Used KOBELCO / LEO LTA #293642502 for sale

URL successfully copied!

Tap to zoom

ID: 293642502

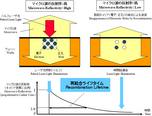

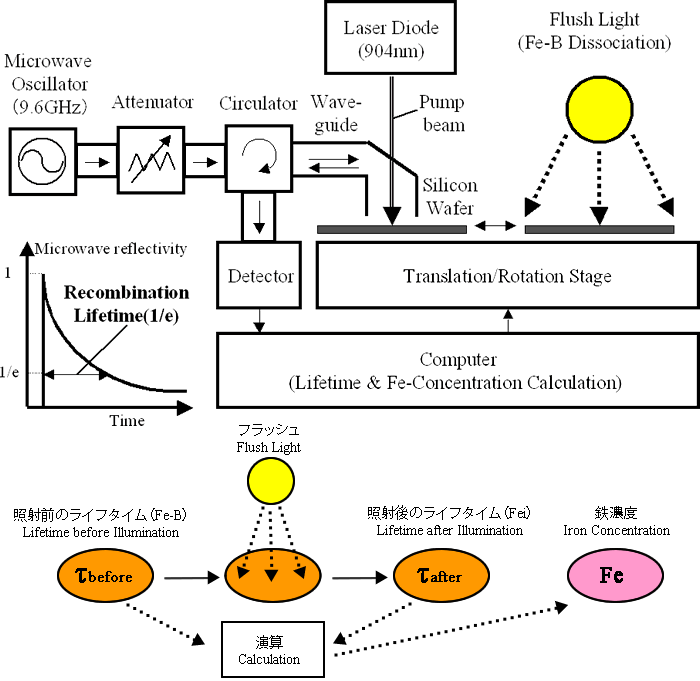

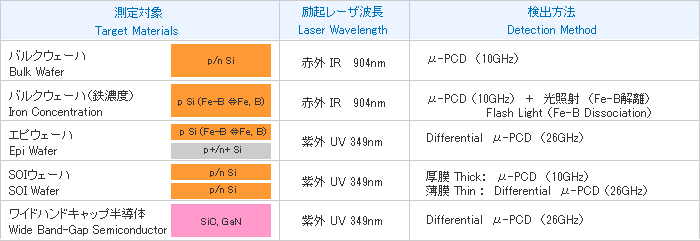

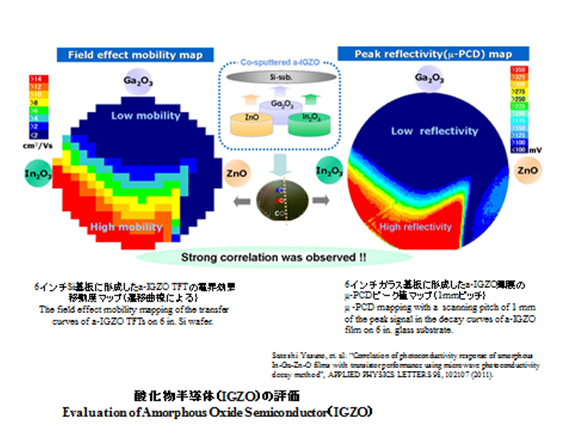

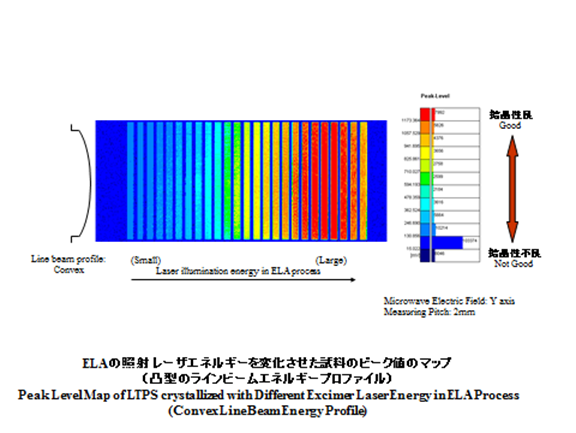

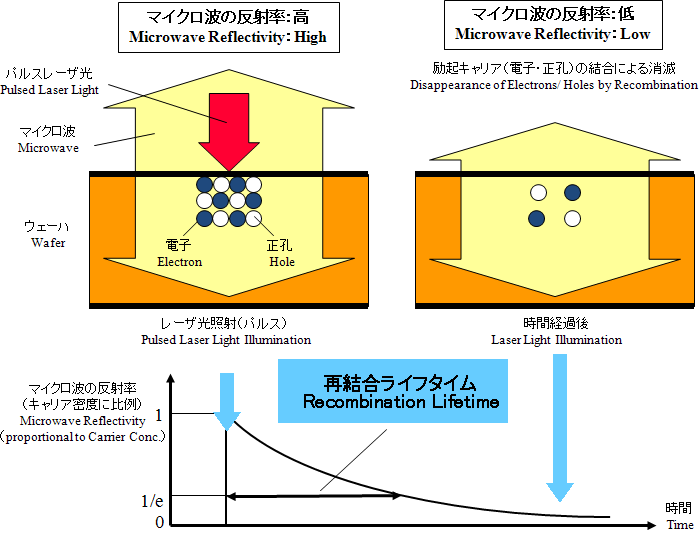

Lifetime measurement system

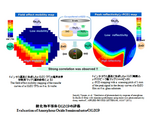

Iron concentration measurement

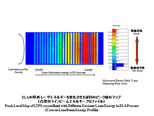

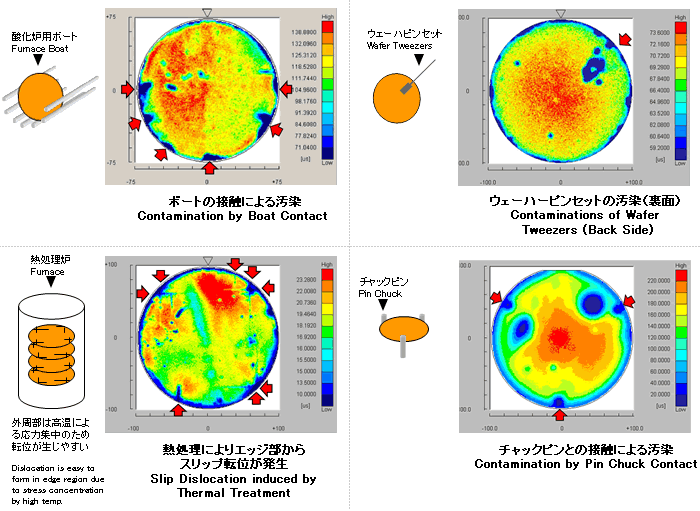

Ample measuring / Indicating modes

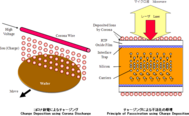

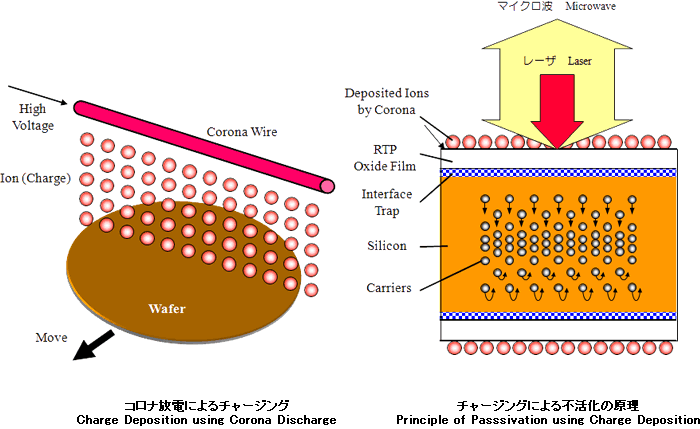

OX Film / Silicon interface.

KOBELCO / LEO LTA equipment is a state-of-the-art wafer testing and metrology system designed to measure the geometric and electrical characteristics of semiconductor wafers. Its primary application is in verifying conformance to spec and guaranteeing process stability, as well as providing comprehensive information on wafer-to-wafer variations. The unit is equipped with two stages that simultaneously measure a wafer's geometrical features (surface texture and thickness) and electrical parameters (resistivity and insulation). The first stage takes up to 16 physical measurements of the wafer, including surface profile, dimensions and non-conductive material such as oxides or other insulating layers. The second stage performs precision electrical measurements of the wafer, including contact resistance and insulation resistance. The machine uses a patented dual-test approach, allowing for real time data assessment on both the geometrical and electrical characteristics of a wafer. This allows for high throughput testing, reducing testing time and saving valuable production time. In addition, the tool is able to automatically detect defects and small variations, helping producers maintain process stability. The asset is designed forrepeatability and precision. All measurements are repeatable and precise to within micro-meters. The precise repeatability of the model also enables wafer stacking without affecting measurement accuracy. The precise accuracy of the equipment is further enhanced with special algorithms that make contact resistance measurements achievable up to a piciohm scale. LEO is an efficient, yet powerful wafer testing and metrology system. With its dual-test approach and precise repeatability, this unit allows for rapid and accurate measurement of both geometrical and electrical characteristics of a wafer. This ensures process repeatability and enables better control over production. In addition, the machine is designed to minimize production time by requiring only one pass for accurate results.

There are no reviews yet