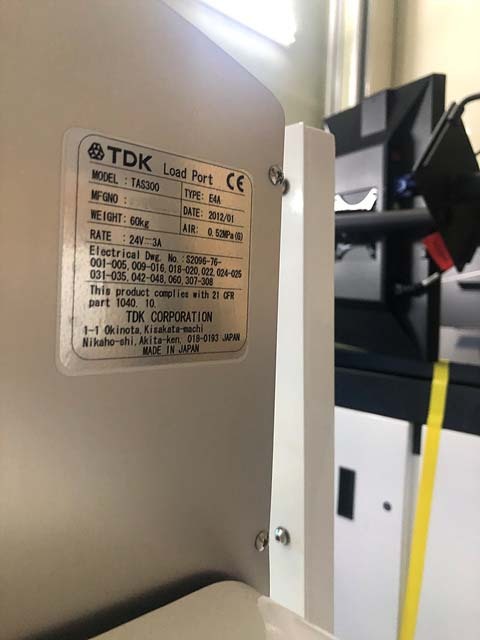

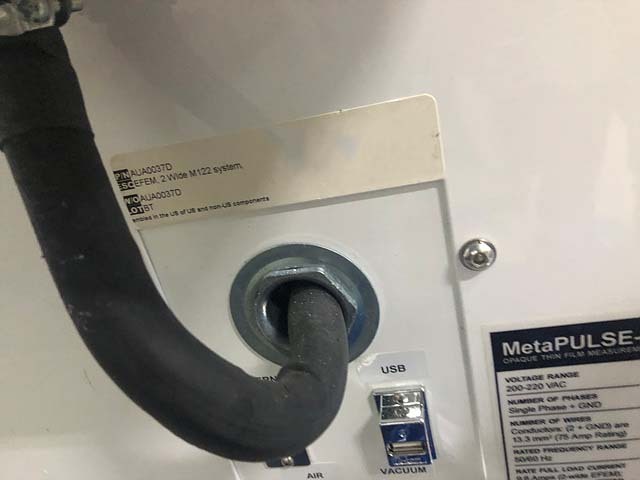

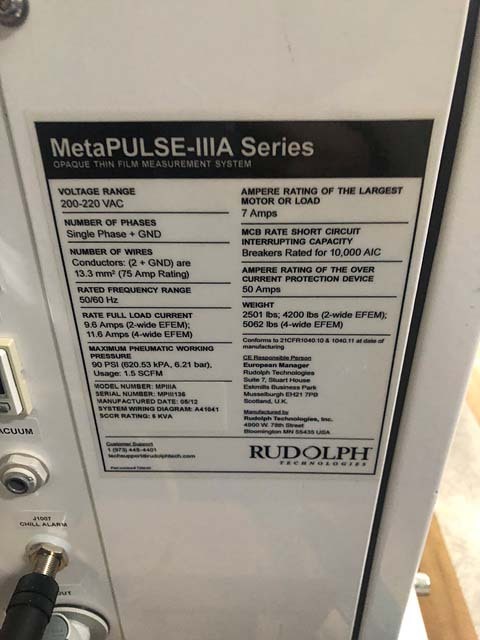

