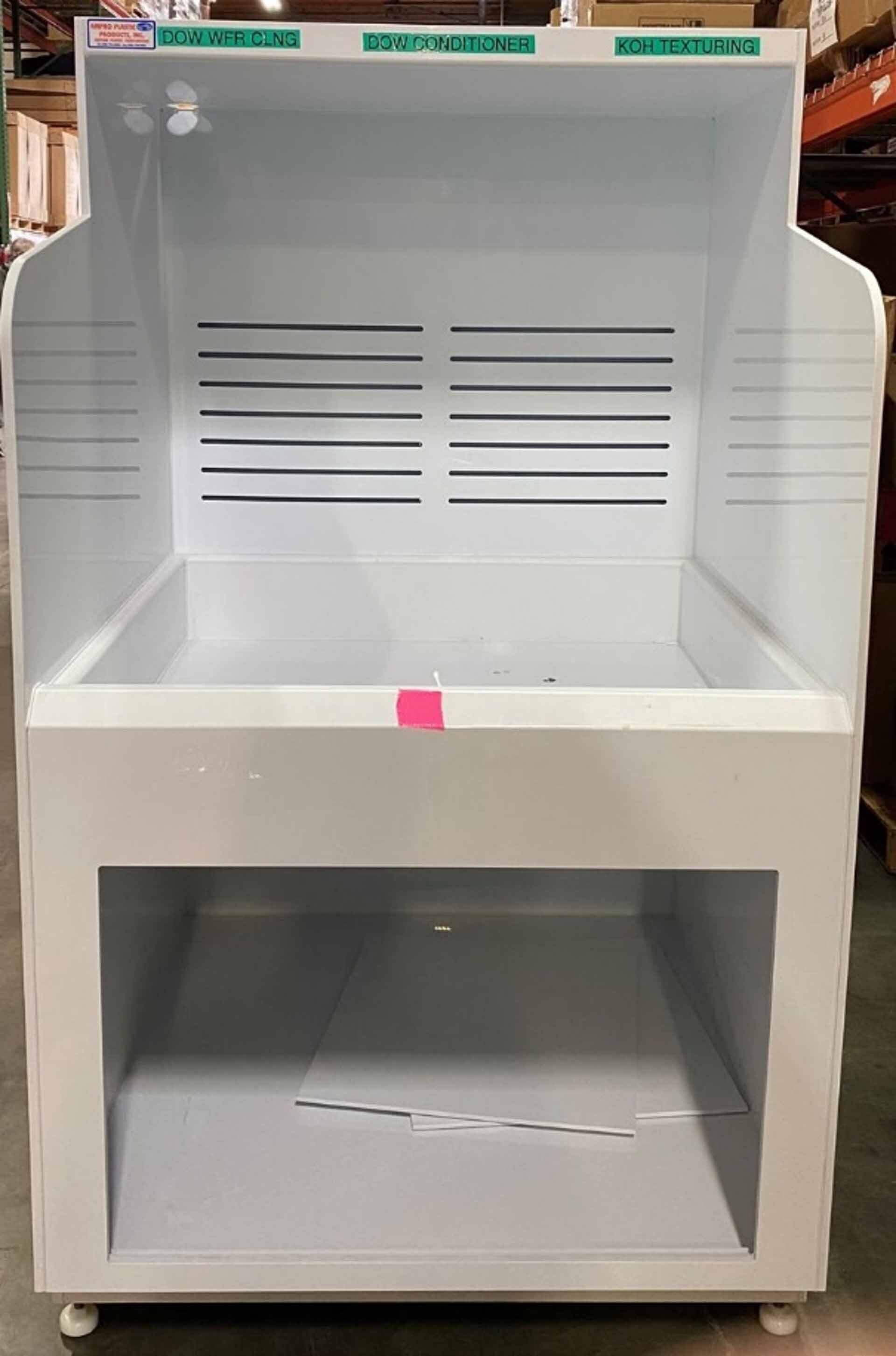

Used AMPRO PLASTIC PRODUCTS Custom #293597558 for sale

URL successfully copied!

