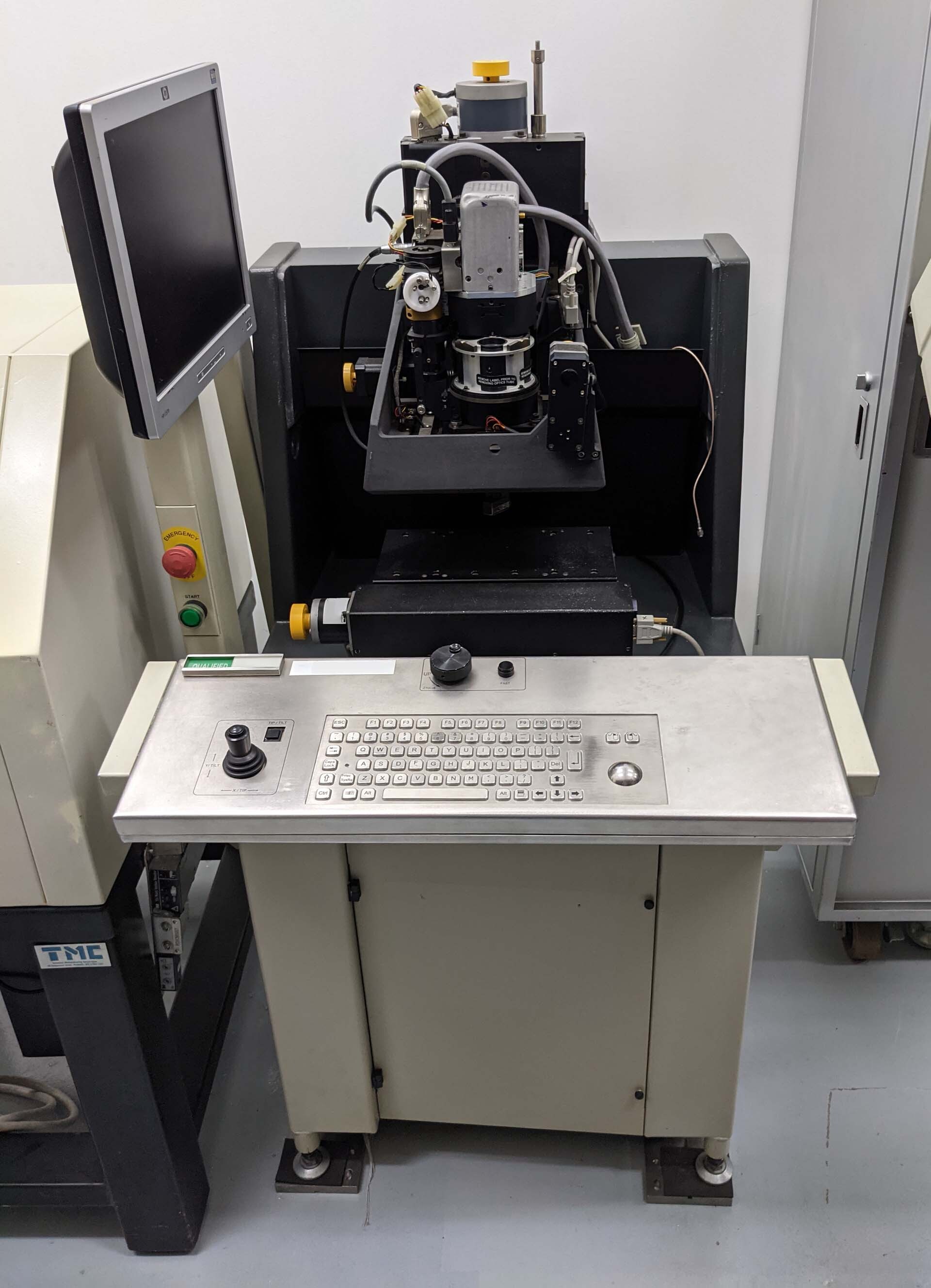

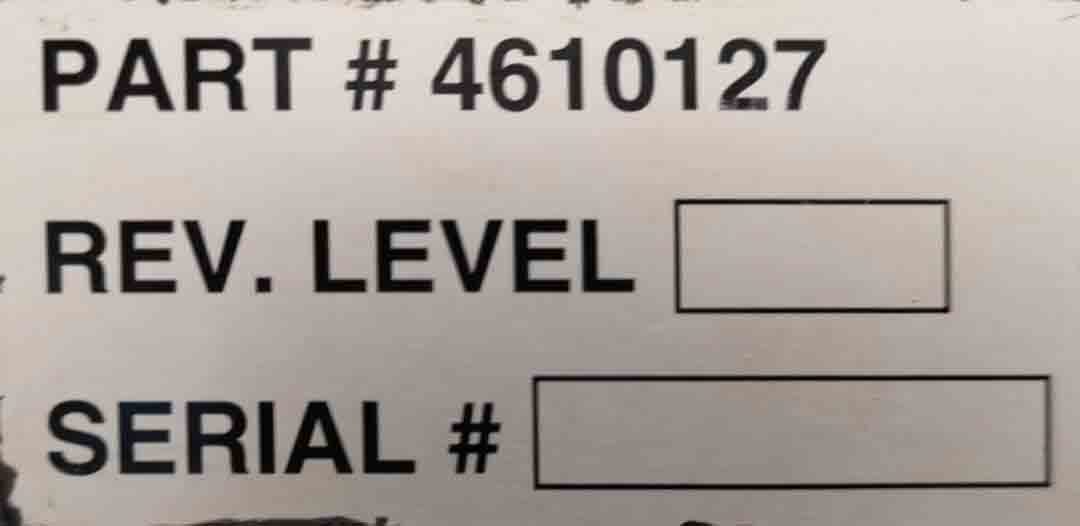

