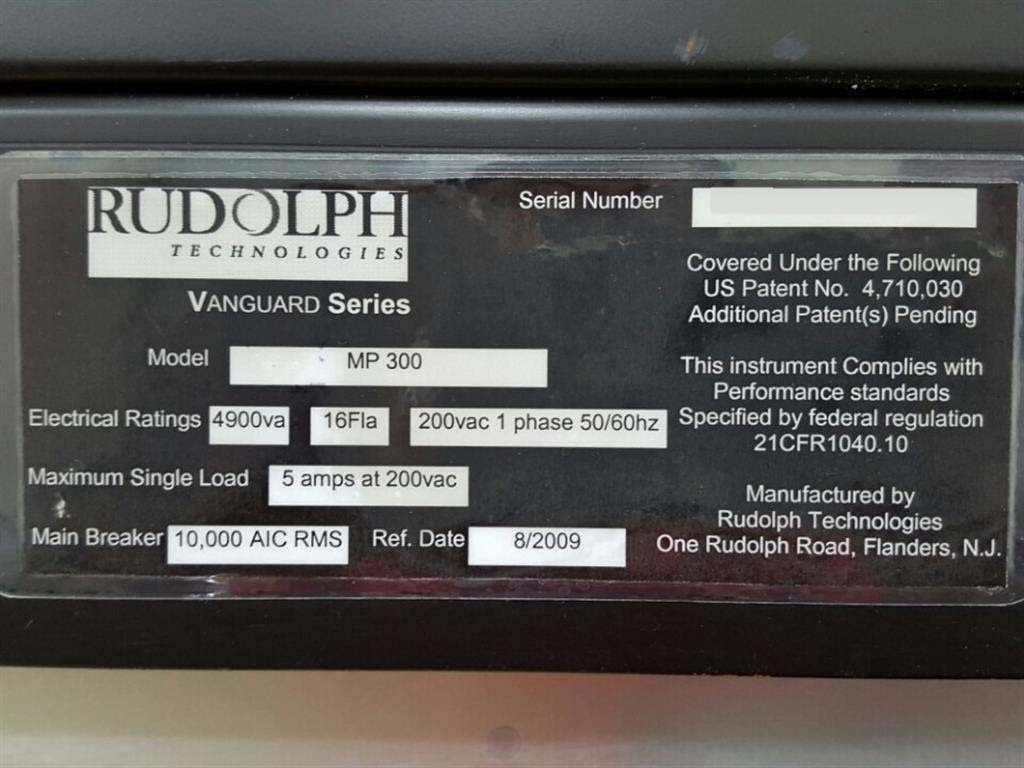

Used RUDOLPH MetaPulse 300 #9083733 for sale

URL successfully copied!

Tap to zoom

ID: 9083733

Wafer Size: 8"

Vintage: 2009

Thickness measurement system, 8"

2009 vintage.

