Used RUDOLPH MetaPulse 300 Cu #9124175 for sale

URL successfully copied!

Tap to zoom

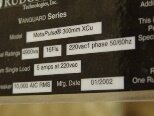

ID: 9124175

Wafer Size: 12"

Vintage: 2002

Thin film measurement system, 12"

Ultrathin at 45 nm technology node to thick opaque films

Picosecond laser sonar (PULSE tm) technology

Product measurement are enabled with small spot size & non-contact

Non-destructive measurement method

RMS roughness

Material density

Adhesion

Material phase and interlayer reactions

Low-k and ultra low-k ILD modulus capabilities

2002 vintage.

RUDOLPH MetaPulse 300 Cu is a wafer testing and metrology equipment that is designed for use in semiconductor fabrication processes. The system uses a 300 mm wafer size and can process both silicon and non-silicon wafers. It is capable of providing optoelectronic measurements for both critical dimension (CD) and optical surface properties (OSP). MetaPulse 300 Cu unit uses a KrF excimer laser, which is a type of short-wavelength laser that is capable of producing nanometer-level accuracy. It is also equipped with an optical scatterometer, which is used to measure the Optical Properties of the wafer surface, including coating thickness, total extent of defects, and more. The machine has a powerful 2K CCD line-scan camera, which can operate at high speeds to accurately measure a wide range of parameters. It is also equipped with a multi-wavelength spectrophotometer for high-resolution spectral imaging, as well as an e-beam patterning tool for rapid pattern recognition. The asset is equipped with advanced software algorithms and data processing techniques, which allow it to deliver highly accurate results. It supports historical traceability, data-driven statistical process control, and graphical visualization of profile data. RUDOLPH MetaPulse 300 Cu model is designed for use in a range of fabrication processes, including wafer thinning, rapid defect template application, as well as overlay optimization. It is also capable of simulating ultra-shallow junctions, and measurement of mask registration and critical dimension. The equipment ensures accuracy and throughput efficiency, making it an ideal choice for any fab process. Its advanced functionality and robust design make it a reliable choice for any wafer fabrication process.

There are no reviews yet