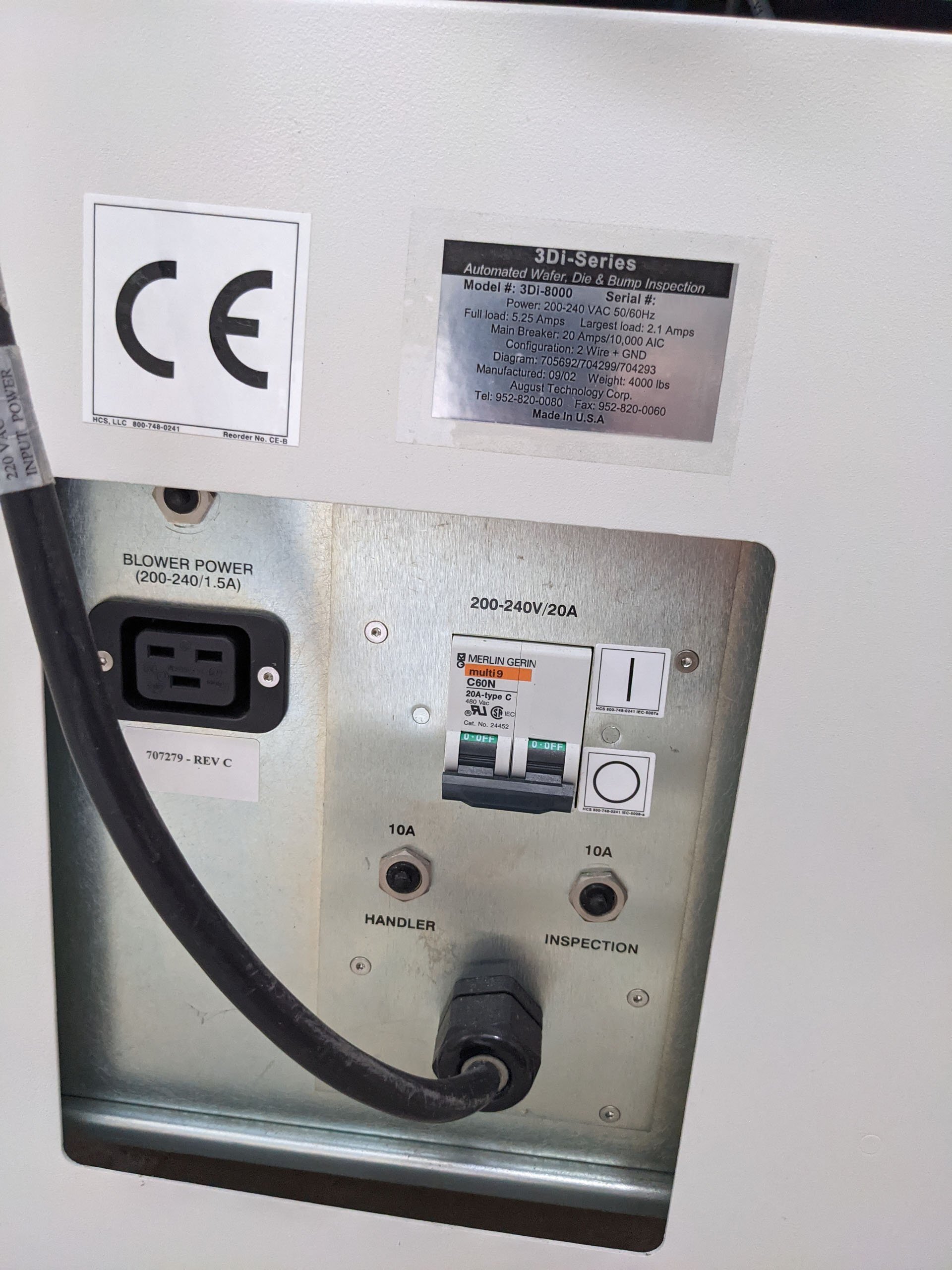

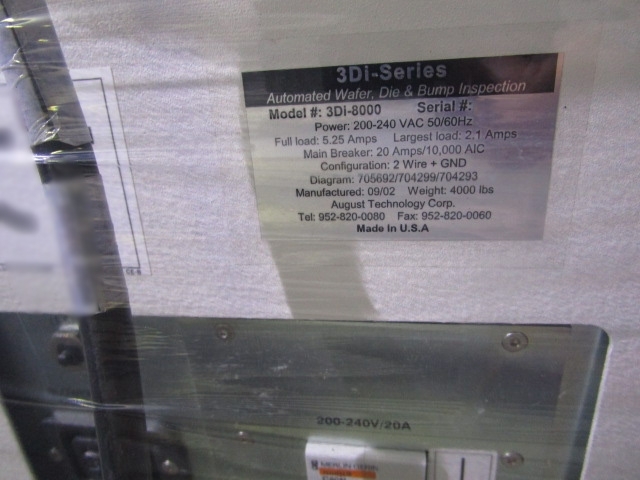

Used RUDOLPH / AUGUST 3DI 8000 #9206004 for sale

URL successfully copied!