Tap to zoom

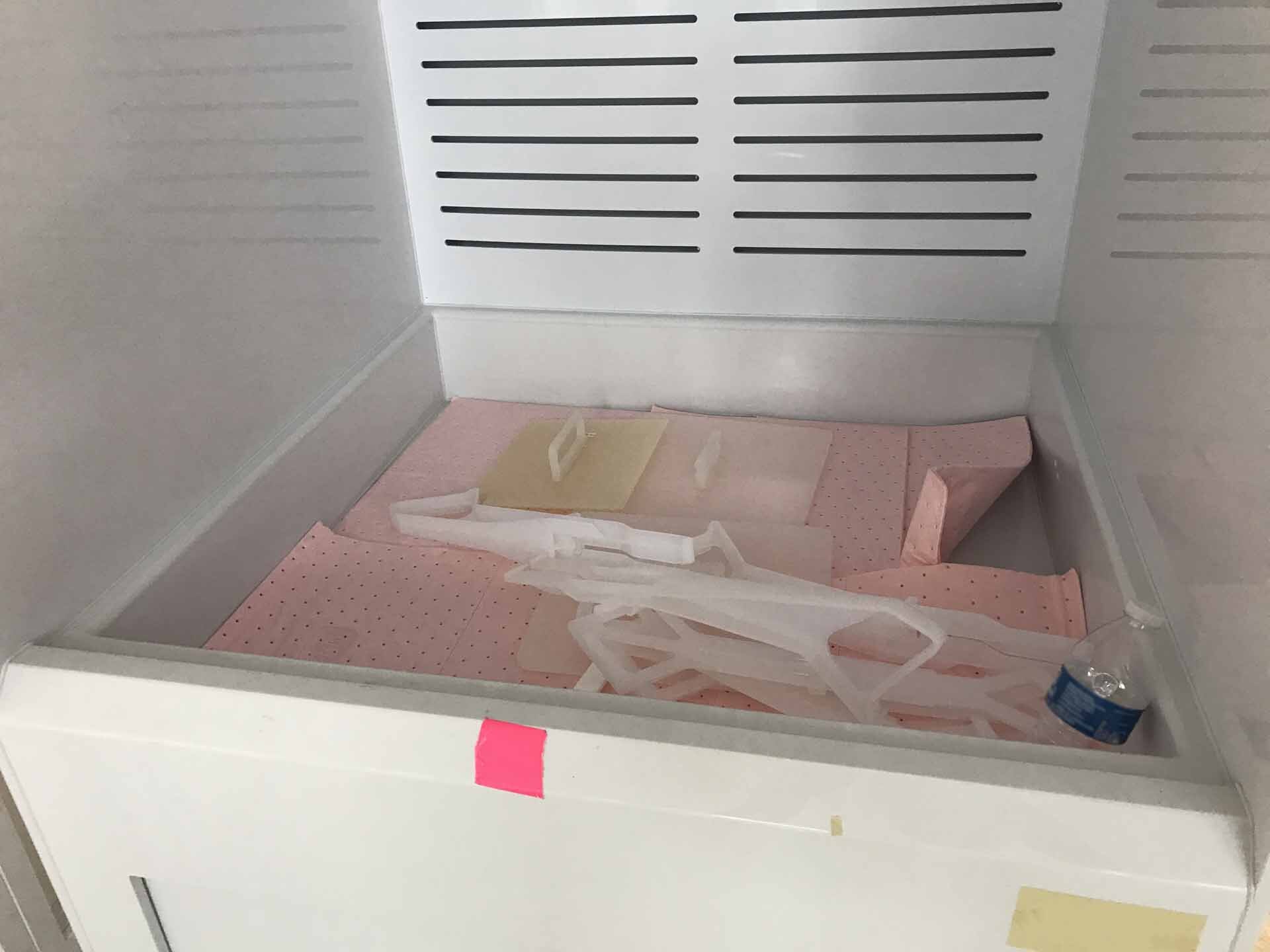

AMPRO PLASTIC PRODUCTS Custom Wet Station offers an innovative and efficient way to handle the engineering and fabrication of innovative Custom plastic fabrication projects. This customizable equipment can be configured to suit the application and provide AMPRO PLASTIC PRODUCTS Custom plastic fabrication at an affordable price. The wet station operates on an automated system that uses water to cool and lubricate plastic materials, helping to reduce the risk of cracking, warping and other problems that may arise during the fabrication process. This unit is capable of quickly and easily shaping Custom plastic parts, with maximum flexibility and accuracy. The wet station features a unique top-down approach to AMPRO PLASTIC PRODUCTS Custom plastic fabrication. This approach allows the user to easily and quickly customize the shape and size of plastic projects. This proprietary technology is highly accurate and safe to use, ensuring that projects are completed in no time. Custom wet station also offers a wide range of services for AMPRO PLASTIC PRODUCTS Custom plastic fabrication. These services include thermoforming, hot-stamping, 3D printing, drilling, planing, and more. Additionally, the station is able to provide complete assembly and finishing of plastic components. Plus, the wet station has convenient automation controls that allow the user to quickly adjust the speed and precision of the process. This makes the machine extremely user-friendly and allows a wide range of Custom plastic projects to be completed with minimal fuss. The wet station also features a built-in tank and proportioning tool. This tank is capable of holding up to 300 gallons of manufacturing fluid. The tank is then heated and cooled as needed to prevent over-heating or under-cooling of the plastic material. This ensures that the process is safe and consistent for each project. Plus, AMPRO PLASTIC PRODUCTS Custom wet station also has an integrated filtration asset. This filtration model captures particulates, ensuring that only clean, pure water is used in the production process. This prevents plastic defects from occurring and keeps the plastic parts clean and free from contamination. Finally, the wet station is designed for easy operation and maintenance. It is easy to set up, use, and maintain and comes with a detailed user manual and troubleshooting guide. This makes it a reliable equipment for producing high-quality Custom plastic prototypes, components, and products.

There are no reviews yet