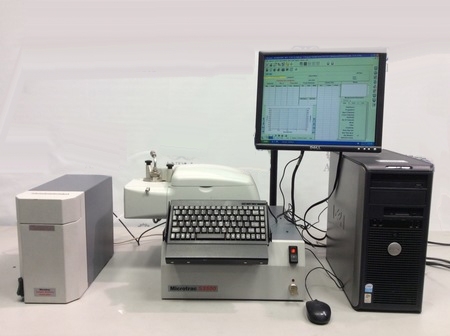

Used MICROTRAC S3500 #9215422 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9215422

Vintage: 2006

Micron particle counter system

With sample delivery system

Tri-laser system

Particle size: 0.02 to 2800 microns

Standard range: Wet: 0.24 to 1400 um

Ranges (Wet, dry)

Basic: 0.7-1000 um, 0.7-1000 um

High: 2.75-2800 um, 2.75-2800 um

Standard : 0.24-1400 um, 0.24-1400 um

Special : 0.086-1400 um , 0.24-1400 um

Extended: 0.021-2000 um, 0.24-2000 um

Enhanced: 0.021-2800 um, 0.24-2800 um

Precision:

CV=0.7%, Spherical glass beads D50: 642 micron

CV=1.0%, Spherical glass beads D50: 56 micron

CV=0.6%, Spherical glass beads D50: 0.4 micron

Lasers: Wavelength 780 nm

Power: 3 mW Nominal

Detection system: (2) Fixed photo-electric detectors

Optimal scattered light detection

0.02-163 degrees using (151) detector segments

Data handling:

Data storing format: ODBC

Encryption: Microsoft access databases

Data integrity: FDA 21 CFR Part 11

Typical analysis time: 10 to 30 seconds

Environmental:

Temperature: 10° C-35°C

Humidity: 90% RH

Storage temperature: -10° C-50° C

Pollution: Degree 2

Physical case: Steel and impact resistant plastic

Exterior surfaces: Corrosion resistant paint / Plating

Dry operation:

Maximum pressure: 100 psi

Minimum flow rate: 5 CFM-50 psi

Free of dry contaminants

Moisture / Oil

Vacuum: Exceed 50 CFM

Includes:

Computer

Power cord

Cables

Power

AC Input: 90-132 VAC, 1 Phase, 47 - 63 Hz

200-265 VAC, 1 Phase 47 63 Hz

Power consumption: 10-30 Seconds

2006 vintage.

MICROTRAC S3500 is a wafer testing and metrology equipment designed to analyze semiconductor wafers in order to ensure that they meet manufacture standards and expectations. It has been specifically developed for wafer metrology needs and provides a reliable, high-precision solution to complete all necessary tests. MICROTRAC S 3500 utilizes advanced laser scanning techniques that detect several parameters, including electrical properties such as conductivity, optical properties such as transmittance, and structural parameters such as lift-off and step heights. The built-in hardware of S3500 allows for an efficient and reliable test process. It consists of a scanning head with a three-axis mirror system that is adjustable for optimal scanning performance and angle resolution. This is aided by an optical objective for the scanning head to capture images, along with the necessary control electronics. Additionally, the unit also offers a variety of software-based modules to enable the user to analyze the collected test data quickly and accurately. S 3500 features a main controller unit and graphical user interface with Windows operating machine compatible software. It is designed to offer maximum measurement range, accuracy, and repeatability to enhance the speed of the wafer testing process. The tool is also equipped with a geometry scan module and automated masking technology to avoid any adverse results due to the masking process. This guarantees accurate results that can be directly compared to preceding or succeeding scans. MICROTRAC S3500 is also able to gather data from multiple sensors at the same time, allowing for more accurate test results. Furthermore, it includes powerful metrology capabilities such as two- and three-dimensional imaging, spot-size mapping, critical-dimension (CD) determination, and thin-film physical property measurements. In addition to its automated hardware and software solutions, MICROTRAC S 3500 also provides extended service and support options. The asset is delivered with training-on-site, webinars, software updates, 24/7 hotline service, and engineering service contracts for the best possible use of the model by the user. Furthermore, the equipment is regularly maintained to ensure maximum performance and accuracy of the test results. Overall, S3500 is a reliable and user-friendly wafer testing and metrology system designed to reduce cost, increase efficiency, and ensure quality of wafers. Its integrated features and quality assurance support make it an ideal choice for industrial wafer testing and analysis.

There are no reviews yet