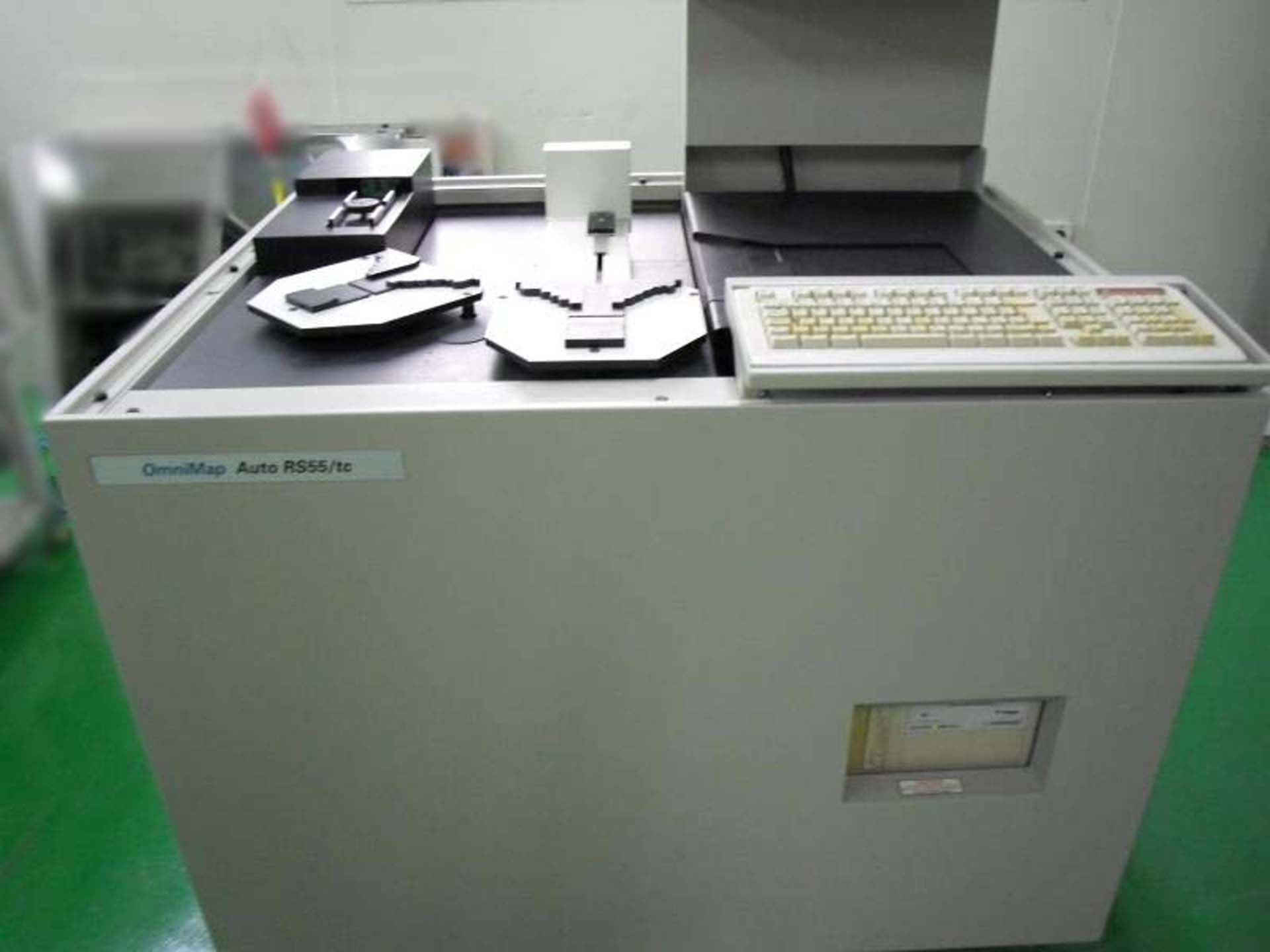

Used KLA / TENCOR RS-55TCA #9191837 for sale

URL successfully copied!

Tap to zoom

ID: 9191837

Vintage: 1995

Automatic resistivity mapping system

Type: Probe B

Measurement specifications:

Measurement range: <5 mohm/sq to >5 mohm/sq

Typical measurement time: 3.5-4.5 Seconds per test site

NIST(NBS) Standard wafers corrected to 23°C: ±1 %

Measurement repeatability: <0.2%

Temperature measurement accuracy: ±0.5°C

Temperature measurement repeatability: ±0.5°C

Routine check: 1-30 Sites programmable

Contour / 3-D map

Diameter scan: 49, 81, 121, 225, 361, 441, 625 Sites

XY Map: Up to 1200 Sites programmable

Probe qualification: (20) Sites

P-N Typing

Single / Dual configuration options

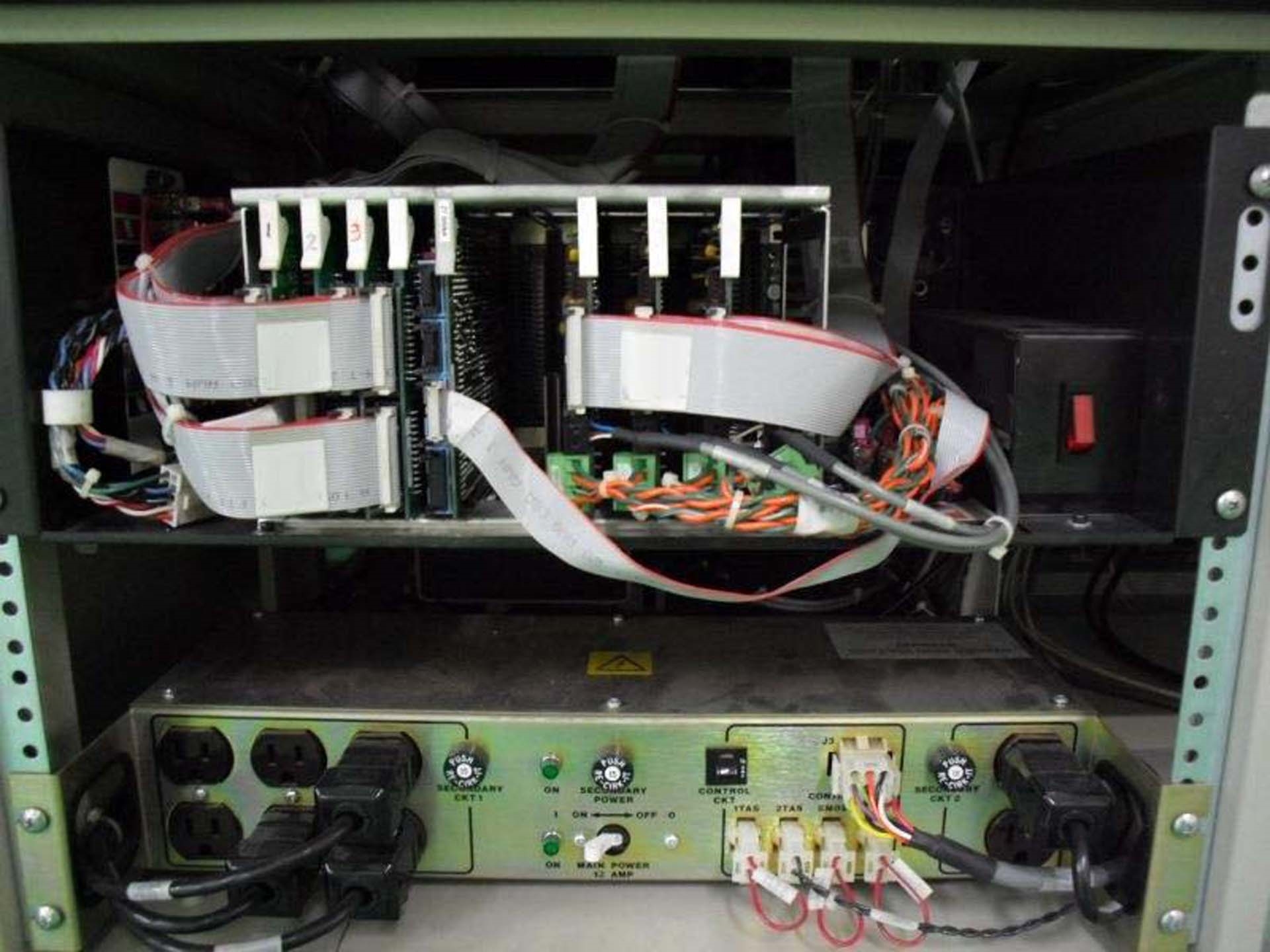

Hardware specifications:

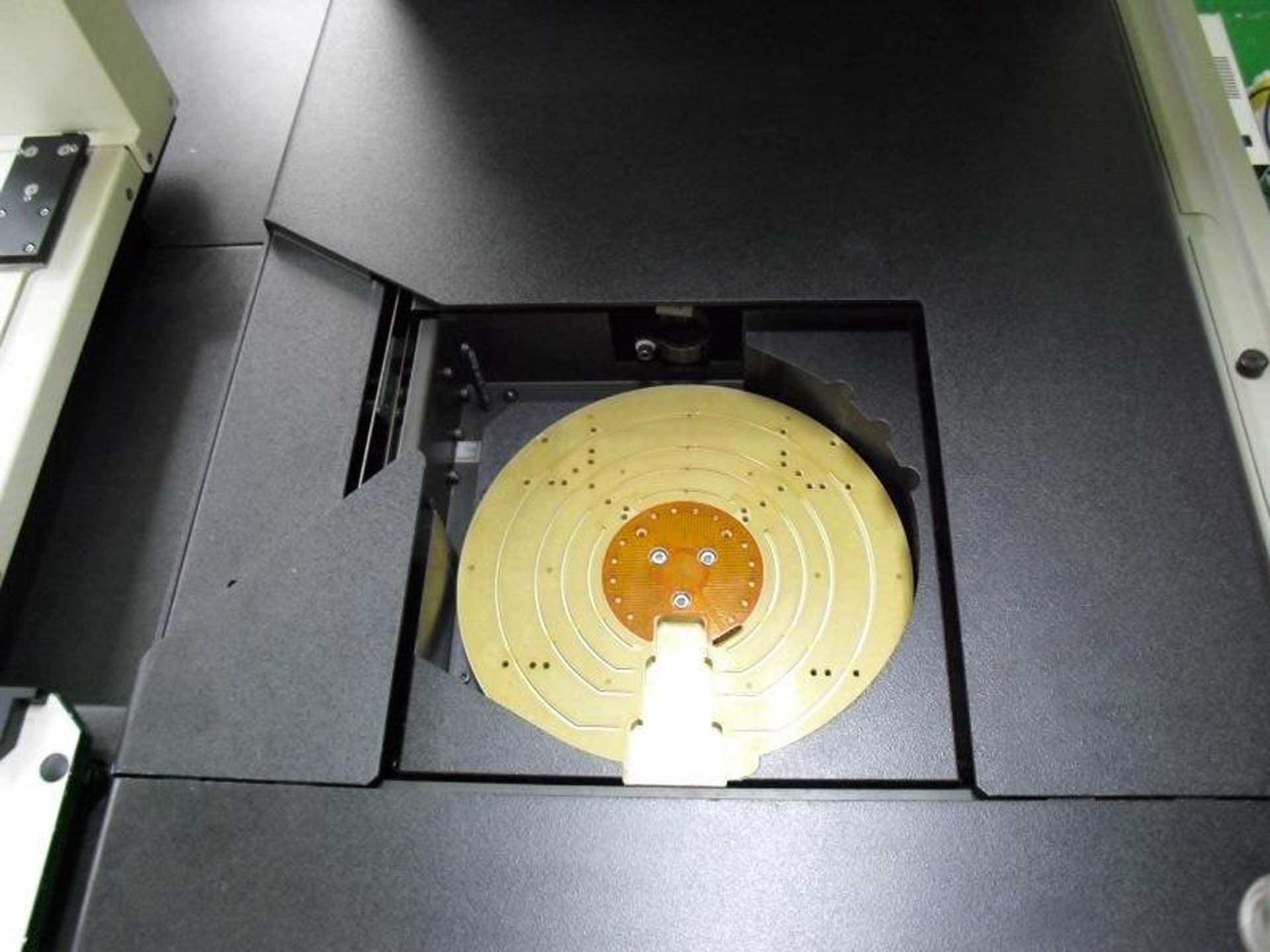

Standard wafer sizes: 100, 125, 150 & 200 mm

Thick substrate option: 6 mm Thick materials

Color HP paintjet printer

Dot matrix printer

High resolution color monitor

Power requirements: 115/230 V, <8 A, 50/60 Hz

Vacuum: 500 mm Hg

Vacuum: 300 mm Hg

Pressure: 40-50 psig (3.3 bar)

Pressure: 40-60 psig (3.3 bar)

