Used DNS / DAINIPPON FC-3100 #9176488 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9176488

Vintage: 2012

Wet stations

(3) Chemical baths

(3) Quick drain rinse baths

Low pressure dry

2012 vintage.

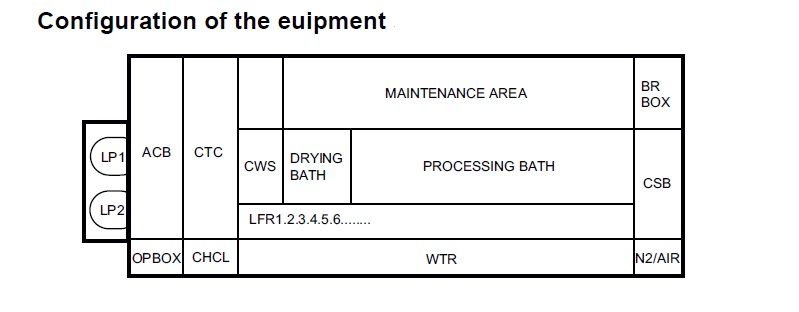

DNS / DAINIPPON FC-3100 is a fully automated wet station ideal for medium to large-scale production. The 4th generation of wet etching/cleaning systems, this model incorporates the latest design features and integrated technology to reduce processing time and increase throughput. The graphical user interface (GUI) on DNS FC3100 makes it easy to control the equipment using intuitive "Smart" buttons on the control panel. All set-up, start, stop, and emergency shutdown functions are conveniently located at the touch of a button. The system also features a bar-code reader for easy card reader operation. The machine uses continuous flow technology with an integrated hood for reducing cross contamination and preventing odors from chemical exposure. The hood's motor-driven exhaust arm is programmable and can be adjusted to suit the local exhaust requirements of the environment. The integrated automation unit of DAINIPPON FC 3100 streamlines wet process steps, from substrate cleaning to etching and drying. This allows for faster, more consistent production with reduced energy and chemical use. The machine features two processing tanks that can hold up to 60 liters of solution each and is capable of operating at temperatures up to 60°C. DNS / DAINIPPON FC3100 includes an automated chemical delivery tool with onboard-metering for precise chemical dosages. This reliable, hands-free asset ensures process control and repeatability. The drop-in bay for chemical tanks utilizes a simple mechanical-locking model for easy access. FC-3100 also features a dynamic built-in filtration equipment to ensure maximum substrate safety and product quality. It includes a sediment filter for coarse debris, mechanical filters for fine debris, and an inline polarization system for residual cleaning. The filtration unit also helps reduce chemical use and waste. DNS FC 3100 utilizes a batch-passive condensate management machine to safely and conveniently return excess condensate to the processing tanks. The condensate management tool ensures that processed subtrates remain on-spec at all times. With its robust feature set and advanced capabilities, FC 3100 is an ideal choice for chemical etching and cleaning applications in medium to large-scale production. The asset's built-in automation, intuitive control panel, and reliable performance provide increased throughput and greater process control.

There are no reviews yet