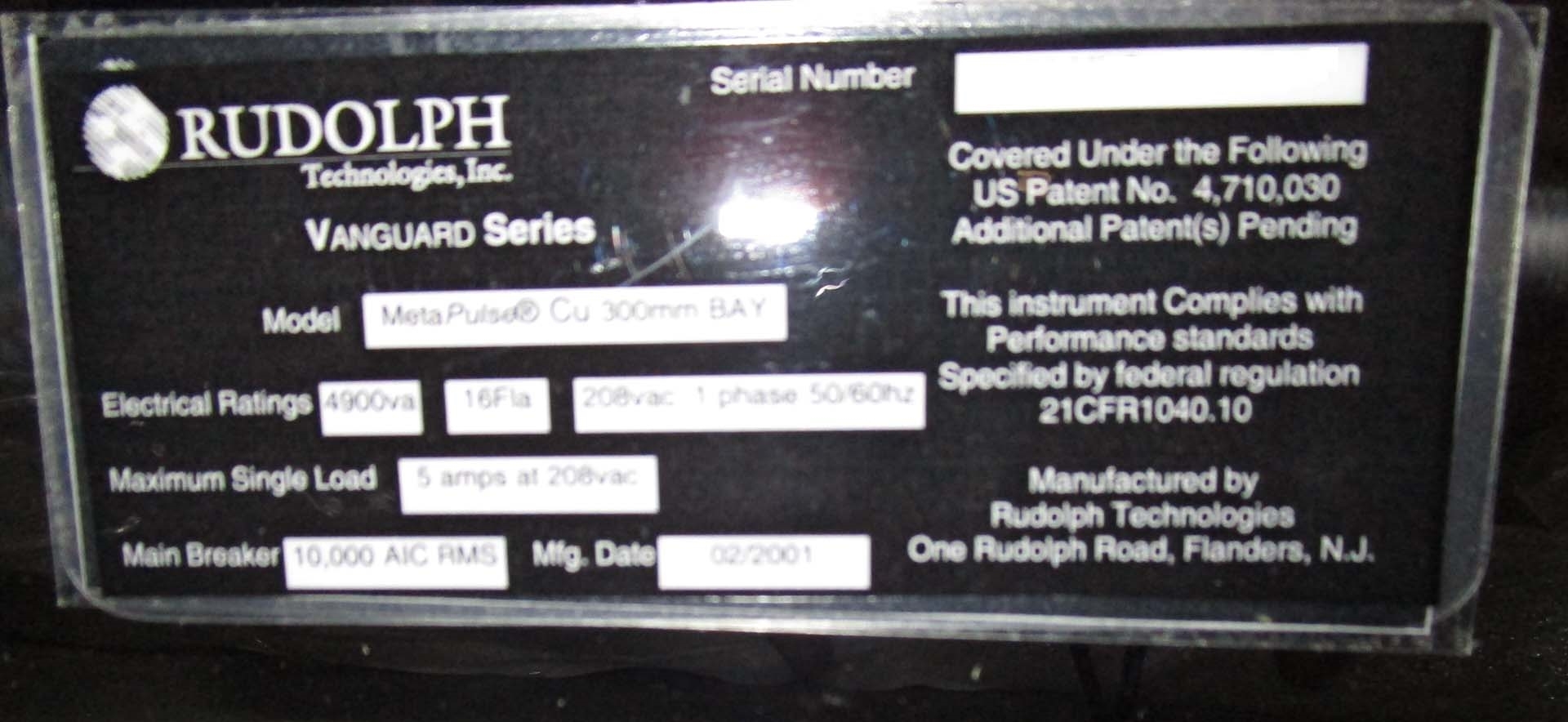

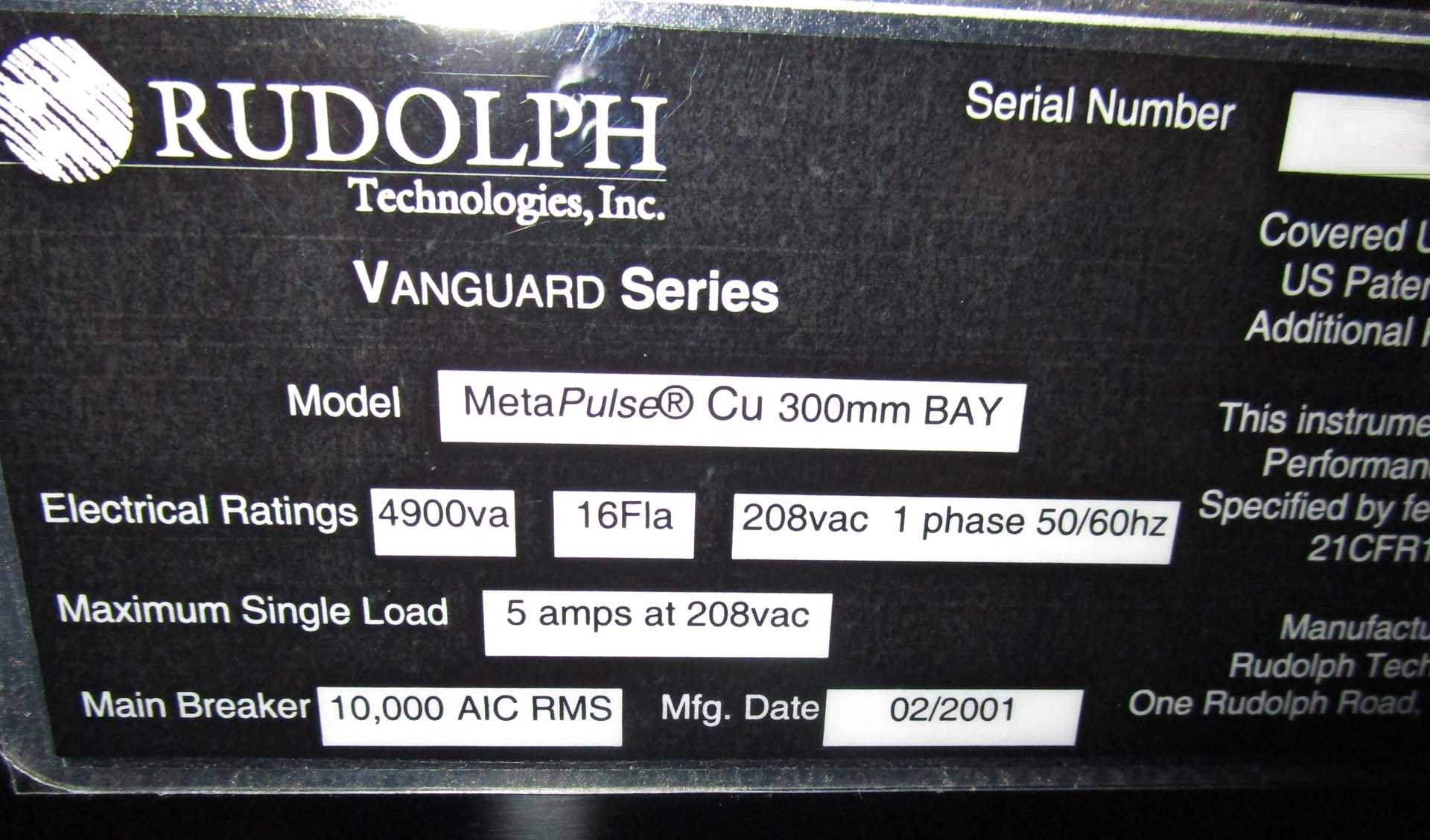

Used RUDOLPH MetaPulse 300 Cu #9233986 for sale

URL successfully copied!

Tap to zoom

ID: 9233986

Wafer Size: 12"

Vintage: 2001

Thin film measurement system, 12"

2001 vintage.

