Used DNS / DAINIPPON FC-3100 #78944 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 78944

Wet station, 12"

Cassette Interface:

(2) 12" FOUP

4-Tank System:

Tank #1: SPM

Tank #2: SPM

Tank #3: ONB

Tank #4: HF

CSB1 = NH4OH

CSB2 = H2O2

CSB3 = SPARE

CSB4 = HF

CSB5 = HF

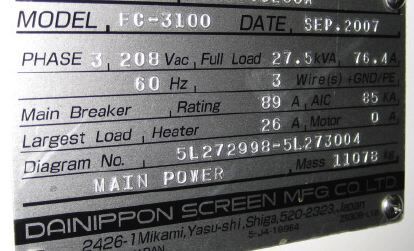

Diagram 5L272998-FL273004

LUFRAN Model 144-6UU6-R6 – DI Water Heater

Chemicals Used: Hydrofluoric Acid AQUEOUS, IPA, Hydrogen Peroxide, Ammonium Hydroxide, Sulfuric Acid, Carbon Dioxide, N2

Electrical Requirements: V 208, 3-Phase, 3-Wire, 50 / 60 Hz

2007 vintage.

DNS / DAINIPPON FC-3100 wet station is a high-performance and cost-effective automated processing platform for semiconductor manufacturing. The unit has been designed with both advanced automation and process control systems in order to reduce intervention, minimize variability, and increase yield throughout an IC manufacturing process. DNS FC3100 consists of a two-chamber wet station processing capability. The first chamber is a wet process module, which facilitates the priming, etching, rinsing, and cleaning of wafers. The process chamber is controlled by a sophisticated, advanced process control system and offers a buffet of efficient, risk-free methods of wafer processing. This includes mixing recipes, adjusting temperature and pressure settings, controlling the flow and level of liquid within the chamber, and monitoring current conditions. The chamber also features an accurate pressure measure, automated process control, and an on-board wafer sorter. The second chamber of DAINIPPON FC 3100 is the drying module, which takes place after the wet process module has been completed. This chamber utilizes a combination of heat, chemical vapor deposition, and direct-current (DC) sputtering processes for drying off the wafers and ensures optimal removal of excess liquid residues. This also helps eliminate distortions caused by inconsistency in the residue removal process. After the wafers have been dried off, a wafer sorter automatically sorts and aligns them before they are sent to their next process. Furthermore, FC3100 wet station also features an active fault monitor, which displays the current conditions in the process chamber and assists with adjustments of parameters related to the current status of the process. In addition, real-time feedback and process knowledge help to ensure that the best outcomes and efficiency are continually achieved. Through its efficient design, integrated automation and process control systems, FC-3100 is an essential resource for those looking for high-performance, cost-effective handling and process control of their wafers.

There are no reviews yet