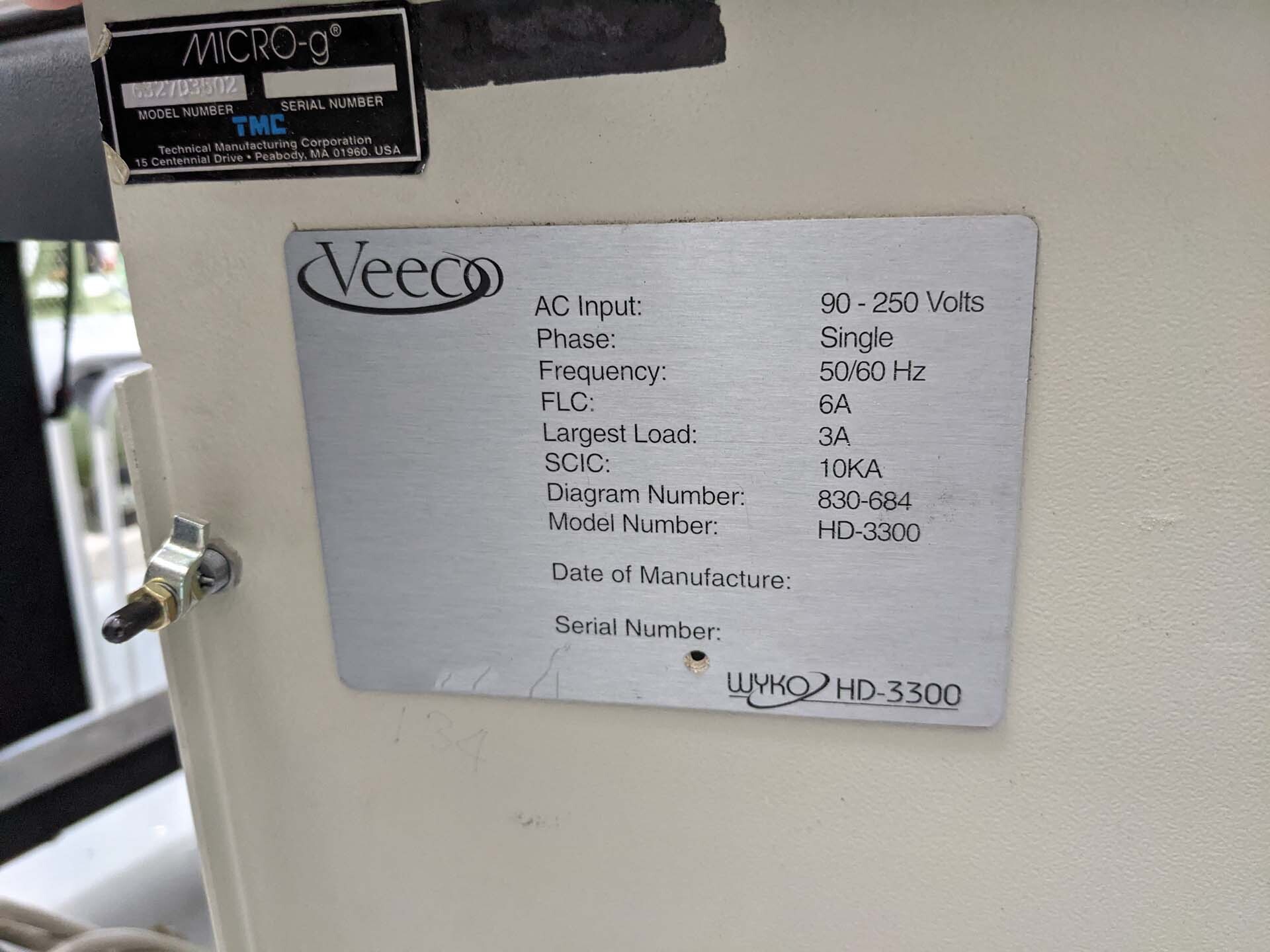

Used WYKO / VEECO HD 3300 #9277354 for sale

URL successfully copied!