Tap to zoom

ID: 9206004

Wafer Size: 12"

Vintage: 2002

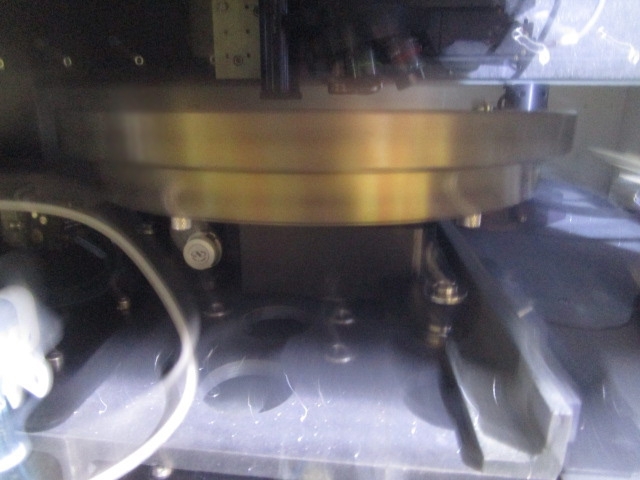

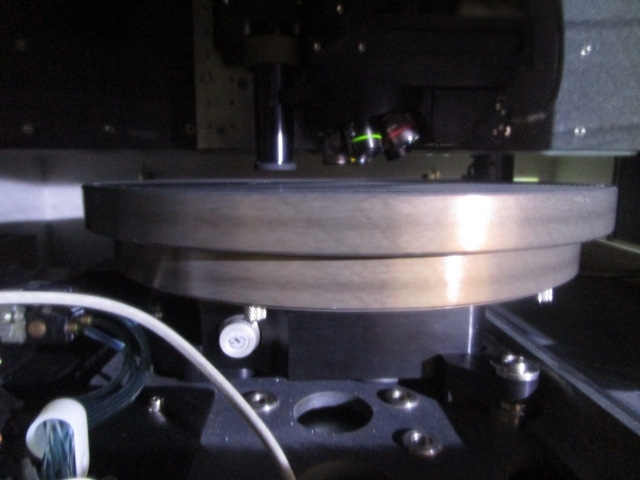

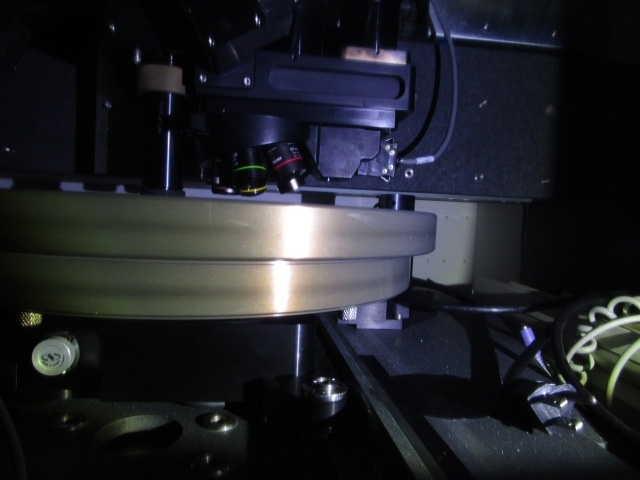

Wafer bump inspection system, 12"

2002 vintage.

