Used RUDOLPH Reflex TT #293671014 for sale

URL successfully copied!

Tap to zoom

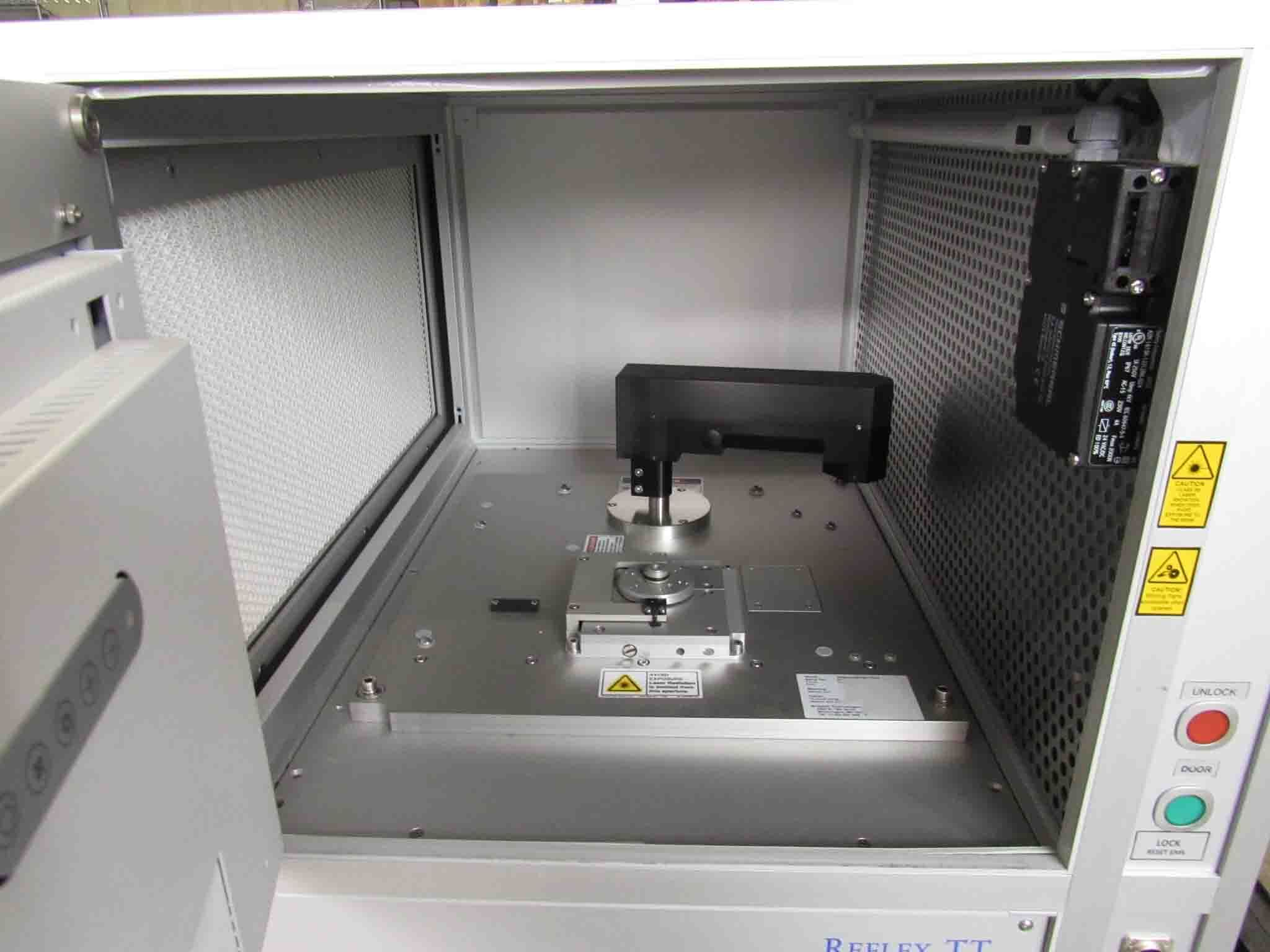

RUDOLPH Reflex TT is a cutting-edge wafer testing and metrology equipment that combines advanced optics and proprietary pattern recognition algorithms to provide high-precision, non-contact testing and measurements of semiconductor wafers. Reflex TT system is capable of characterizing various surface features and properties on semiconductor wafers, including bump height, photovoltaic cell size, and slurry coating. Additionally, it is designed with an automated image analysis feature, which allows for rapid and comprehensive characterization of the target application. RUDOLPH Reflex TT unit has multiple components, working together to deliver accurate results in a short period of time. It is composed of a Wafer Handler, a Machine Vision Machine, an Illumination Tool, and a Pattern Recognition Asset. The Wafer Handler is the automated, robotic model that handles and positions the wafer on the worktable. The Machine Vision Equipment is the combination of digital cameras and optics that captures high-resolution images of the wafer. The Illumination System provides the necessary lighting to enhance the quality of the captured images. Finally, the Pattern Recognition Unit is the computer machine that uses the acquired images to generate test results. Reflex TT tool has several benefits over traditional testing methods. First, it offers non-contact testing of semiconductor wafers. This eliminates the risk of damaging the wafers during testing. Second, high-speed imaging and pattern recognition technologies enable RUDOLPH Reflex TT asset to provide faster and more accurate measurements compared to manual systems. Additionally, this model has a high accuracy of up to 0.1 microns, ensuring precise and reliable results. Overall, Reflex TT is an advanced, efficient equipment for wafer testing and metrology. It is designed with robust components and advanced optics and imaging systems to provide high-precision measurements with minimal effort. Furthermore, its automated and non-contact capabilities eliminate the risk of damaging wafers during testing, resulting in accurate and reliable results. Finally, its speed and accuracy enable quick and precise measurement of semiconductor wafers, making it a valuable asset for the semiconductor industry.

There are no reviews yet