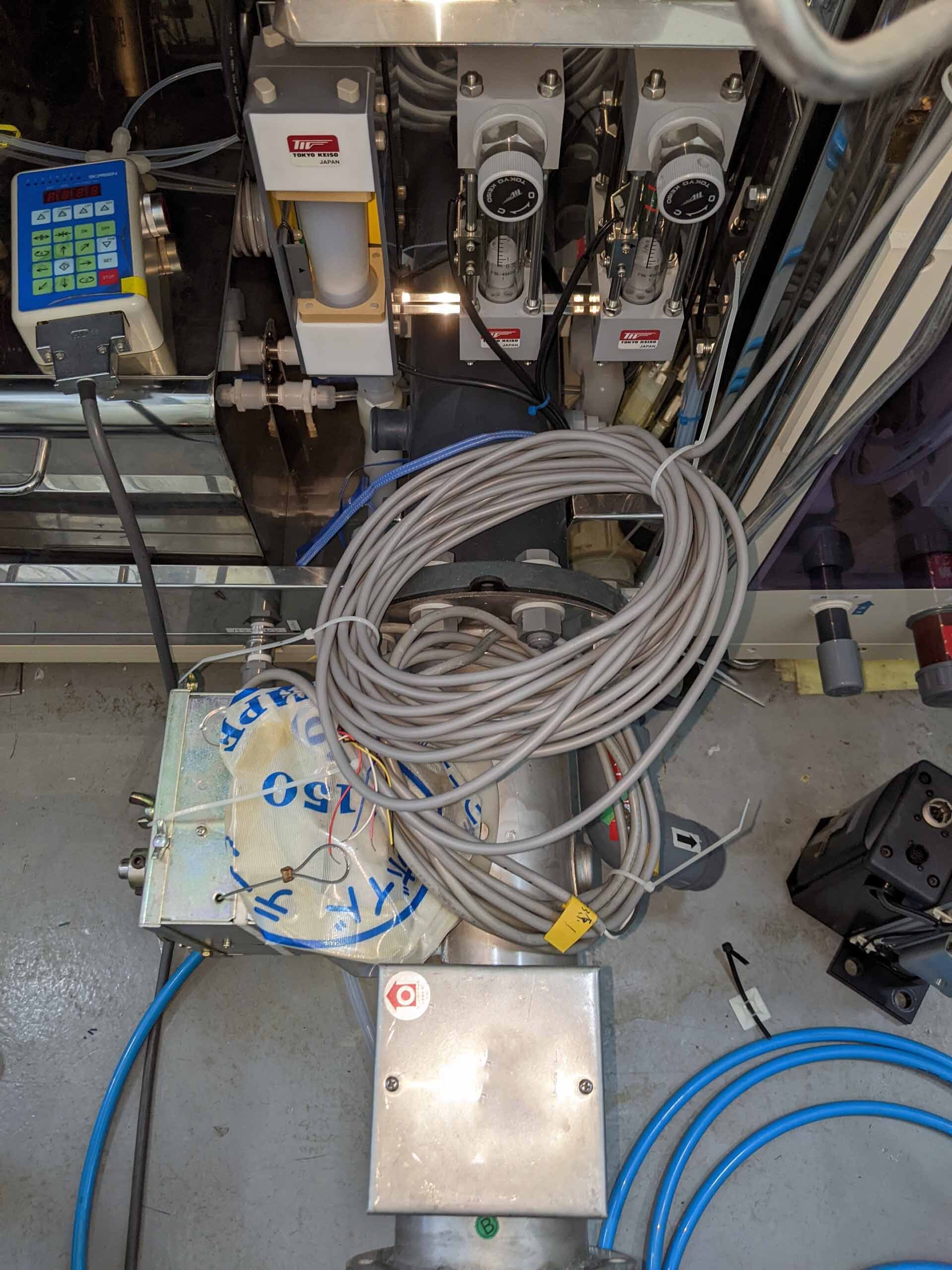

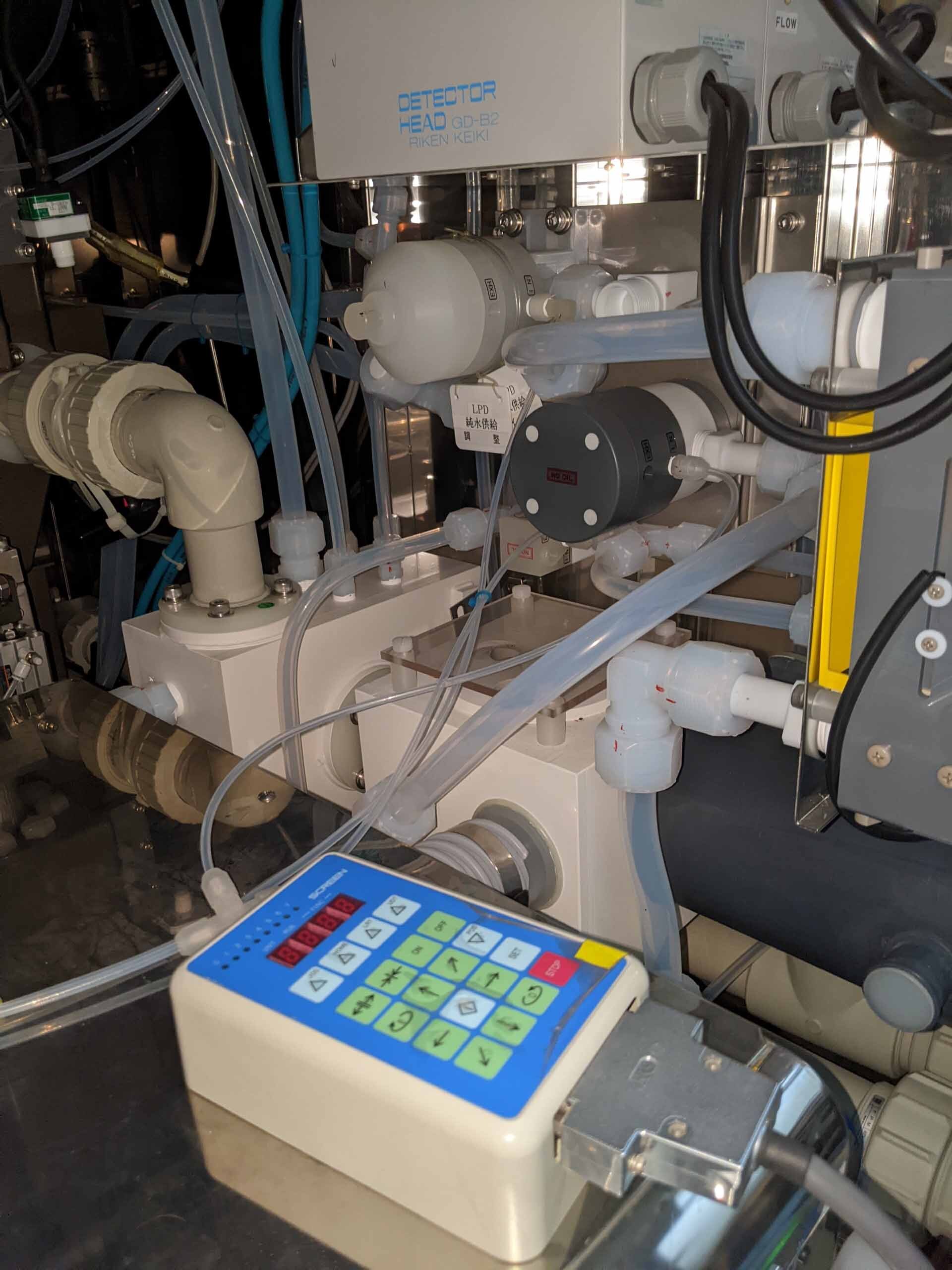

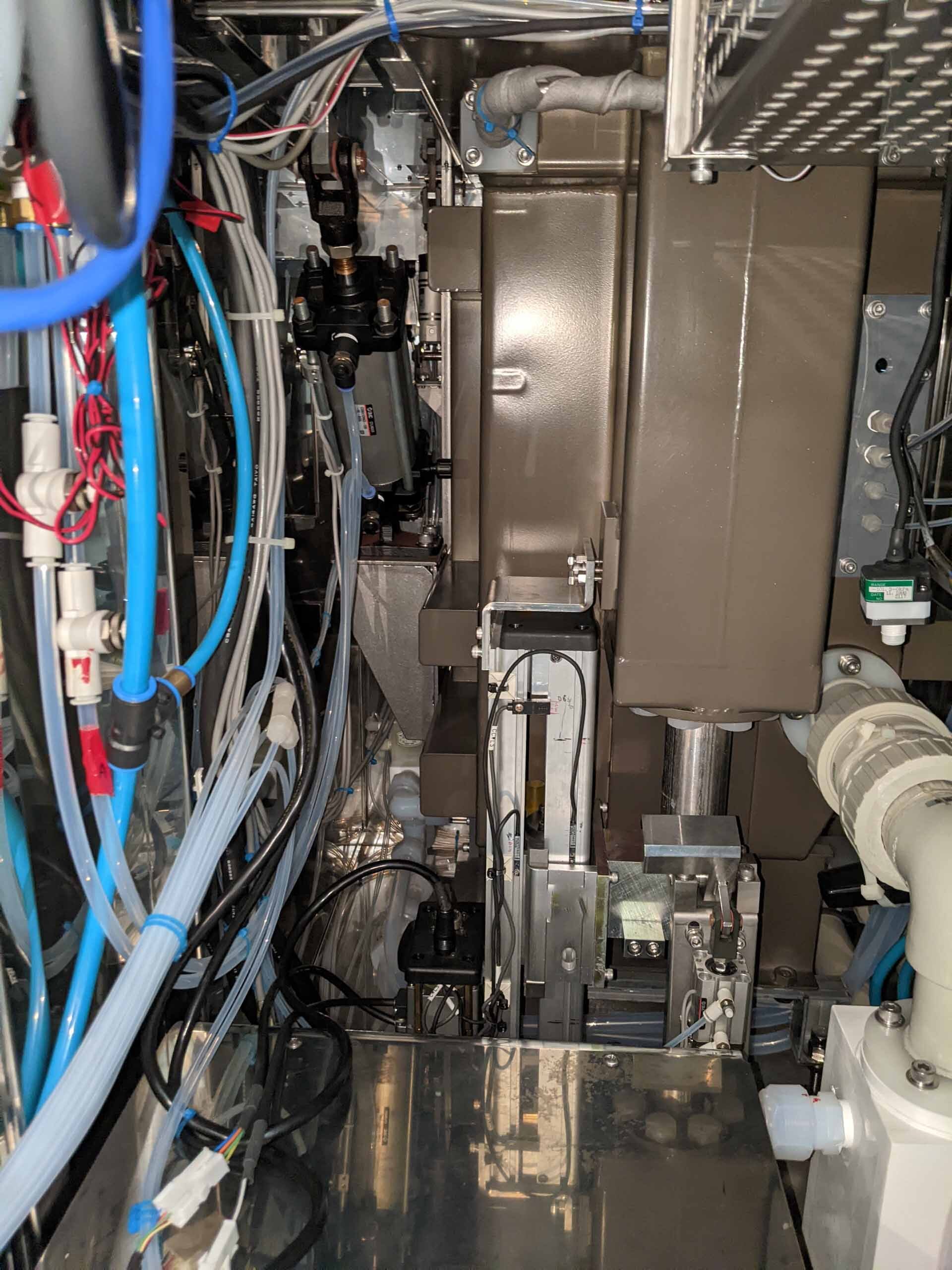

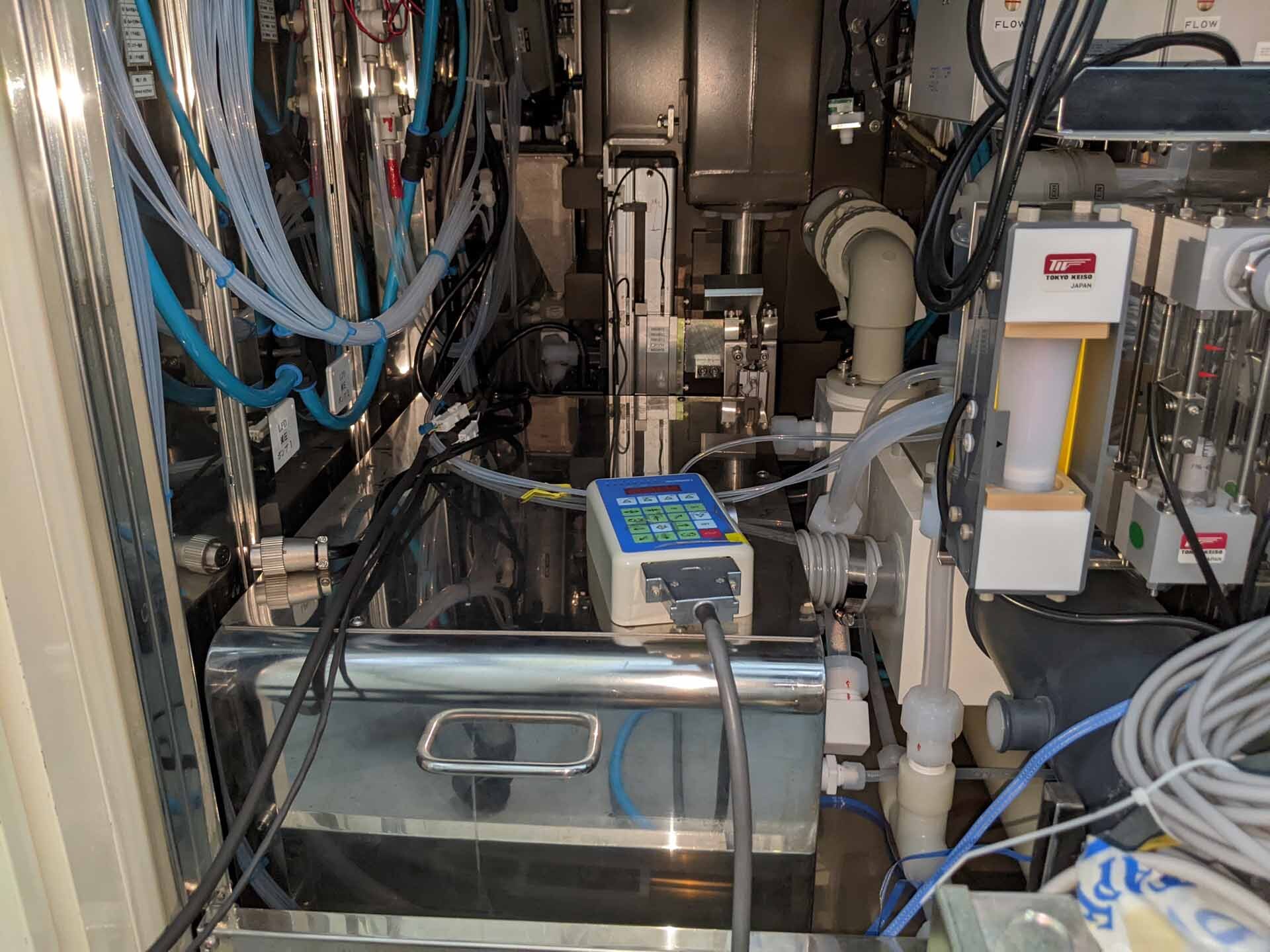