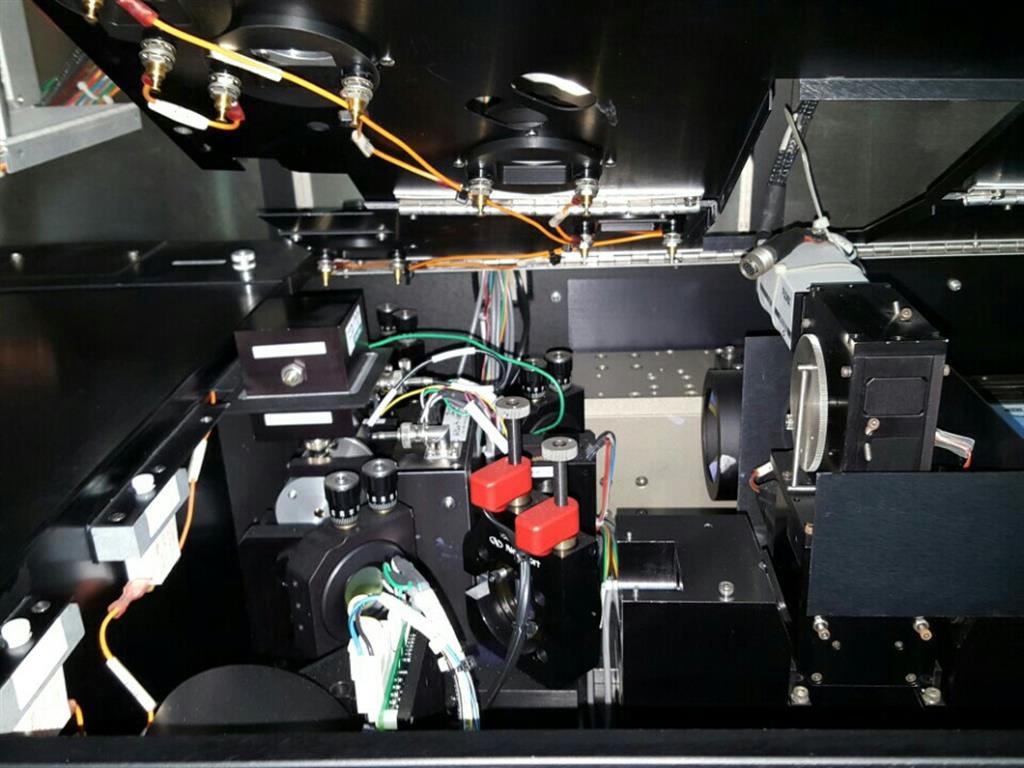

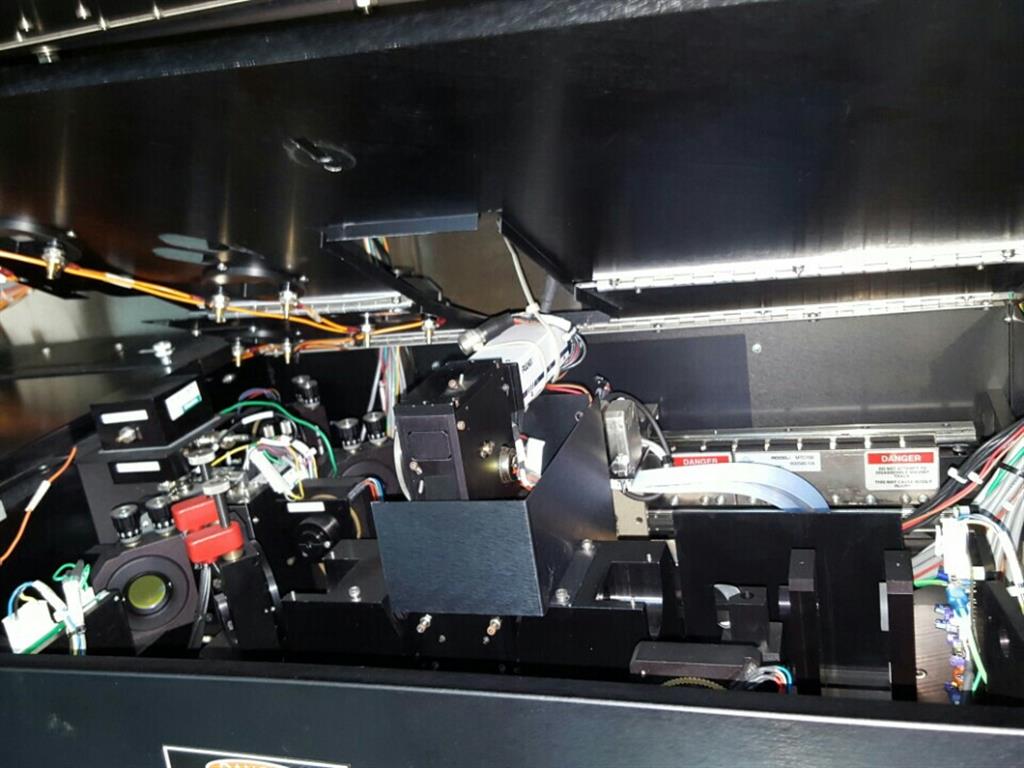

RUDOLPH MetaPulse 300 is an automated wafer testing and metrology equipment designed to improve the accuracy and reliability of processes in the semiconductor industry. MetaPulse 300 utilizes high-precision optical, scanning, and electrical analysis tools to measure wafer performance metrics. It supports operating frequencies up to 300MHz and integrates easily into existing production lines. The system is designed for high throughput and high cycle-time accuracy, ensuring precise and accurate test results. The unit is equipped with multiple measurement and inspection subsystems including: optical inspection, surface roughness and topography, wafer electrical characteristics, and a 300MHz defect inspection machine. These subsystems allow for high-resolution analysis of parametric variation and fault detection. The uni-directional scan tool is equipped with external trigger electronics which enable multiple programs to run in parallel. The asset also offers a range of integrated solutions to monitor and maintain data accuracy. These include: automated test control, wafer environmental control, data acquisition and analysis, real-time reporting, and defect pattern recognition. RUDOLPH MetaPulse 300 is also compatible with all major SPC software packages, allowing for quick and easy integration into existing production processes. The model is reliable and highly efficient. It eliminates the need for manual analysis, which improves operational efficiency and increases throughput. It also ensures repeatability and traceability of wafer testing and metrology processes, making it suitable for monitoring, data benchmarking, as well as quality control applications. In conclusion, MetaPulse 300 automated wafer testing and metrology equipment is a reliable and efficient test solution for the semiconductor industry. It offers precision scanning and measurement capabilities, and enables streamlined integration with existing production processes. The system improves operational productivity and ensures data repeatability and traceability.

There are no reviews yet