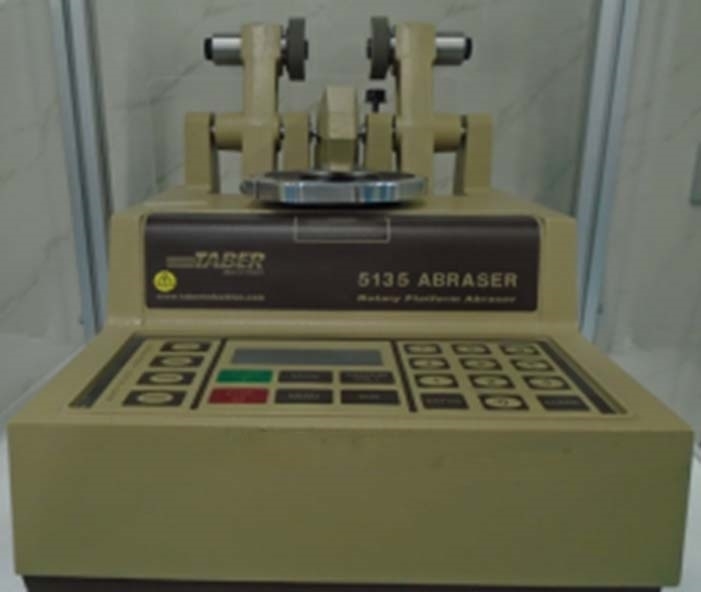

Used TABER 5135 #9253557 for sale

URL successfully copied!

Tap to zoom

ID: 9253557

Rotary platform abraser

Spare parts:

Qty / Model / Description / UOM / Vintage

(5) / 133338 / Collet kits / NOS / 2010

(1) / - / Calibration verification kit / NOS / 2010

(1) / CS-10F / Wheels / NOS / 2010

(2) / - / Loads (1000 G) / NOS / 2010

(2) / - / Loads (500 G) / NOS / 2013

(1) / H-18 / BS23A1 / Calibrate wheels / NOS / -

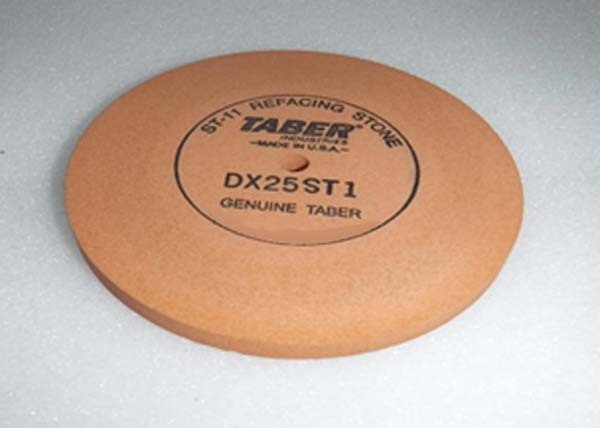

(2) / ST-11 / Refacing stone cards / NOS / -

(8) / S-36 / Specimen mounting cards / NOS / -

(1) / ST-11 / DX25ST1 / Refacing stone / NOS / -

(11) / 132467 / Collets / NOS / -

(99) / S-11 / Refacing discs / NOS / -

Brush.

TABER 5135 is a state-of-the-art wafer testing and metrology equipment designed to enable rapid, comprehensive analysis of wafer surfaces. This system is fitted with an elastomeric reference arm that supports the exchange of reference materials, which makes it ideal for both flat and contoured wafer surfaces. It is also equipped with a compact air-bearing spindle and an integrated motion unit which are capable of determining the dimension, shape, and surface finish of wafers with high accuracy and repeatability. 5135 incorporates a number of advanced features that makes it an ideal tool for wafer metrology. The machine features an integrated CCD camera, which enables precise imaging of the wafer surface. It also has a fully automated alignment tool that utilizes specialized algorithms to set the exact sample position. With the incorporation of a vacuum asset, the model can reduce sample flexure, meaning that highly accurate measurements can be achieved over the entire sample surface. In addition, TABER 5135 also feature several inspection technologies such as advanced three-dimensional (3D) scanning, digital image correlation, and white light interferometry. These technologies allow for both intrusive and non-intrusive surface analysis, as well as measurements such as flatness, waviness, roughness, defect detection, and area measurements. The equipment is also designed to reduce errors, as it monitors normal and abnormal variations in the data analysis. 5135 is also equipped with a fully functional operating system featuring a range of user-friendly tools to simplify the user experience. The unit is compatible with multiple PC based software packages, which makes it suitable for any application. These packages can be used for data acquisition, report creation, and complex analysis. Its user-friendly graphical user interface (GUI) grants users easy access to functions such as automated setup, data acquisition, data analysis, report generation, and calibration. To sum up, TABER 5135 is a powerful and reliable wafer testing and metrology machine that provides precise and highly accurate results. With an elastomeric reference arm, integrated motion tool, and advanced inspection technologies, this asset ensures comprehensive surface analysis that will allow manufacturers to meet high quality and safety standards. Its easy-to-use interface and automated setup and analysis make 5135 a must-have tool for any wafer metrology lab.

There are no reviews yet