Tap to zoom

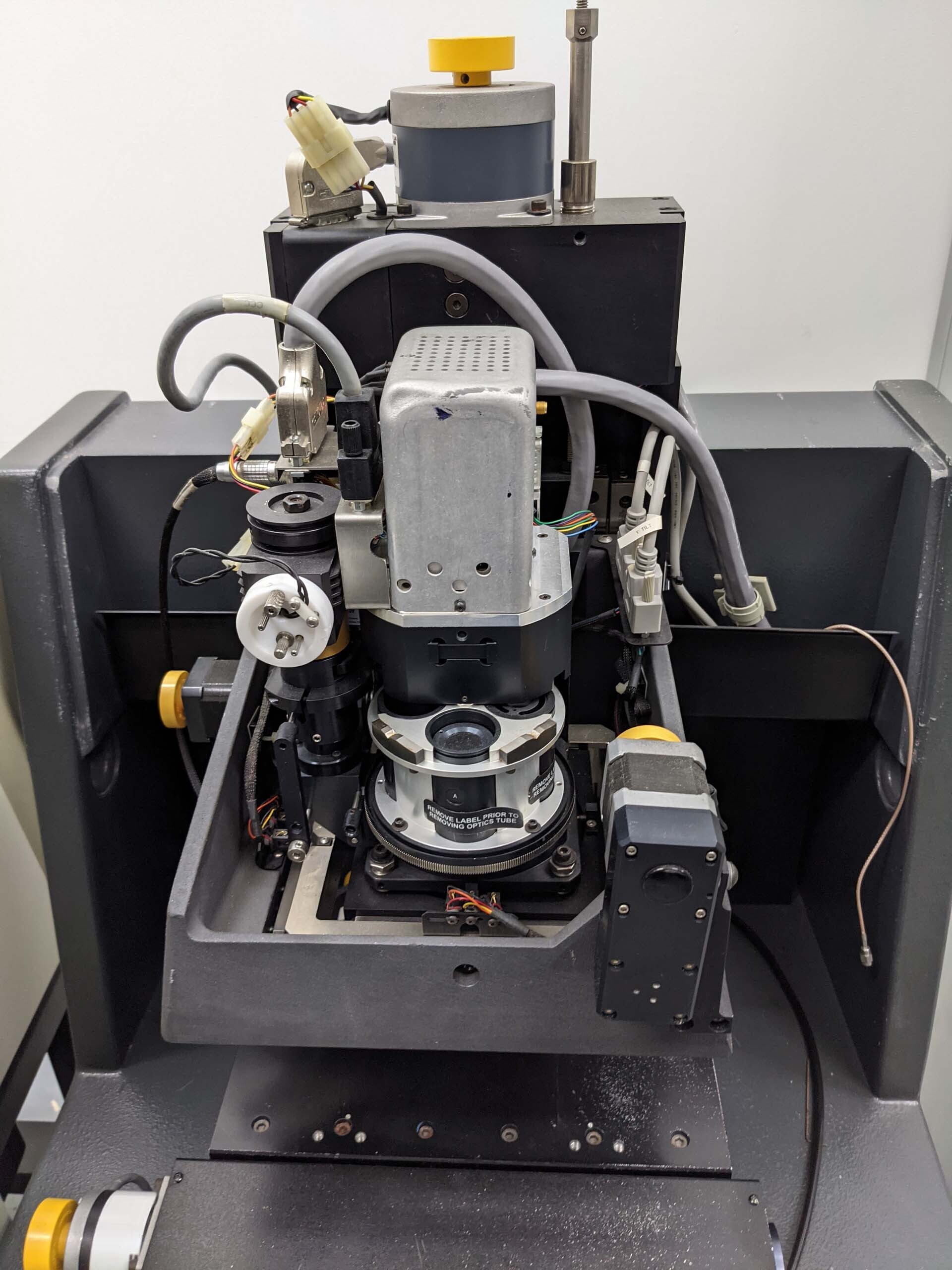

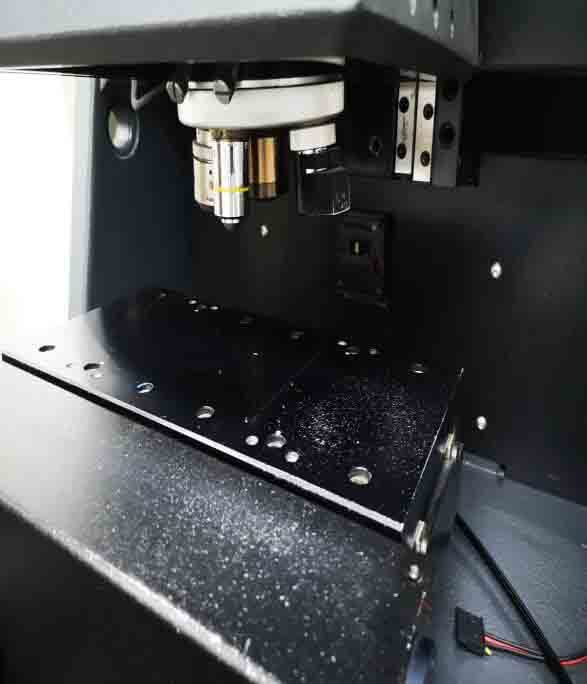

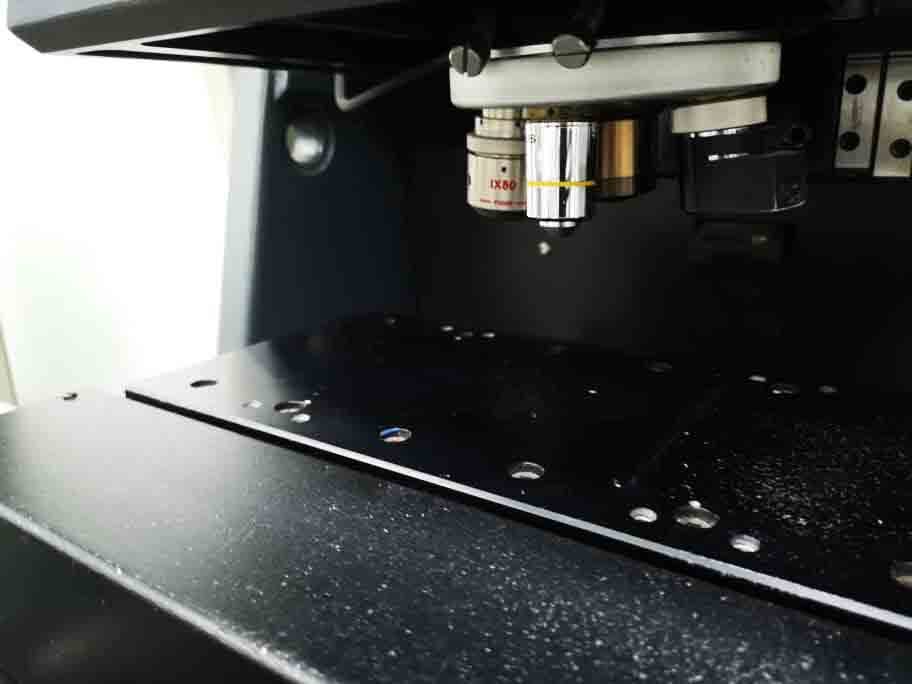

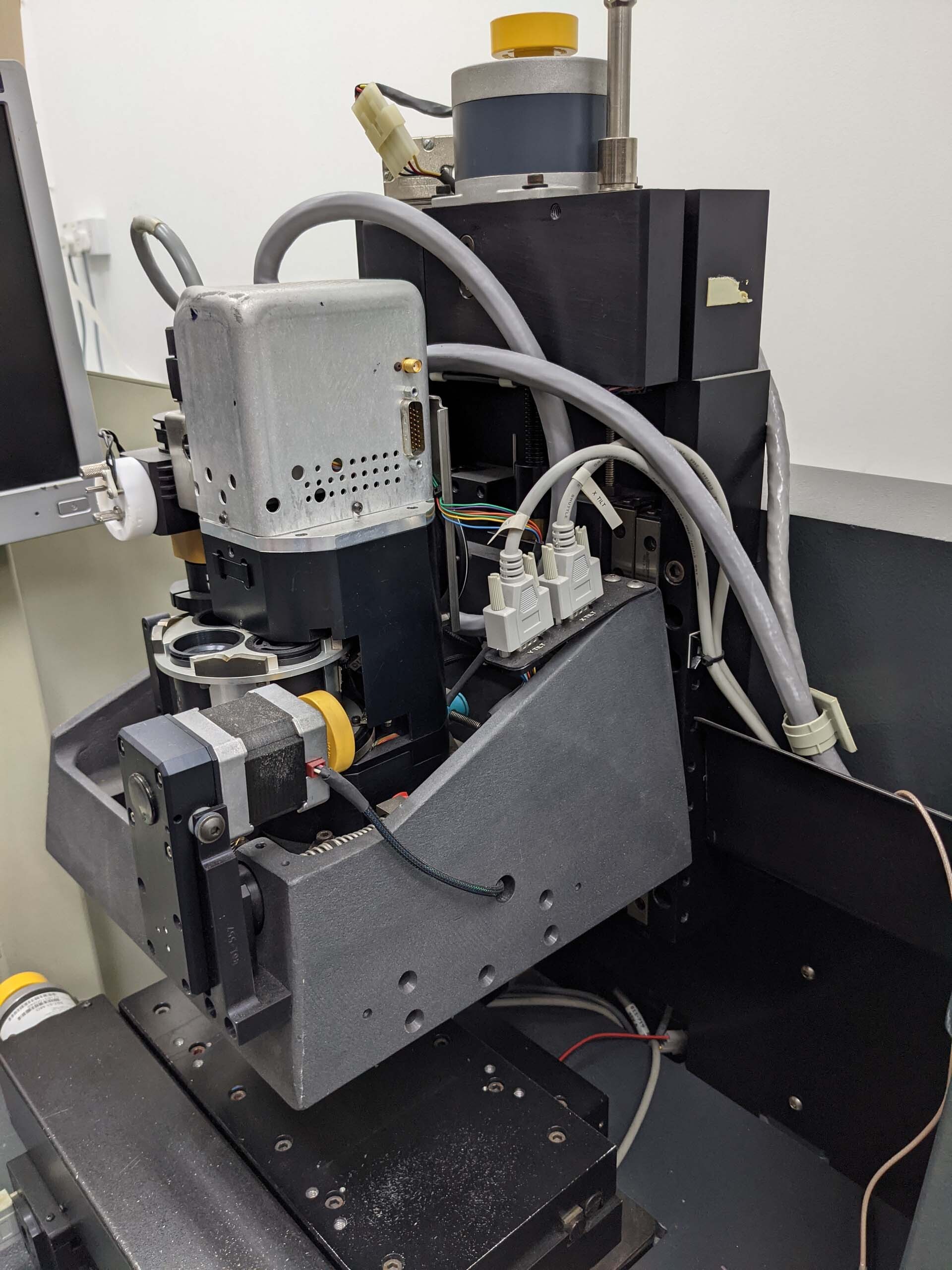

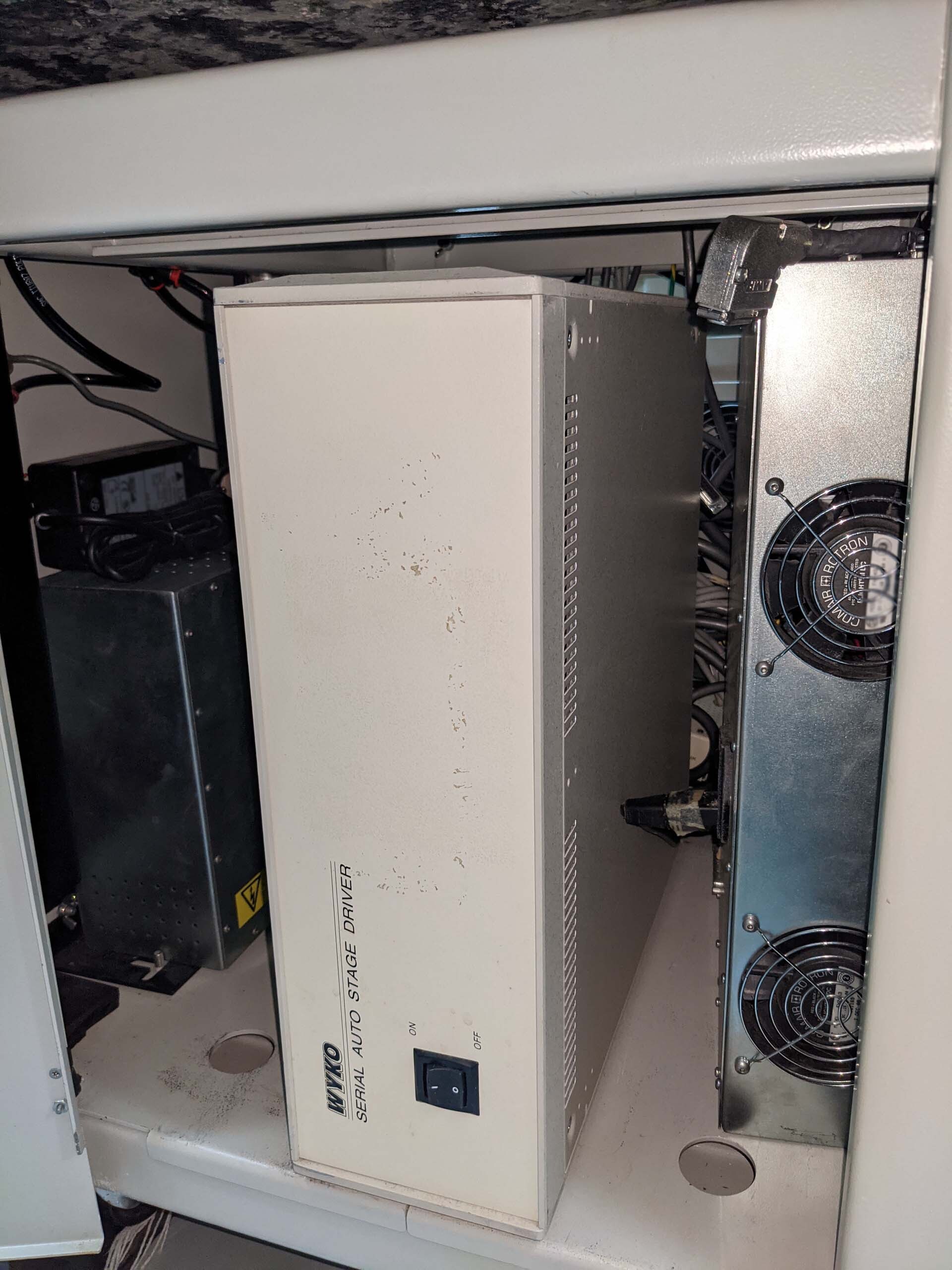

WYKO / VEECO HD 3300 is a multifaceted wafer testing and metrology equipment that is designed to help detect and diagnose issues in the manufacturing process of integrated circuits. WYKO HD 3300 system offers outstanding performance for non-destructive testing of materials used for the fabrication of semiconductor devices