Used RUDOLPH WS 3840 #9392887 for sale

URL successfully copied!

Tap to zoom

ID: 9392887

Vintage: 2009

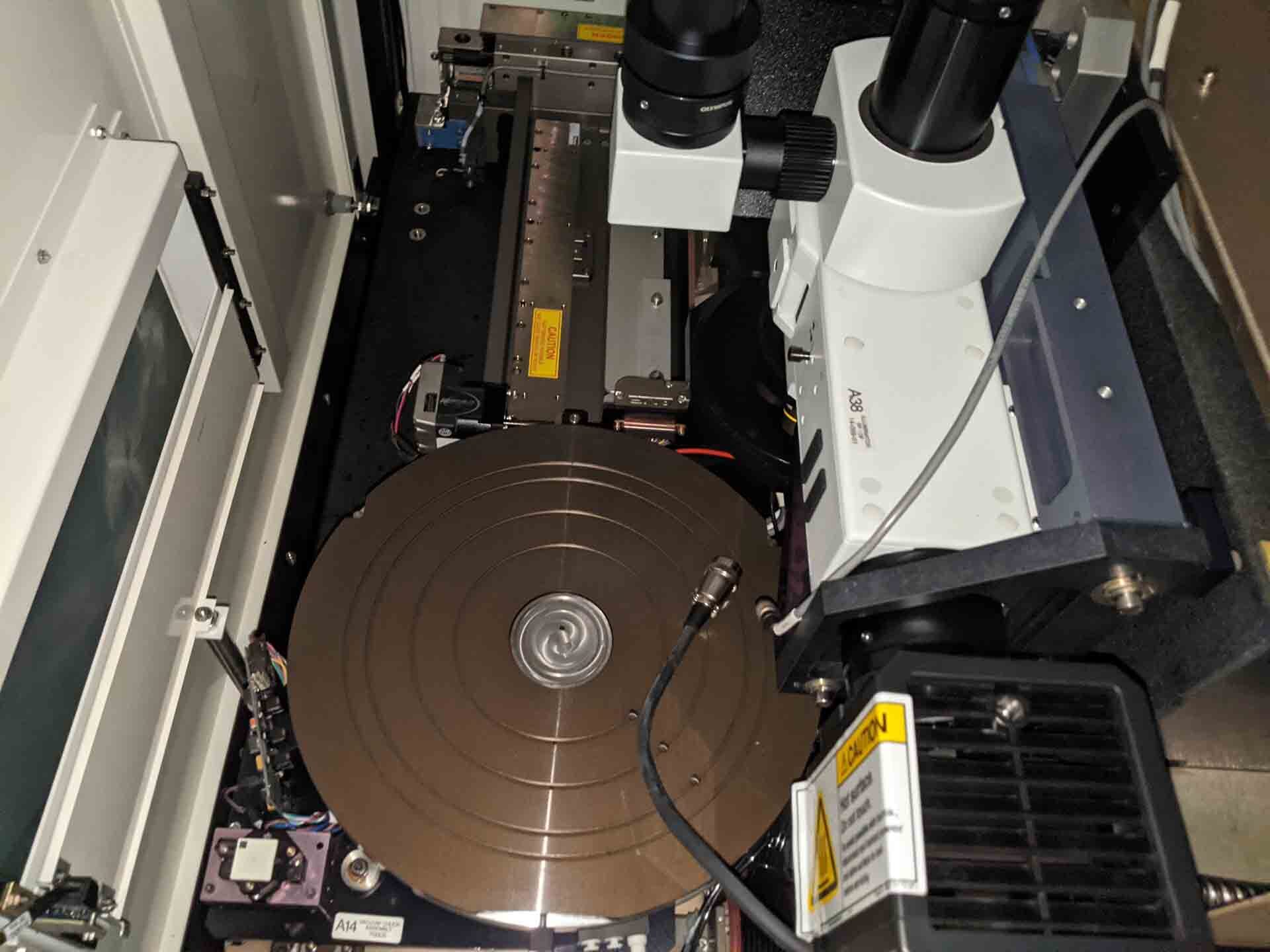

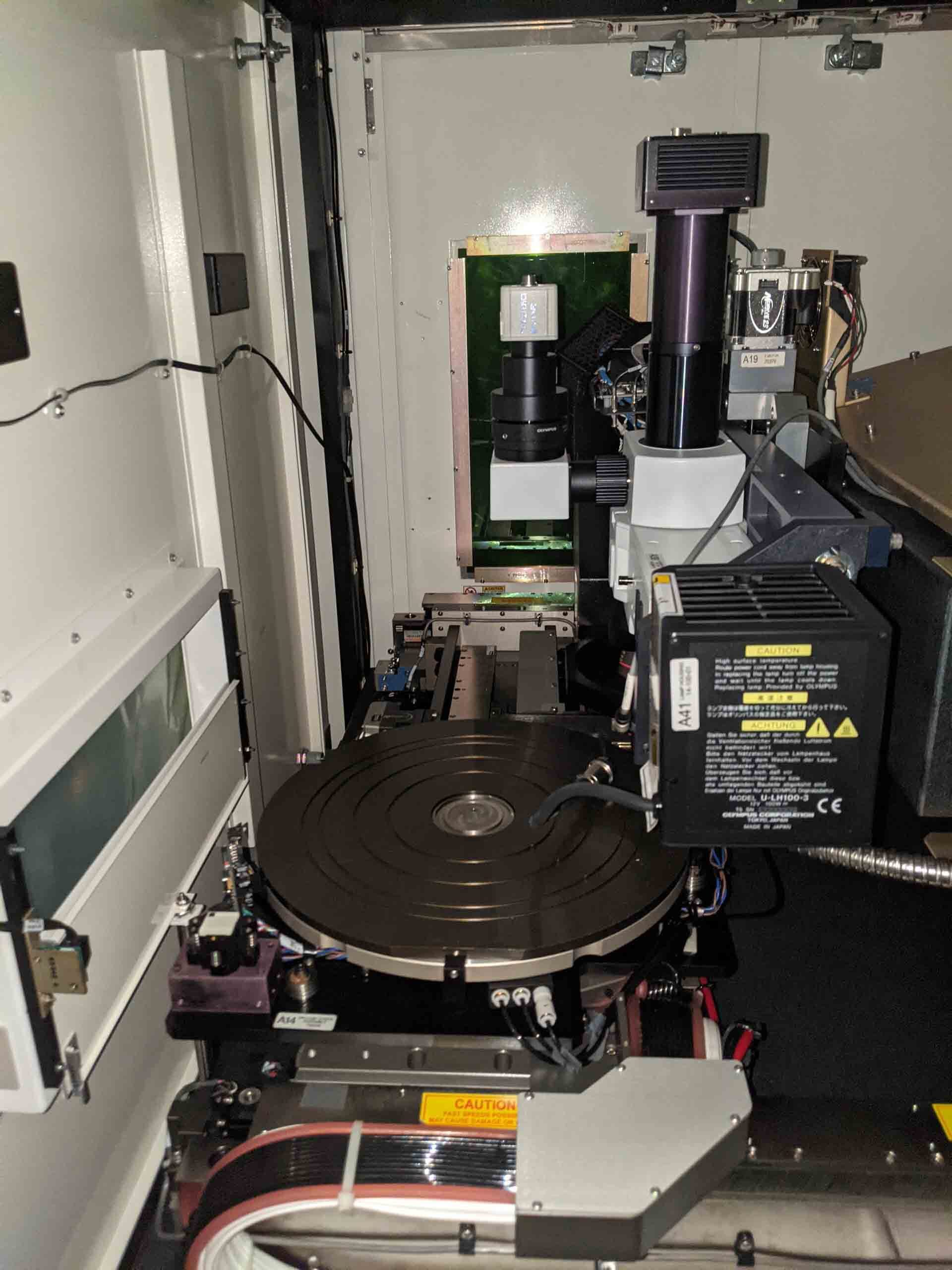

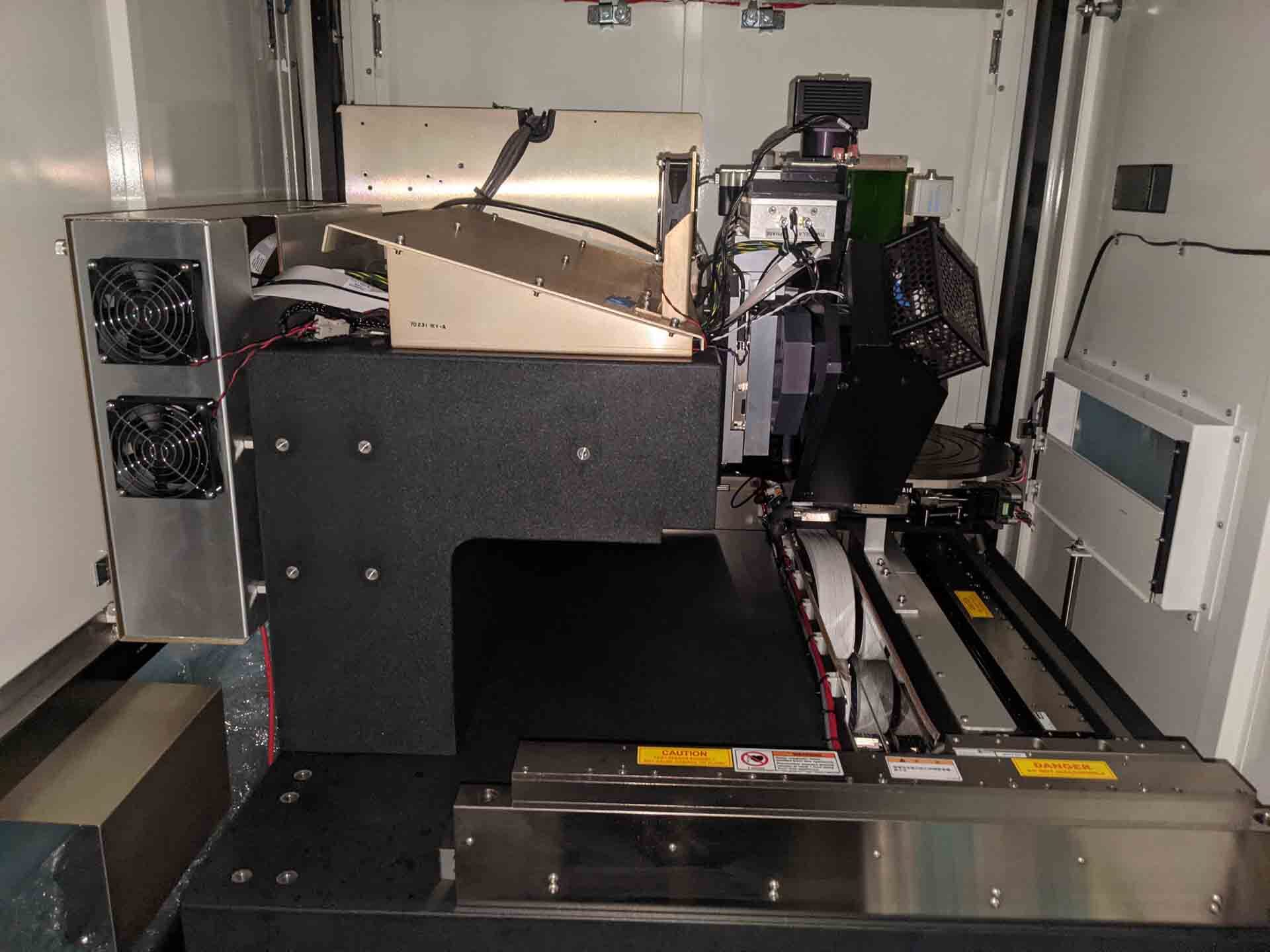

Bump inspection system

(2) Load ports

Chamber

2009 vintage.

