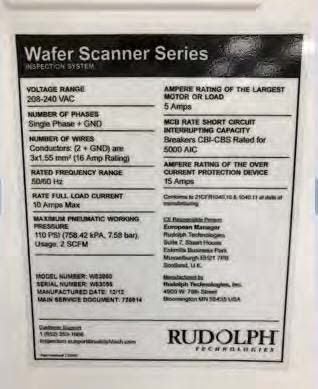

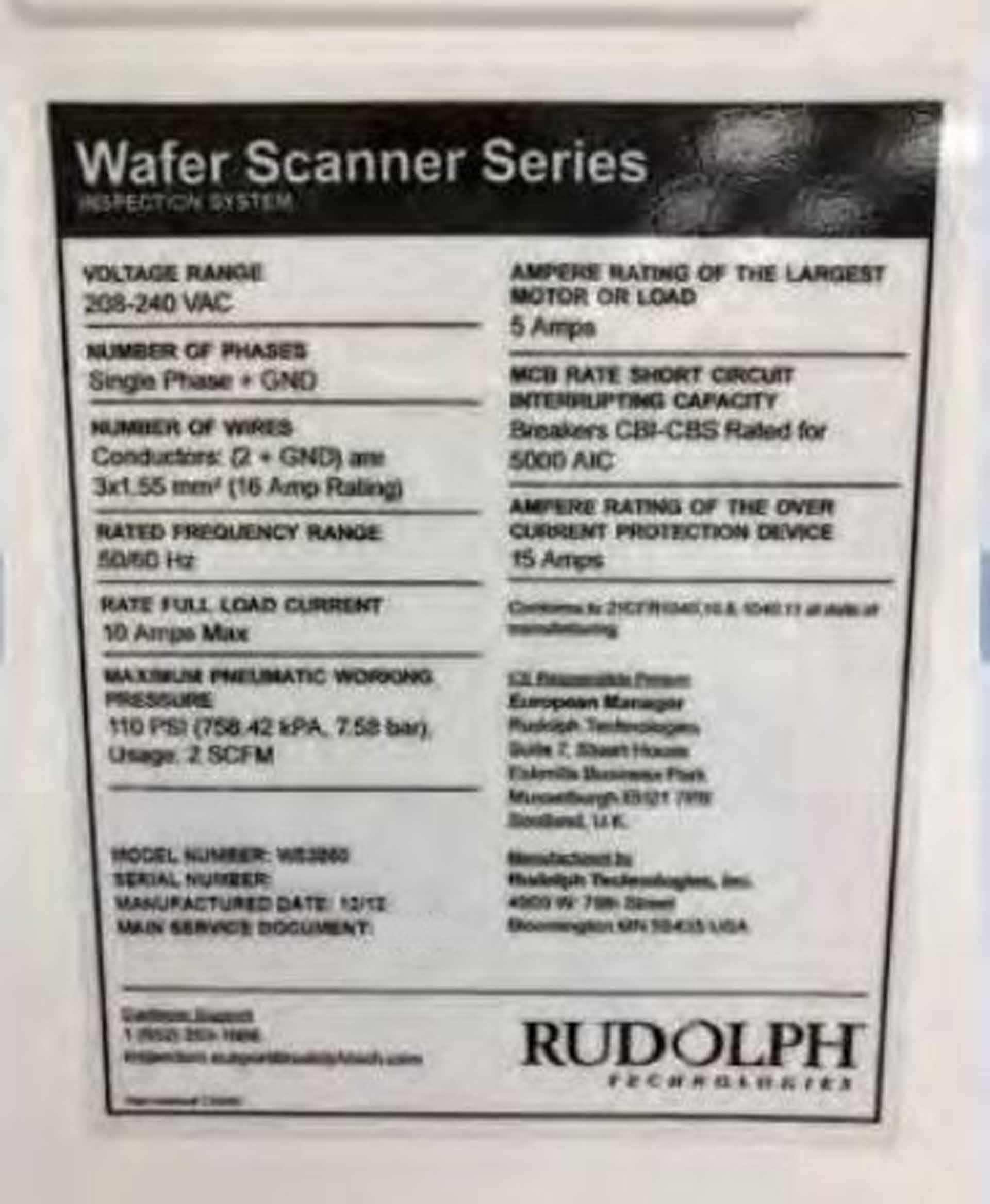

Used RUDOLPH WS 3880 #9394409 for sale

URL successfully copied!

