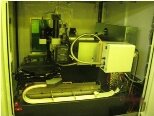

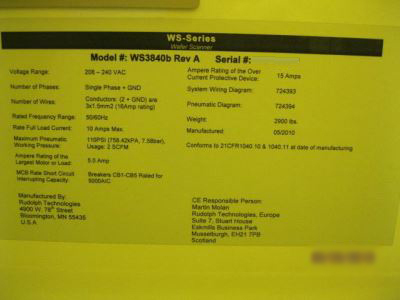

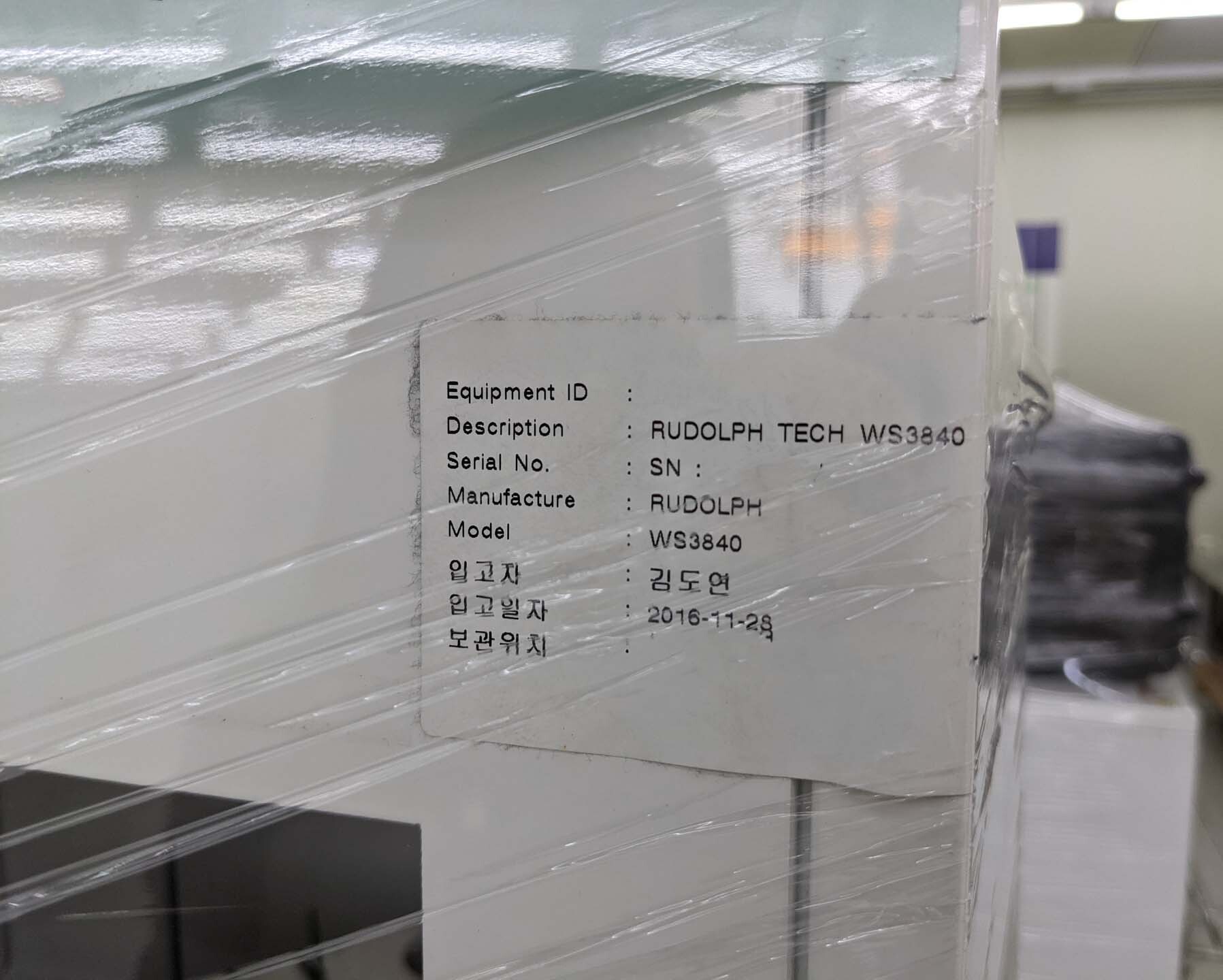

Used RUDOLPH WS 3840 #9136132 for sale

URL successfully copied!

