Used KOBELCO / LEO LER #293642527 for sale

URL successfully copied!

Tap to zoom

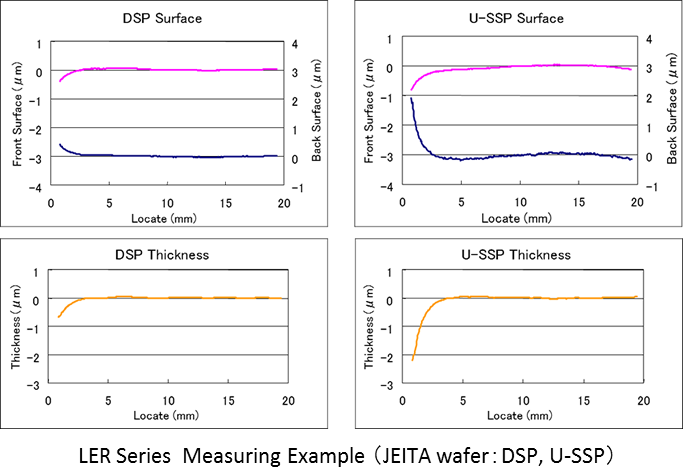

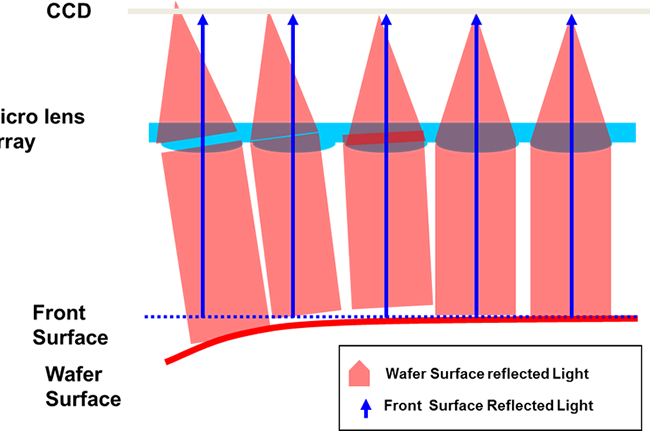

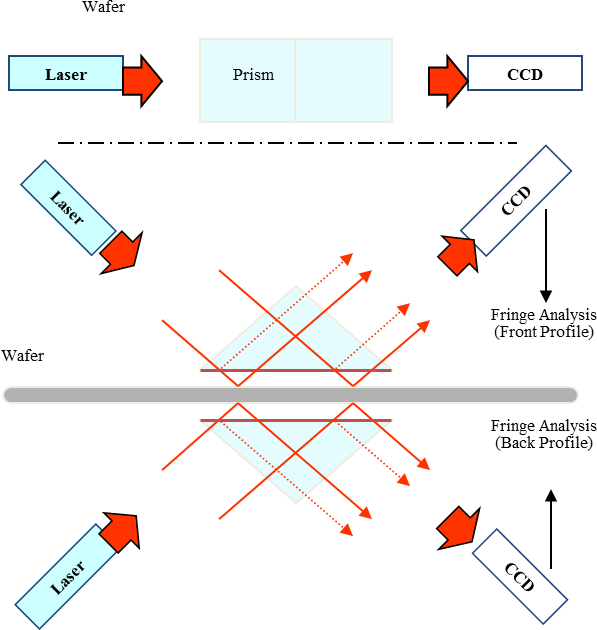

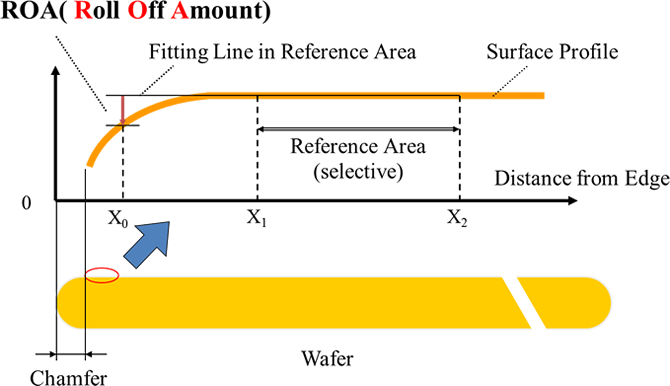

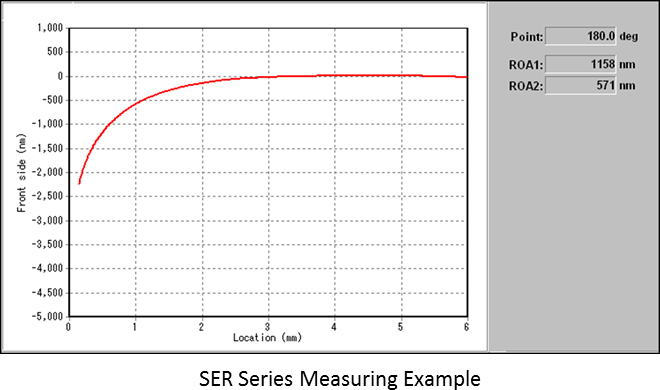

KOBELCO / LEO LER is a high-tech wafer testing and metrology equipment for semiconductors. The system is designed to accurately analyze and inspect wafers during the wafer fabrication process. It utilizes cutting-edge technology to provide high-precision measurements of wafers, and ensure the highest quality possible. LEO LER uses a combination of various metrology measurements, such as chromatic control, interferometry, and scanning electron microscopy. Chromatic control measures the color of a sample, allowing for the identification and detection of any defects on the wafer. Interferometry uses a rotating mirror to interfere light waves, allowing for the analysis of the wafer's surface topography. Meanwhile, scanning electron microscopy is an imaging technique that uses electrons to form an image of the wafer's composition. Moreover, KOBELCO LER unit is capable of performing 3D imaging of entire wafer surfaces. This is done by combining all of the metrology measurements and data collected from the scans. The machine is then able to detect defects, surface abnormalities, and different materials present on a wafer. It can also measure the thickness and orientation of features, such as gates and spacer lines. Additionally, LER implements a number of advanced features to ensure high accuracy and reliability. For example, the tool utilizes an automatic defect inspection capability, which allows operators to monitor the process in real-time. Furthermore, a comprehensive wafer identity recognition asset is implemented to ensure consistent results and accuracy. Overall, KOBELCO / LEO LER is an incredibly advanced model that provides a comprehensive and accurate analysis of semiconductor wafers. With its powerful array of metrology measurements and advanced features, the equipment offers users a reliable and accurate means of testing and inspecting wafers.

There are no reviews yet