Tap to zoom

ID: 9394409

Vintage: 2012

Bump inspection system, 12"

XPort

Wafer scanner, ISO class 1

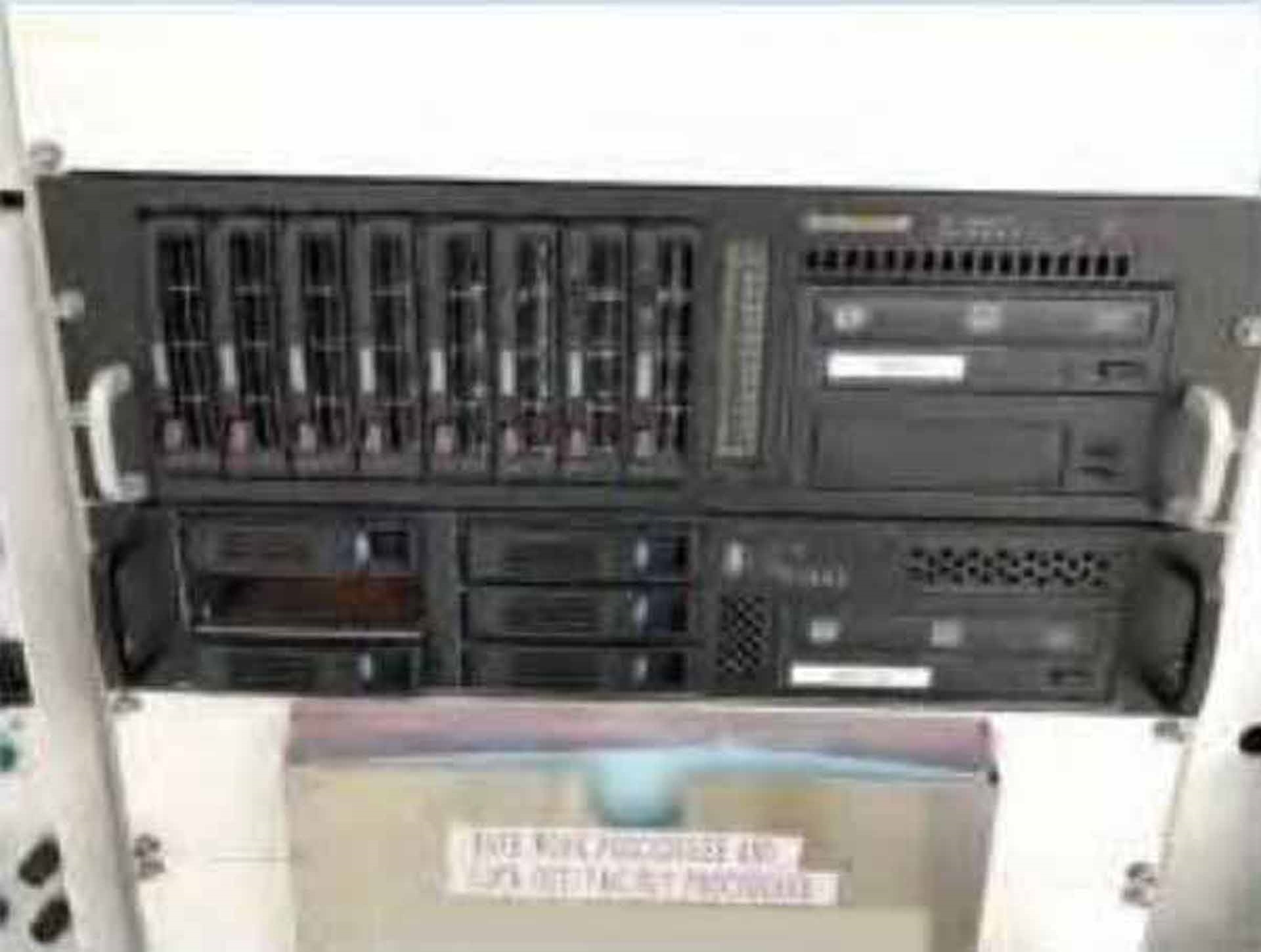

EFEM Outfitted with dual arm robot

XPort capable of handling:

Standard wafer thicknesses (725 um) down to 400 micron thickness for 12" wafers

Standard features:

Automated whole wafer handling

Dual arm vacuum assist backside wafer handling

End effector

Integrated laminar clean air flow mini-environment (ULPA Filtration)

Robot with integrated mapper

BROOKS VISION ATR9100 Loadports (Without mapping)

BROOKS VISION Load ports, 12"

Capabilities:

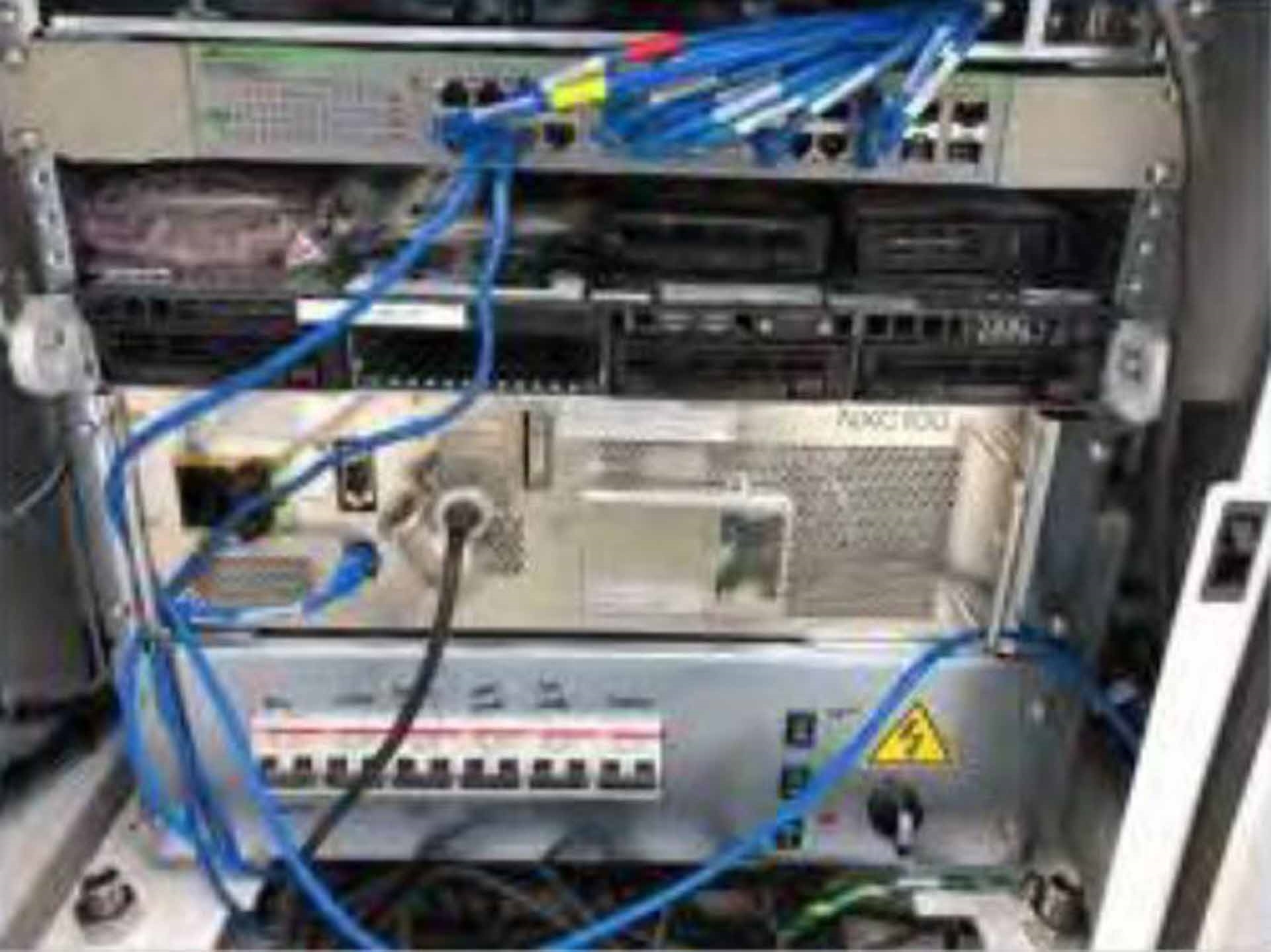

LCD User interface

(30) Predefined fab specific indicators, labels, and buttons

Customized indicator, labels, and buttons

E84 OHT Ready

E99 Carrier ID Ready

Class 3B Laser at 830 nm wavelength (For 3D measurement)

WS3880 3D sensor assy / Computer: 5 um / 8 MHz

Standard 3D height verif wafer, 12": 24 um

Ringlight assy clearance: 3.5 mm

LMPLFL20XBD Objective: 20x

XPort Dual OCR

Aerobar XPort Ionizer assy, 44"

Clean air supply ionizer (AXi / XPort)

Bar code reader

UPH

USB

2012 vintage.

RUDOLPH WS 3880 Wafer Testing and Metrology System is an advanced analysis tool designed to measure various critical parameters on wafers and other substrates. It combines a range of metrology and testing technologies into one platform, providing users with precise and repeatable measurements for process monitoring and improvement. The device consists of four integrated metrology and testing technologies. The first is Optical Assist Technology (OAT), which provides real-time information about wafer defects with a resolution of up to 0.5 μm. Its second technology is CONTACT scanning laser Microscopy (CLM), which examines topography and roughness at the micro- and nano-levels. Third, RUDOLPH WS3880 uses CCD Image Analysis (CIA) to identify and analyze particles and defects. Lastly, the Scanning Capacitance Microscopy (SCM) technology is designed for accurate 3D characterization of wafer parameters. WS 3880 is an all-in-one system that allows for automated data acquisition, analysis and reporting. Utilizing the latest technologies and algorithms, it provides unparalleled accuracy and repeatability in comparison to traditional metrology and testing tools. Its automated testing process makes it ideal for use in quality control applications. The device is perfect for a wide range of applications, including process development, process control, and failure analysis. It is able to measure parameters such as surface roughness, image contrast, particle size and shape, void/void location, line width/line topology, doping, grain size, dopant defects, oxidation depth, and crystalline structure. In addition, it can perform automated measurements on non-flat substrates, as well as surface and bulk contaminants. In order to control the testing process, WS3880 is equipped with a powerful measurement controller. This precision-calibrated controller allows users to monitor and manage testing parameters with ease. Additionally, the device can interface with a laboratory information management system for data collection, analysis, and reporting. Overall, RUDOLPH WS 3880 is an excellent choice for wafer testing and metrology. Its integration of cutting-edge technologies, automated testing process, and precision measurement controller make it one of the most reliable and accurate metrology and test systems in the market.

There are no reviews yet