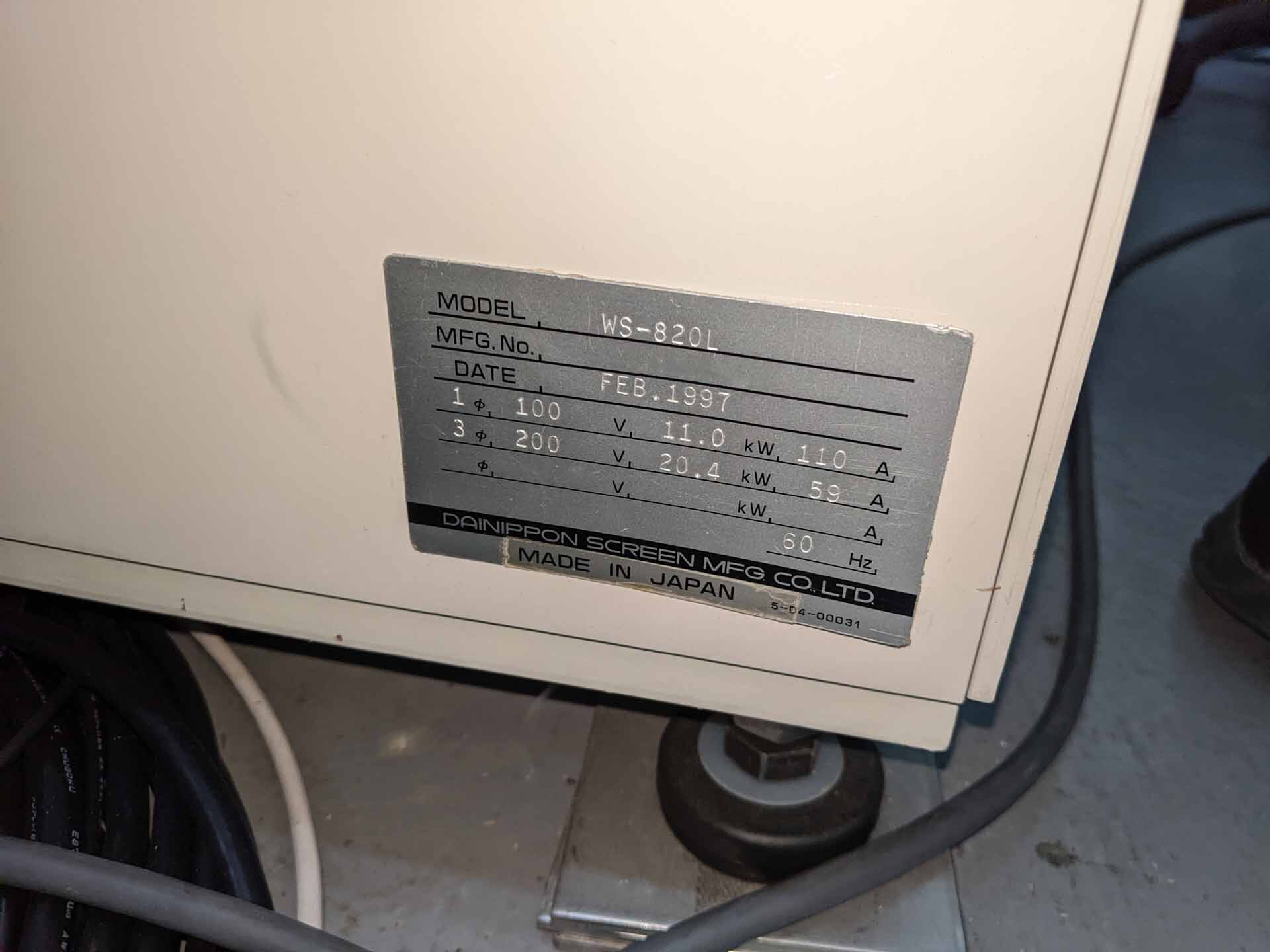

Used DNS / DAINIPPON / SCREEN WS-820L #9389670 for sale

URL successfully copied!

Tap to zoom

ID: 9389670

Wafer Size: 8"