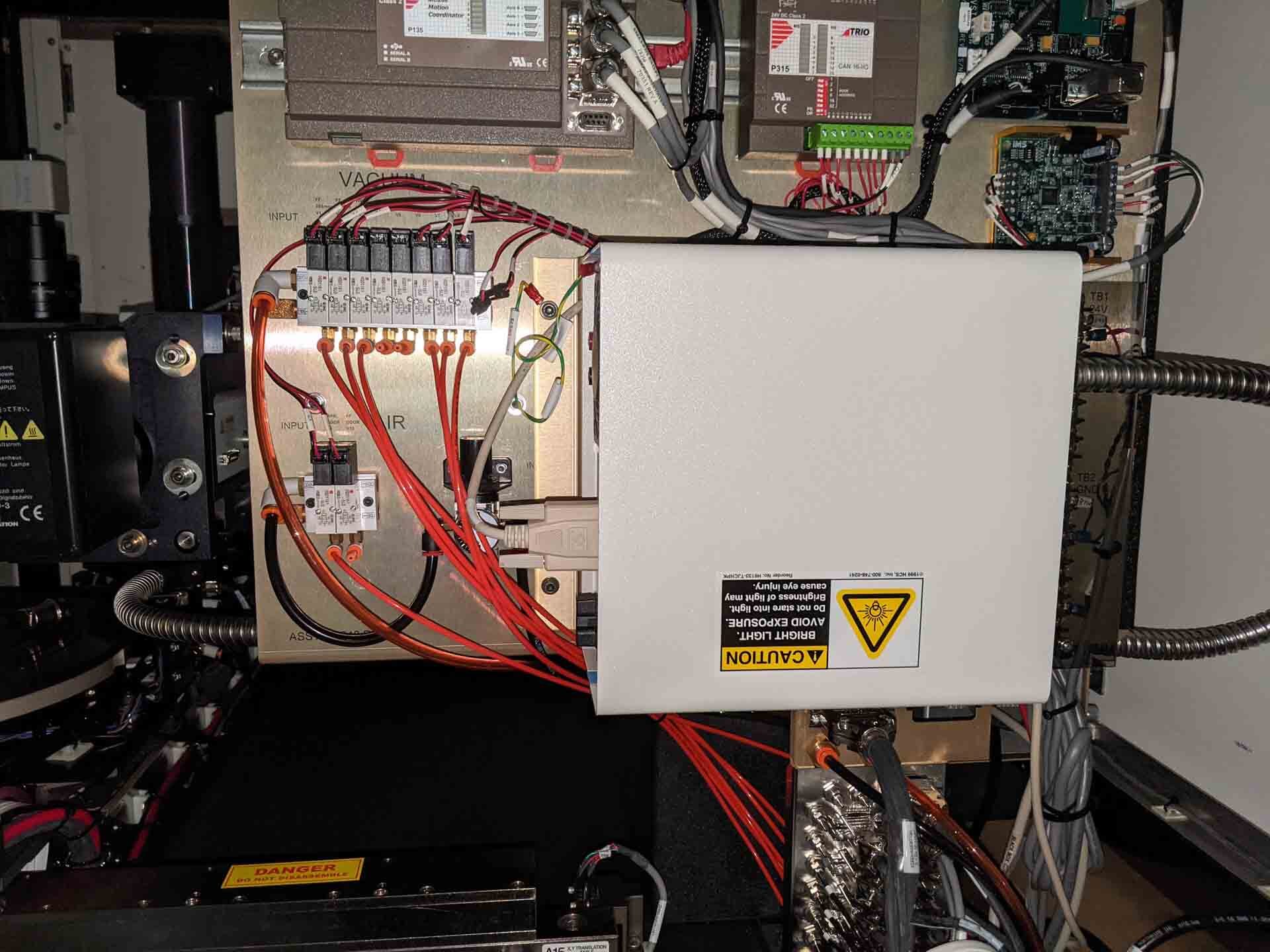

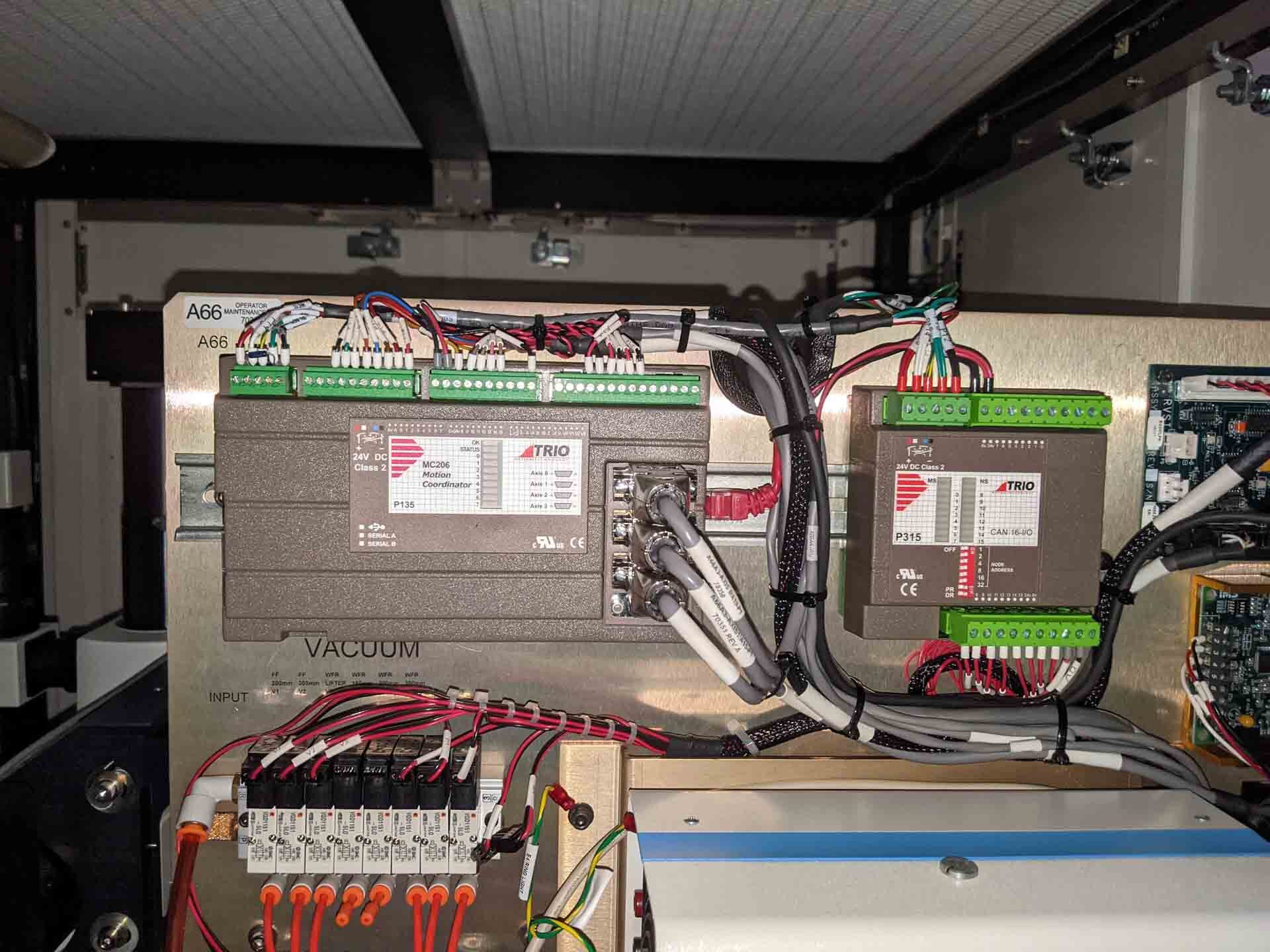

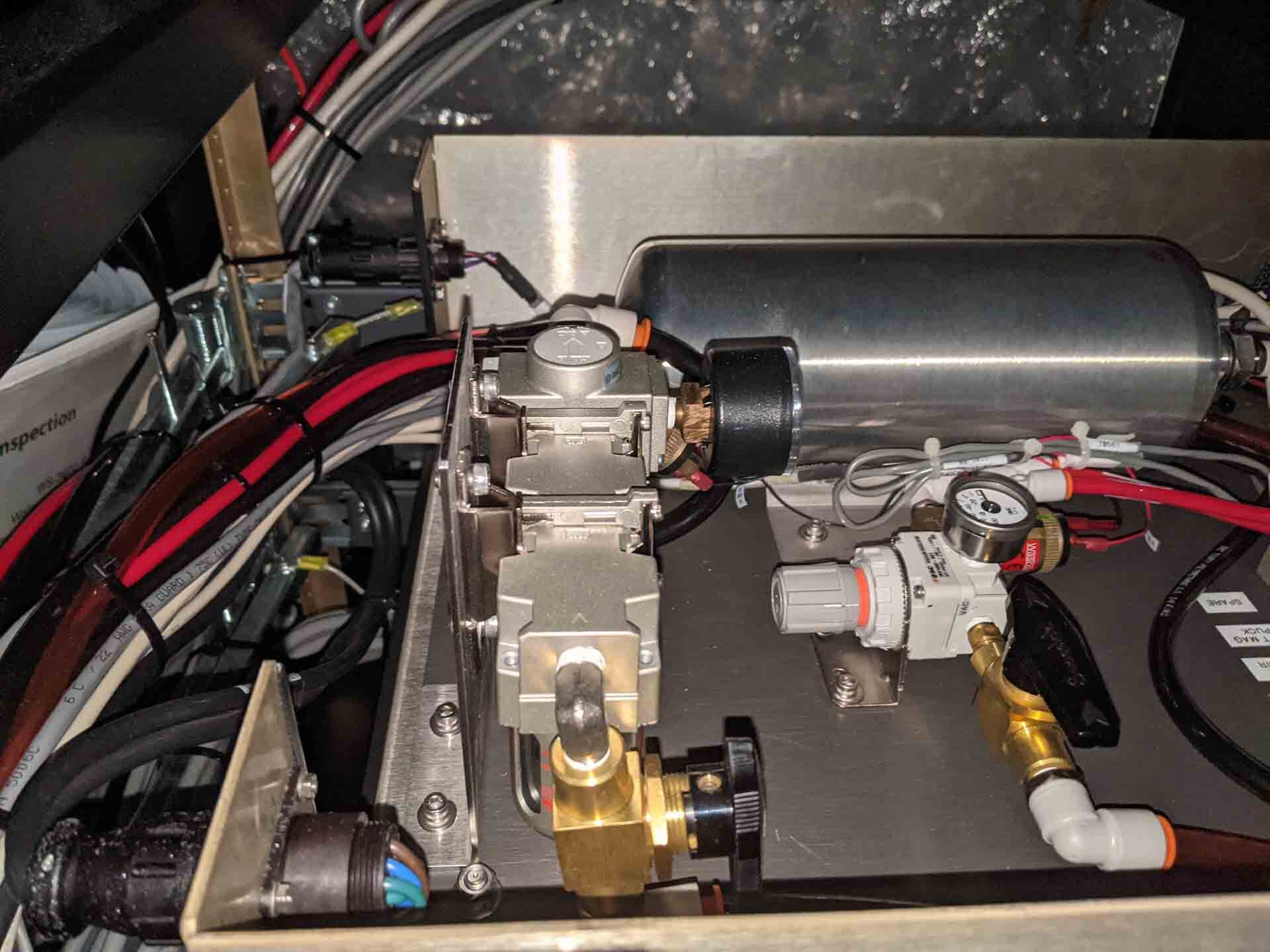

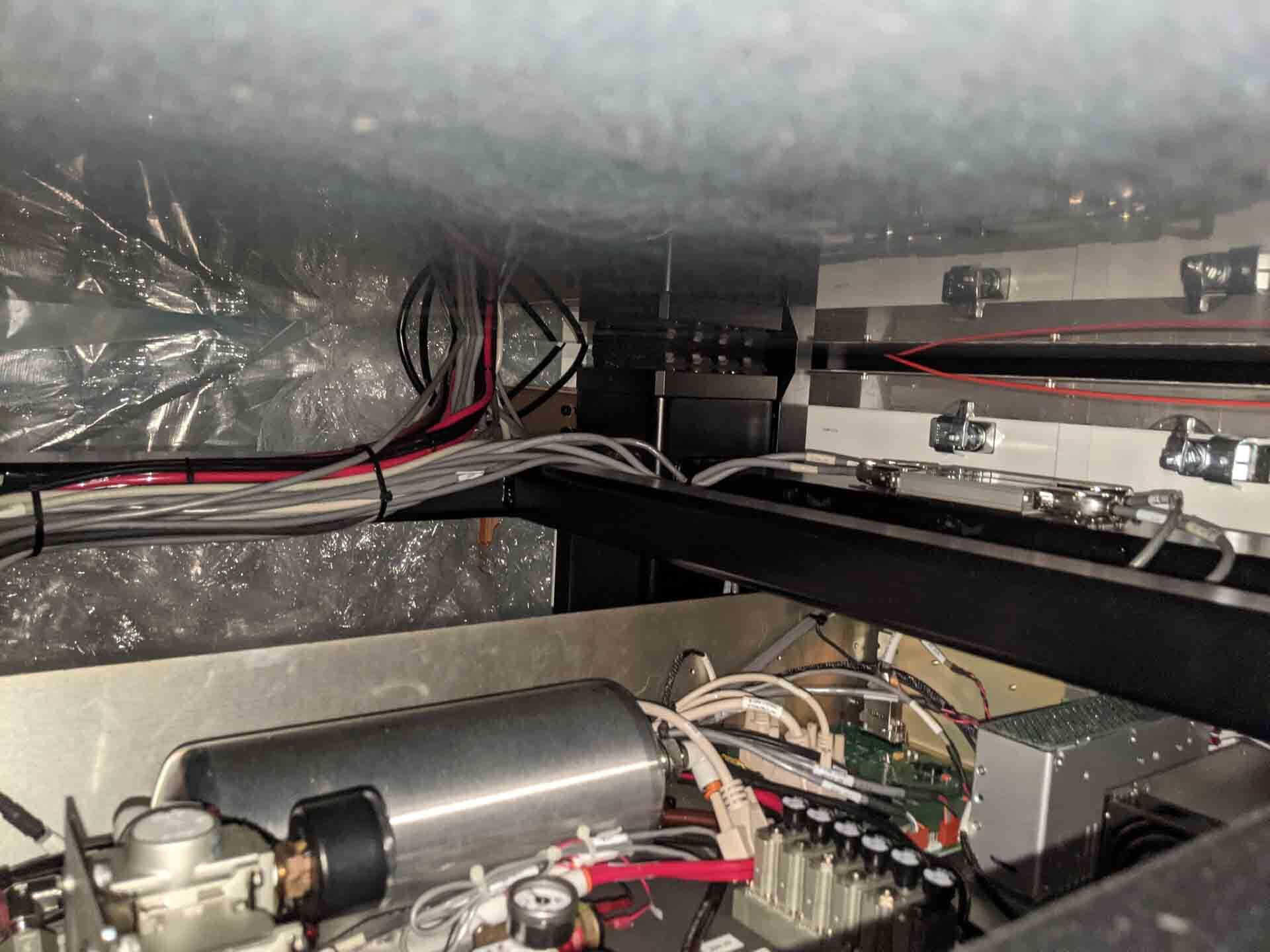

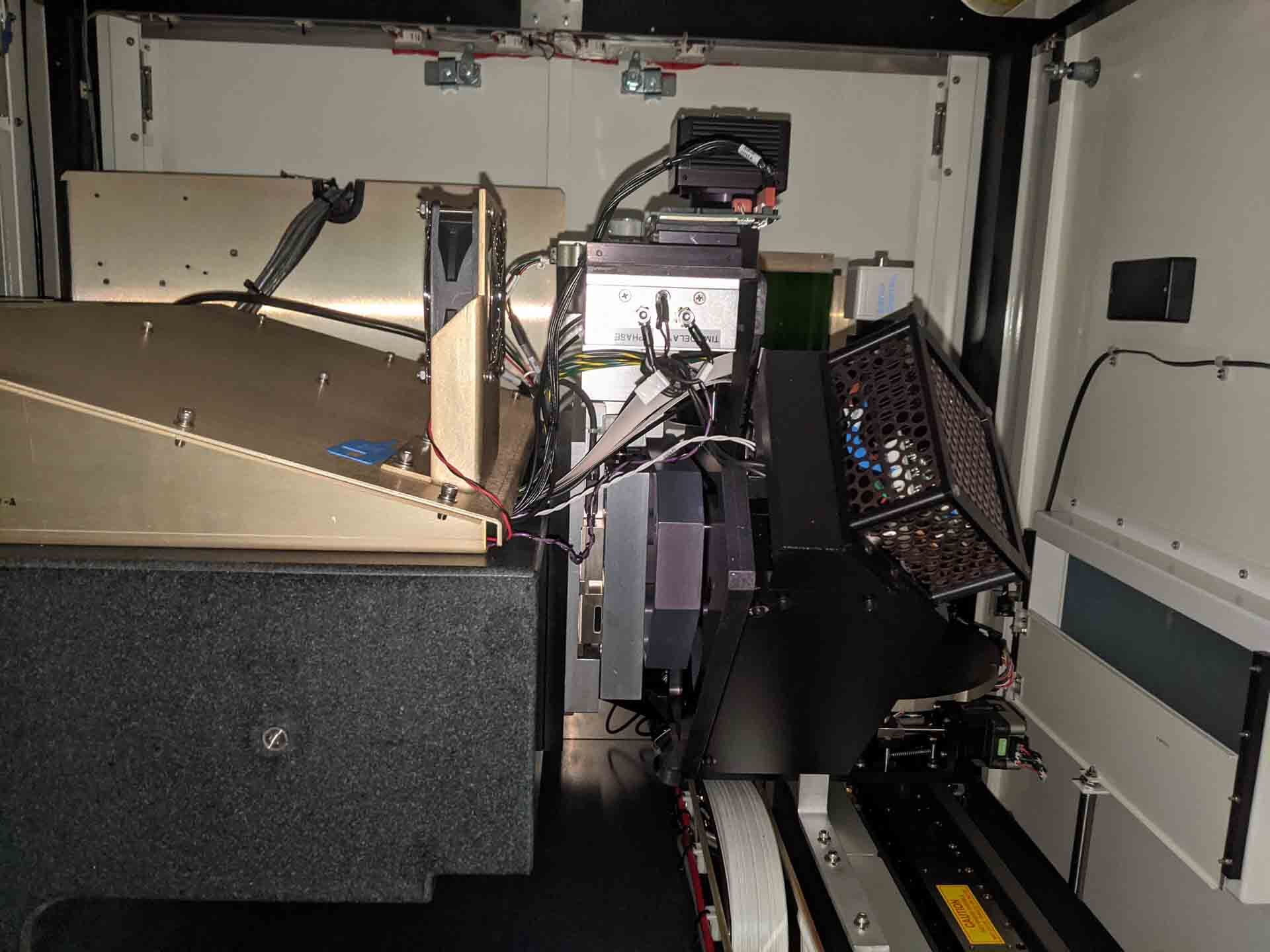

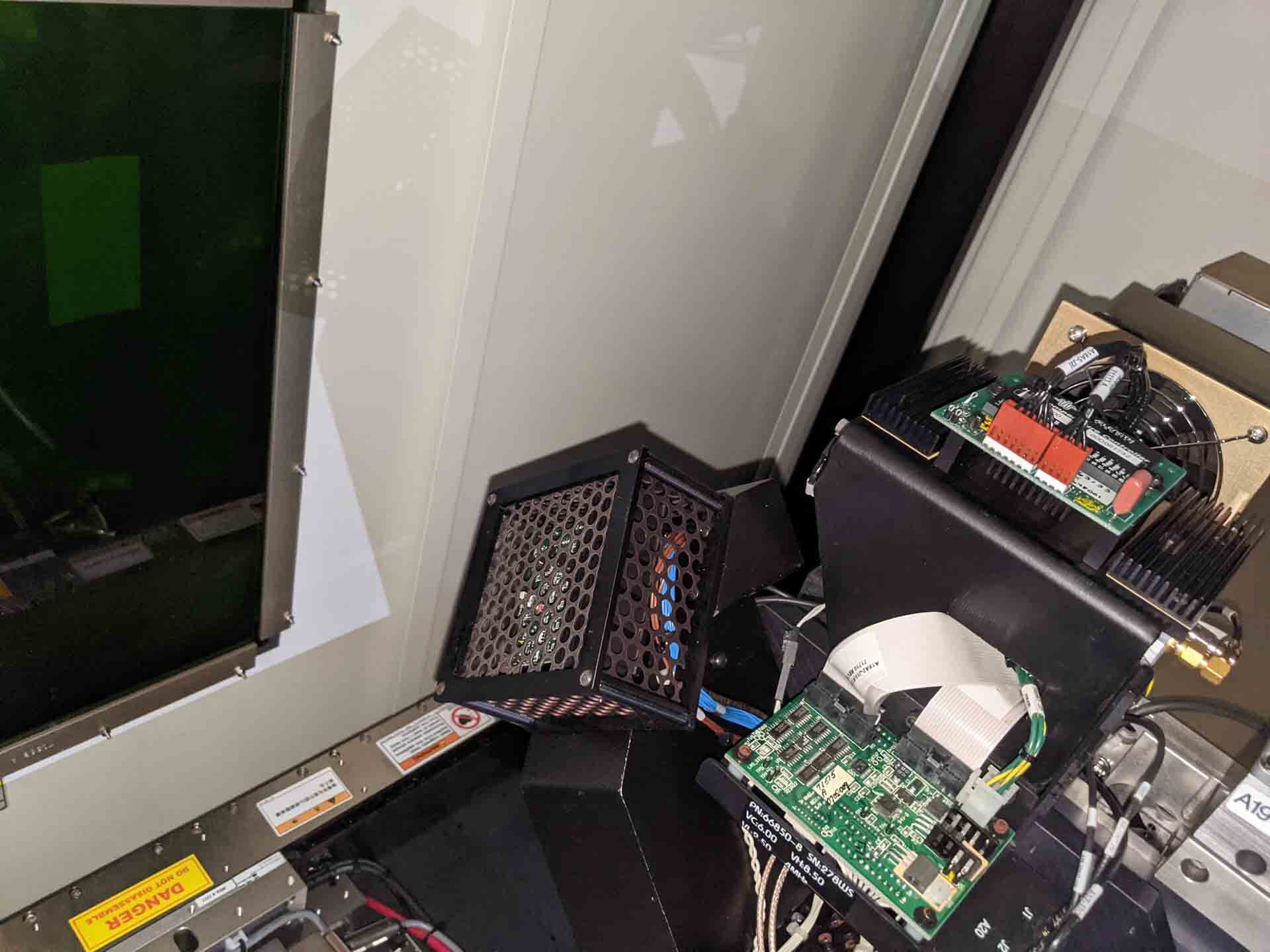

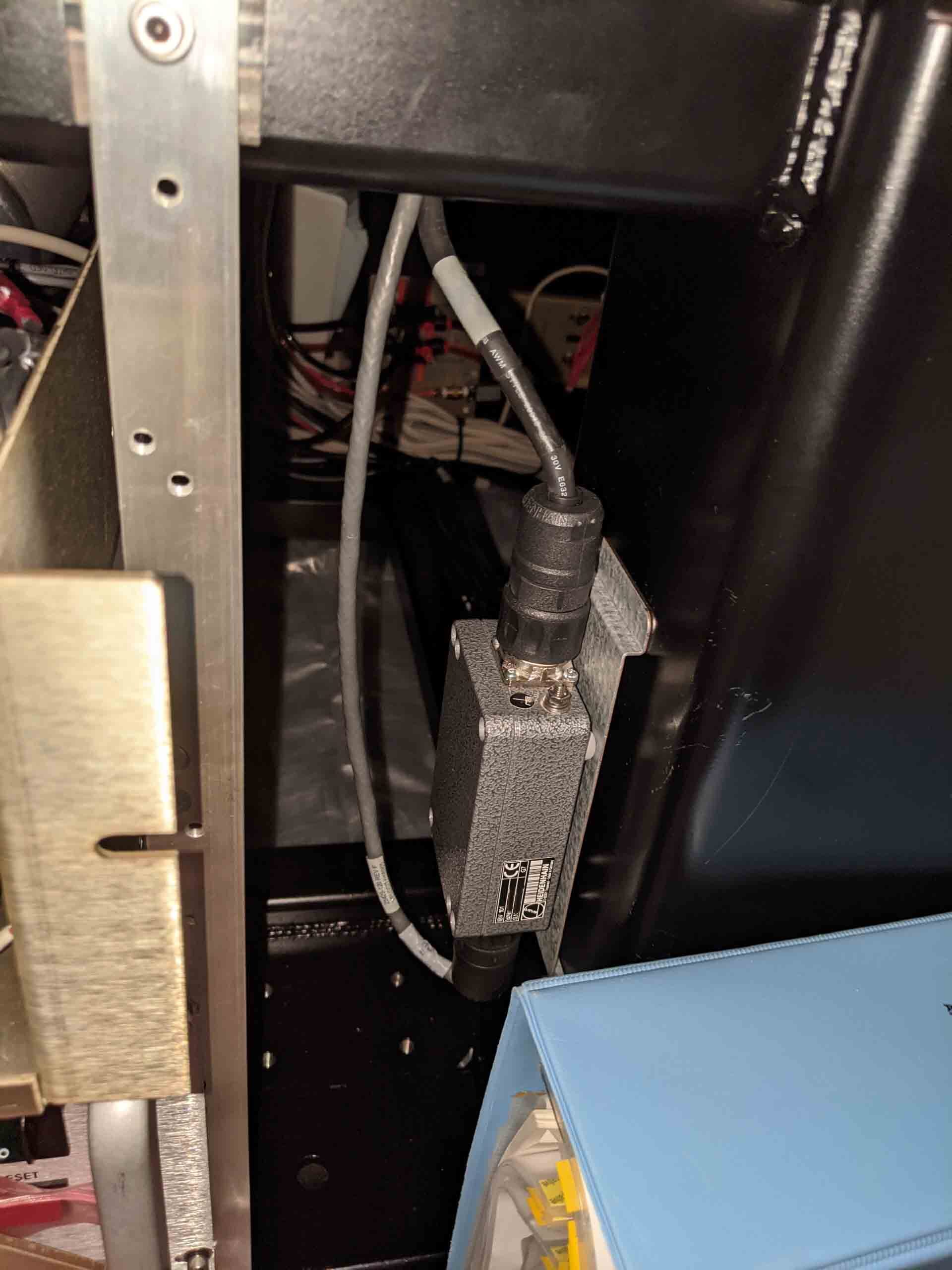

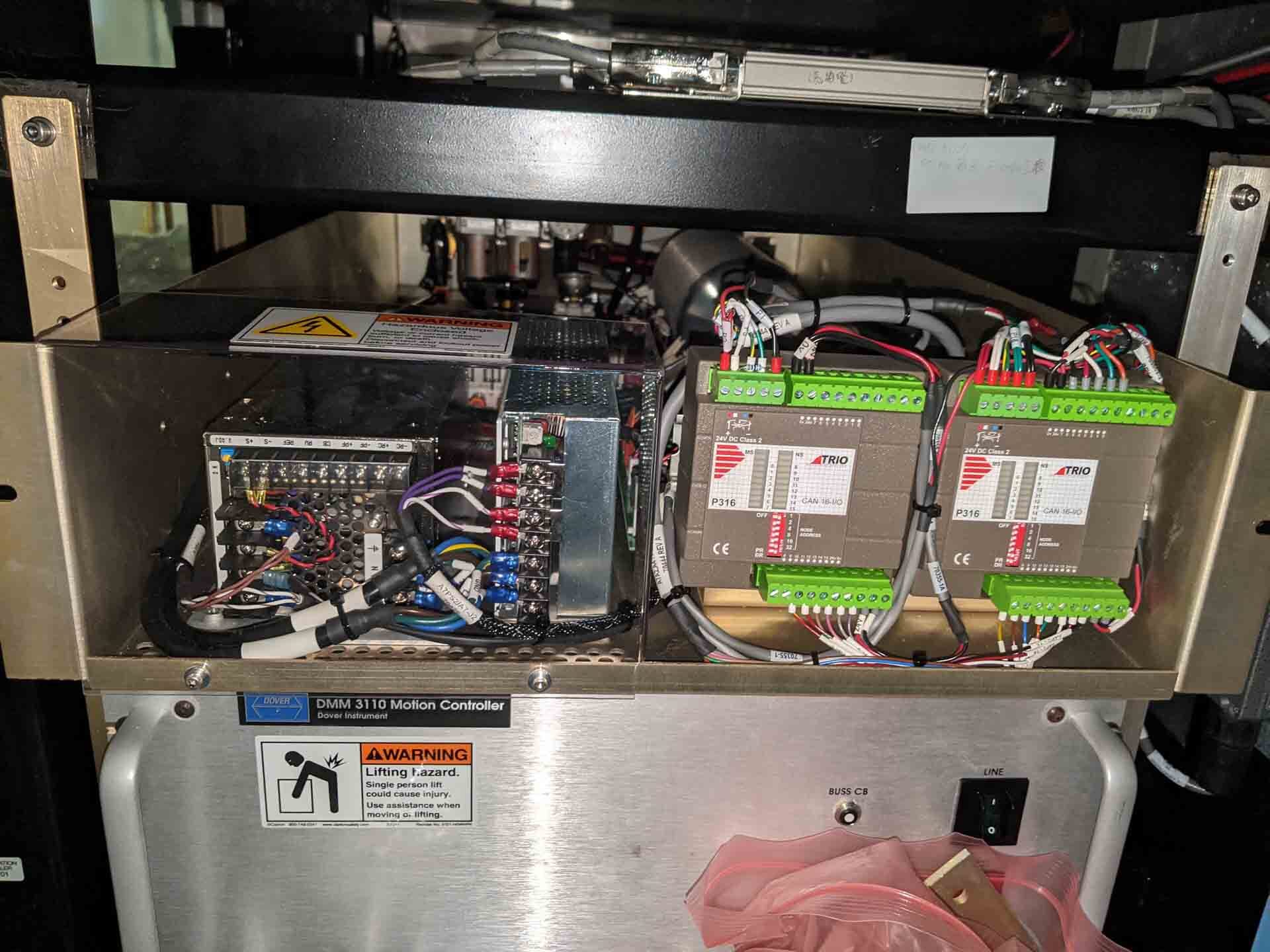

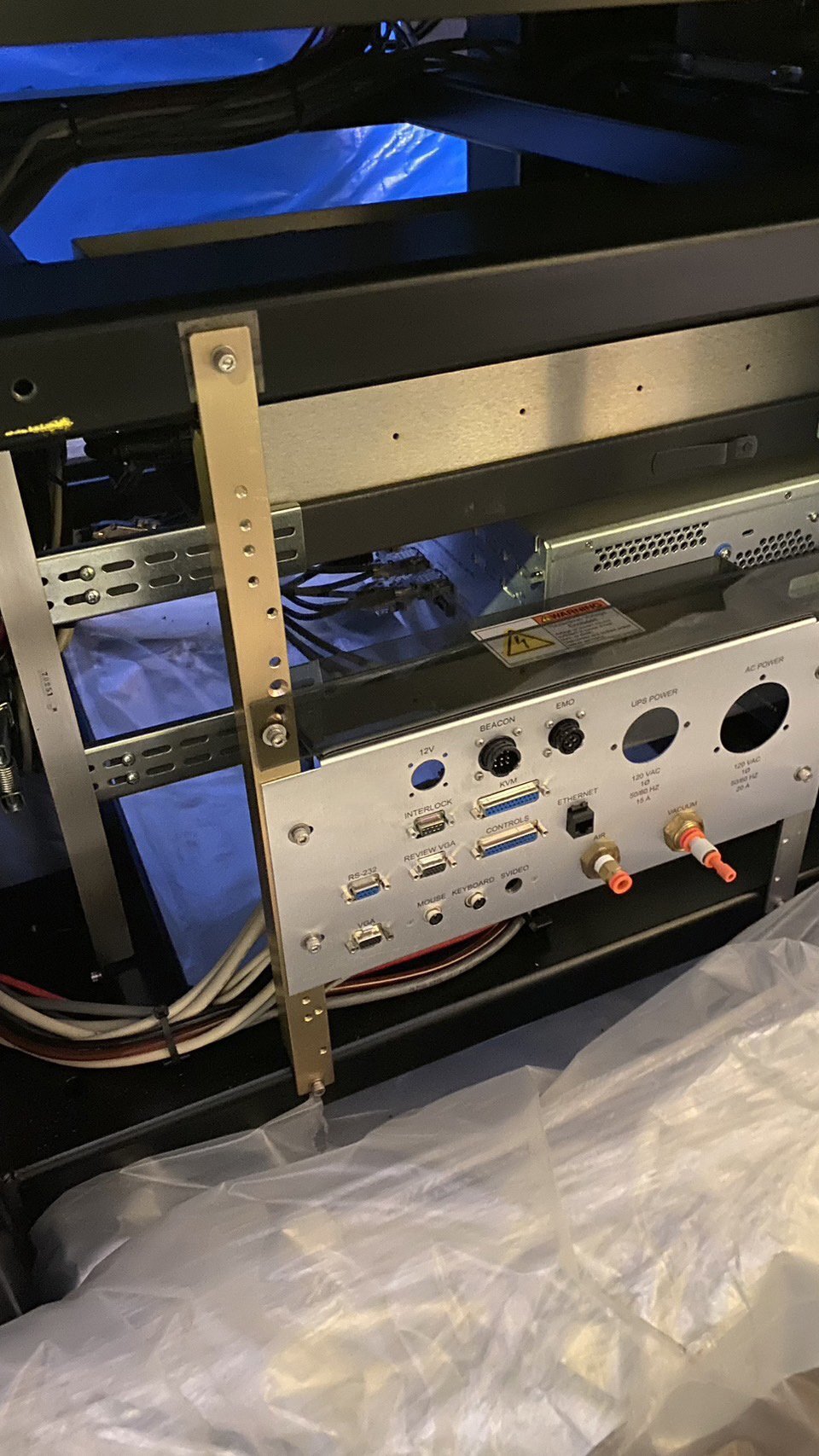

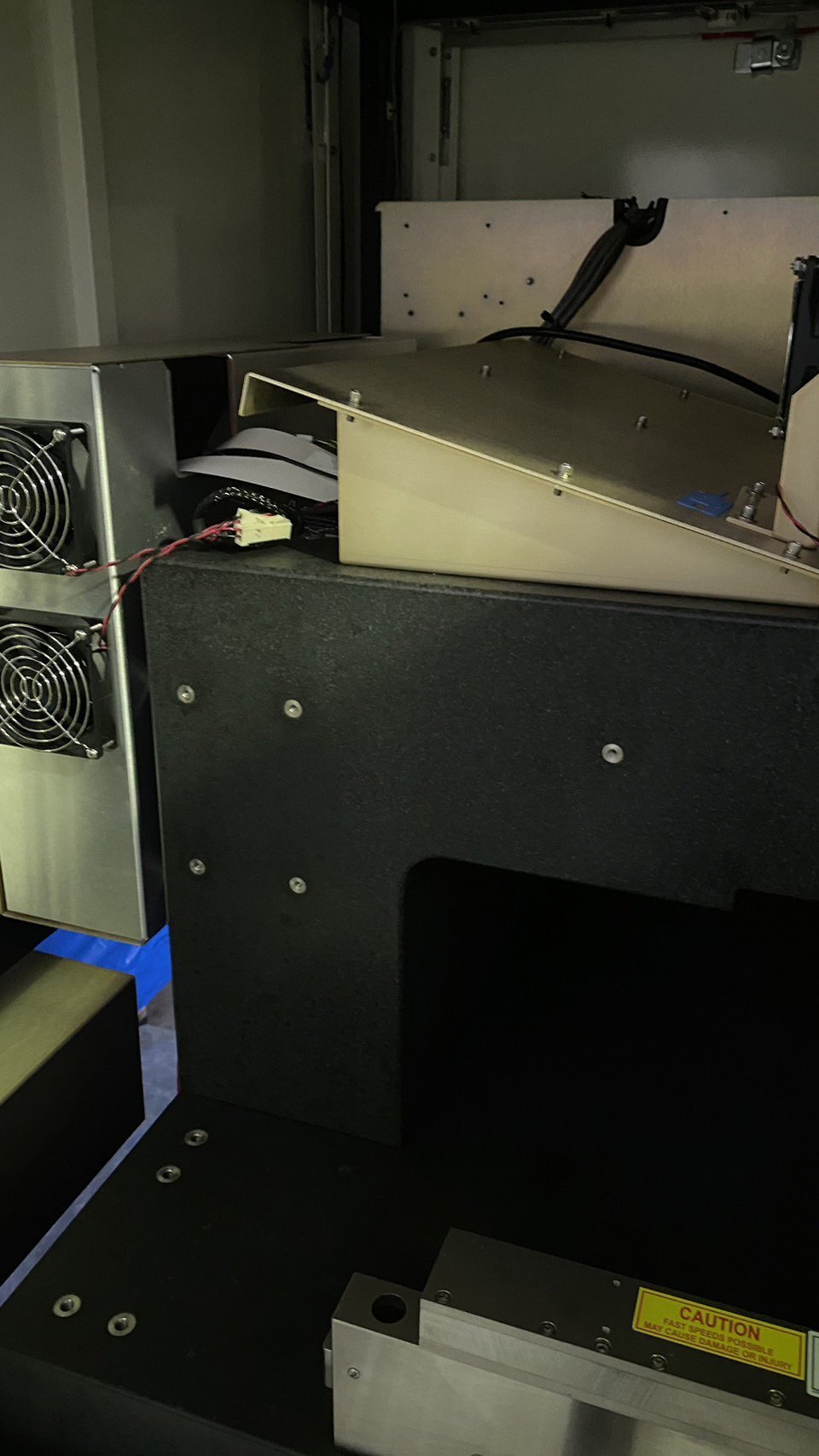

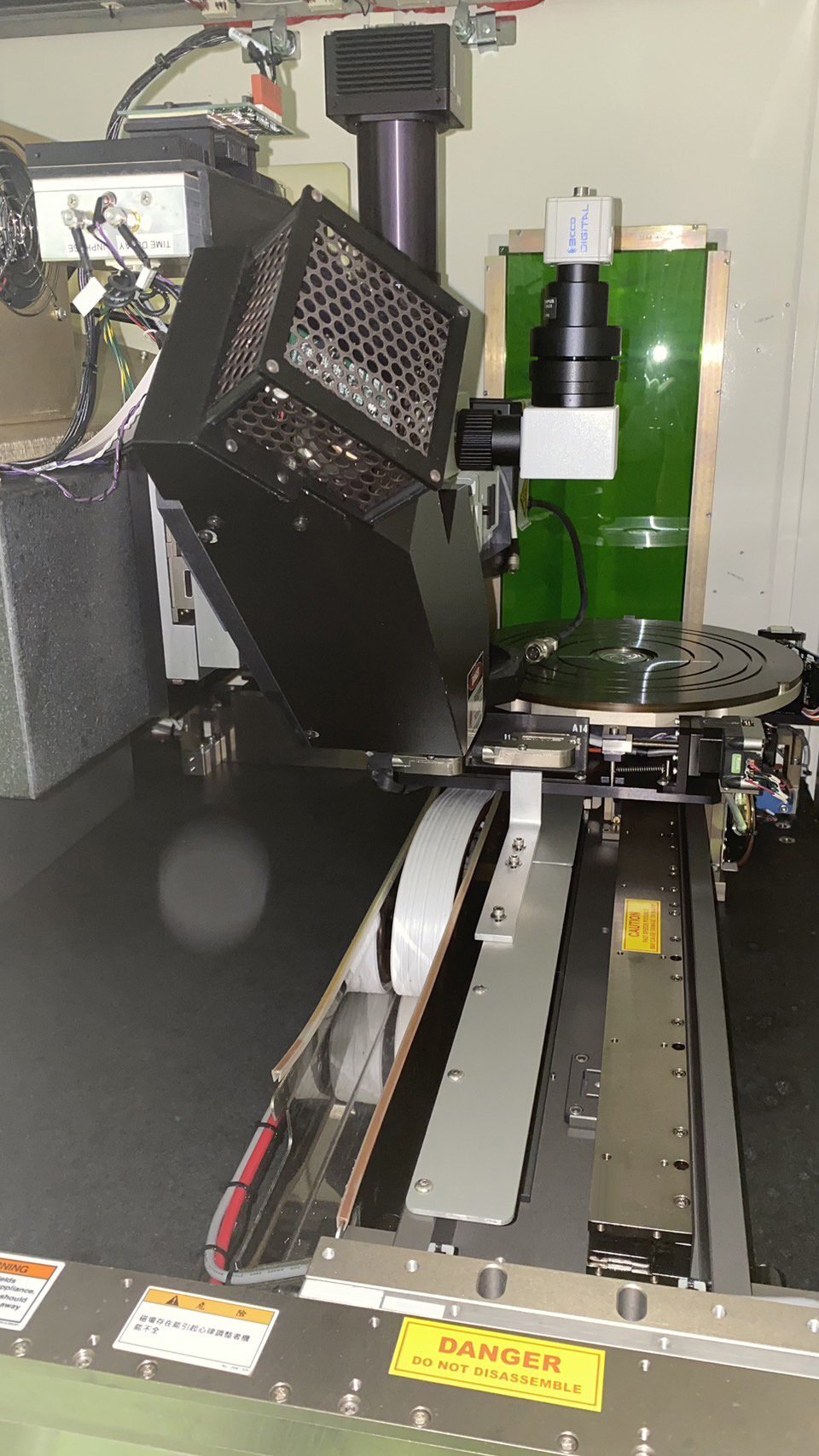

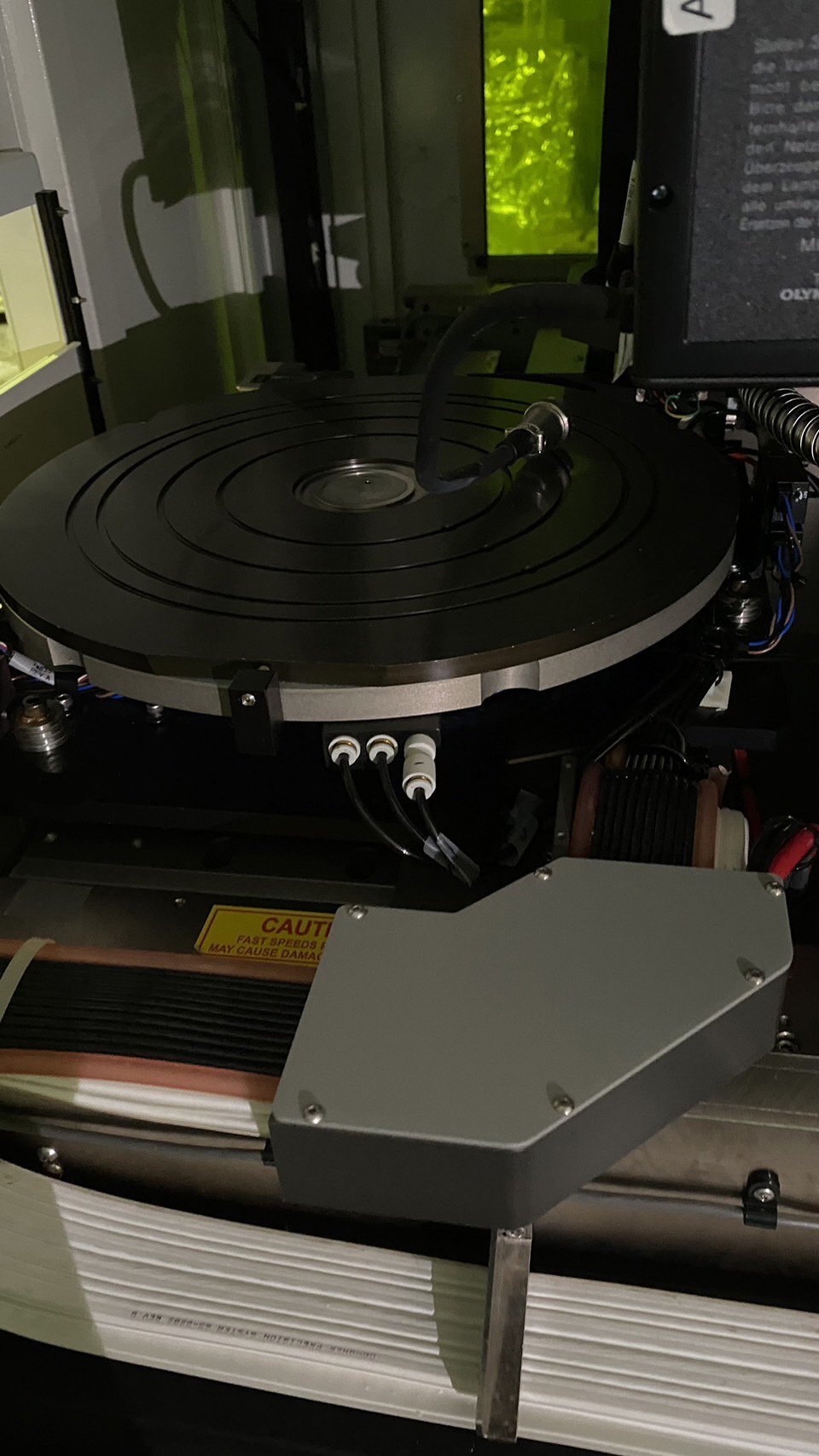

