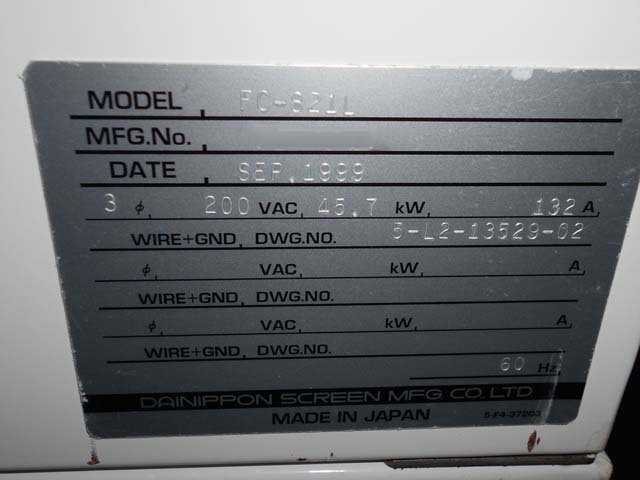

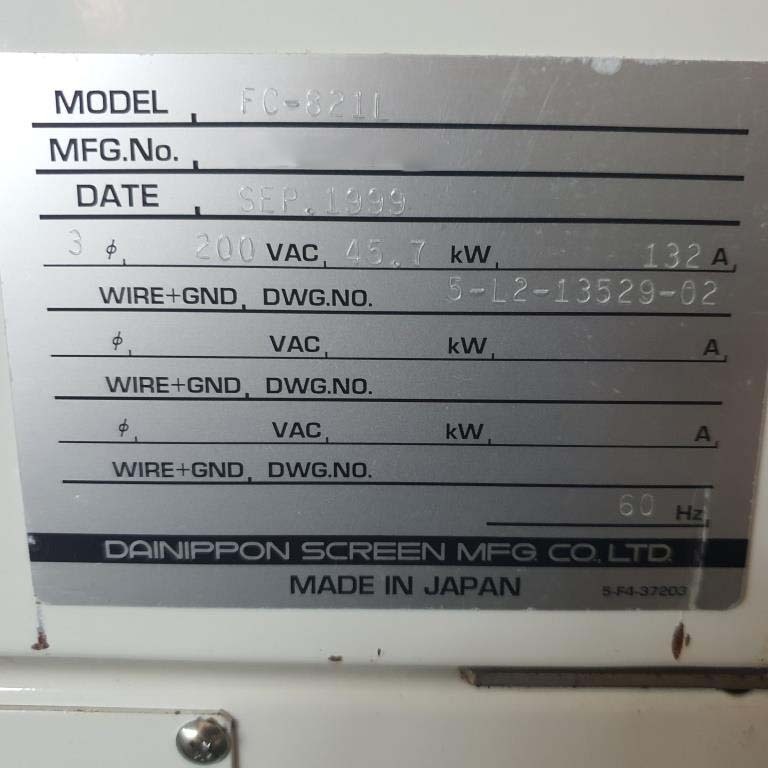

Used DNS / DAINIPPON FC-821L #293586553 for sale

URL successfully copied!