Vintage: 1997

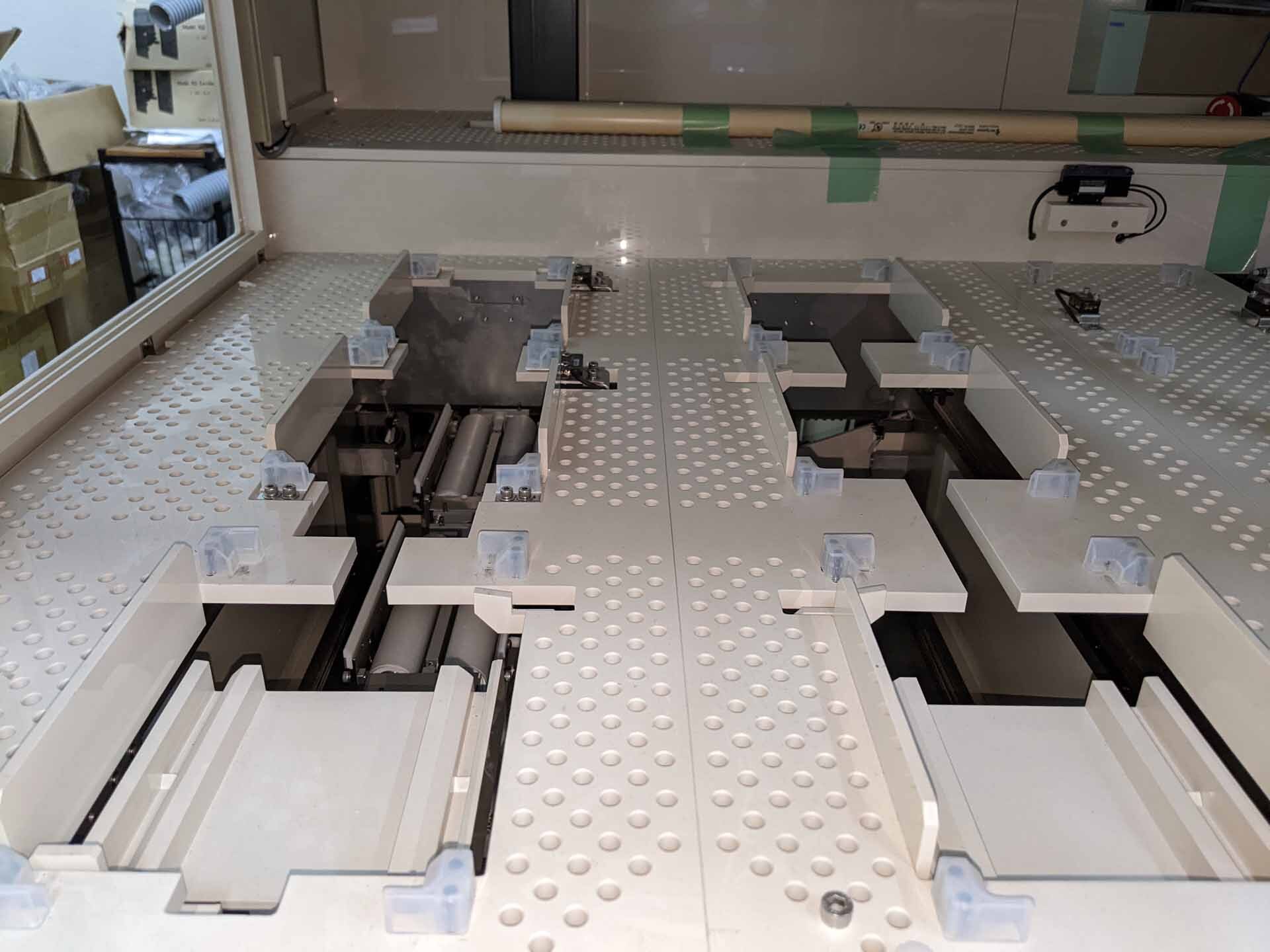

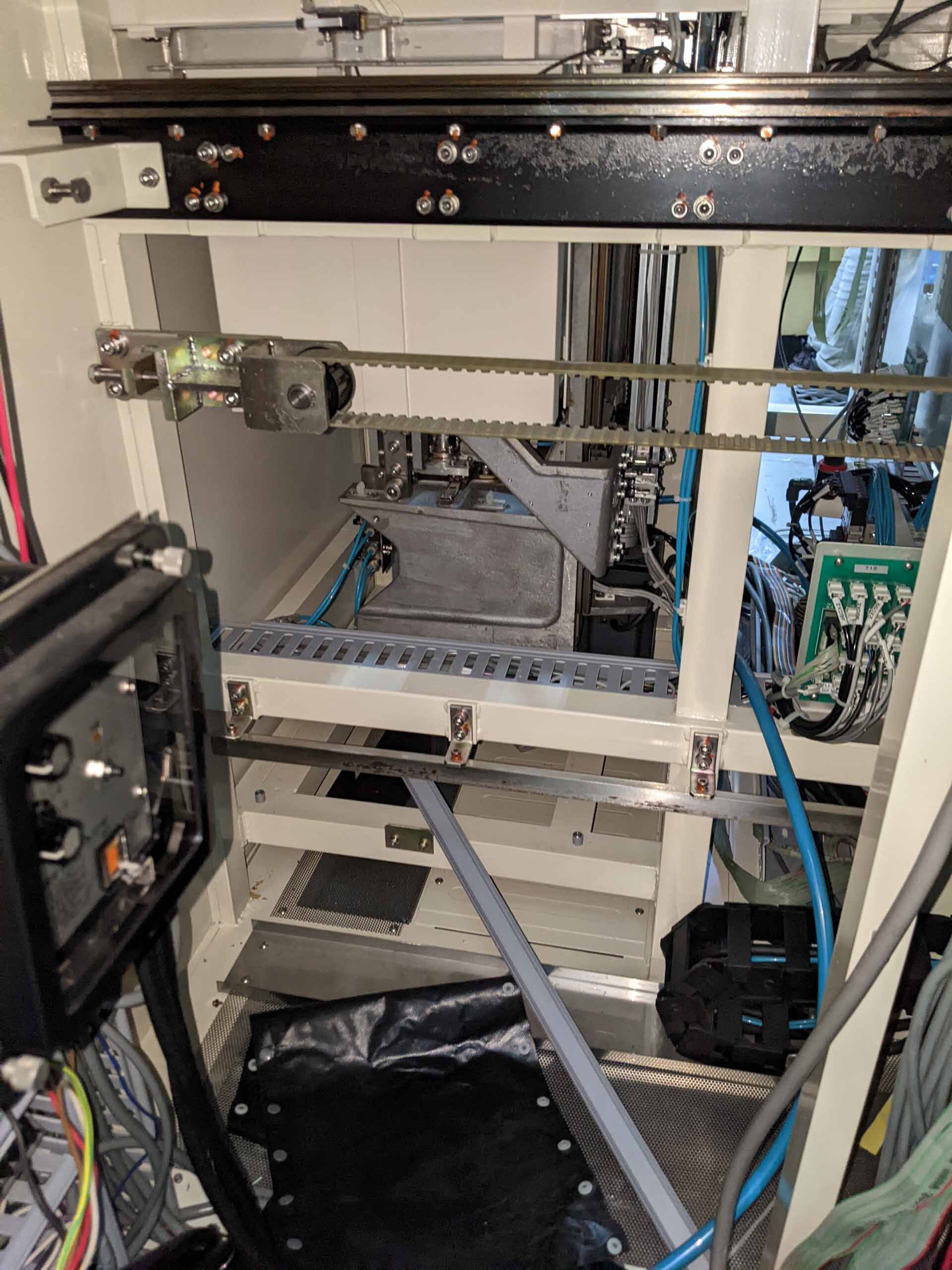

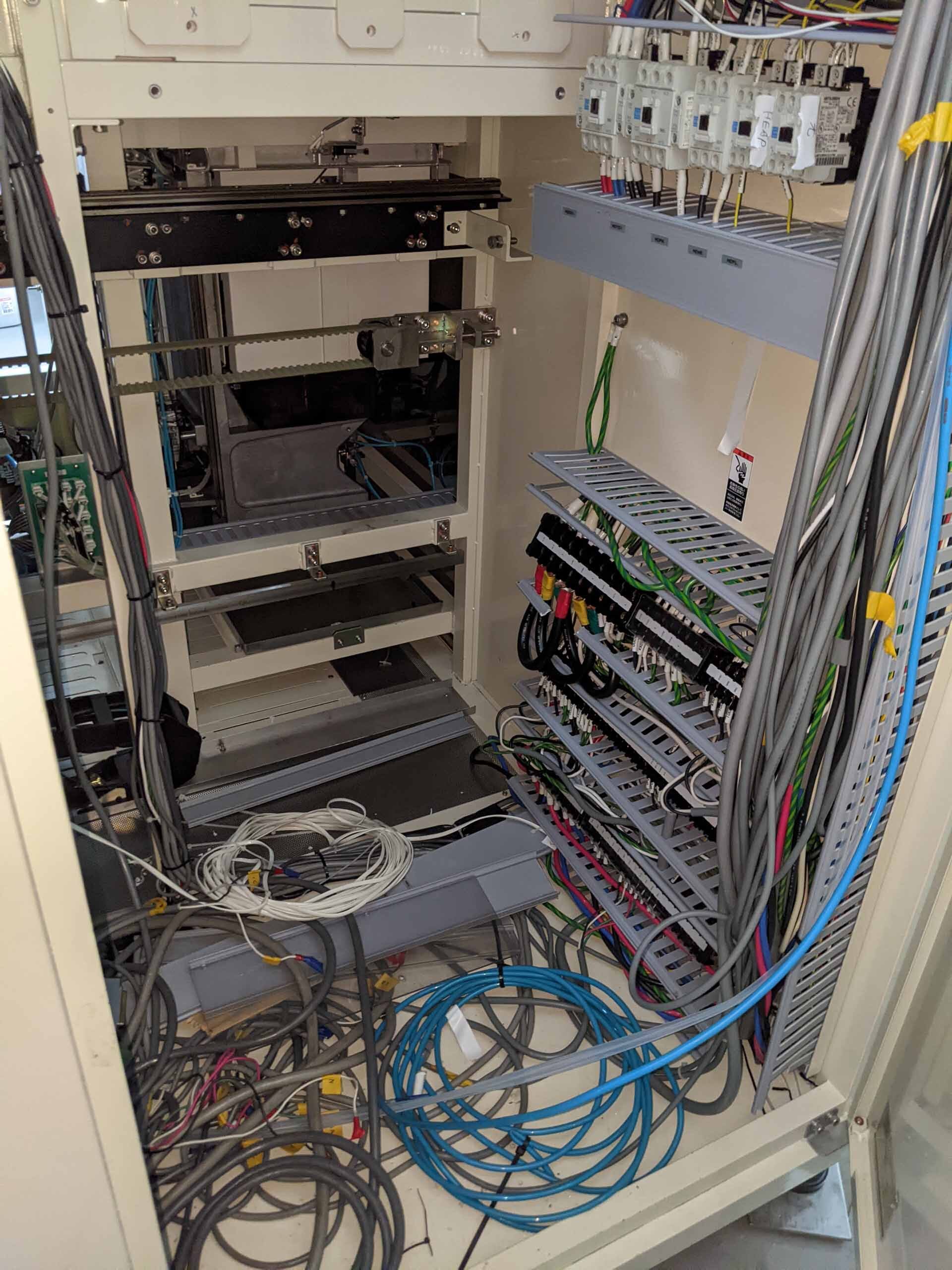

