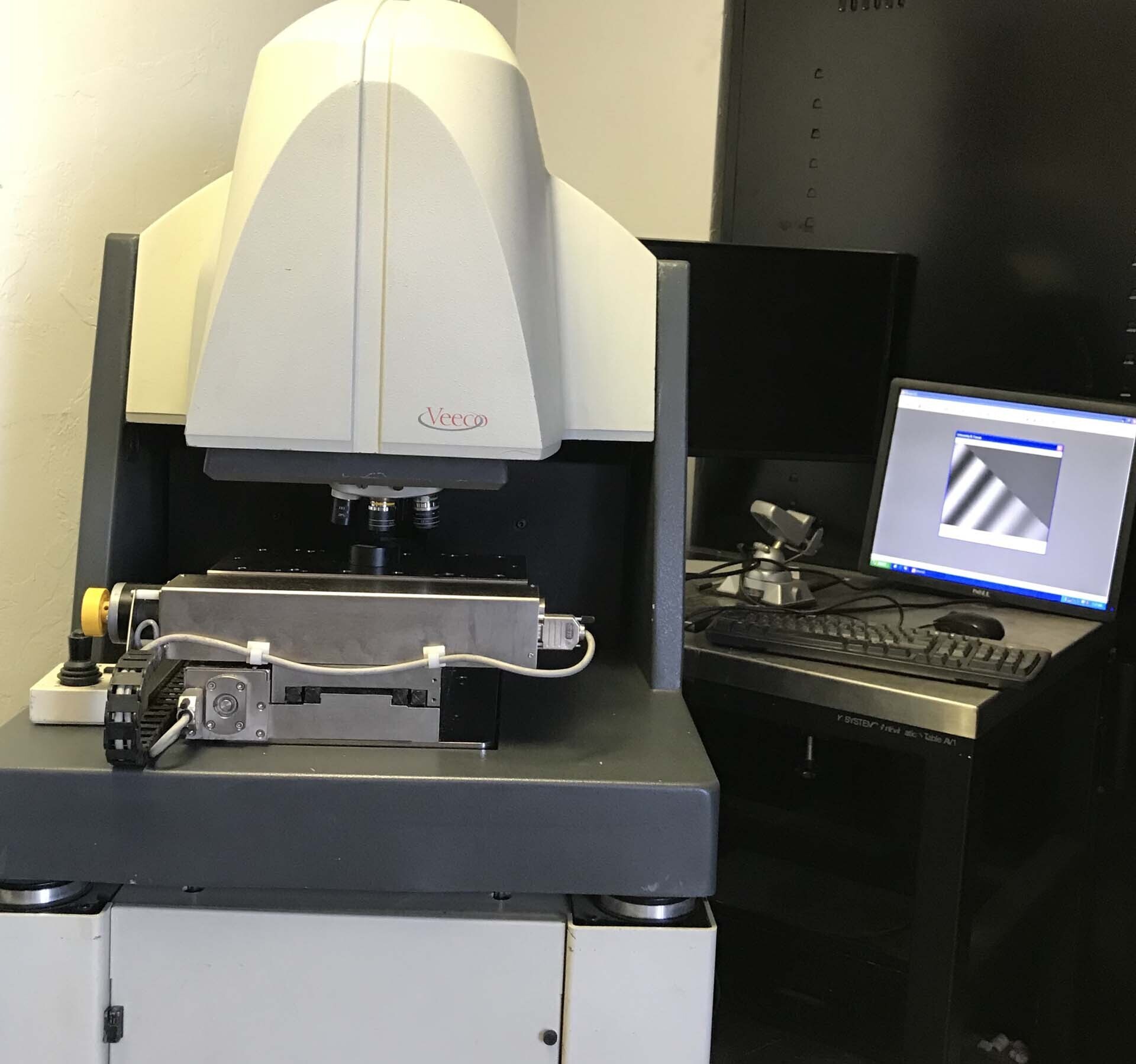

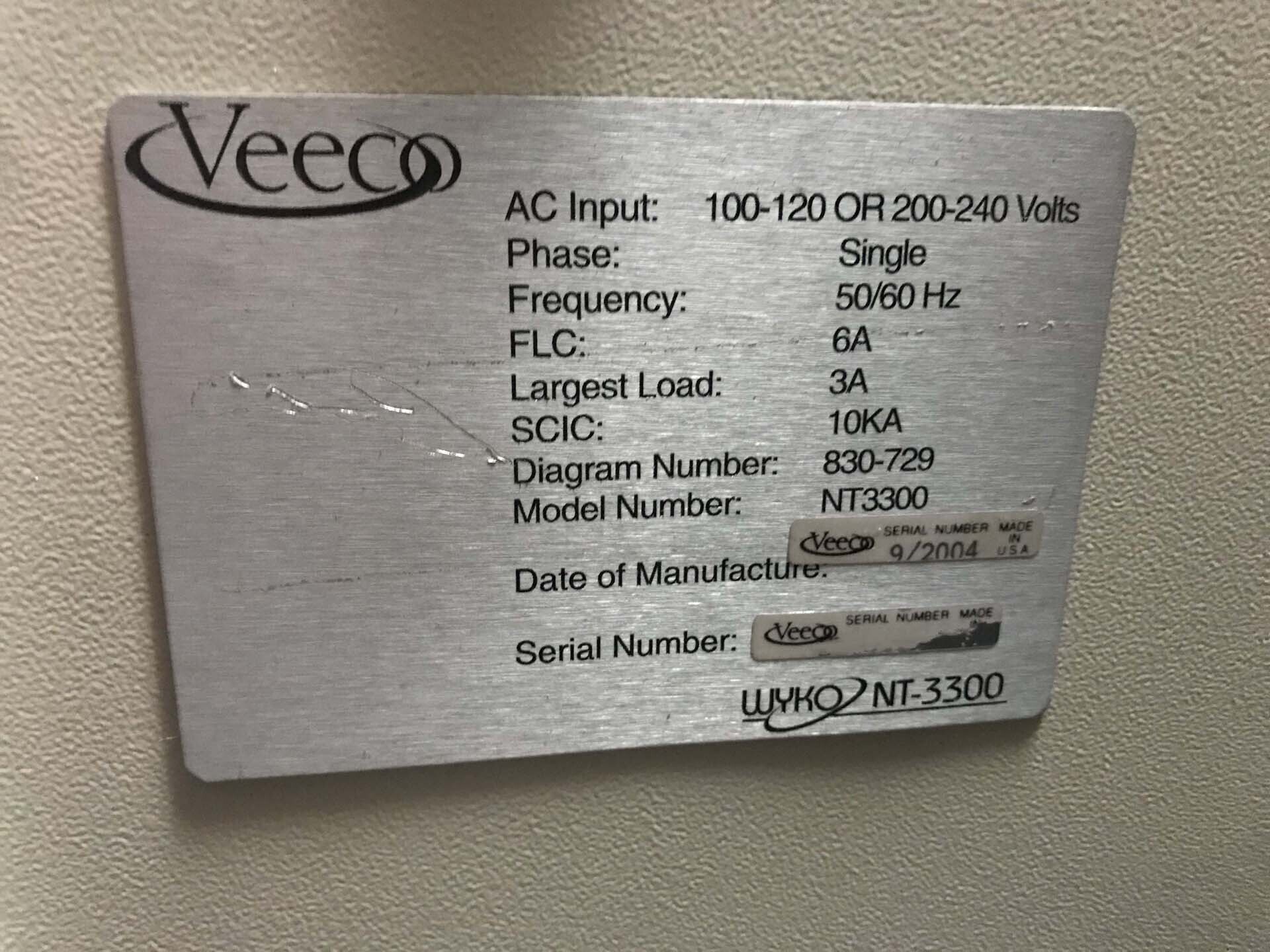

Used WYKO / VEECO NT 3300 #9304712 for sale

URL successfully copied!