Tap to zoom

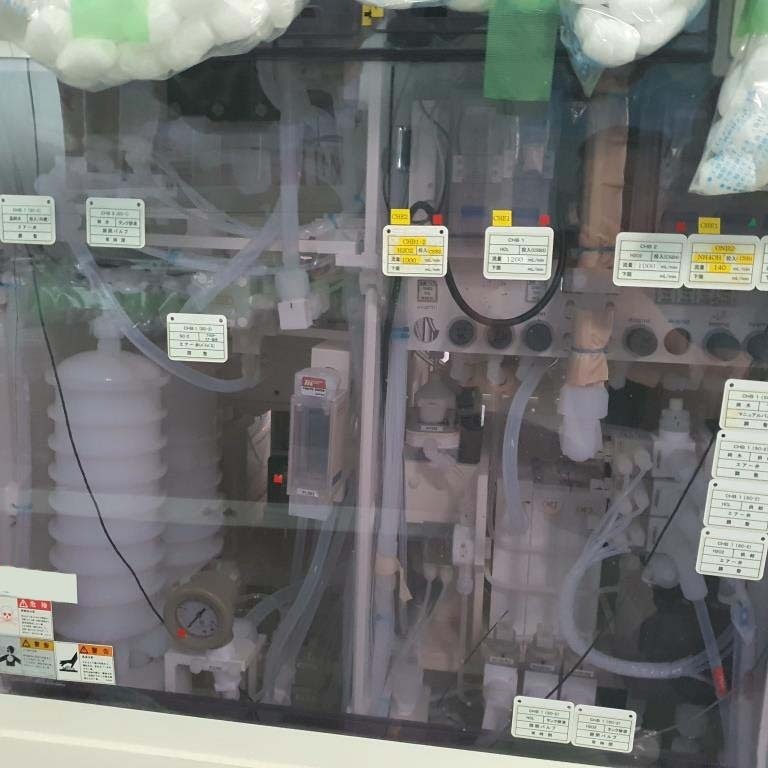

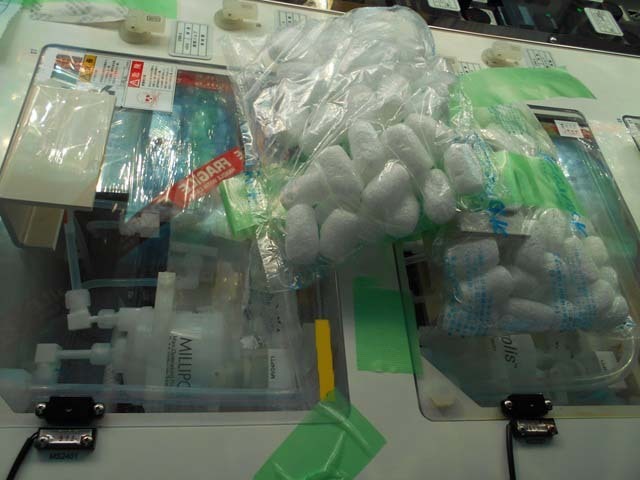

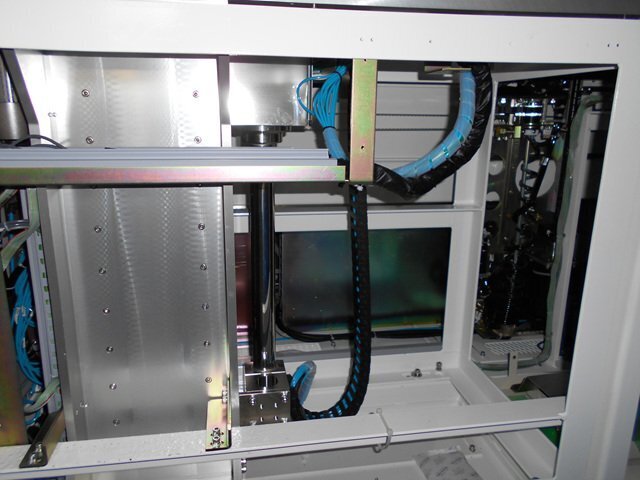

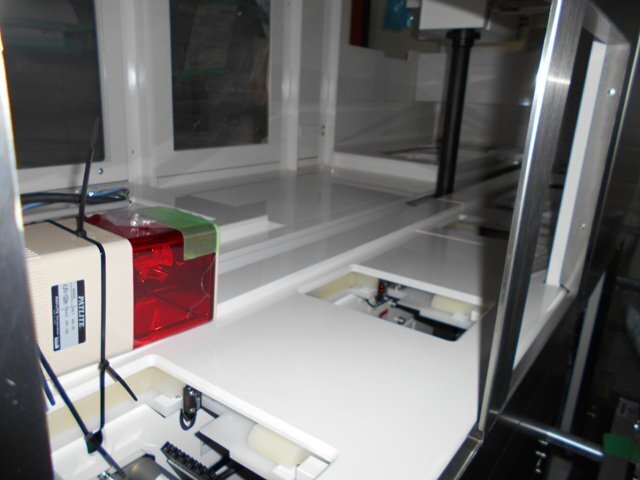

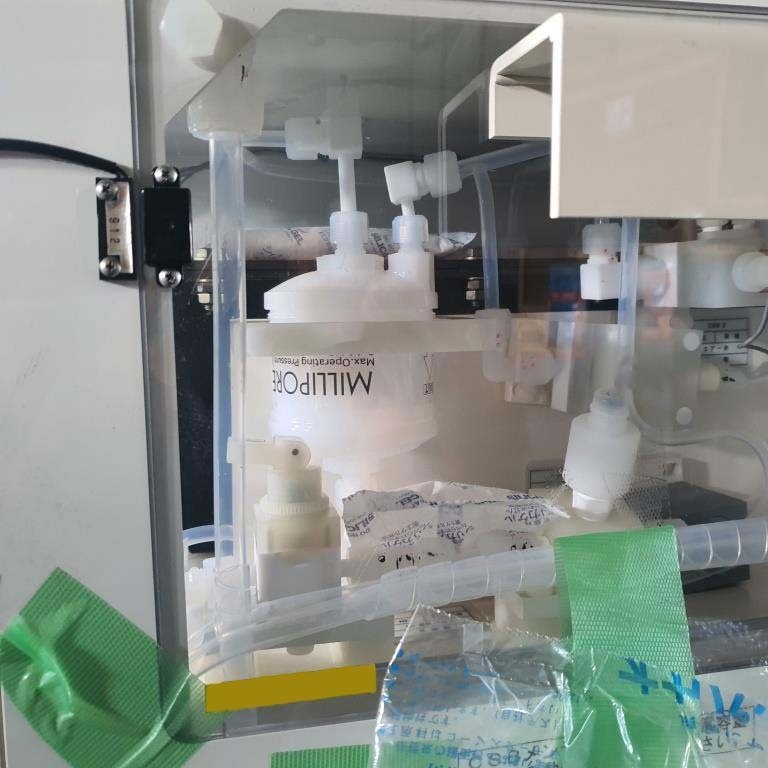

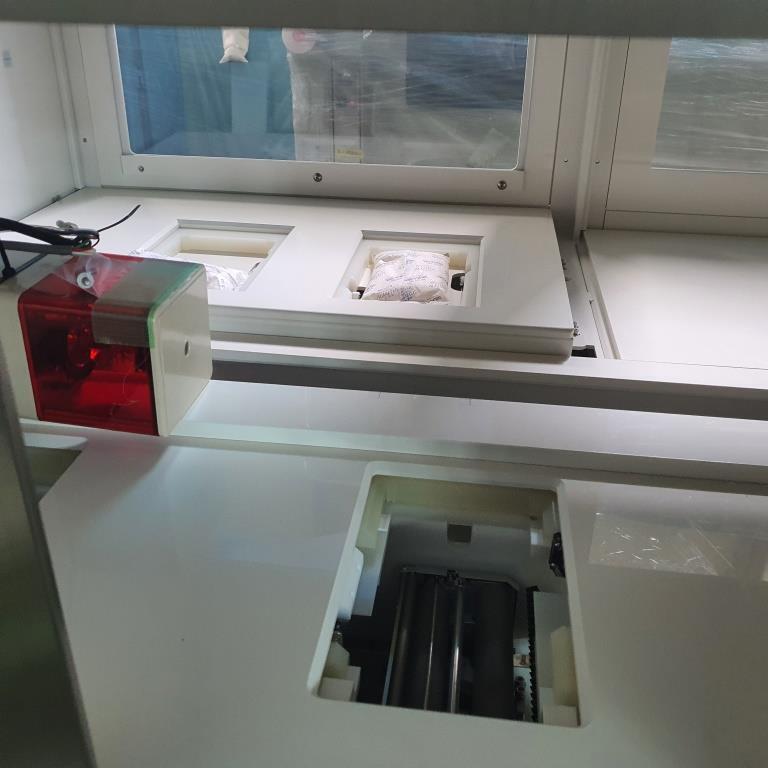

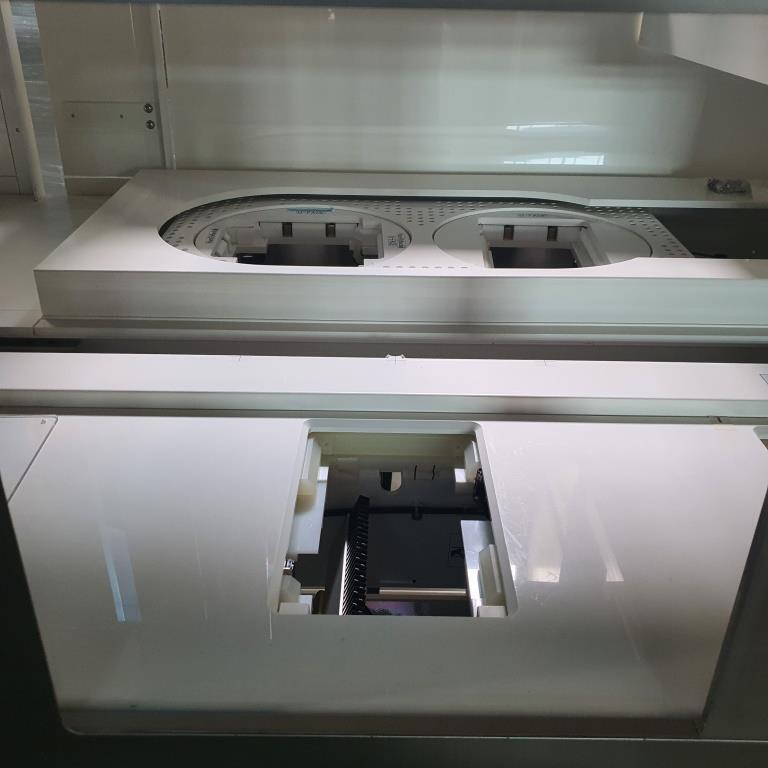

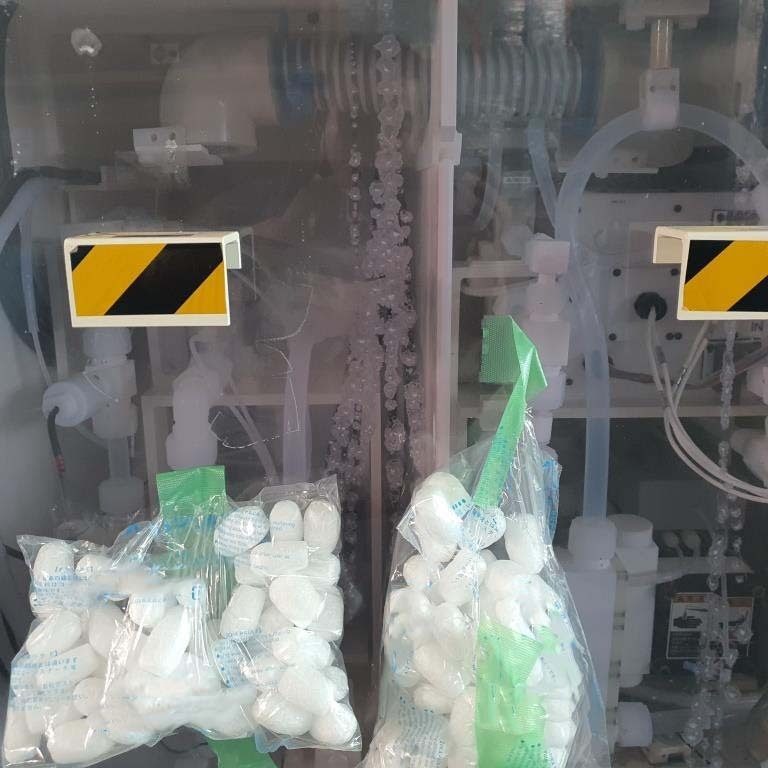

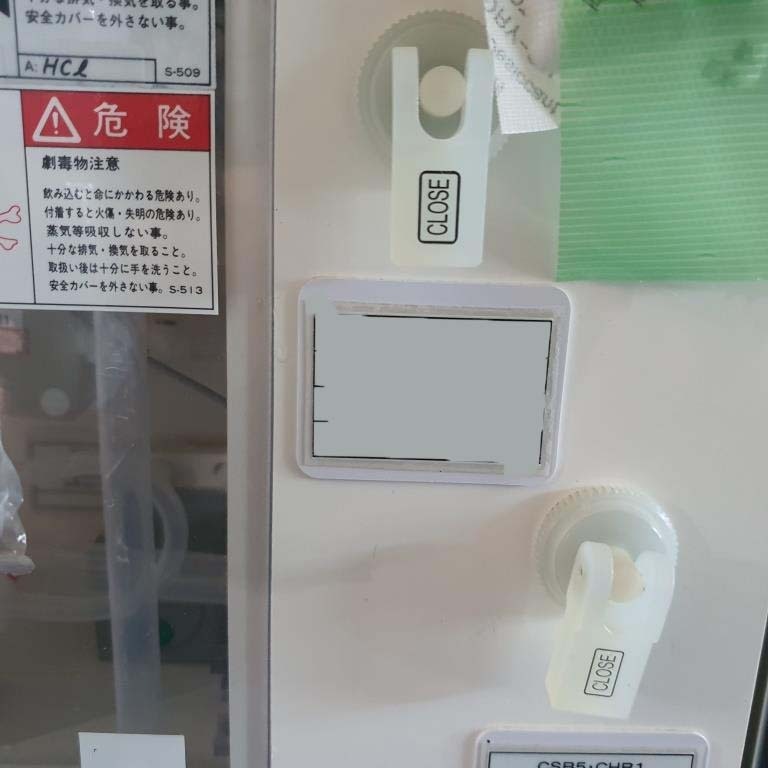

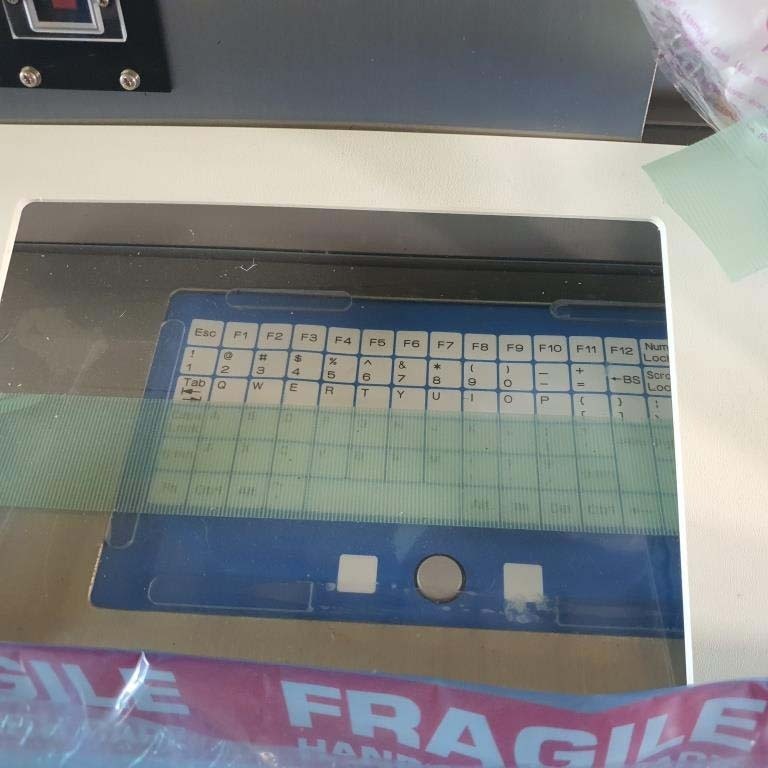

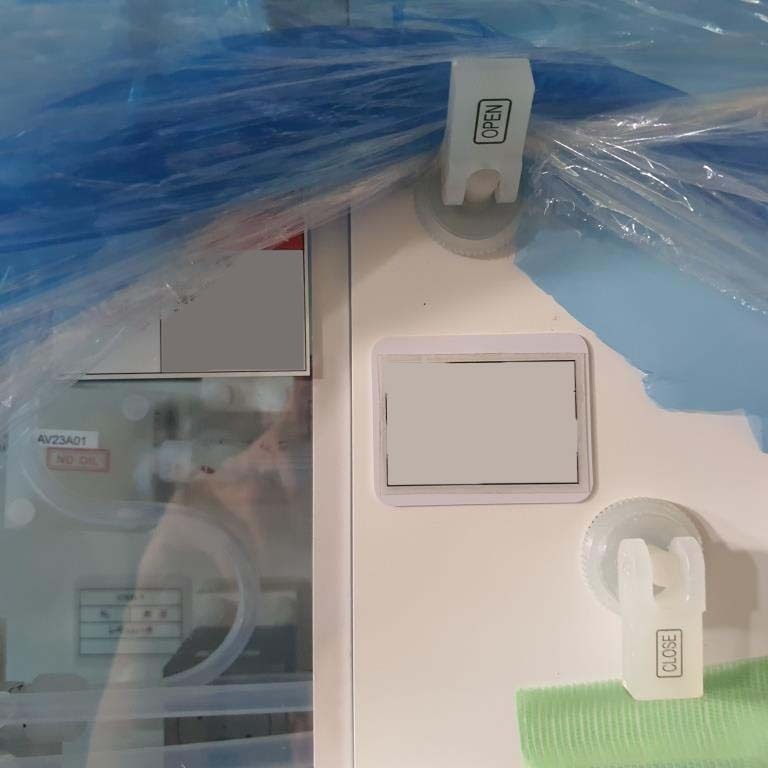

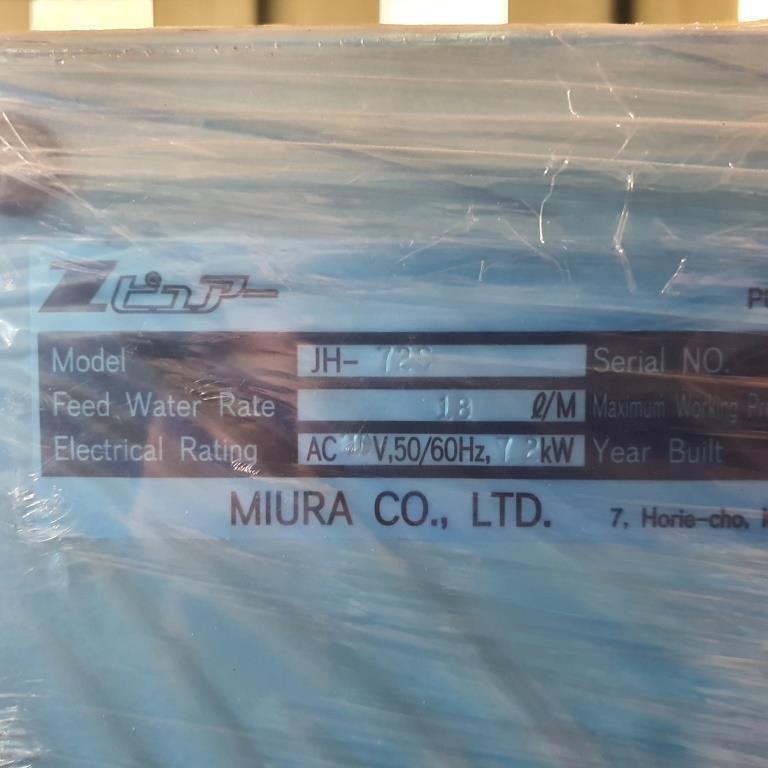