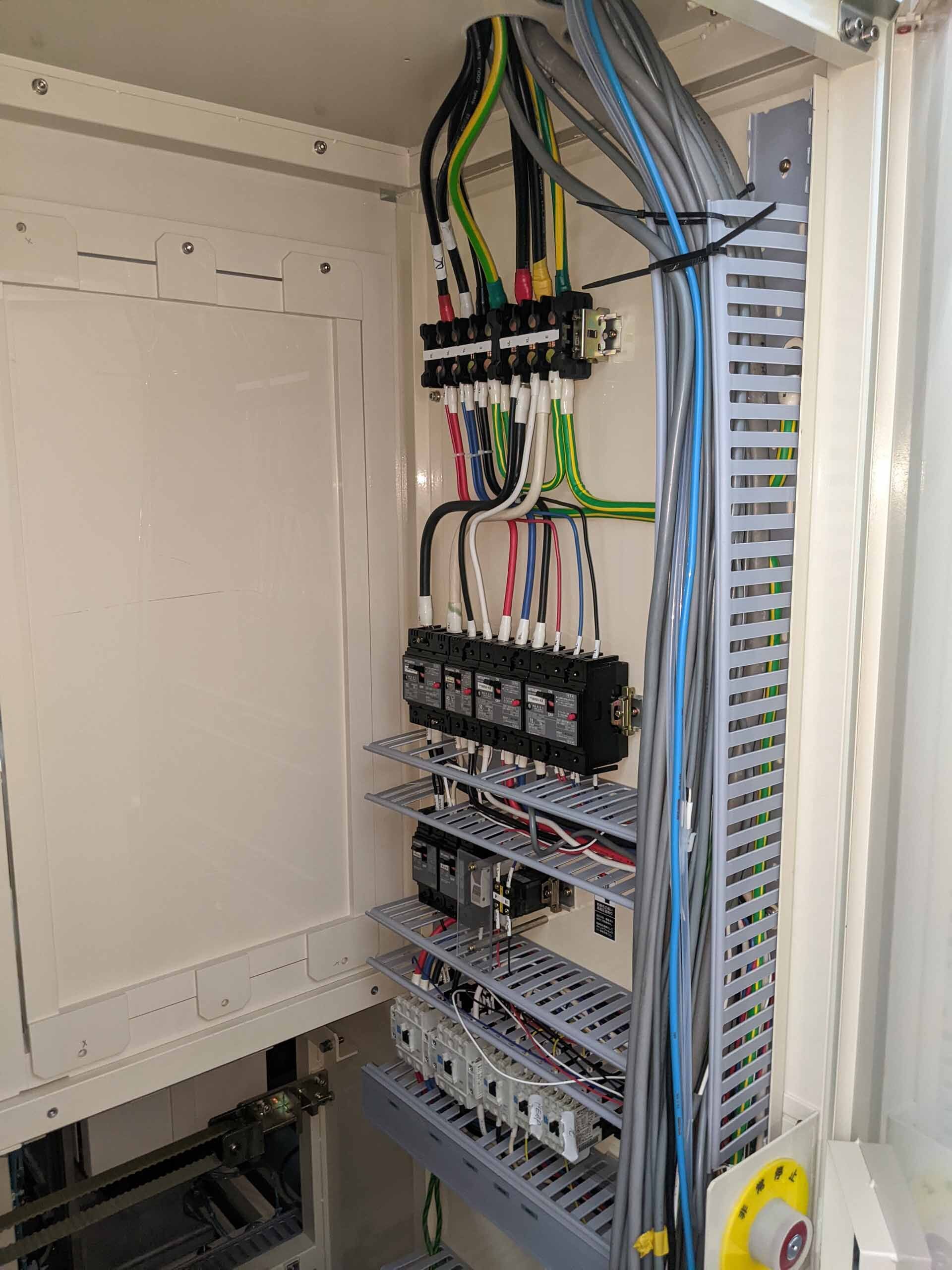

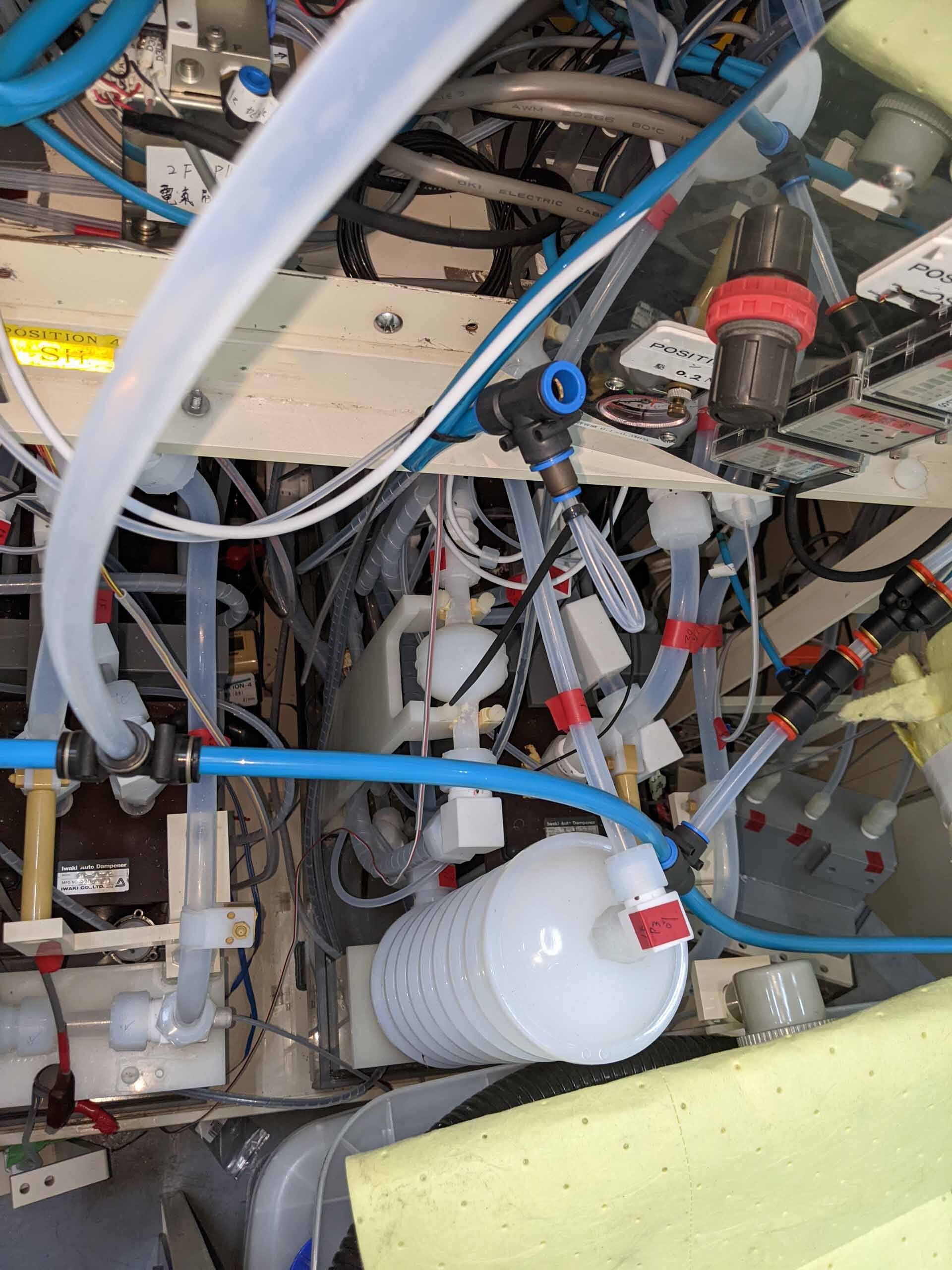

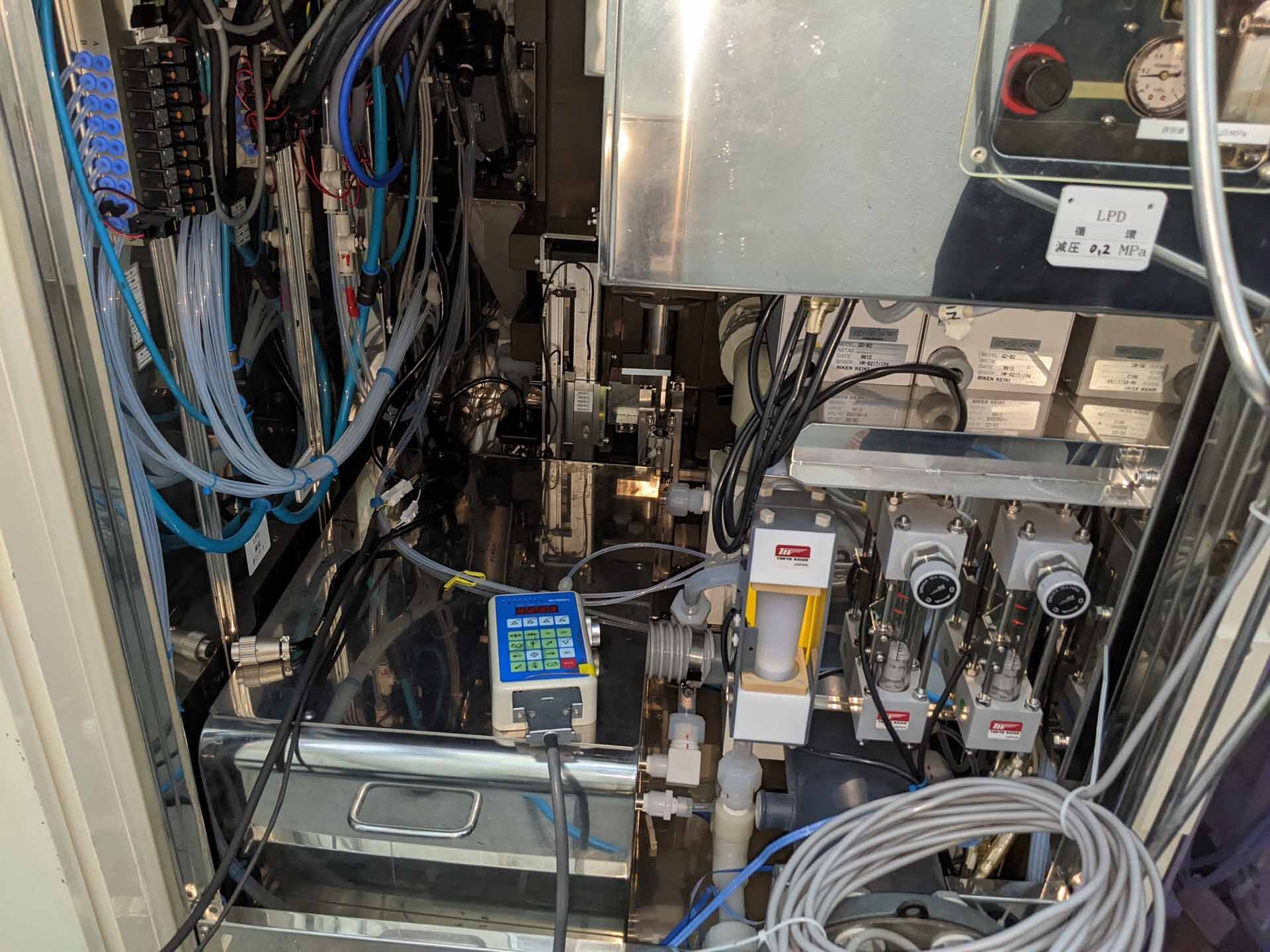

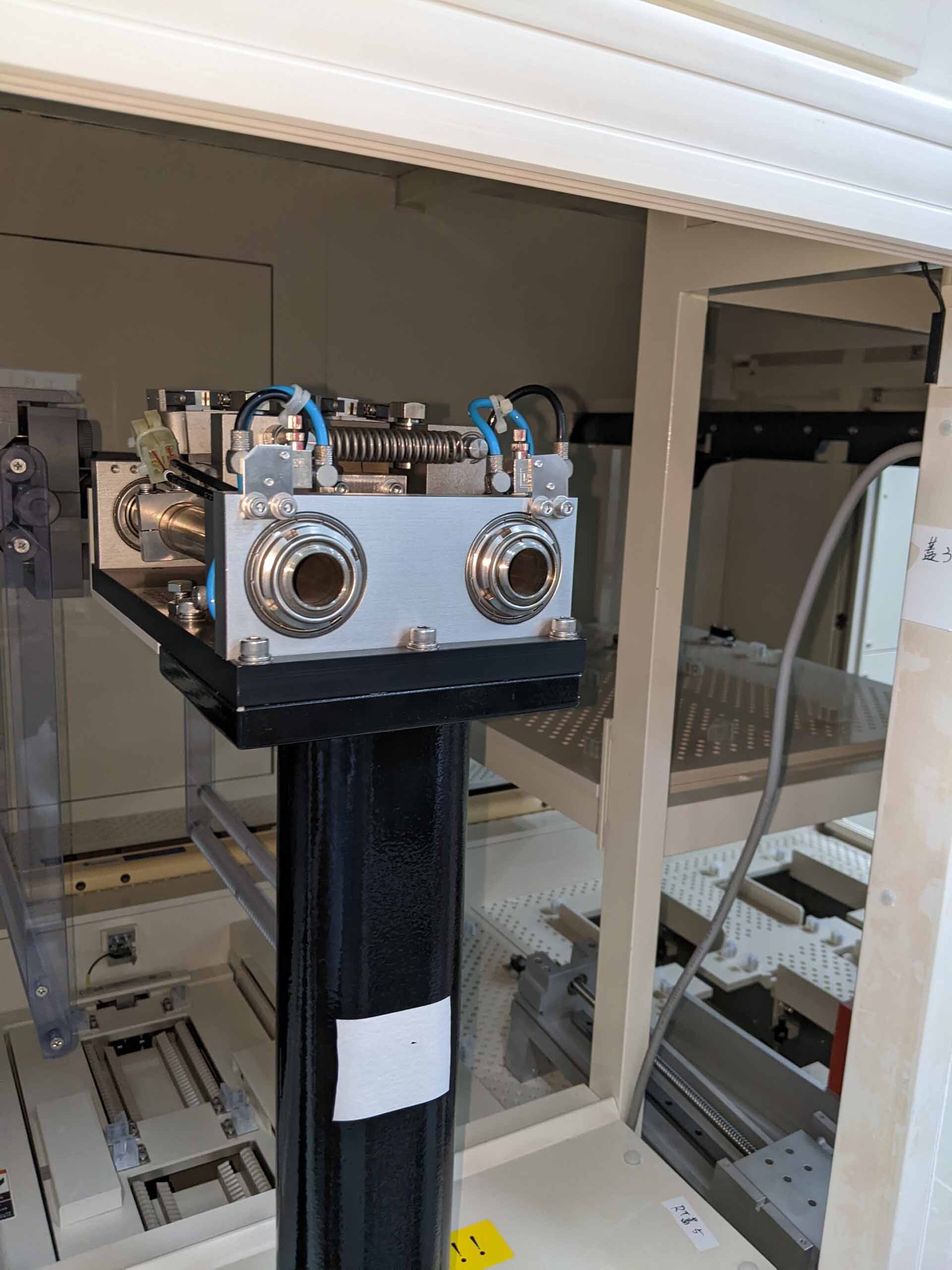