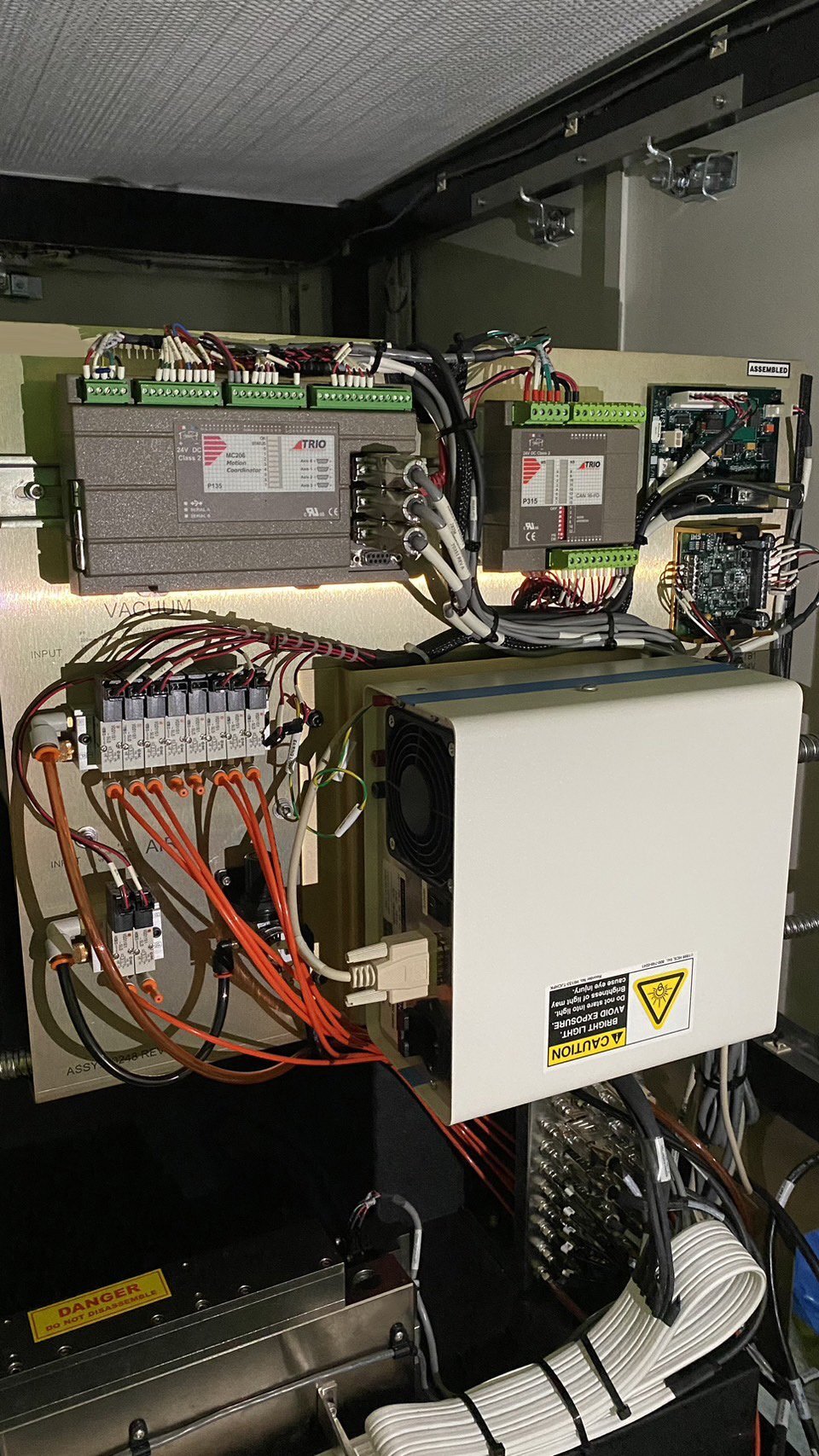

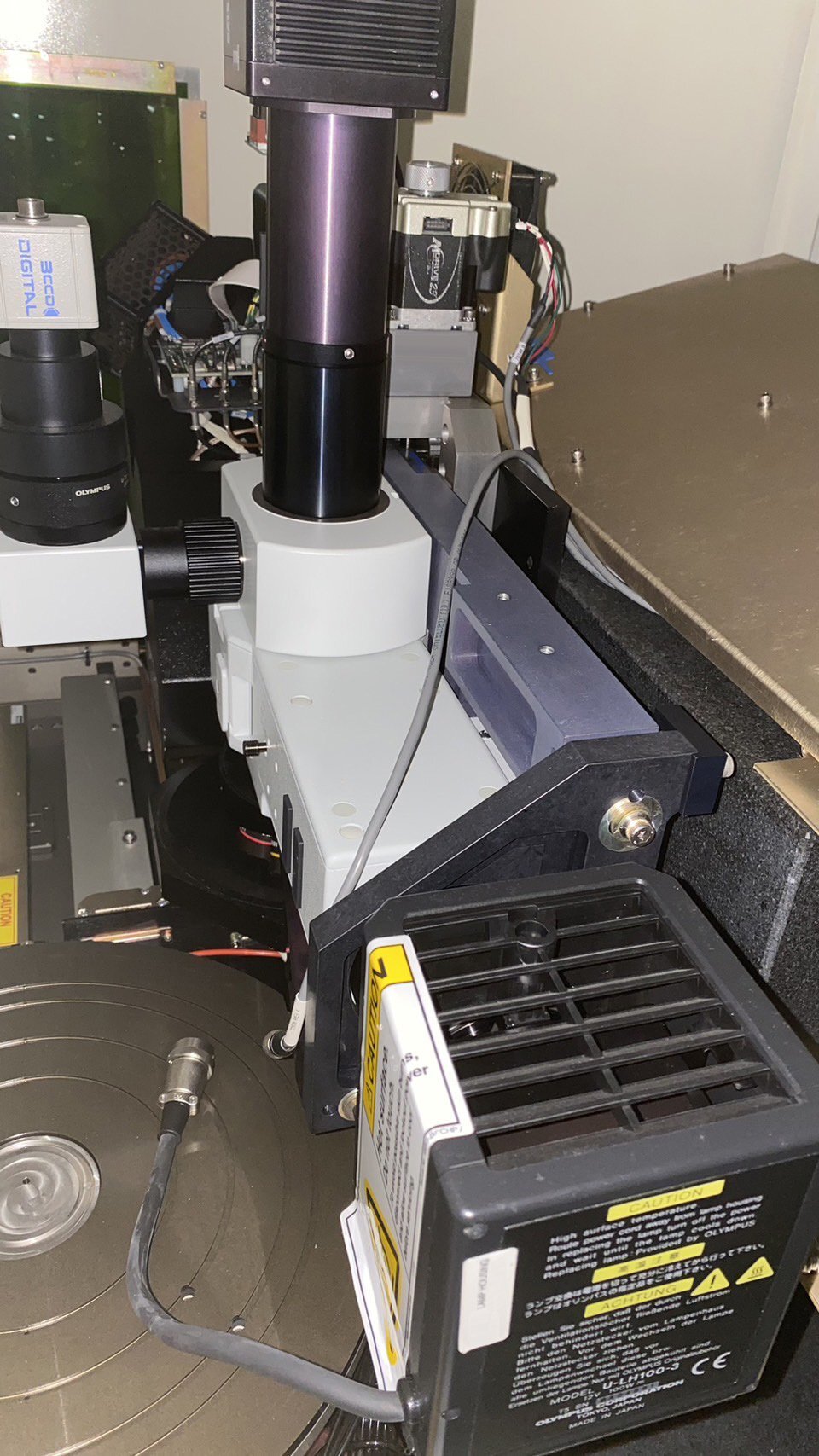

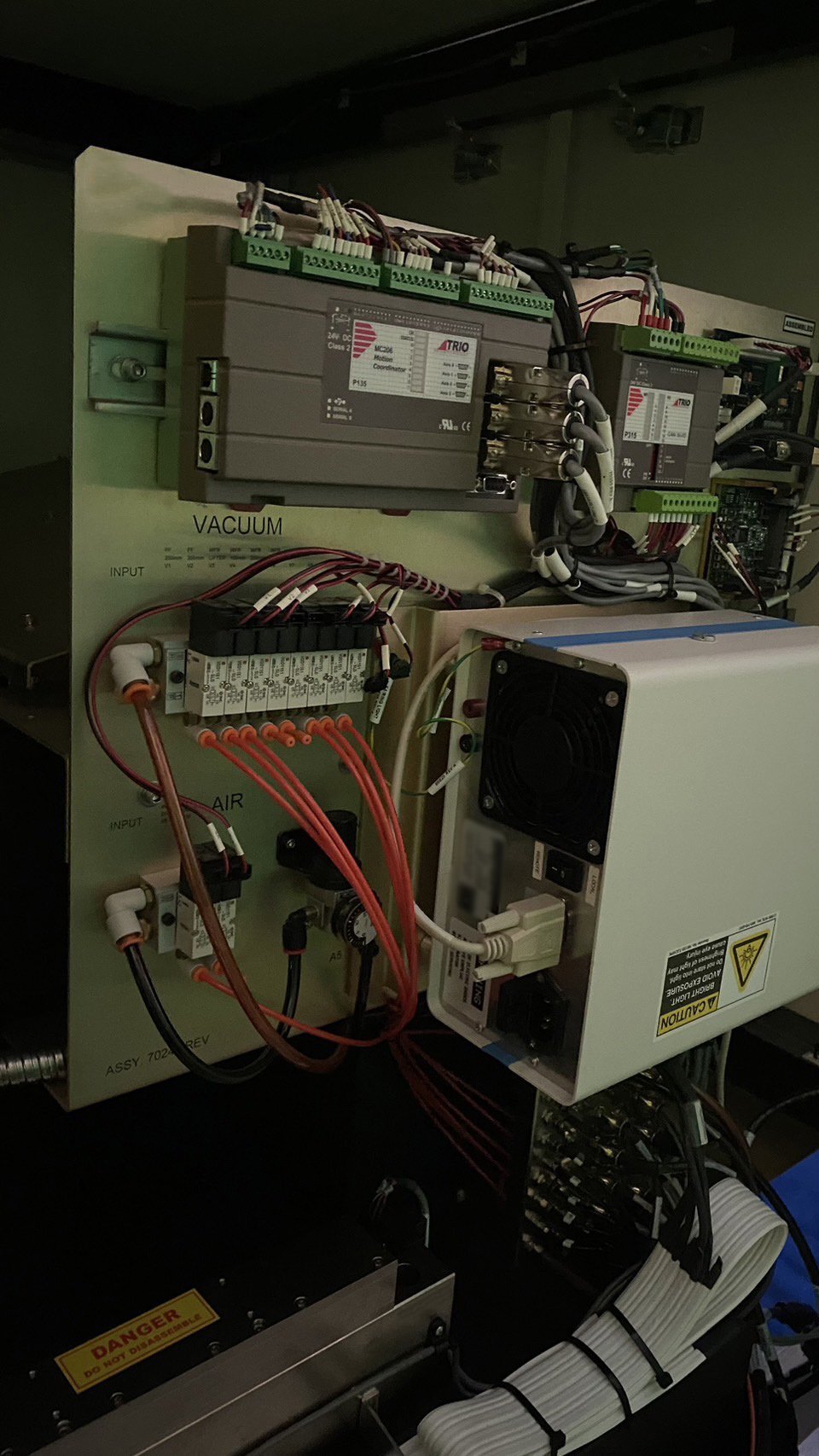

RUDOLPH WS 3840 is a state-of-the-art wafer testing and metrology equipment developed for highly sensitive analysis of wafer features. The system is valued by researchers, for its outstanding accuracy and reproducibility are based on a combination of optical and X-ray techniques. It uses advanced optical and X-ray techniques to image and measure various