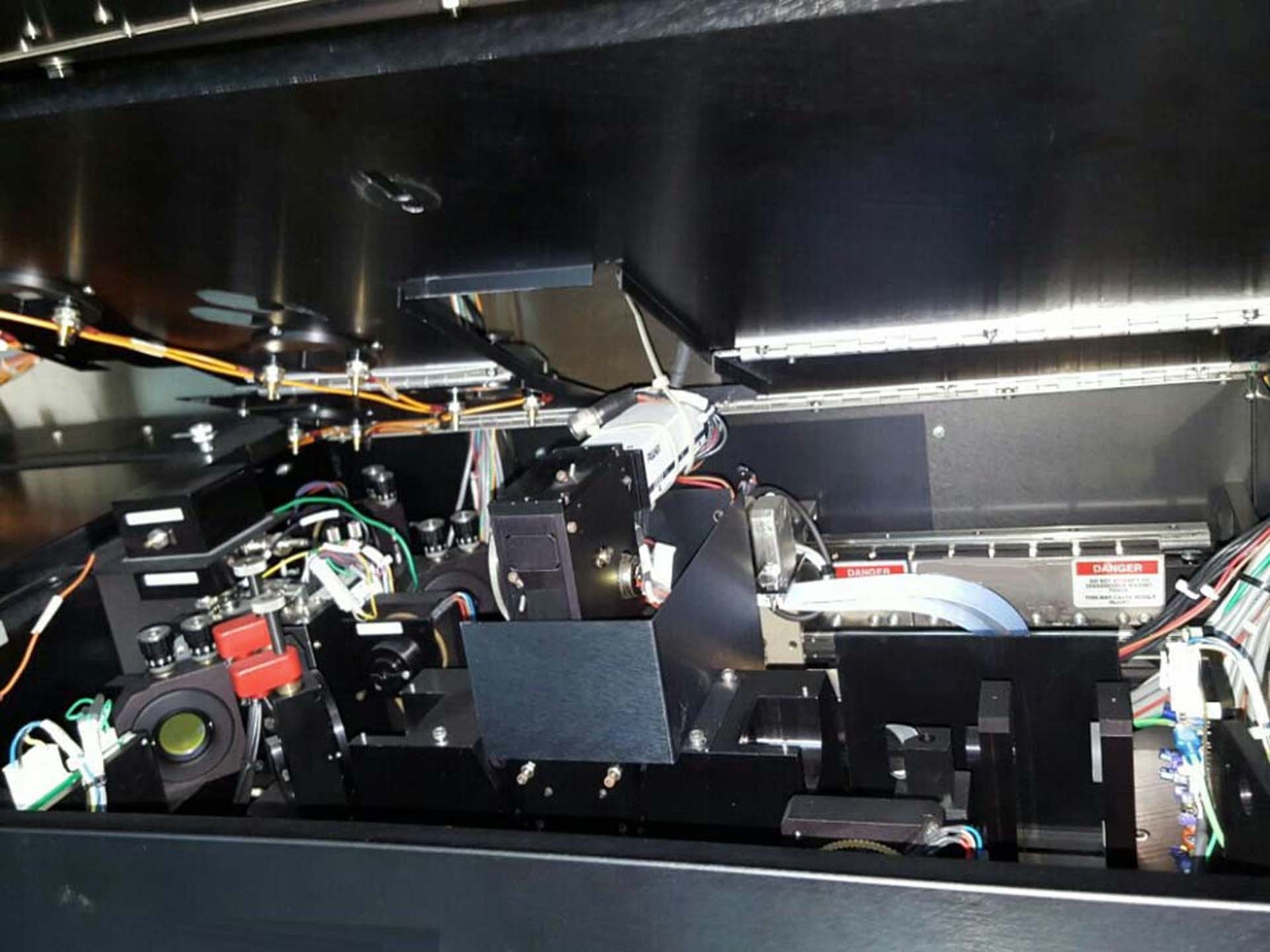

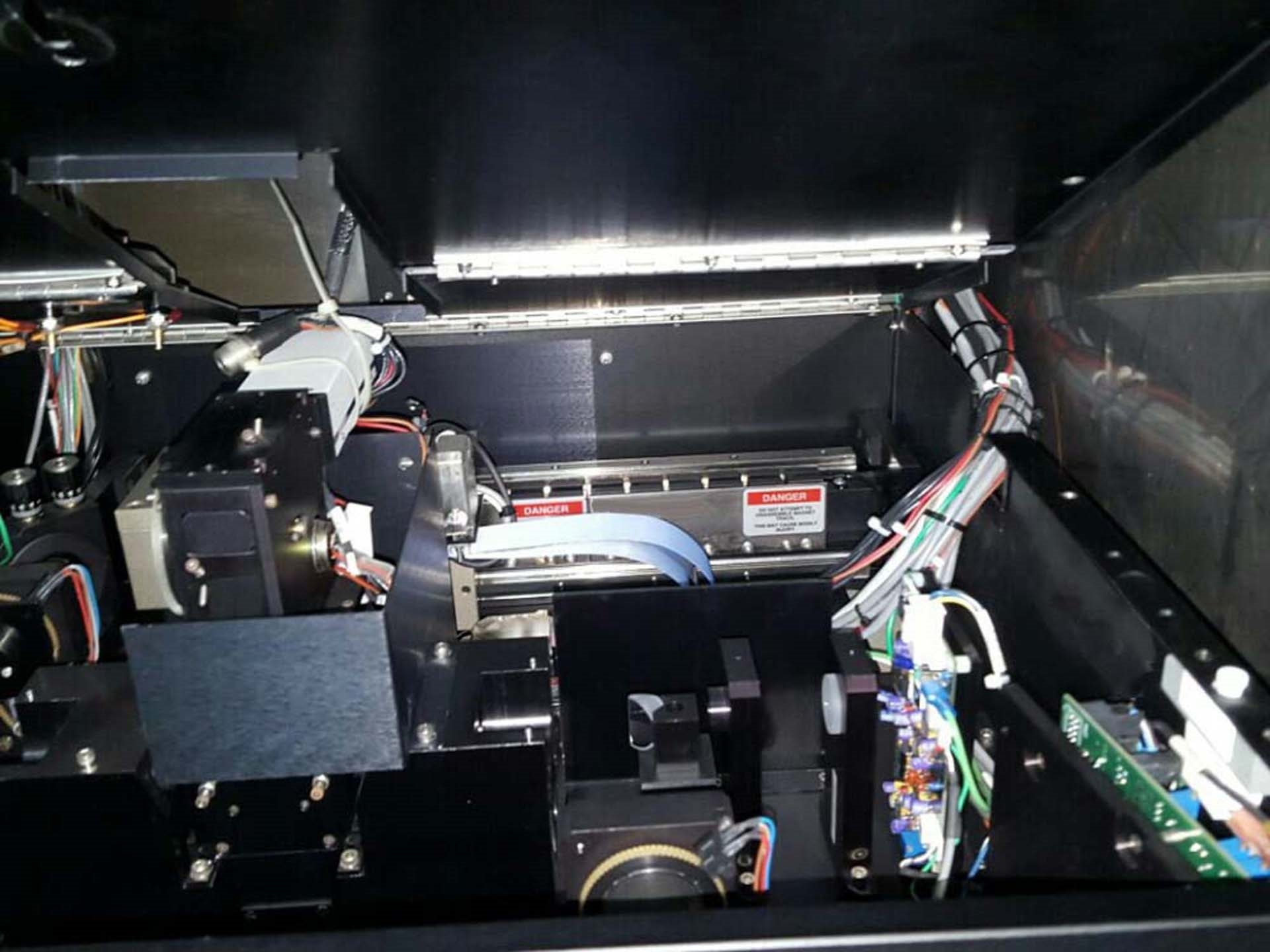

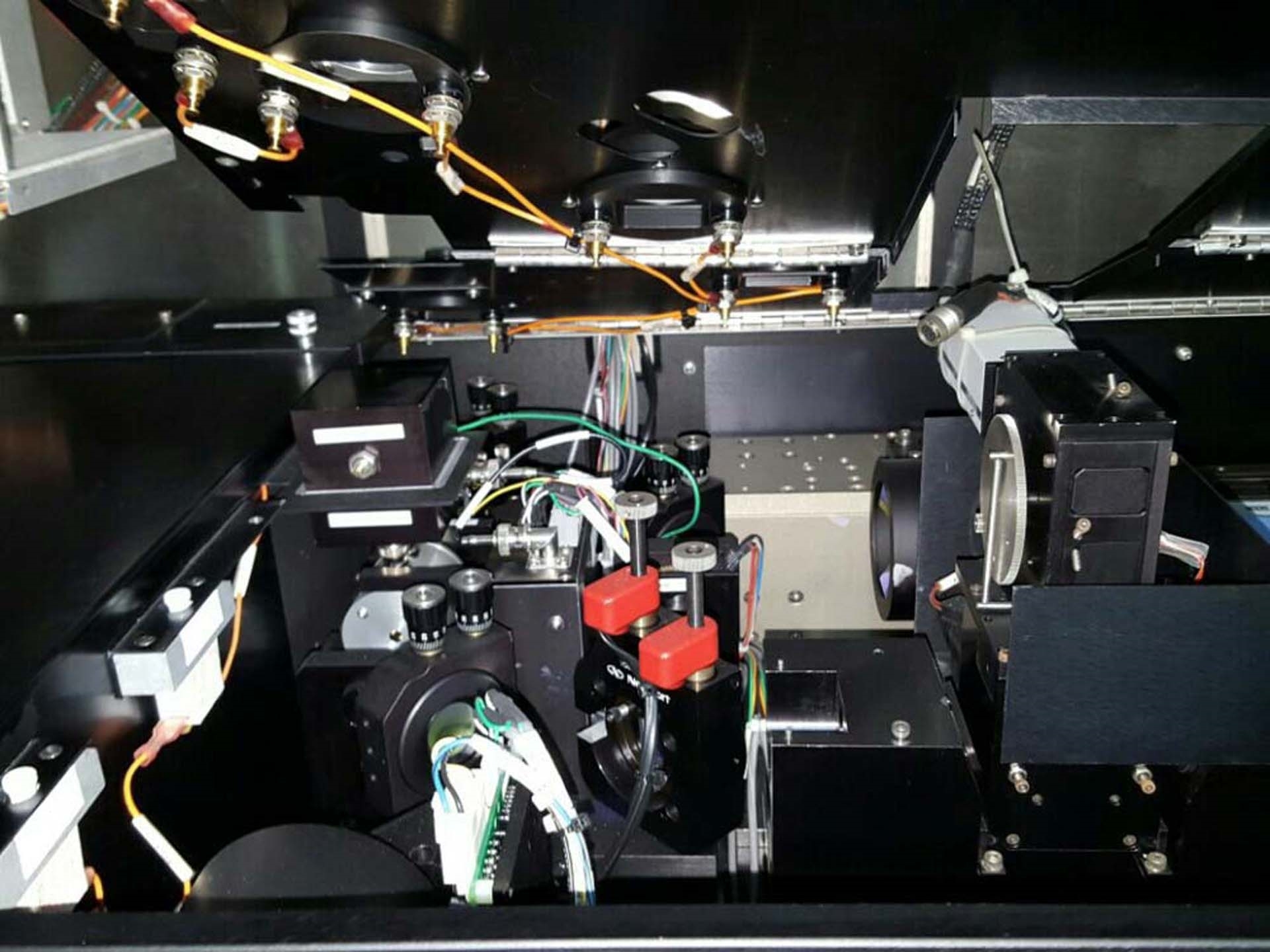

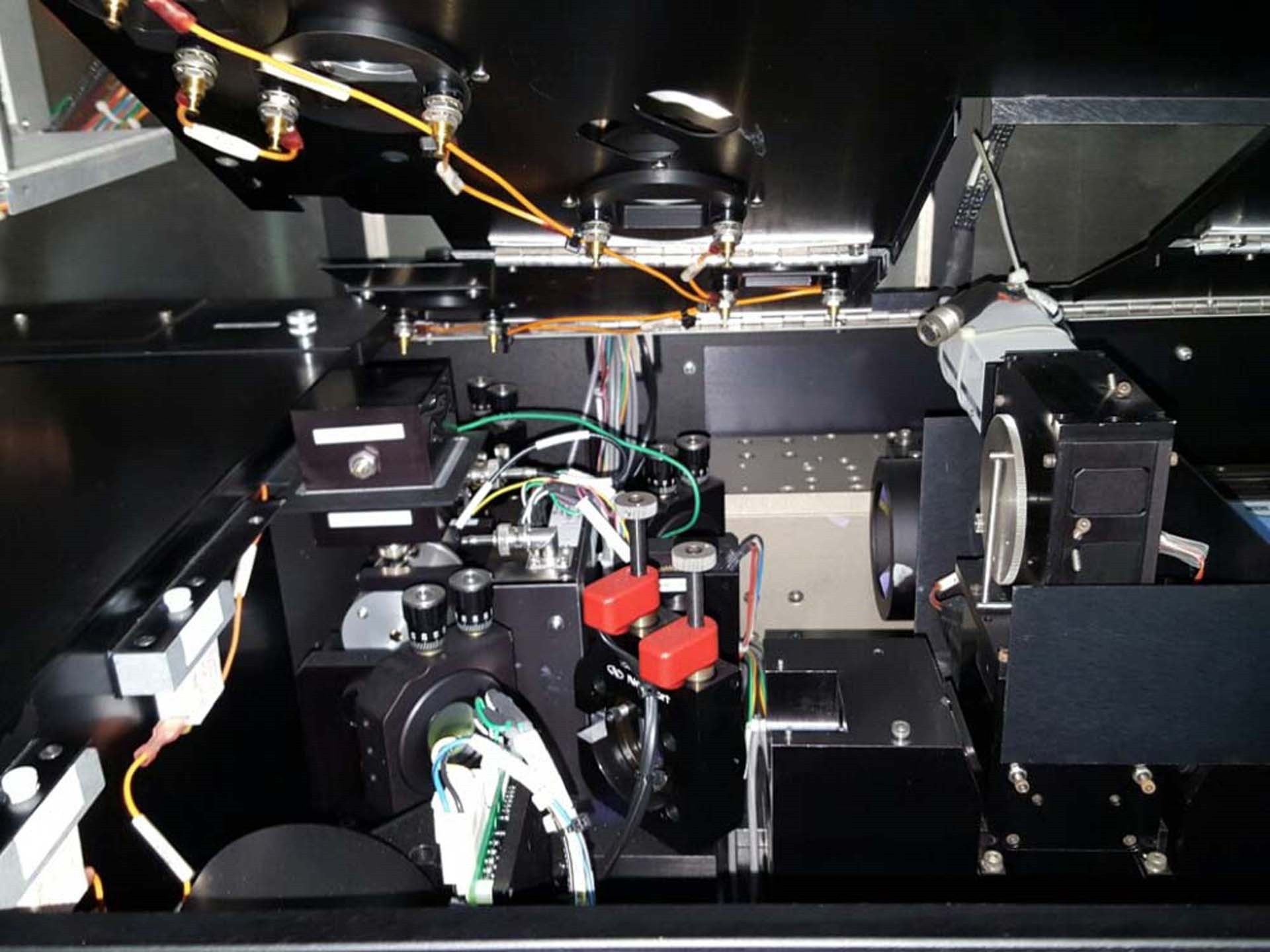

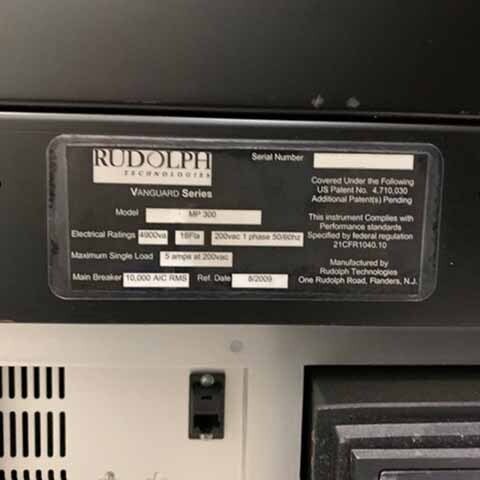

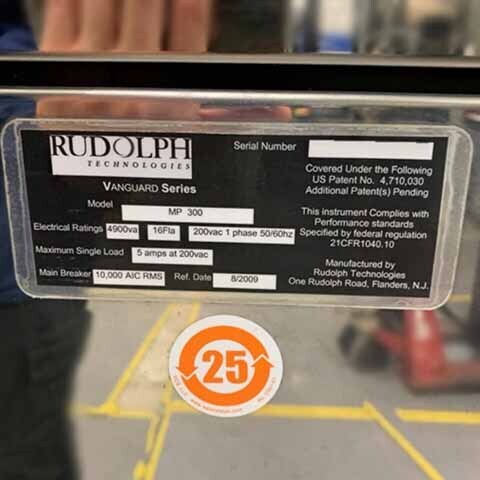

Used RUDOLPH MP 300 #9098967 for sale

URL successfully copied!

Tap to zoom

ID: 9098967

Wafer Size: 8"

Vintage: 2009

Thin film measurement system, 8"

2009 vintage.

RUDOLPH MP 300 is a powerful wafer testing and metrology equipment developed for cutting-edge semiconductor