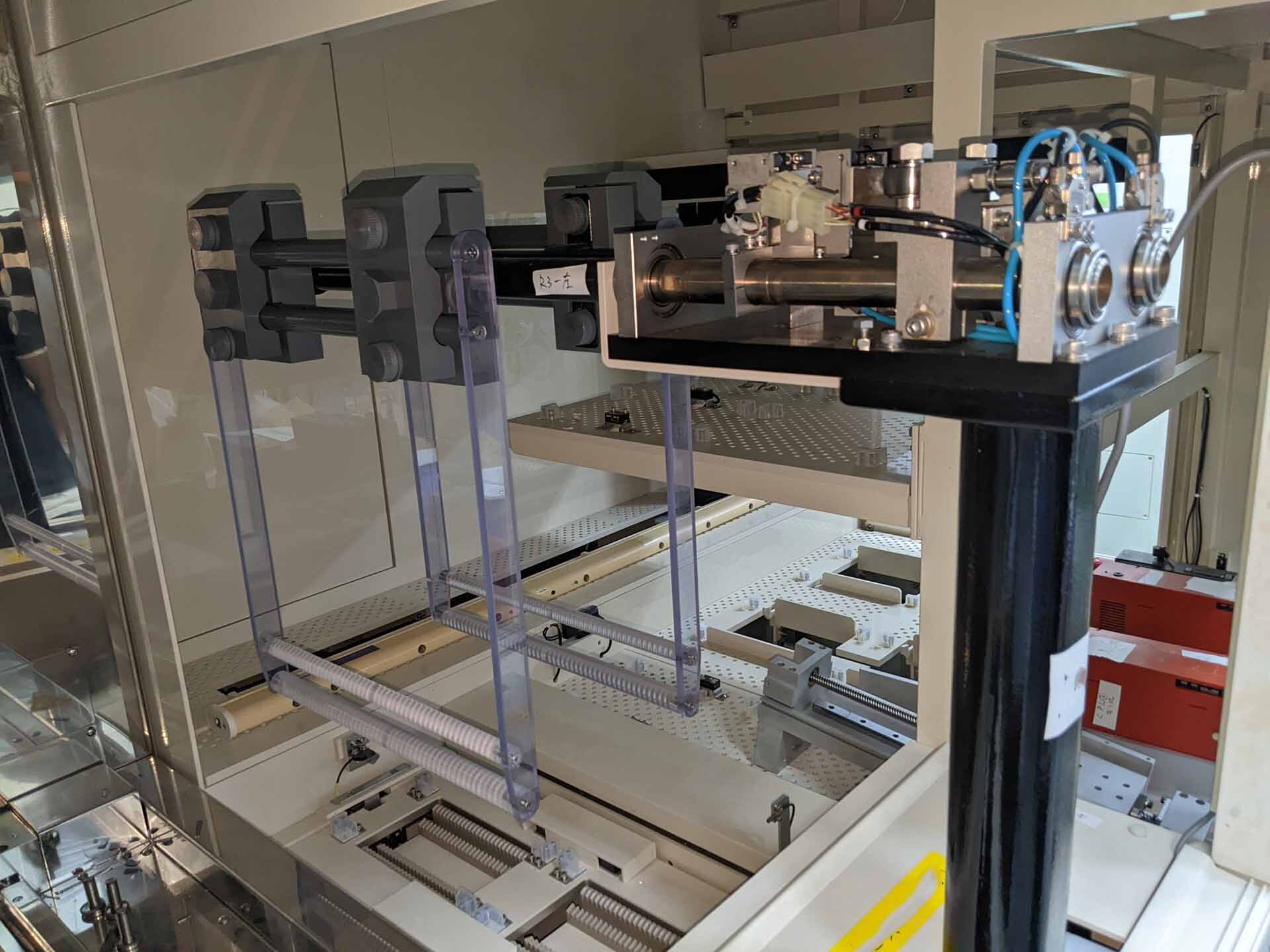

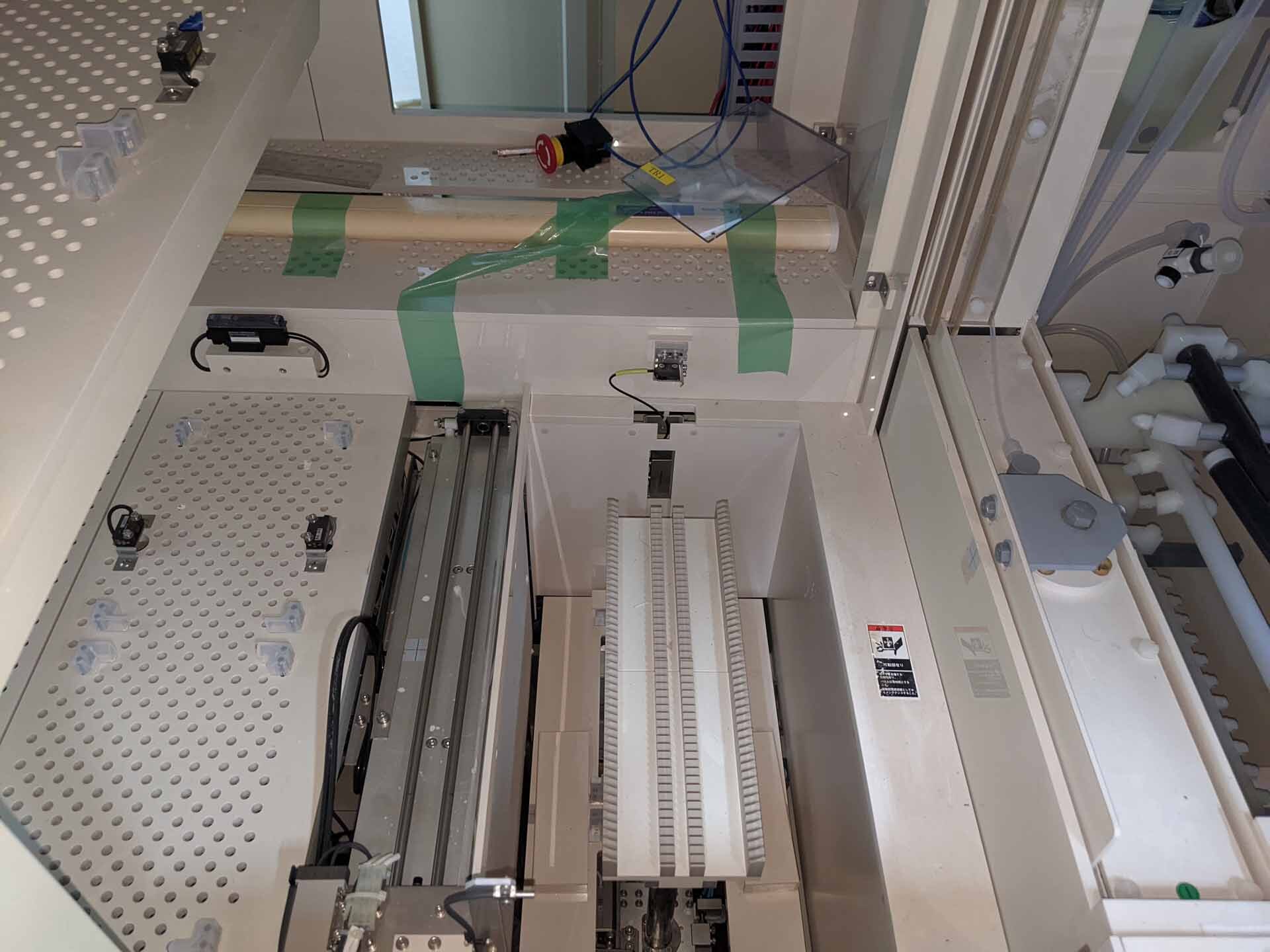

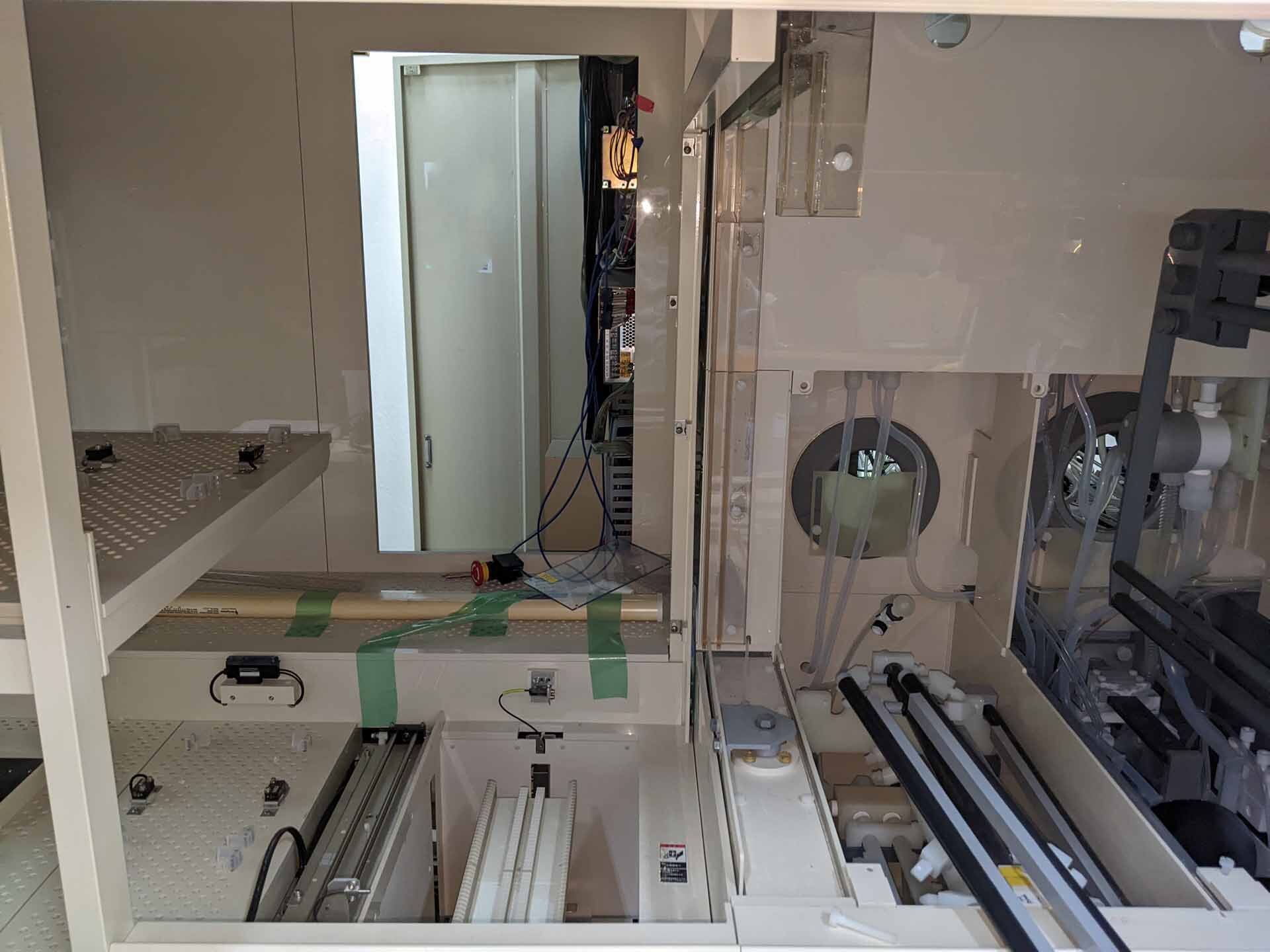

Wet station, 8"