Tap to zoom

ID: 9304712

Vintage: 2004

Optical 3D surface profiler

Measurement technique:

Optical phase-shifting

White light vertical scanning

Interferometry

Measurement capability:

Three-dimensional

Non-contact

Surface profile measurements

COHU 1100 Analog camera

With digital interface board

Digital swap compatible res for 3300: 6612

Camera array size for 3300: 640 x 480

Upgraded LED for 3300

Objectives: 1.5x, 2x

Measurement array:

Maximum array: 736 x 480

Standard: 1000 x 1000

Light source: Tungsten halogen

Lamp: Automated filter selection

Stages:

Manual: ± 2"

X/Y Translation: 200 mm (± 50.8 mm)

Rotation: ± 90°

Tip / Tilt: ± 6°

Options:

Automated: ± 4" (101.6 mm)

X/Y Translation

Automated R/f

Rotation: 360°

Radius: 4" / 8" (101.6 mm / 203.2 mm)

Tip / Tilt head: Motorized / Automated

Optical assembly:

Integrated

Computer-controlled illuminator

Automated discrete zoom with magnification sensing

Automated stages

Closed-loop precision vertical scanning assembly

RS170 Video display: 230 mm

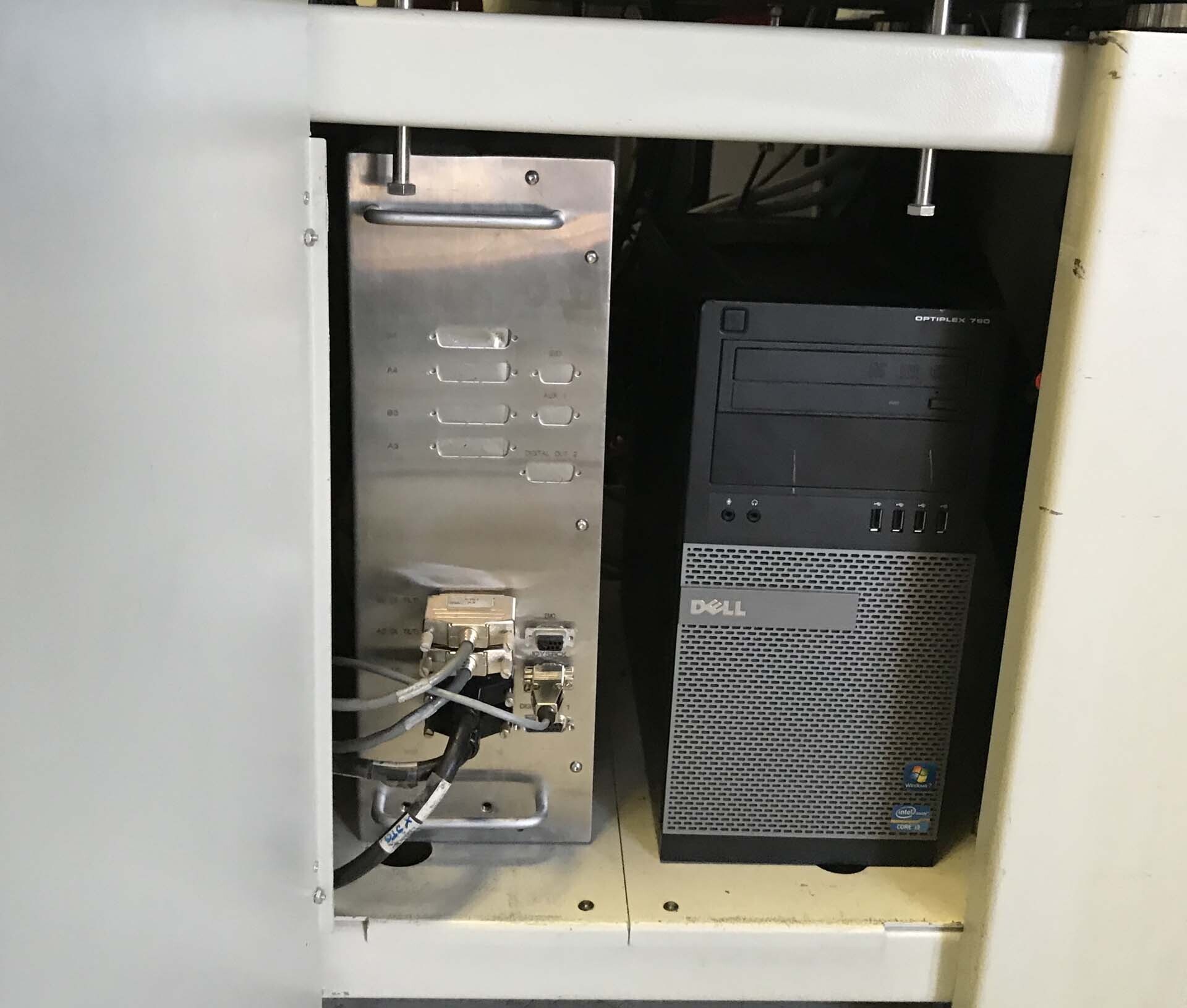

PC Computer

Processor: Pentium

SVGA Monitor, 17" (430 mm)

Live image stays up on SVGA through measurement

Processor: G5

Computer: Windows XP

(24) Monitors

Advanced analyzer

Stitching

Fast automation

GALIL 4-Axis controller

Stage: 8 x 8

Motorized nosepiece

With objective: 5x, 50x

LED Illumination

Performance:

Vertical measurement range:

Standard: 0.1 nm to 1 mm

Vertical resolution: <1A Ra

RMS Repeatability: <0.01 nm

Scan speed:

Standard: Up to 7.2 µm/sec (288 µin./sec)

Lateral spatial sampling: 0.08 to 13.1 µm

Field of view: 8.24 mm to 0.05 mm

Maximum slope: 25° to 1.8°

Reflectivity: 1% to 100%

Environment:

Temperature range: 15° to 30°C (59°F to 86°F)

Non-condensing humidity range: <80%

Power requirements:

Compressed air: 60 - 100 PSI

Input voltage: 100-120 VAC / 200-240 VAC, 50/60 Hz

Power consumption: <300 W

With stage: <400 W

2004 vintage.