Tap to zoom

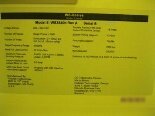

ID: 9136132

Wafer Size: 12"

Vintage: 2010

Bump inspection system, 12"

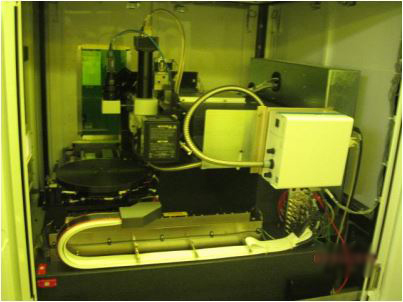

Granite base air bearing XY stages

Vacuum chuck with rotation for 5", 6", 8" and 12" wafers

Z Slide for focus control and wafer loading / Unloading

OLYMPUS Optical head with 5 positions auto lens turret

Bright field lighting

Low angle dark field lighting

Objective lenses: 1.25x, 2.5x, 5x and 10x

4K TDI Line scan camera & electronics

Image frame grabber

Dual quad core XENON processor PC based 2D vision engine

Computer with 3.2GHz P4 processor

RAM: 1GB

Hard disk: 250 GB

(2) Hot swap bays

CDRW / DVDRW

Operating system: Window XP

Console arm with (2) flat panel color monitors

Keyboard and mouse

(4) Positions light tower

Data analysis and reporting

Color defect review

Mini-environment fan / Filter units (ISO Class 2)

Electronic wafer maps (KLAINF, EF, WWW, Semi G85 and SECS S12)

721713 Option

Xport

Wafer scanner

ISO Class 1 clean high speed wafer handling EFEM outfitted

With dual arm robot

Wafer thicknesses: (725um)

Down to 400 microns thickness for 12" wafers

Down to 190 microns thickness for 8" wafers

Automated whole wafer handling

Dual arm vacuum assist backside wafer handling

Minimal contact end effector

Integrated laminar clean air flow mini-environment (ULPA Filtration)

Robot with integrated mapper

721753 2 Option

Bridge load port

BROOKS Vision / Cassette pivot, 8"

XENON Dual quad processor 2D vision engine

72054 1 Option, 3D Inspection, Hi Res 3D Sensor

High resolution: 4 MHz

3D Sensor scans up to a .6mm swath

Depth of field: 200um

1U Rack mount chassis

Dual INTEL quad-core XENON processor 2.5 GHz

DRAM: 2GB

SATA Hard disk drive: 250 GB

CD ROM Drive

Ethernet

RUDOLPH PCIDSP Board

(5) Microns ultra high resolution 3D sensor

716983 1 Standard, 3D Height Verif Wafer, 100um, 300mm

716810 1 Option, Dual OCR

X Port

66807 1 Computer, Remote defect review

Wafer capability, 8"-12"

Ultra flat chuck: <5 Microns chuck

2010 vintage.

RUDOLPH WS 3840 is a wafer testing and metrology equipment designed for semiconductor device companies. It is an automated system to integrate and analyze metrology data from multiple measurement devices. The unit consists of a series of high-performance workstations connected to a central server, each processing and storing metrology data from a single measurement device. It is capable of processing multiple types of metrology data, including wafer area, pitch, die size, and die placement. The machine is highly accurate and repeatable, capable of detecting and analyzing changes in device structure quickly. It also features advanced 2D imaging functions to analyze defect counts and wafer features such as protrusions and die count. The tool also includes a host of other features, including easy-to-operate and intuitive software that allows users to quickly set up and access analysis data. It also features a parameter driven asset that allows customization of analysis data, output formats and user preferences. To ensure accuracy, the model utilizes pattern recognition to detect and analyze small variations in design. This includes adaptive optics which can adjust focus or provide improved illumination through an array of lenses. The equipment is built with a robust design, allowing for high levels of reliability and durability. It also provides advanced scalability, allowing users to easily perform large-scale metrology tasks. Finally, the system offers high levels of security, allowing for remote access and operations. It is compliant with several industry standards and comes with comprehensive support services, including installation, training and maintenance. In conclusion, RUDOLPH WS3840 is an advanced wafer testing and metrology unit designed to meet the needs of semiconductor device companies. It provides users with a range of features and capabilities, allowing for accurate and efficient metrology testing.

There are no reviews yet