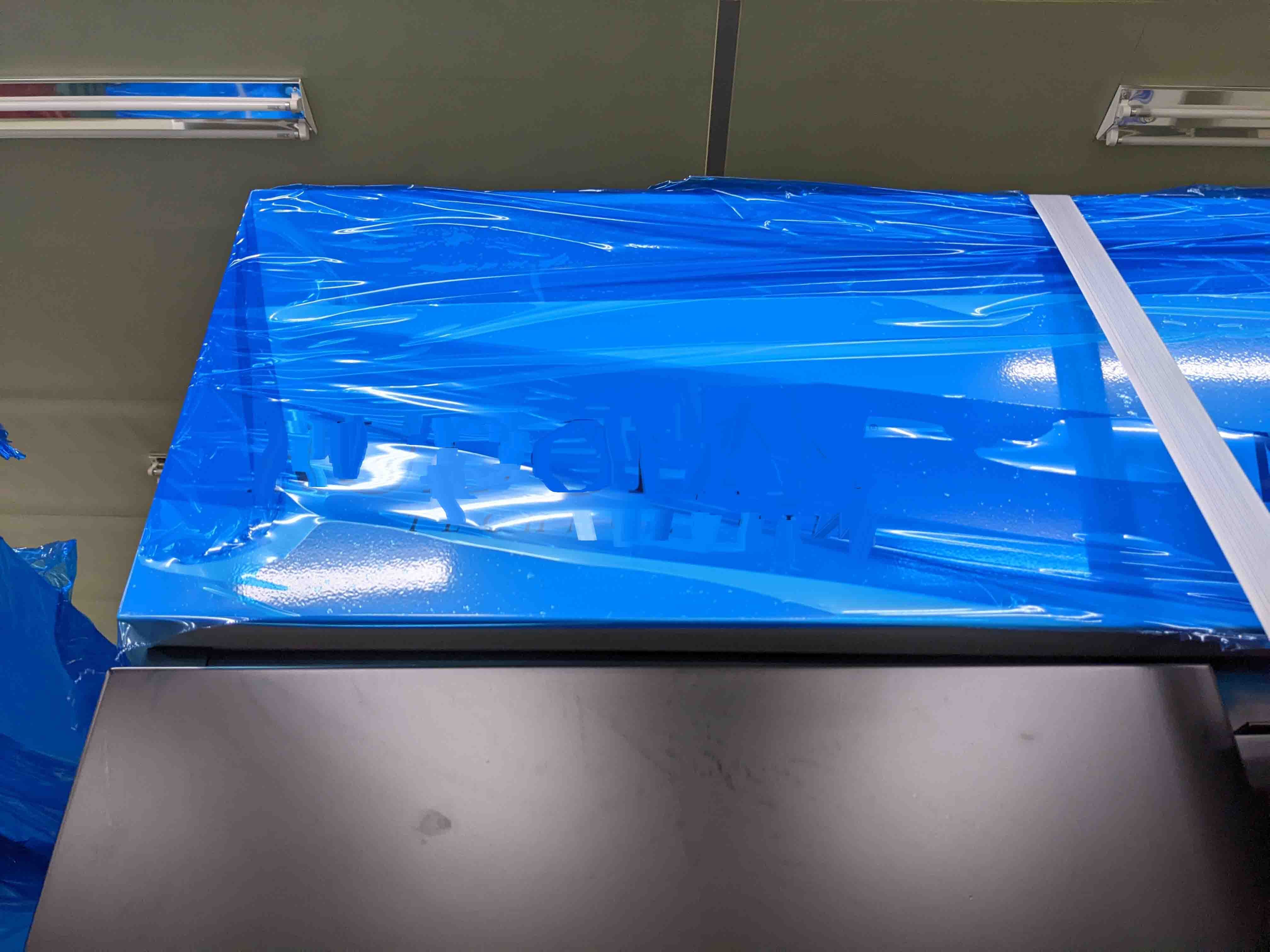

Used RUDOLPH MP3-300A #9401492 for sale

URL successfully copied!