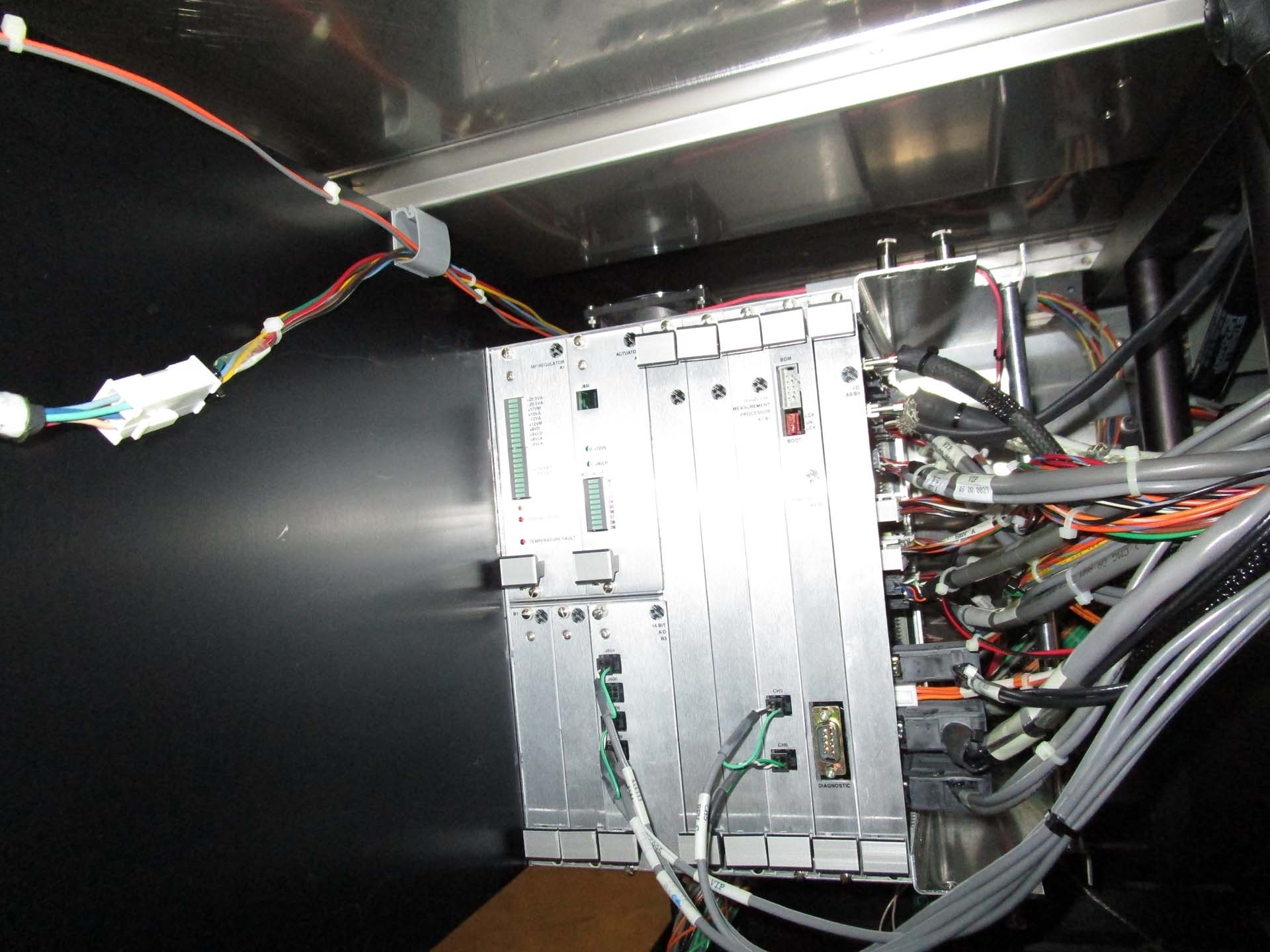

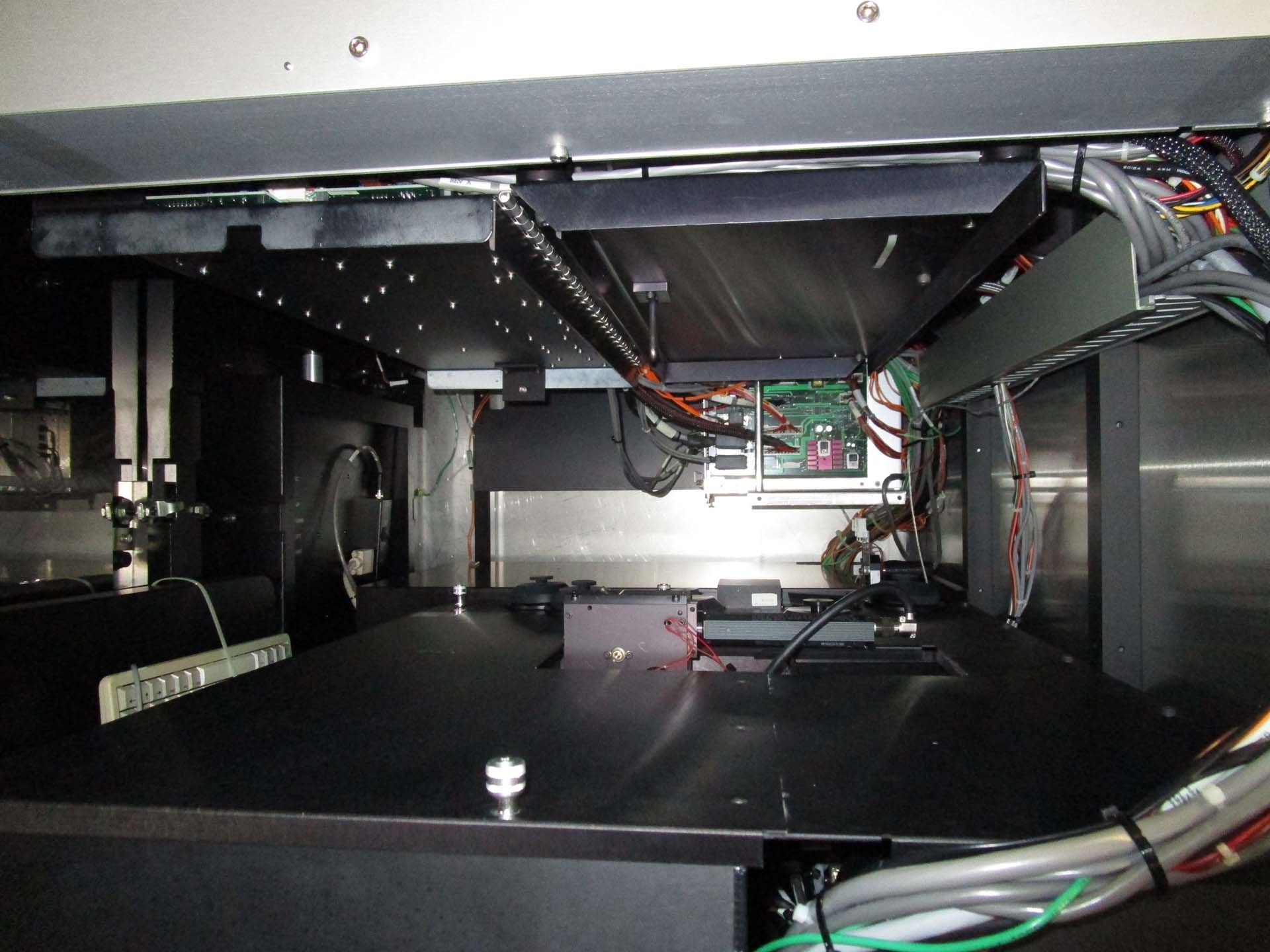

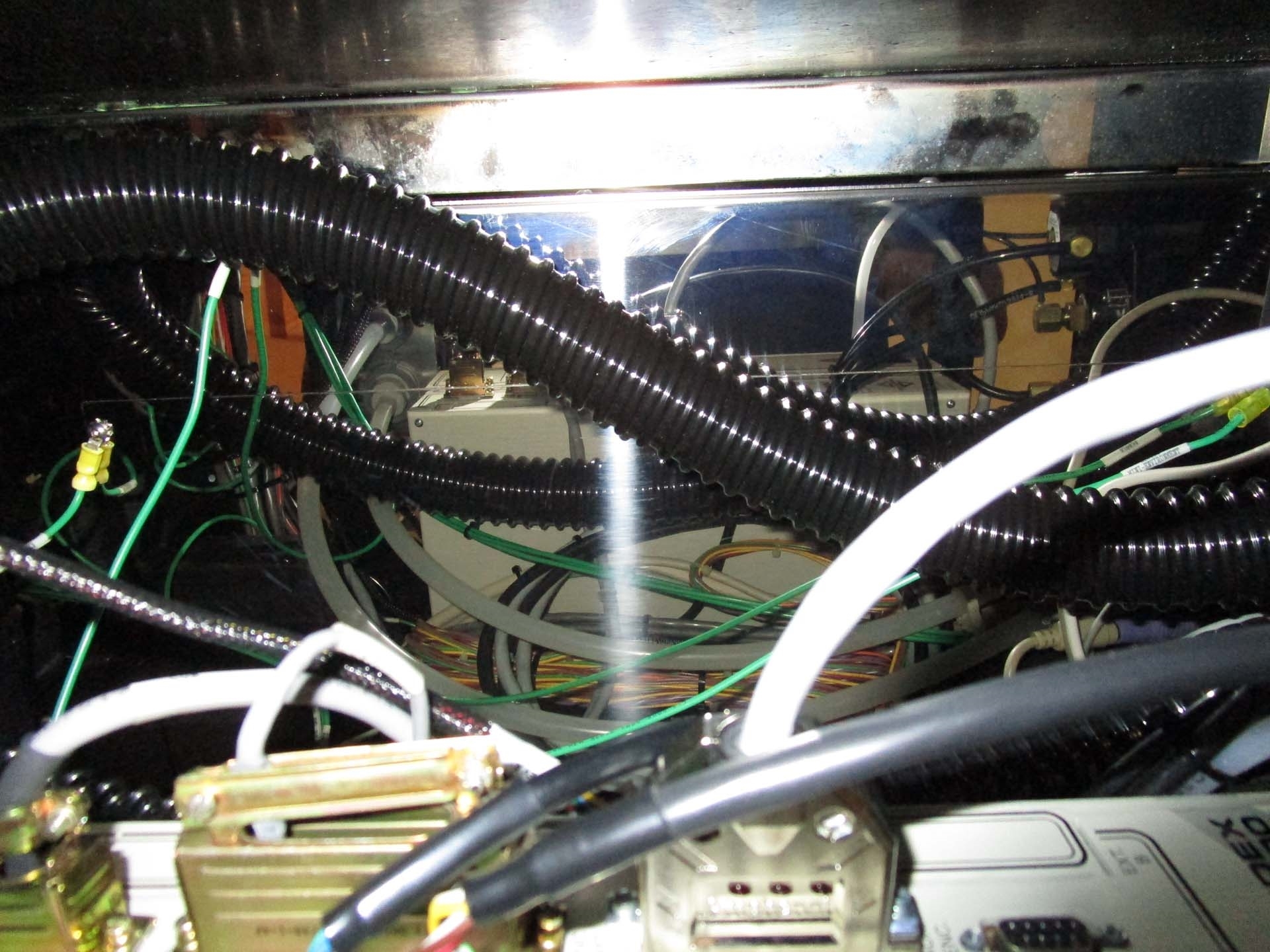

RUDOLPH MetaPulse 300 Cu is an advanced wafer testing and metrology equipment from RUDOLPH Technologies, Inc. It is designed for maximum performance and accuracy for the analysis of a wide range of wafer sizes and geometries. The system offers a wide range of capabilities, including high-resolution imaging, pattern recognition, and integrated design rule checking (DRC) which provides comprehensive electrical testing of integrated circuit features, with results that meet industry standards. In addition, the unit offers advanced metrology capabilities, including in-die defect detection, topography measurements, and line width measurements. MetaPulse 300 Cu has a modular design that incorporates the latest in laser and optics technology. The machine can be used for a variety of wafers, from high-density (2µm) to high-performance (10µm). The tool incorporates a laser interferometry asset that is adjustable to different thicknesses to accommodate wafers of different thickness. The model features a camera equipment that is capable of capturing high-resolution images and complex patterns, and a robot arm to enhance precision. The system can capture images up to 512 x 512 pixels in size, with a maximum field of view of 46 mm x 46 mm. The unit also includes advanced software to automate process steps, such as automatically aligning components, optimizing image acquisition, and calculating test results. The machine is capable of analyzing multiple layers of wafers with multiple layers of data, thereby ensuring that electrical test results are up to industry standards. The tool also offers a wide range of connectivity options, including Ethernet, USB, and optical. In addition, the asset features a comprehensive support package, which includes an on-site maintenance package, a user-friendly interface, and comprehensive technical support. RUDOLPH MetaPulse 300 Cu is a versatile model designed to meet the most stringent requirements of the wafer testing and metrology industry. It offers a combination of performance, accuracy, and convenience that make it an ideal choice for automated wafer testing and metrology.

There are no reviews yet