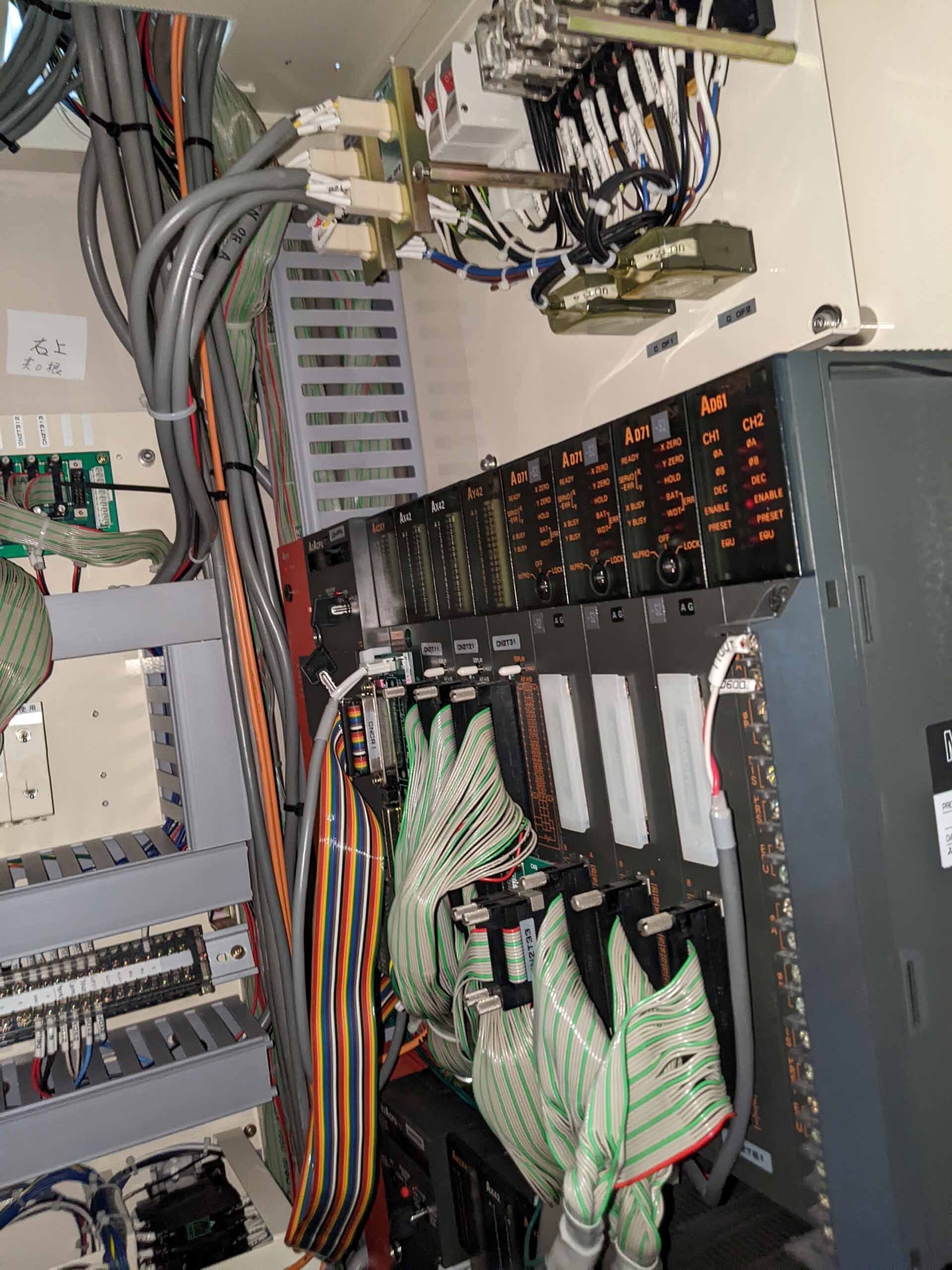

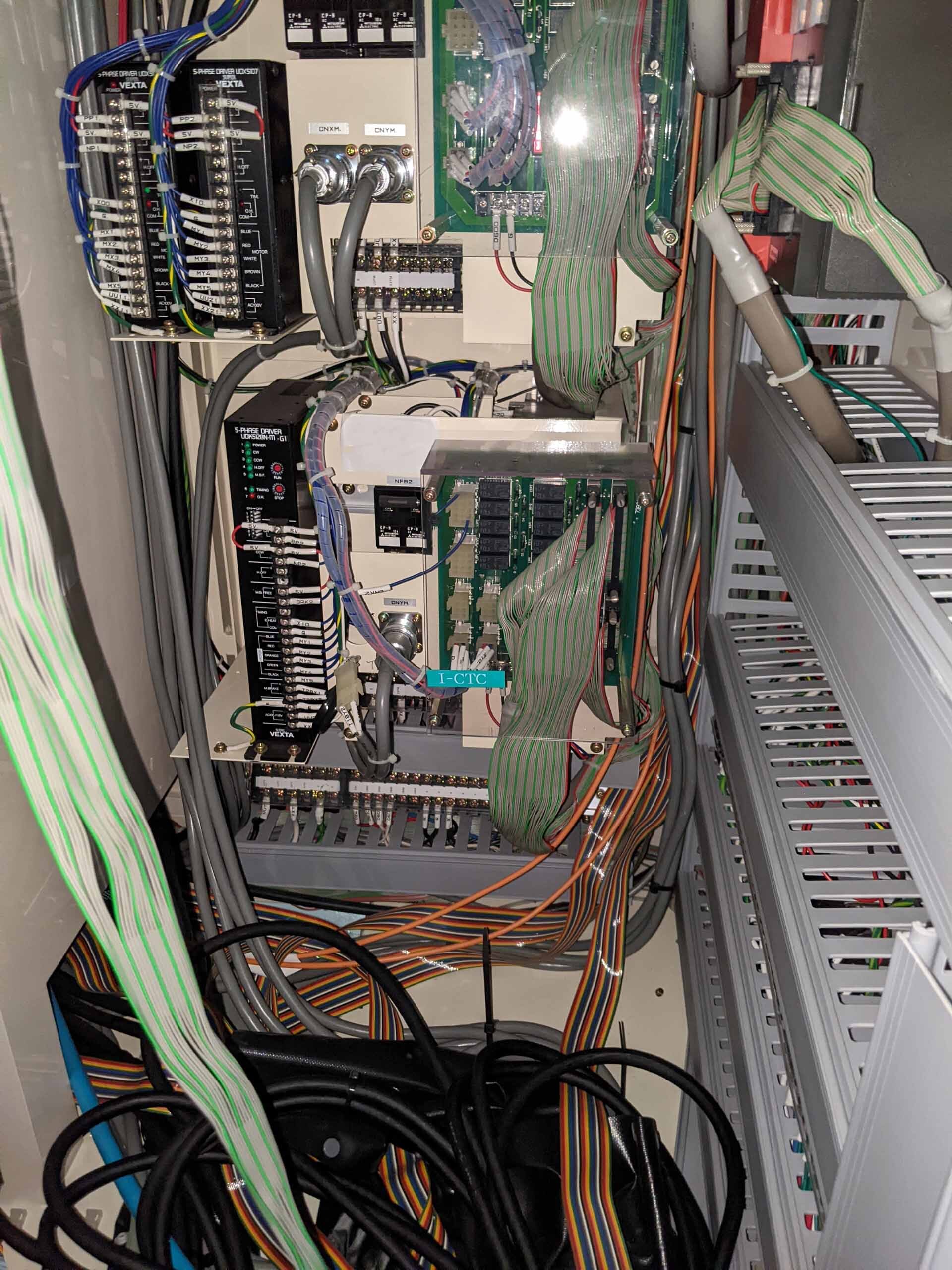

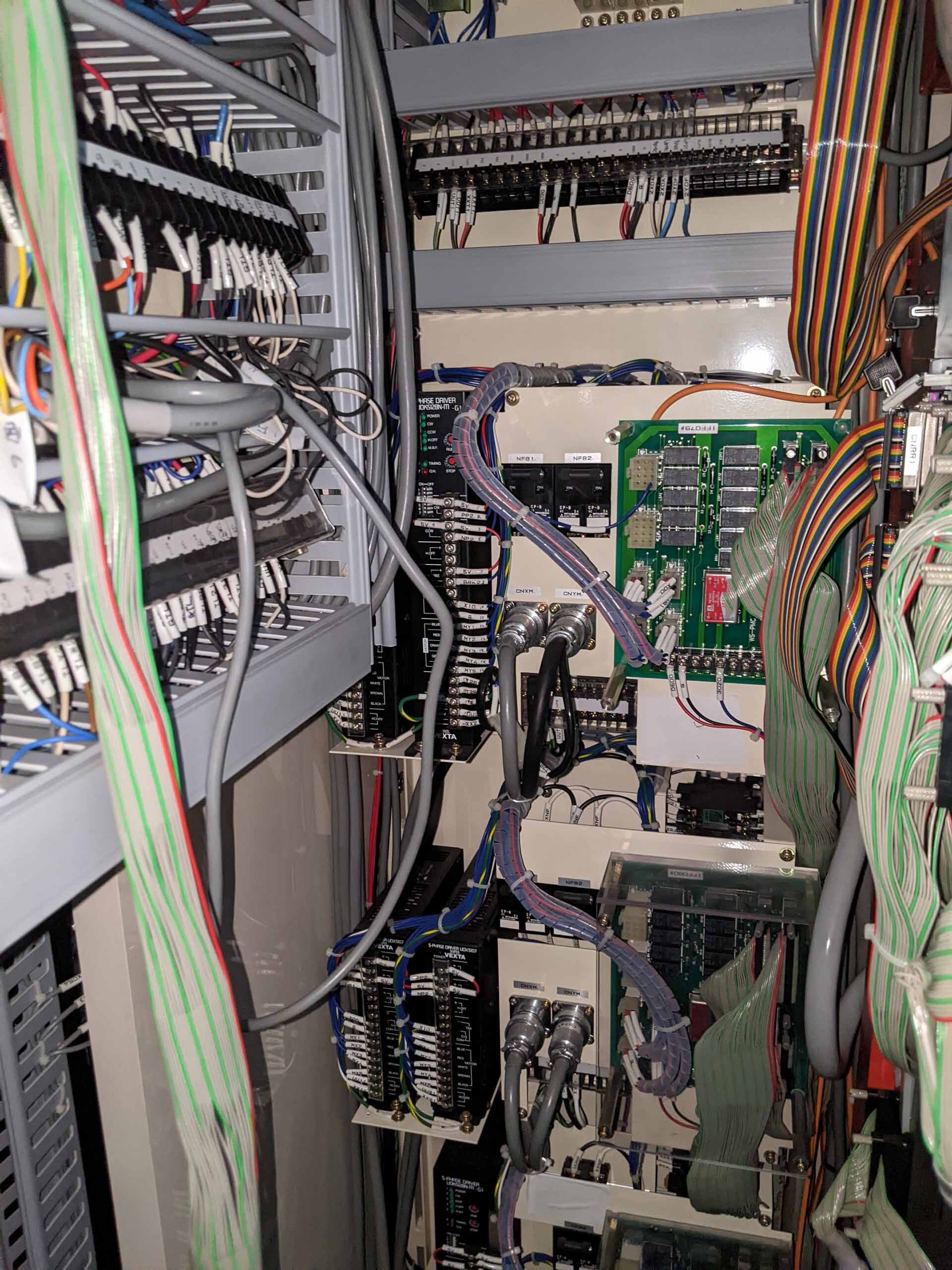

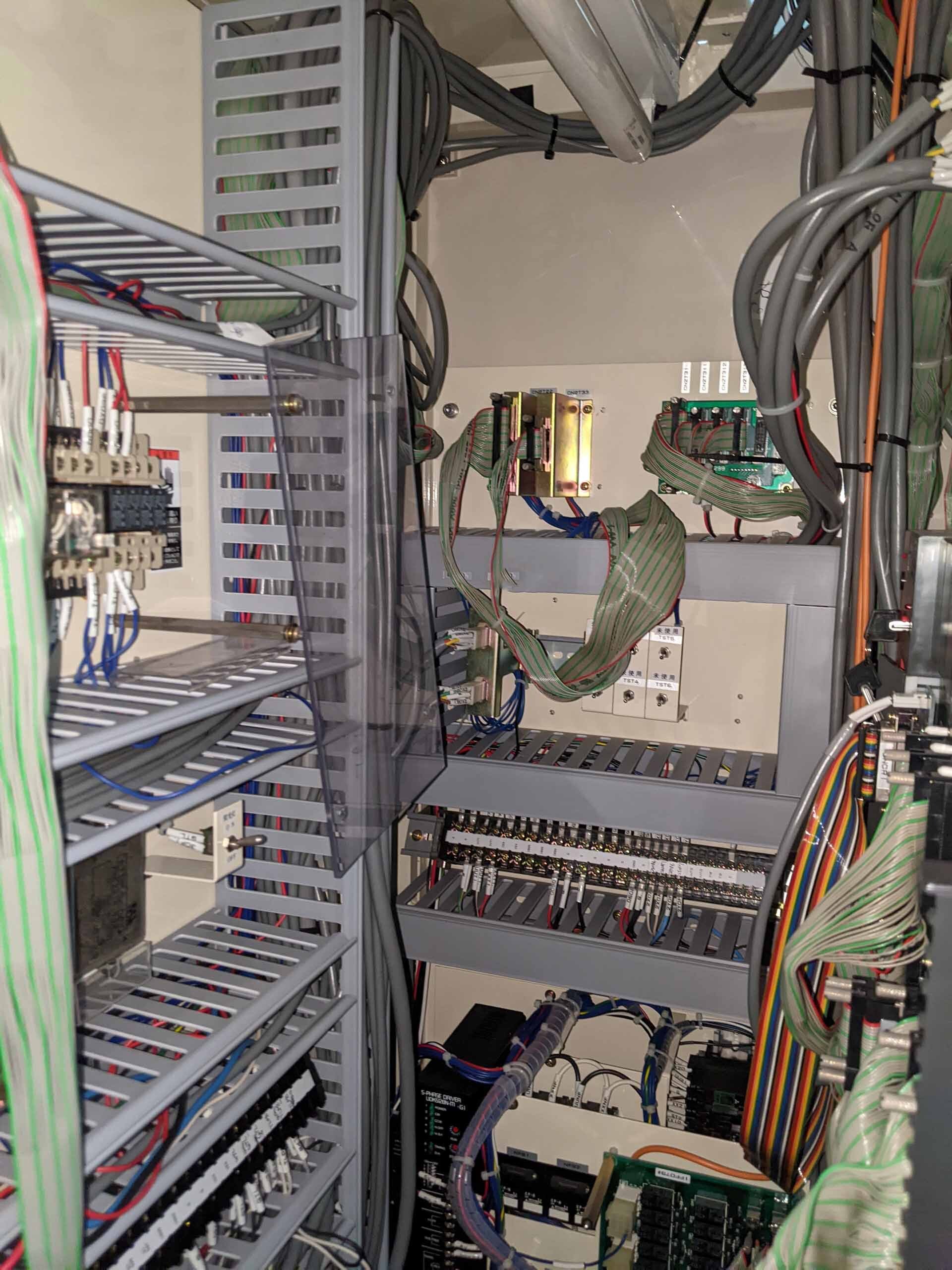