Tap to zoom

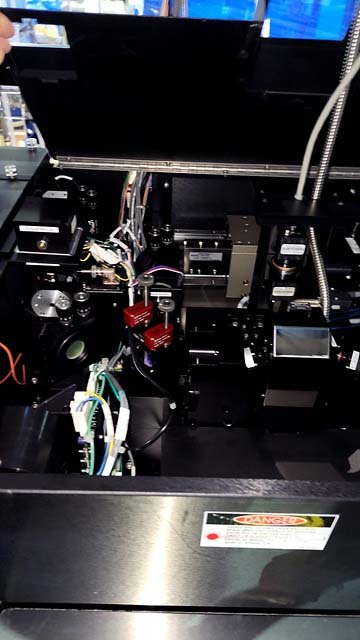

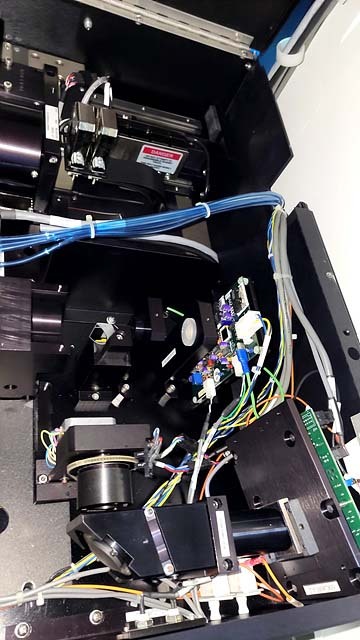

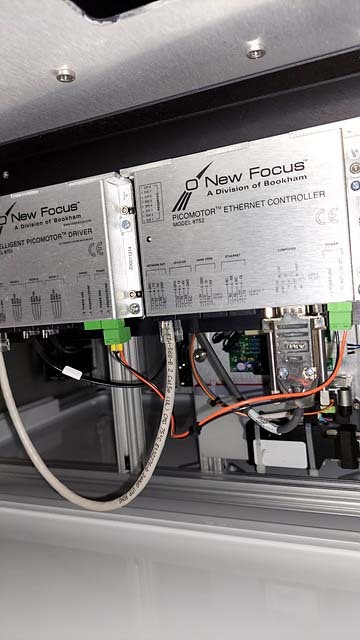

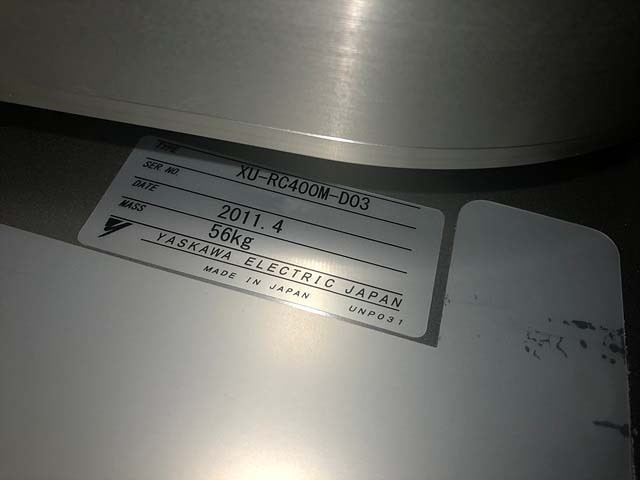

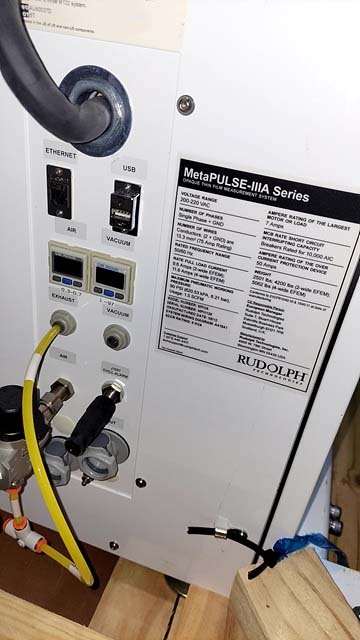

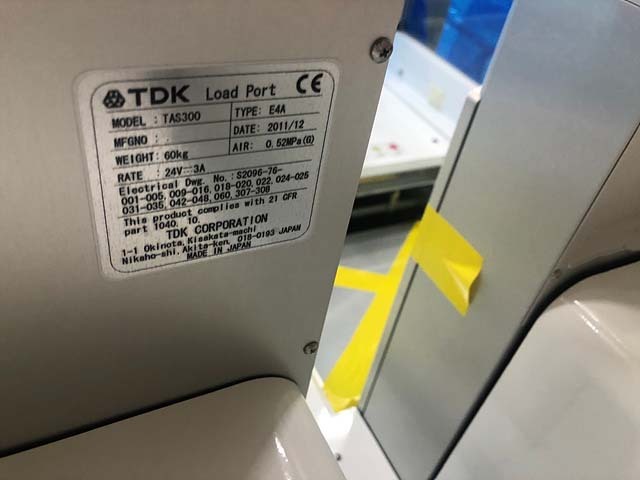

RUDOLPH MP3-300A is a high-end wafer testing and metrology equipment designed for use in advanced semiconductor manufacturing processes. This system is capable of critical measurements, including critical dimensions (CD) and profile, as well as a range of other wafer parameters such as surface roughness, surface topography, and defect classifications. The unit is based on a direct-drive stage, with high accuracy and repeatability, and a sophisticated optical setup. This lets the machine measure wafers with a high degree of precision and accuracy and deliver repeatable results. MP3-300A features a unique four-way pattern recognition tool that allows it to detect and identify defects quickly and accurately. This critical stage of the inspection process is aided by an integrated tool of optics and lights which provide form critical data about the conditions of the wafer surfaces. These results can then be shared with other systems and processes to provide additional insight into the wafer's condition. The asset is also comprehensive in terms of its data output and analysis. A range of options such as charting, graphic analysis, histogram and trend analysis, and reporting are available to ensure users have access to all the critical data they need to ensure high-quality production and operation. The model also allows for a variety of 3D surface inspection. To enable this, the equipment includes a large collection of accessories, including a specialized inspection head, stage, and probe calibration, that enable it to provide a thorough and accurate assessment of the wafer's overall condition. Furthermore, RUDOLPH MP3-300A's large touch-screen monitor allows for easy and intuitive operation. This allows for setup to be accomplished with minimal effort and input, allowing for rapid and accurate testing of wafers. Additionally, the system is designed for flexibility in terms of production and throughput. This is carried out via a dedicated "job selector" task, which automates the unit for repeatable runs for maximum efficiency. In short, MP3-300A is a high-end wafer testing machine designed to measure a variety of parameters with a high degree of precision and accuracy. The tool ensures quick and accurate identification of defects and allows for sophisticated 3D surface inspection and analysis of results. Additionally, the asset offers a range of features to assist in setup and operation, ensuring high-quality output and maximum throughput.

There are no reviews yet