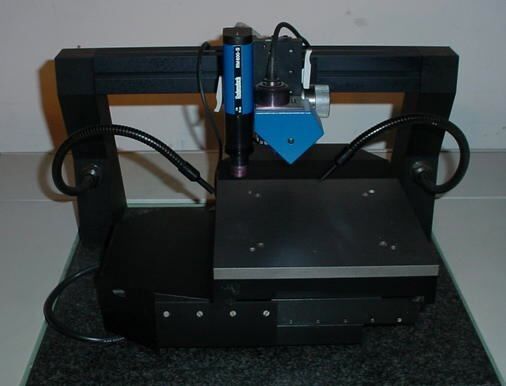

Used RODENSTOCK RM600 3-D/C #77221 for sale

URL successfully copied!

Tap to zoom

ID: 77221

Laser profilometer, topography measuring station, as-is with known computer problem. 100mm x 100mm x 50mm high scan travel.

RODENSTOCK RM600 3-D/C equipment is a wafer testing and metrology system manufactured and distributed by RODENSTOCK, an established supplier in the semiconductor industry. This automated metrology unit is designed for QA inspectors in the semiconductor and electronics industry, and is used to rapidly, accurately and cost-effectively measure wafers for defects in both 2-D and 3-D surface geometry. The machine features a high-resolution, optical-based imaging technology that uses a combination of 3D laser scanning and high-resolution camera imaging to measure surface areas up to 600mm in diameter. The 3D laser scanner is used to capture the profile of a wafer's surface in ultra-high resolution while the high-resolution camera provides detailed views at various zoom levels. The software then creates a 3D representation of the wafer's surface which can be viewed, measured and analyzed. RODENSTOCK RM600 3-D/C tool is fully automated, allowing quick and easy operation. It uses advanced algorithms to measure and identify defects, allowing it to quickly detect defects and accurately measure the size, shape, position and depth of the defect. The software also offers color coding for defect categorization, allowing for quicker and more efficient sorting of defects. In addition, the asset incorporates an array of other features, such as built-in tracking for improved throughput, software for statistical analysis and reporting, and a powerful user interface for configuring and customizing the model. Additionally, the equipment is highly customizable with user-defined parameters to maximize acquisition speed, accuracy and complexity. Overall, RODENSTOCK RM600 3-D/C system is a powerful and reliable wafer testing and metrology unit that offers accurate and efficient defect inspection and analysis. It is an ideal solution for semiconductor and electronics industry quality assurance departments that require an automated, high-performance machine to reliably and quickly analyze wafers for defects.

There are no reviews yet