manufacturing. It uses advanced industrial sensors and detectors to identify key manufacturing characteristics and characteristics of RUDOLPH MP300 wafers, such as die composition, wafer yield, uniformity, and electrical properties. With a self-aligning stage and a patented micron-tolerance wafer positioning system, the machine can accurately and reliably measure and document the characteristics of up to 450 wafers of varying sizes simultaneously. MP-300 uses a high-resolution camera to capture and analyze wafer images, along with specialized illumination techniques, to measure the surface and lamination of each individual wafer. An on-board computer program allows the unit to measure and compare the die and wire patterns of each wafer, as well as to measure temperature and other environment factors. Additionally, the machine can analyze the precise electrical properties of each wafer to determine its suitability for use in microprocessor, memory and logic circuits. Its advanced algorithms also identify potential defects on the wafer and can help to detect excessive moisture conditions. MP300 also includes a sophisticated control engine that allows for automated wafer testing, measurement collection and analysis, and report generation. The tool can be programmed to perform multiple tests simultaneously on a large array of wafers, allowing for fast and accurate analysis of a large number of tests. Additionally, each RUDOLPH MP-300 can be integrated with other systems, such as ovens and datagraph systems, allowing for remote data collection and reporting. MP 300 is the ideal machine for measuring, testing and documenting the properties of wafers in the highly competitive semiconductor manufacturing industry. Its sophisticated sensors, detectors and advanced algorithms allow for comprehensive and accurate characterization of a wide range of manufacturing characteristics, making it an invaluable tool for process control and analysis. Its reliable and repeatable performance make it an excellent choice for assured semiconductor manufacturing.

There are no reviews yet