486/33 MHz Computer

486/25 MHz Computer

110 MB Fixed hard disk drive

40 MB Fixed hard disk drive

44 MB Removable hard disk

3.5" Diskette drive

1.44 MB Capacity

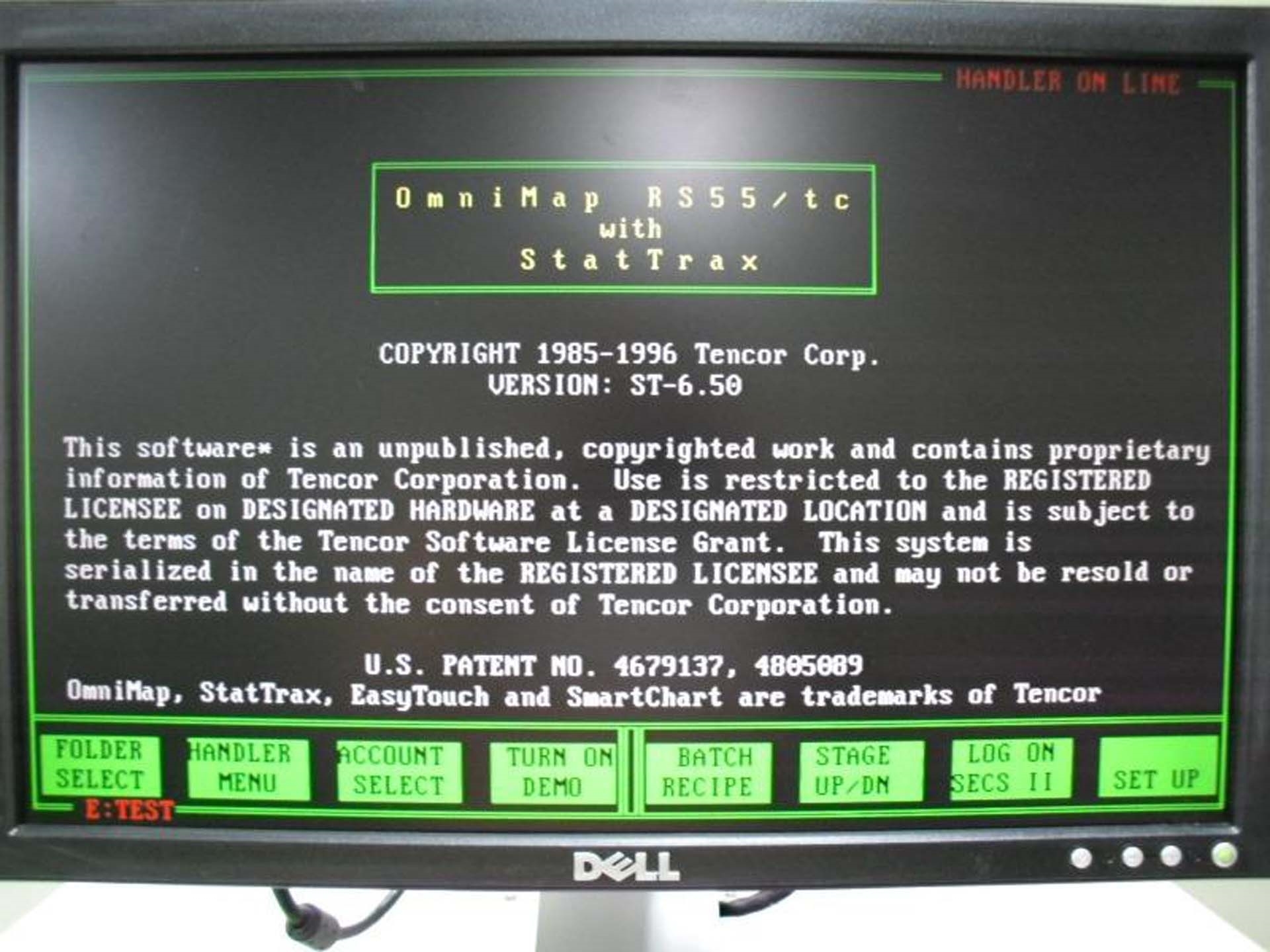

Analysis capabilities:

Contour, XY, Die

3-D Surface maps

Diameter scans

Trend charts

SQC Charts

Histograms

Probe qualification procedure

File editing & data extraction capability

Calibration curves for low-dose monitoring

Average, difference & ratio maps

Data transfer capabilities:

SECS II / RS232 Communication

Enhanced SECS II for fully automated operation

1995 vintage.

KLA / TENCOR RS-55TCA is a wafer testing and metrology equipment used in semiconductor manufacturing. It provides wafer-level measurement and analysis, and can be used to assess a wide range of device parameters such as surface shape, electrode width, size, and geometrical characteristics. The unit is capable of analyzing features of up to 0.8 μm in size, making it an excellent tool for precise testing of sub-micron devices. A major advantage of KLA RS55TCA is its ability to utilize time-resolved measurement techniques to assess sensitive device properties with high accuracy. This is enabled by the system's powerful Phase-Shift Interferometer (PSI) sensor, which works in tandem with a real-time differential signal processor. This combination is able to detect minute changes between observations taken over short time intervals, enabling excellent accuracy in measurement results and faster throughput of testing compared to conventional techniques. The unit is composed of several components. A robotic end-effector is capable of positioning the wafer for scanning across the PSI sensor in a linear motion or a point-based raster scan. A semiconductor belt conveyor and wafer platform provide a secure platform for the wafer during testing. An optical microscope head enables high-resolution magnified imaging of the wafer surface and subsequent data analysis. Finally, TENCOR RS-55 TCA includes an integrated control and analysis unit consisting of a personal computer, an integrated motor control unit, and associated software. This unit is powerful enough to control the wafer positions and process the data from the PSI sensor to produce high-quality results for measurement and analysis. Overall, RS 55 TCA is a powerful wafer inspection and metrology tool that provides excellent accuracy and fast throughput thanks to its time-resolved measurement machine. Its versatile capabilities and integrated control systems make it an ideal choice for advanced semiconductor research and development.

There are no reviews yet