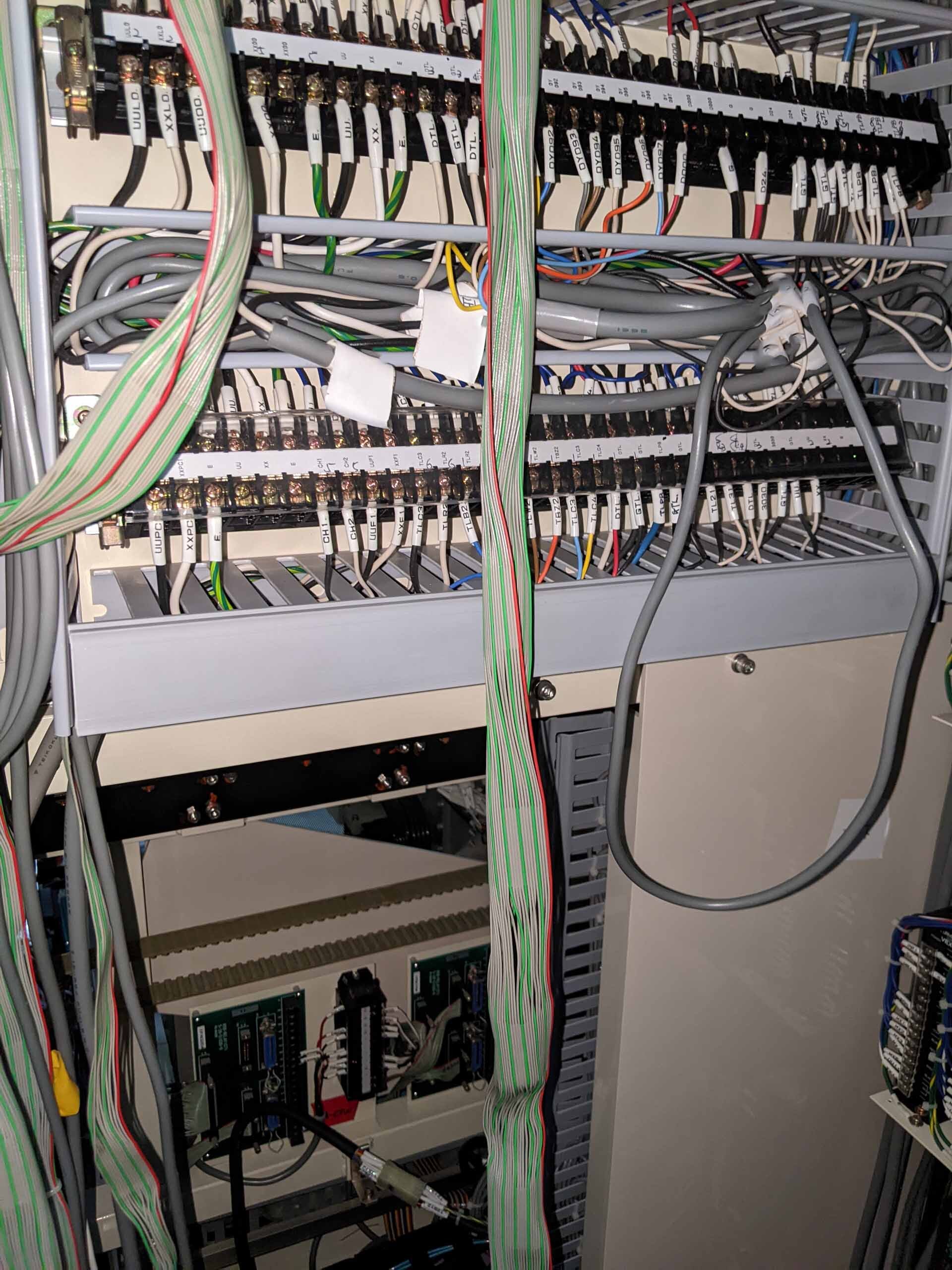

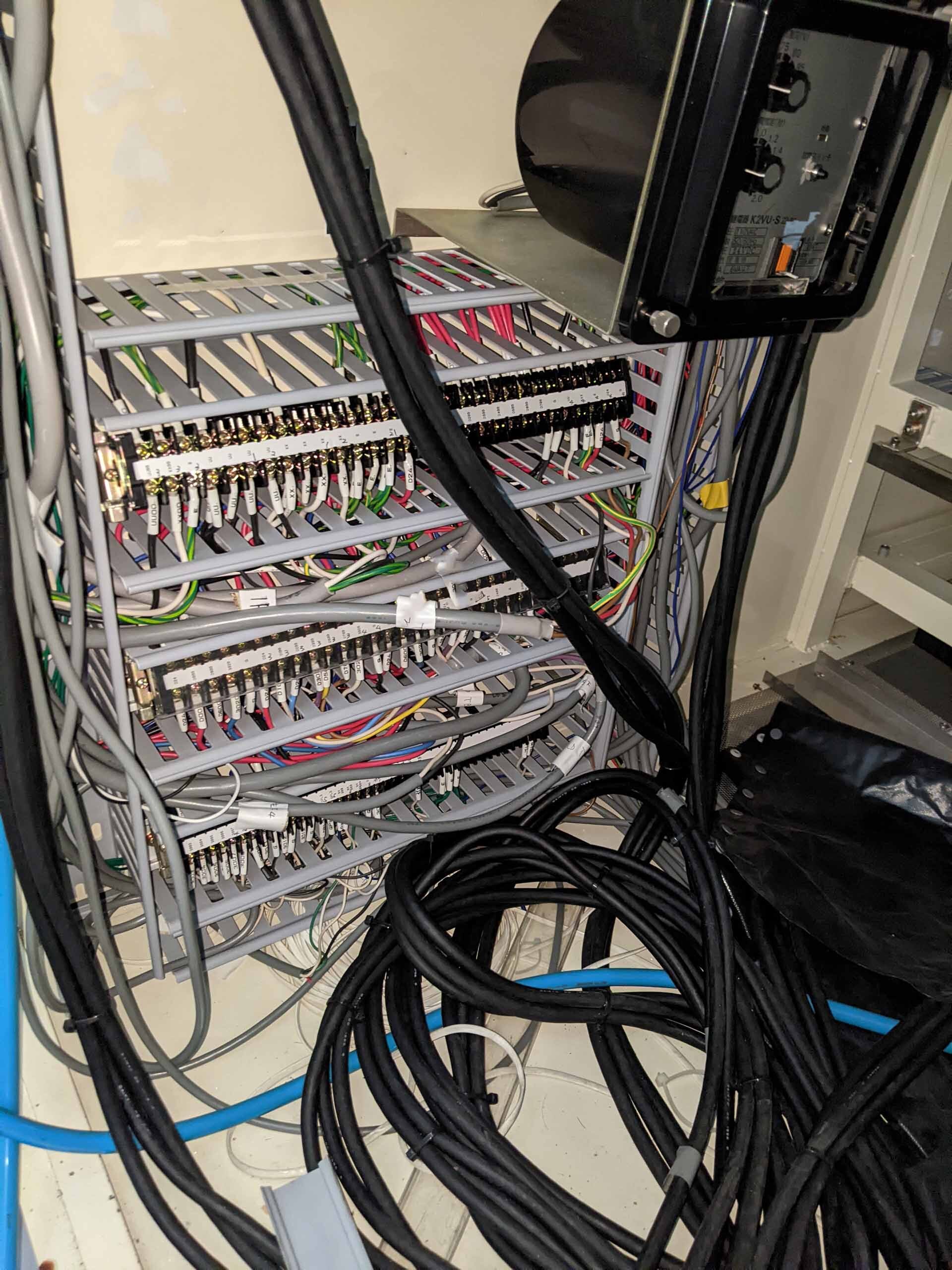

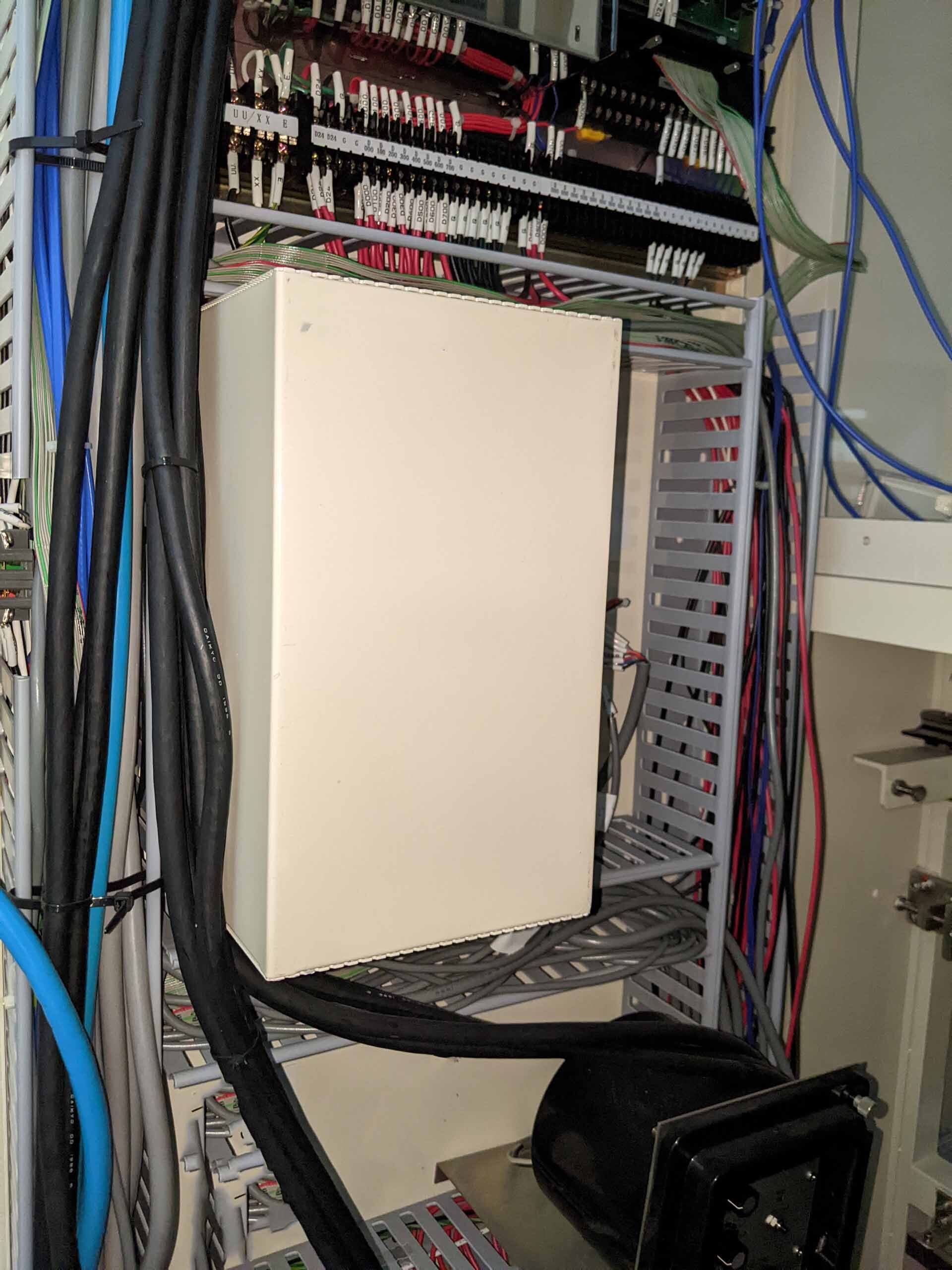