WYKO / VEECO NT 3300 is a wafer testing and metrology equipment used to examine the structure and quality of wafers and other thin film materials. The system incorporates a variety of specialized components, allowing for the analysis of a variety of sample types. WYKO NT 3300 can take measurements with spatial and angular accuracy of 1 μm and 0.1° respectively, and can measure over wafers with diameters up to 300 mm. The unit offers a variety of advanced imaging techniques for inspecting thin film devices up to 50 μm thickness. The imaging options are based on an array of high-precision cameras which are capable of capturing images in various lighting conditions. For example, the machine can switch from brightfield to darkfield imaging, allowing for the detecting of defects that may not otherwise be visible. Additionally, it is capable of scanning in non-visible wavelengths such as ultraviolet and infrared, providing more comprehensive coverage of the sample's surface. VEECO NT 3300 boasts a high-speed, high-resolution microscope. Its design includes a motorized precision stage and auto-focusing technology, allowing samples to be quickly moved or focused at any given location. The tool is also compatible with a range of different optics, giving users the option to select the best magnifications for each measurement and imaging task. In addition to its imaging capabilities, NT 3300 features advanced analytical tools, including surface profilometers and three-dimensional imaging tools. The profilometers measure the profile of surface topography with extremely high precision, allowing the user to assess surface finish, roughness, and other sample details. The three-dimensional imaging techniques enable the visualization of sample features in multiple axial planes. In conclusion, WYKO / VEECO NT 3300 is a powerful and versatile asset for wafer testing and metrology. Its precision imaging and analytical tools offer accurate and detailed insights into sample structure and quality, allowing for the detection and optimization of defects and process related issues.

There are no reviews yet