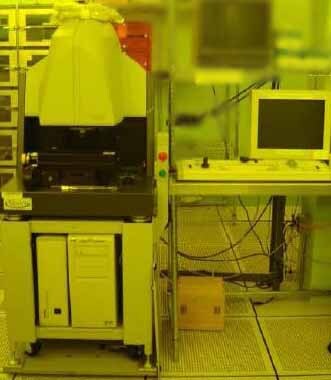

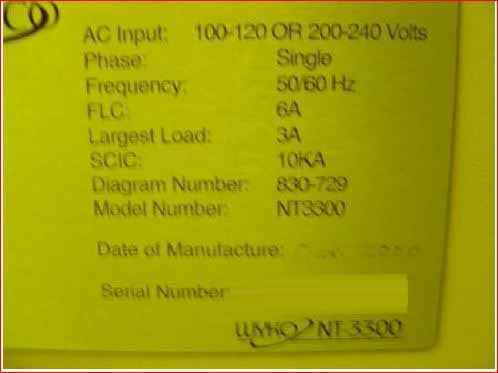

Used VEECO / WYCO NT3300 #9184054 for sale

URL successfully copied!

Tap to zoom

ID: 9184054

Vintage: 2000

Profiling system

Phase shifting interferometry (PSI)

Vertical scanning Interferometry (VSI)

2000 vintage.

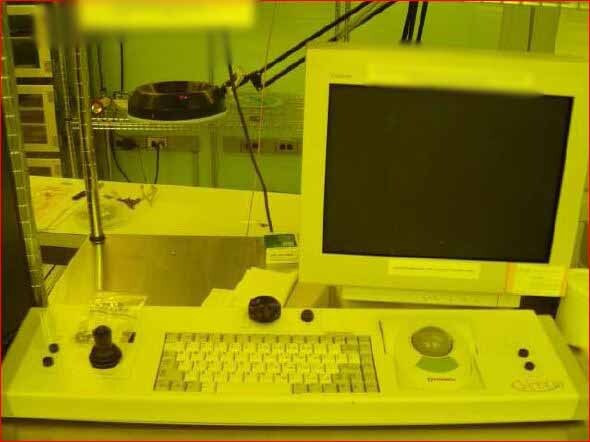

WYCO/Wyko VEECO / WYCO NT3300 is a wafer testing and metrology system specifically designed to meet the requirements of complex semiconductor device manufacturing. It provides a single system to measure and analyze the performance of samples in dense, ultra-miniaturized form. WYCO NT3300 is a powerful tool, enabling manufacturers to quickly and accurately measure up to 32 different parameters. It supports various types of process analysis, including electrical testing, optical profiling, defect scanning and rapid cross-section metrology. The device leverages advanced technologies such as atomic force microscopy (AFM) and structured illumination microscopy (SIM) to provide vital insights into device performance. VEECO NT-3300 also offers advanced features such as an automated user interface and automated image processing. The user interface offers vibrant and easy to use menus and icons for programming, data acquisition, and analysis. The automated image processing feature simplifies the analysis process by employing sophisticated algorithms to quickly detect anomalies and defects. For added convenience, WYCO NT-3300 can be configured to meet specific user requirements. It offers a range of customization options, such as manual override functions, automatic gain control, low-noise operation, and digital library management. All these features can be used for managing samples and experiment parameters. Finally, NT-3300 offers comprehensive monitoring of device performance by capturing multiple cross-sections, including electrical parameters. This helps to identify defects and errors quickly and accurately, enabling manufacturers to produce more reliable products. In summary, VEECO/Wyko NT3300 is an advanced wafer testing and metrology system that provides complete capabilities for assessing device performance. It offers automated user interfaces and image processing, as well as customizable settings to enable manufacturers to get the most out of their device manufacturing process.

There are no reviews yet