properties of a wafer, such as thickness, line width, edge sharpness and pattern uniformity, in high resolution. RUDOLPH WS3840 is composed of a metrology module, a prober platform, and a software package. The metrology module is made up of several components such as an optical microscope, a SEM unit, a charge-coupled device (CCD) detector, and a stage positioning unit. The optics module of the machine uses visible light to observe samples in a high magnification range (up to 25,000X) and to measure the contours of features on the wafer as well as their position. The SEM unit of the tool performs X-ray analysis, where a beam of electrons is sent to the sample to produce an image of the area. The CCD detector captures information from the images produced by both the optics module and the SEM unit, also allowing for the quantitative measurement of the features on the wafer. Finally, the prober platform handles the wafer transport and sample handling, enabling the wafer to be moved between the metrology module and the prober, which contours the contact pads for testing. The software package of the asset allows for the data acquisition, processing, and analysis of the results. Furthermore, the model offers features such as an automated wafer alignment agnostic of wafer orientation and type, as well as improved stage positioning accuracy and repeat-ability. This is enhanced by the equipment's multiple error checking and correction features, reducing operator-imposed errors. Other features include customizable databasing techniques, allowing for the customizable storage of data and the long-term preservation of results. The system also offers advanced industrial-grade safety and control features, including built-in safety interlocks and radiation shielding. This ensures that the unit does not cause damage to the shipped wafer, thereby preventing costly losses or damage. WS 3840 is a highly sophisticated wafer testing and metrology machine, specially designed to meet the demands of advanced research regarding the characterization of wafer features. It offers various features and capabilities in terms of accuracy, safety, and analysis, making it a reliable and versatile tool for measuring the highly sensitive features of a wafer. By combining high-resolution optical and X-ray techniques into a single tool, WS3840 is able to provide reliable and accurate results in a time-sensitive and cost-effective manner.

There are no reviews yet