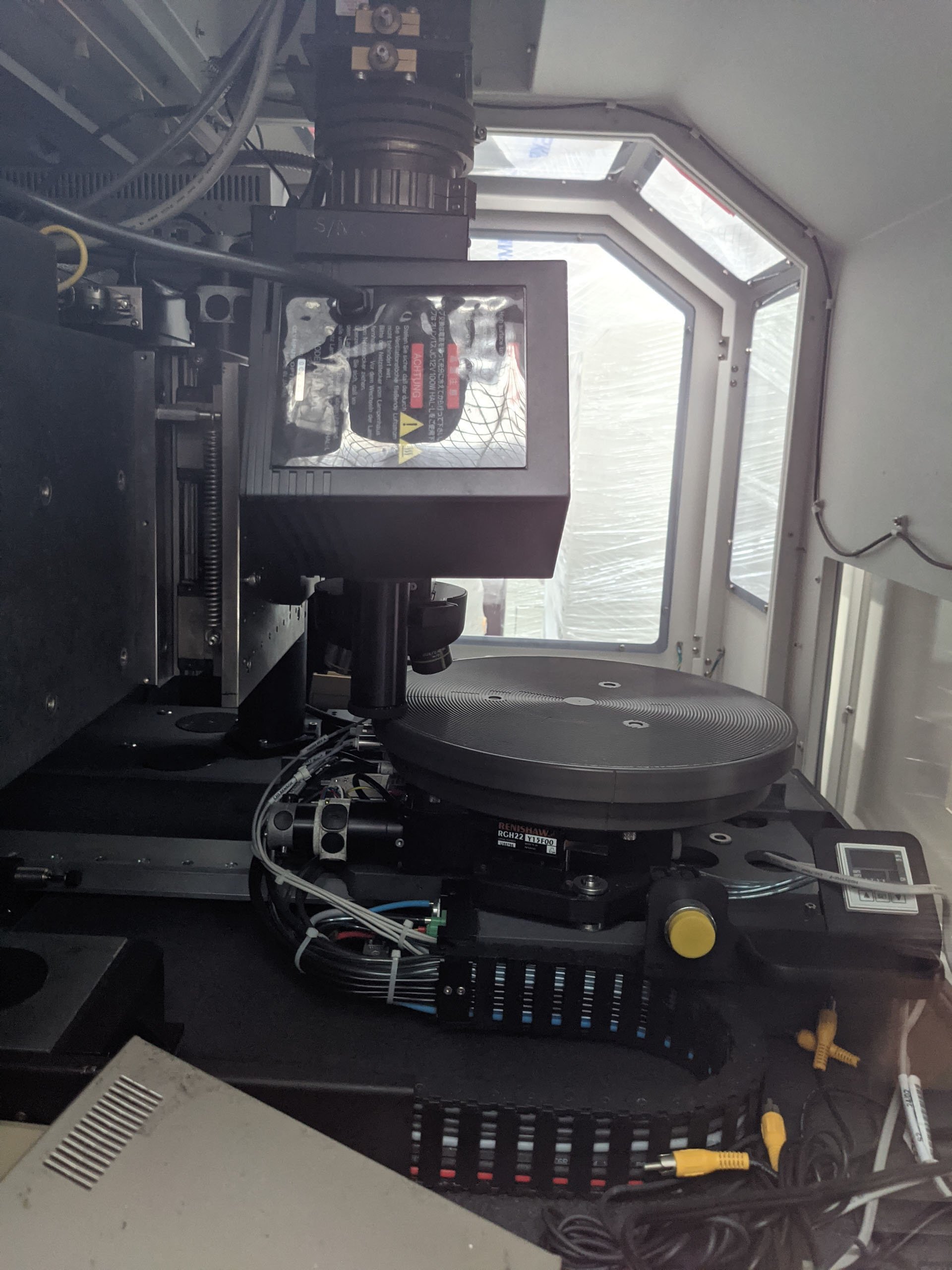

RUDOLPH / AUGUST 3DI 8000 is a fully automated wafer testing and metrology equipment designed to provide superior analysis and testing data. It is capable of measuring various parameters, including stress, strain, electrical properties, and other aspects of material characteristics. Using a variety of data acquisition techniques, it can measure the physical, mechanical, thermal, and electrical performance of a variety of semiconductor materials and structures. AUGUST 3DI 8000 is equipped with a high precision laser interferometer system which enables it to accurately measure and characterize the surface profile of a wafer in 3 axes with a resolution of up to 0.1 nanometers. The unit also features a high-resolution XYRIS 4 stage metrology machine with C-MOS sensors, providing a full field of view in all three axes and able to measure various features, such as line widths, periodicity, and defect/voids with a resolution of 0.1 microns. The tool is also capable of carrying out stress and strain measurements by use of a collimated laser beam asset, where the laser excites the sample's optical effects to detect the deformations due to the stress and strain. The model also offers non-contact measurement of various electrical characteristics such as capacitance, inductance, and resistance. RUDOLPH 3DI 8000 also offers a powerful graphical user interface for managing automated routines. User-defined templates allow the user to modify parameters quickly with predetermined wafer and sample characteristics. With its high-speed data acquisition, image acquisition and processing, and advanced metrology capabilities, 3DI 8000 can quickly analyze and detect defects and other imperfections on wafers. RUDOLPH / AUGUST 3DI 8000 is a compact and self-contained equipment with the capability to perform comprehensive tests on the most advanced semiconductor materials with industry-leading precision. Its advanced non-contact testing and automated routines make it ideal for researchers and engineers in the field of semiconductor material, as it offers a fast and reliable way to analyze and measure the performance of a variety of materials.

There are no reviews yet