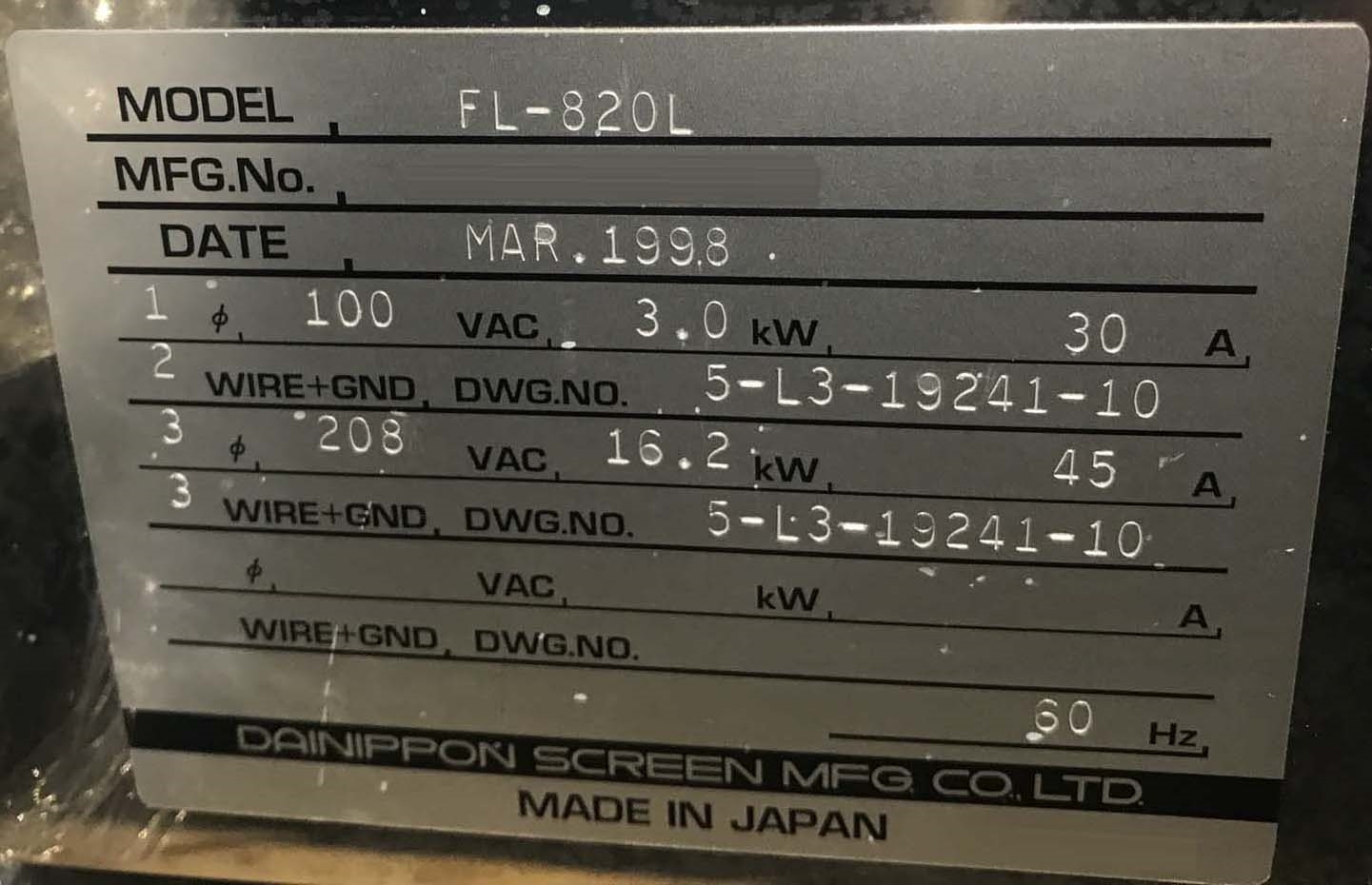

Used DNS / DAINIPPON FL-820L #9232578 for sale

URL successfully copied!

Tap to zoom

DNS / DAINIPPON FL-820L is a multi-purpose wet station designed to provide a range of services for coating, metallizing, electroplating, etching and other surface treatment activities. The station can be used for a variety of substrate materials including metal, glass, plastic, ceramic and other non-metallic materials. The station is fitted with a host of features to make work easier and more efficient. It consists of a four-sided chamber that can be customized to accommodate a variety of applications. On the back of the chamber is a hood that provides a tight seal and prevents liquid from entering the working area. The hood also prevents splashing of corrosive chemicals to the workspace. The station is equipped with an adjustable drain pan that can accommodate up to 10L of liquid and can be easily emptied and re-filled. The chamber is also fitted with two digital temperature controllers to regulate the temperature of the chamber. The temperature controller is water resistant and offers temperature stability up to +10°C. The station is fitted with a host of safety features, including an IR-sensor safety switch, air filtering system, ventilation fan and an emergency stop button. The station also features a filtration system that helps to minimize the amount of material that may enter the bath. Additionally, the station is fitted with a level detector, which monitors the bath level and automatically stops the pump when the bath reaches a certain level. The station is powered by 110V of AC power and has a power consumption rating of up to 500W. The station is suitable for both manual and automated production and can be integrated into assembly lines or on-site process lines. All parameters, such as the flow rate, temperature, pH value and other regulating parameters, can be adjusted easily and monitored conveniently via LCD display. DNS FL820L creates a safe and efficient environment for various wet processes. Its adjustability, low power consumption and safety features make it an ideal choice for coating, metallizing, electroplating, etching and other surface treatment processes.

There are no reviews yet