DNS / DAINIPPON FC-821L is a wet station designed for chemical and electrochemical processing. It is a versatile and reliable platform for wet etching and other material removal processes. It features an automated XY XYZ motion control system, with simultaneous and sequential processing capability. The XYZ motion control system is designed to allow repeatable and accurate sample manipulation, while operating at very fast cycle times. It is equipped with motion control, independent axis status monitoring, and optional auto focus. It also features programmable auto repeat and traceability, allowing users to precisely repeat processes. DNS FC-821L wet station was designed specifically for the removal of thin films by etching, deburring, and abrasive blasting. It features four stainless steel wet process tanks designed to provide an ideal environment for immersion processes. The tanks feature temperature control and adjustable Level Control, allowing users to perform a variety of chemical etching processes. The wet station also includes a built-in spindle for facilitating sample removal. The low speed spindle eliminates any potential for harmful splashing and is designed to encapsulate the sample in a protective housing. All pipes and components on the wet station are made from stainless steel for easy cleaning and maintenance. In addition to the technical features of the wet station, DAINIPPON FC 821L also offers the benefit of a compact design. It can be installed in just a few minutes and its compact size make it easy to move around and store. It features a built-in controller/PC, and all pumps, valves, etc. are connected via industry standard ports. DNS / DAINIPPON FC 821L wet station is a valuable tool for material removal processes. It is accurate, reliable and easy to operate, allowing users to perform wet etching, abrasive blasting, deburring, and other material removal processes quickly and precisely. Due to its performance and features, it is becoming an increasingly popular choice for industrial, medical and research applications.

There are no reviews yet