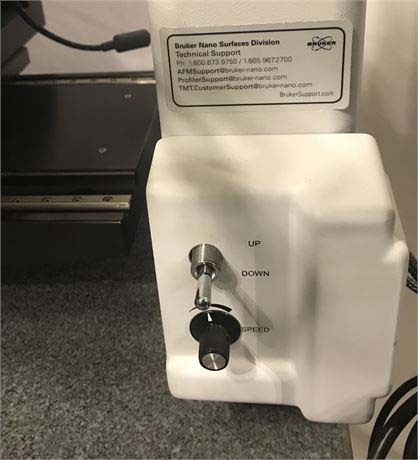

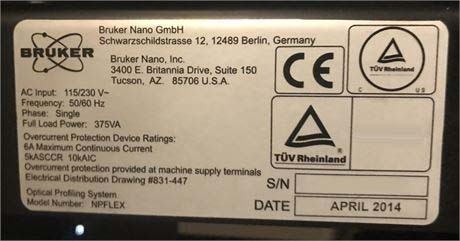

Used VEECO / BRUKER NPFLEX #9309128 for sale

URL successfully copied!

Tap to zoom

ID: 9309128

Vintage: 2014

Optical profiler

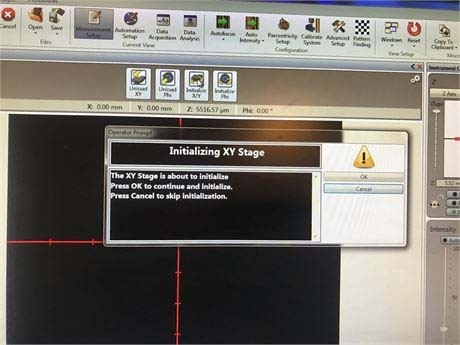

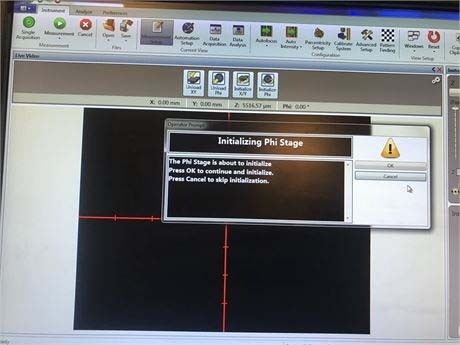

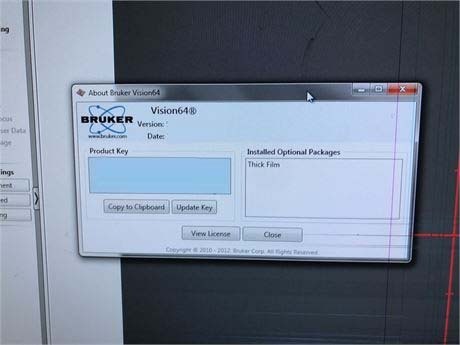

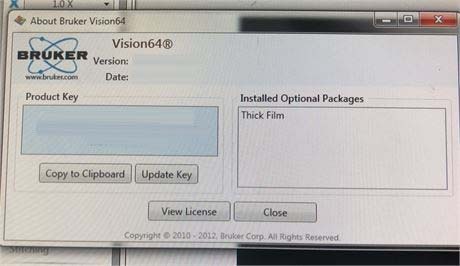

Operating system: Windows 10

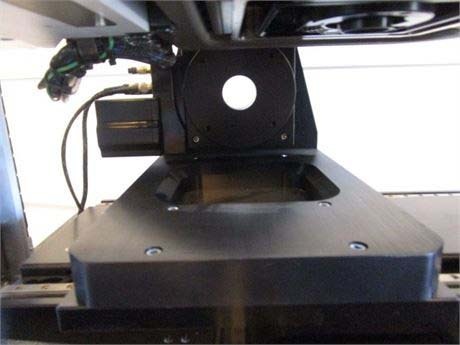

Camera: BASLER SCA640 74fm

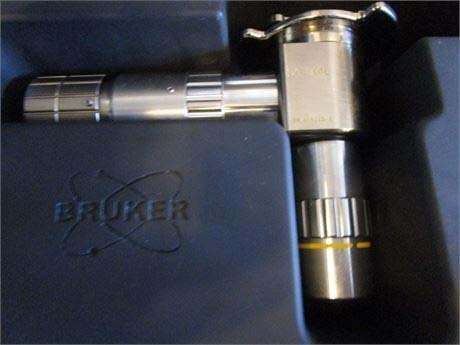

LINNIK LWD objective: 0.5x and 10x

FOV: .55x, 1x, 2x

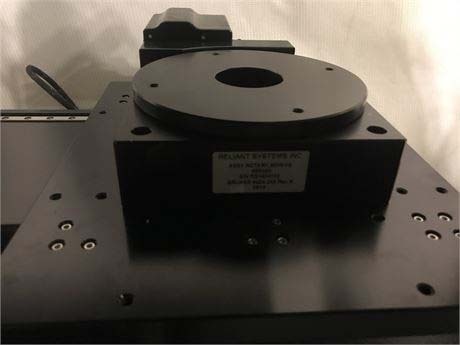

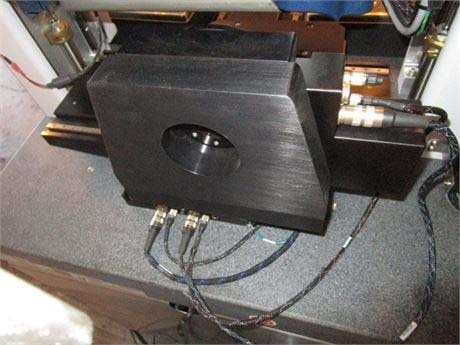

4-Axis stage plus tip / tilt in head carrier

2014 vintage.

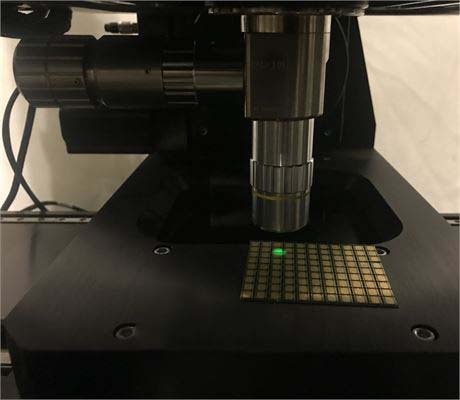

VEECO / BRUKER NPFLEX is an advanced metrology and wafer testing systemly designed for production and research of compound semiconductor materials. This equipment provides a fast and precise non-destructive test of various compounds, including III-V compound semiconductors, on wafers. Using a combination of a visible-light microscope and a near-field scanning optical microscope (NSOM), the system can achieve high lateral resolution (up to 50 nm). The high lateral resolution allows for the investigation of various structures on the samples, ranging from basic features like micro/nano bumps and trenches, to more complex patterns such as Cantilever Probe tips, nanoelectronic devices, and photonic circuits. The unit also has data acquisition and imaging capabilities, which allow for quick measurements and microscopy scans. This enables users to acquire and analyze extensive images with a wide range of parameters, from basic electrical properties like current density and electrical permittivity, to more complex parameter such as the distribution of optical and electrical fields. In addition to data acquisition and imaging, VEECO NPFLEX is also capable of 3D mapping using a combination of multiple microscopy techniques. This allows users to obtain a detailed three-dimensional picture of the wafer surface, by successively imaging fine height details. The 3D mapping capability is particularly useful for nanomanufacturing applications, such as actual line width measurements, surface roughness mapping, imaging of high aspect ratios, and wafer deformation analysis. Overall, BRUKER NPFLEX is an advanced wafer testing and metrology machine that combines high resolution imaging and rapid data acquisition to provide a complete picture of compound semiconductor wafers. This allows users to gain detailed information and analysis about the micro/nano structures on the wafer, making it a perfect tool for those involved in the production and research of compound semiconductor materials.

There are no reviews yet