such as photo resist, lithographic layers, surface defects, etc. VEECO HD 3300 comes with a variety of different components each having their own specific purpose, in order to create a comprehensive, efficient, and accurate unit that can easily detect and diagnose problems in the manufacturing process. HD 3300 is equipped with a high-pressure fluid dispensing machine that is designed to detect and diagnose any issues that occur in the deposition of the lithography layers over the wafer during the manufacturing process. This tool helps identify areas of uneven coverage, defects, or poor composition of the layers. WYKO / VEECO HD 3300 also provides a visualization interface with an integrated camera, to allow for higher resolution imaging and analysis of surface defects. WYKO HD 3300 is also equipped with a pantograph optical profiler that is able to measure 3D surface structures with extremely high accuracy and can be used to detect any micro-scale imperfections. The asset also features an optical interferometer that makes use of monochromatic laser light to measure the intensity and variance of thickness of the layers used in the manufacturing process. VEECO HD 3300 model runs on an industry-leading Windows 7 operating equipment, making the unit user friendly for both novice and professional analysts. The data analysis and display offered by the system is also extraordinary and includes 3D imaging and analysis as well as graphical information. Overall, HD 3300 provides efficient and accurate testing, analysis, and display of materials used in the fabrication process of semiconductor devices.

There are no reviews yet