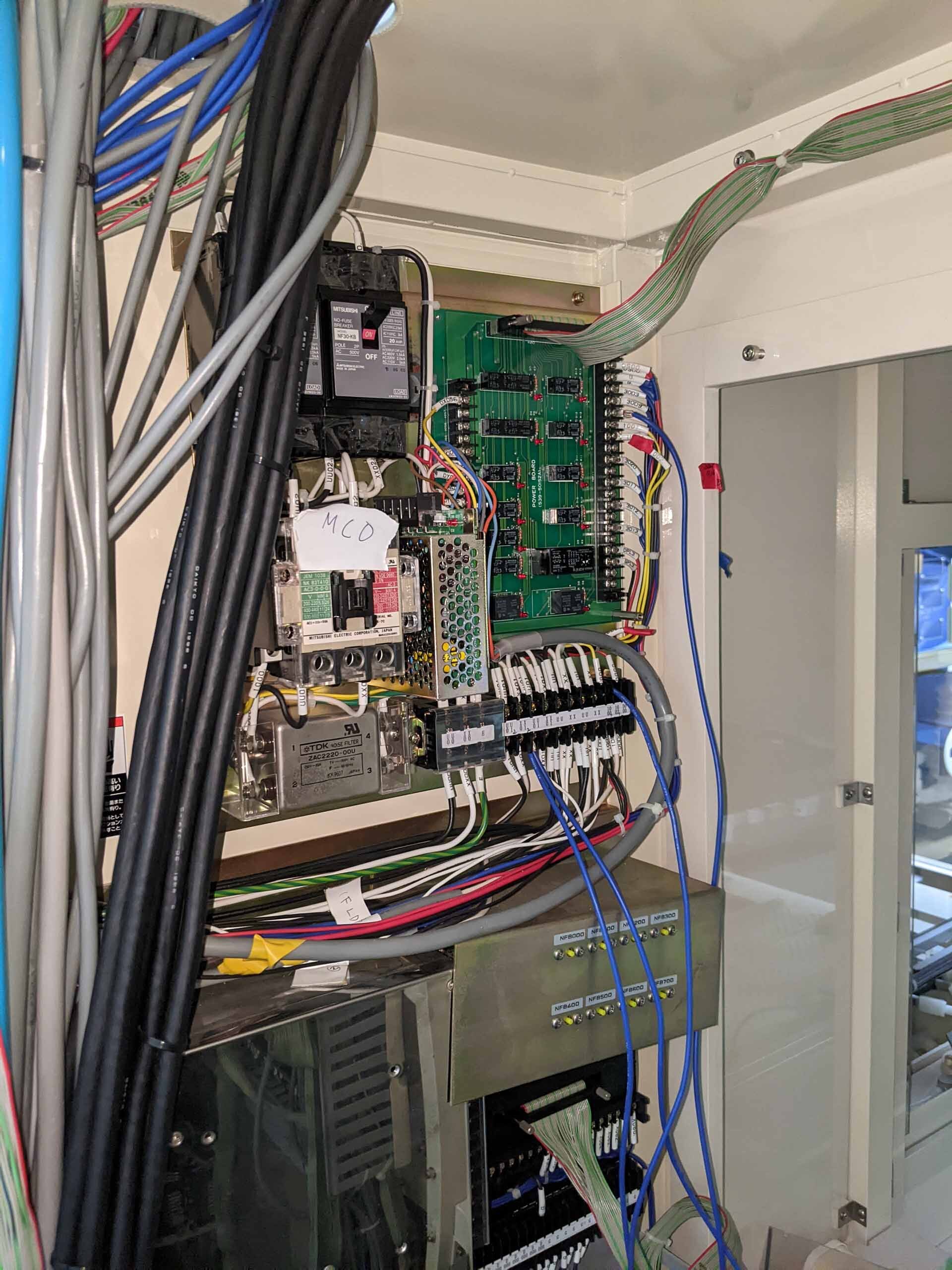

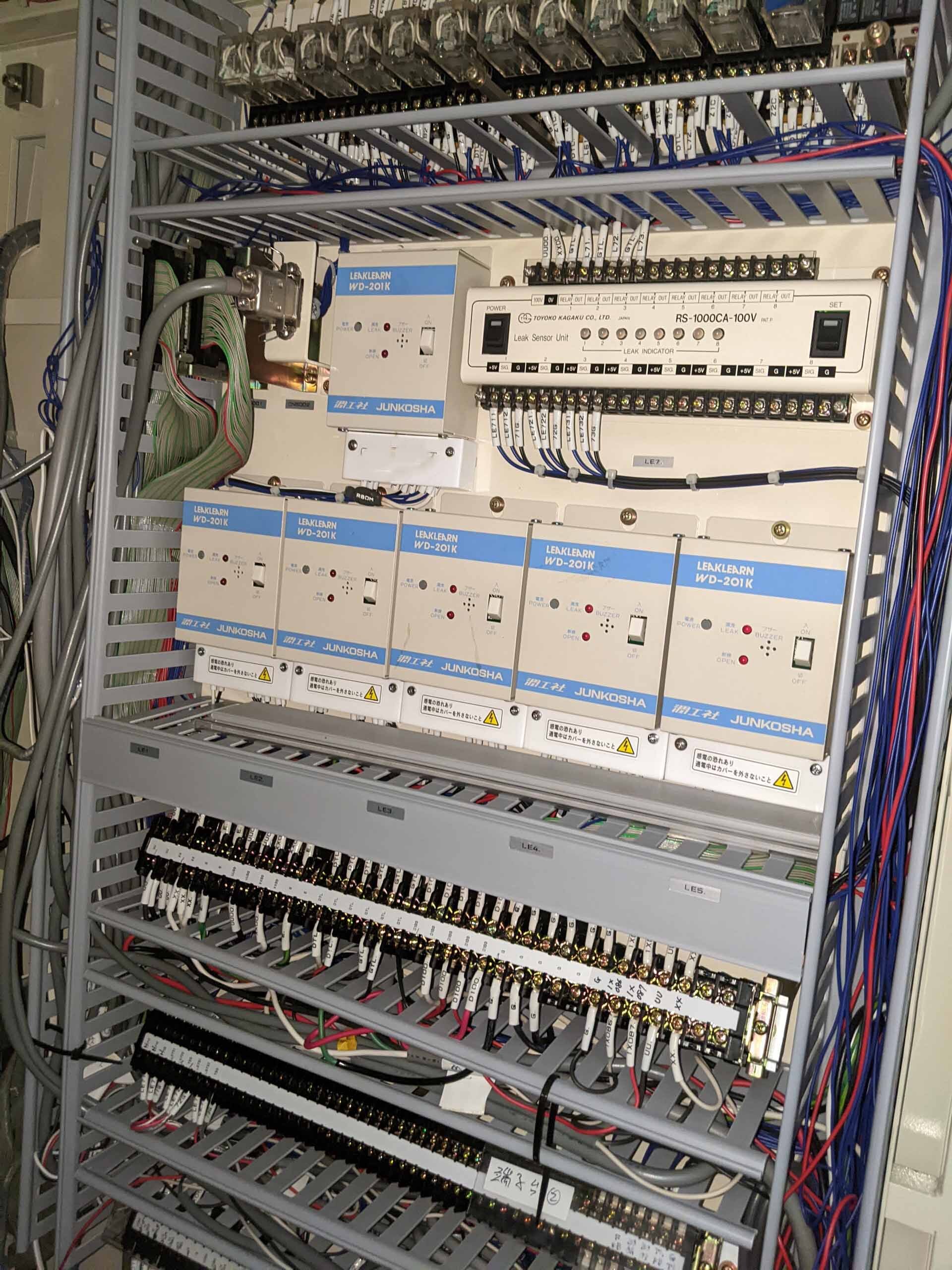

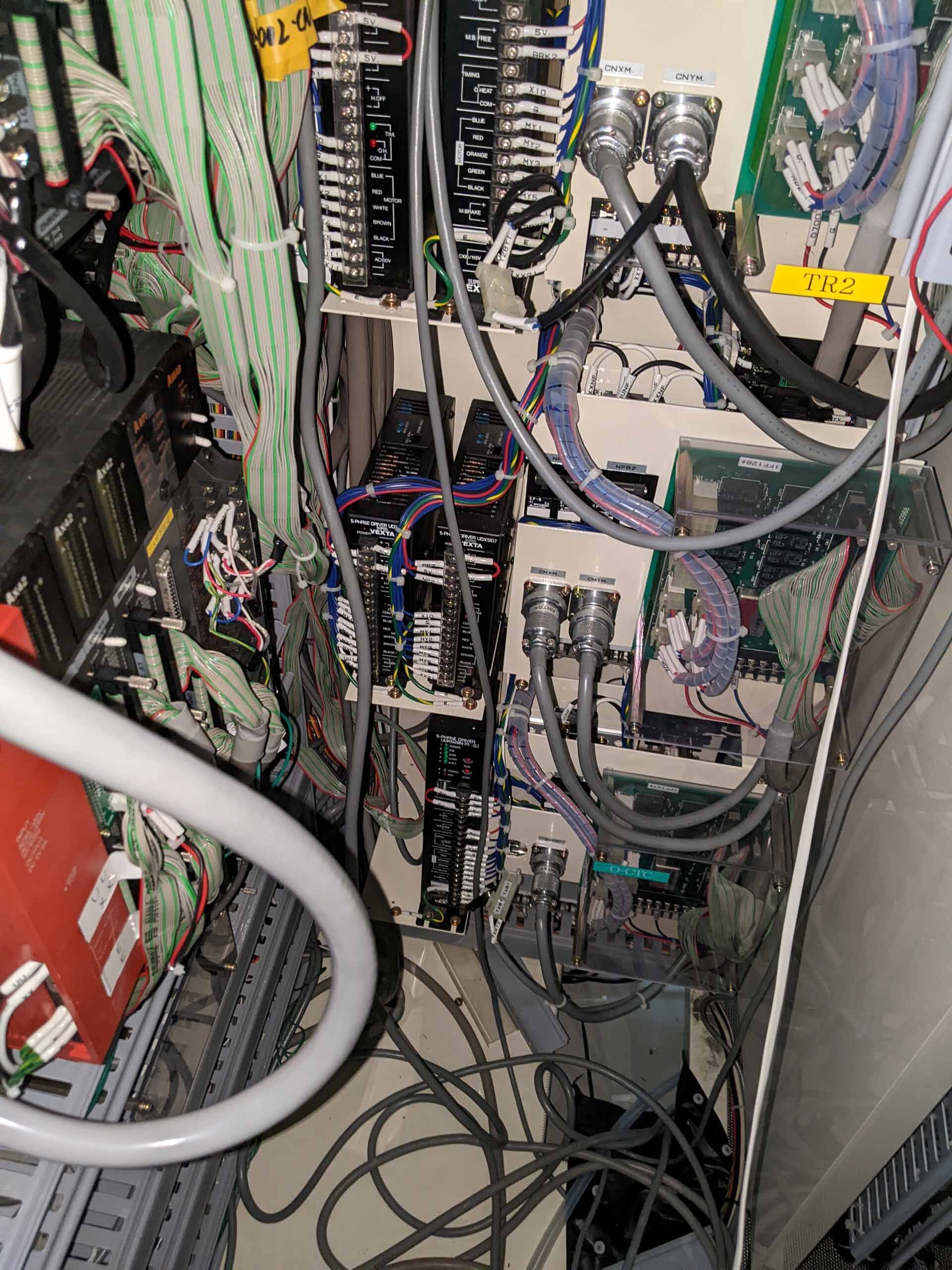

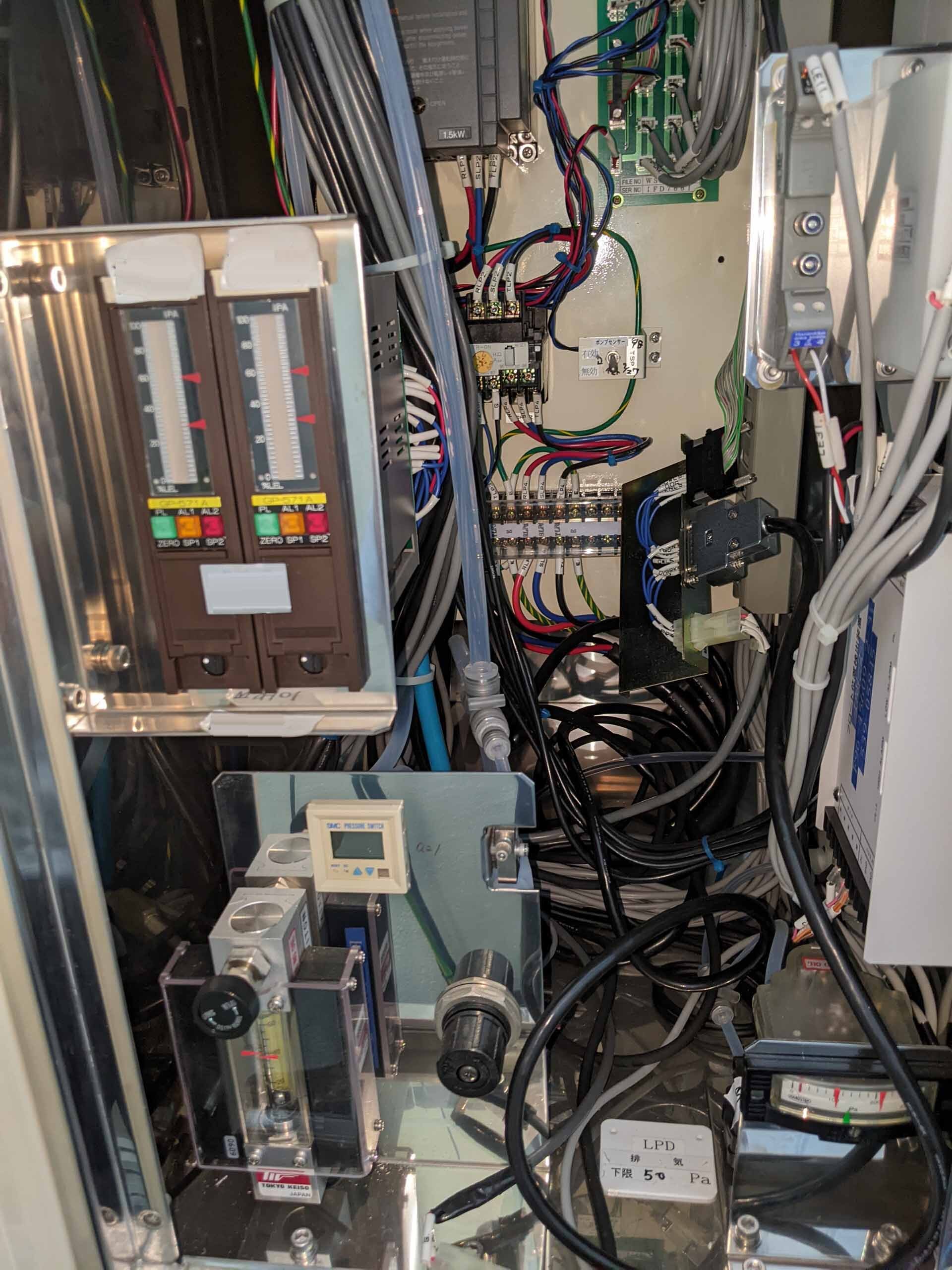

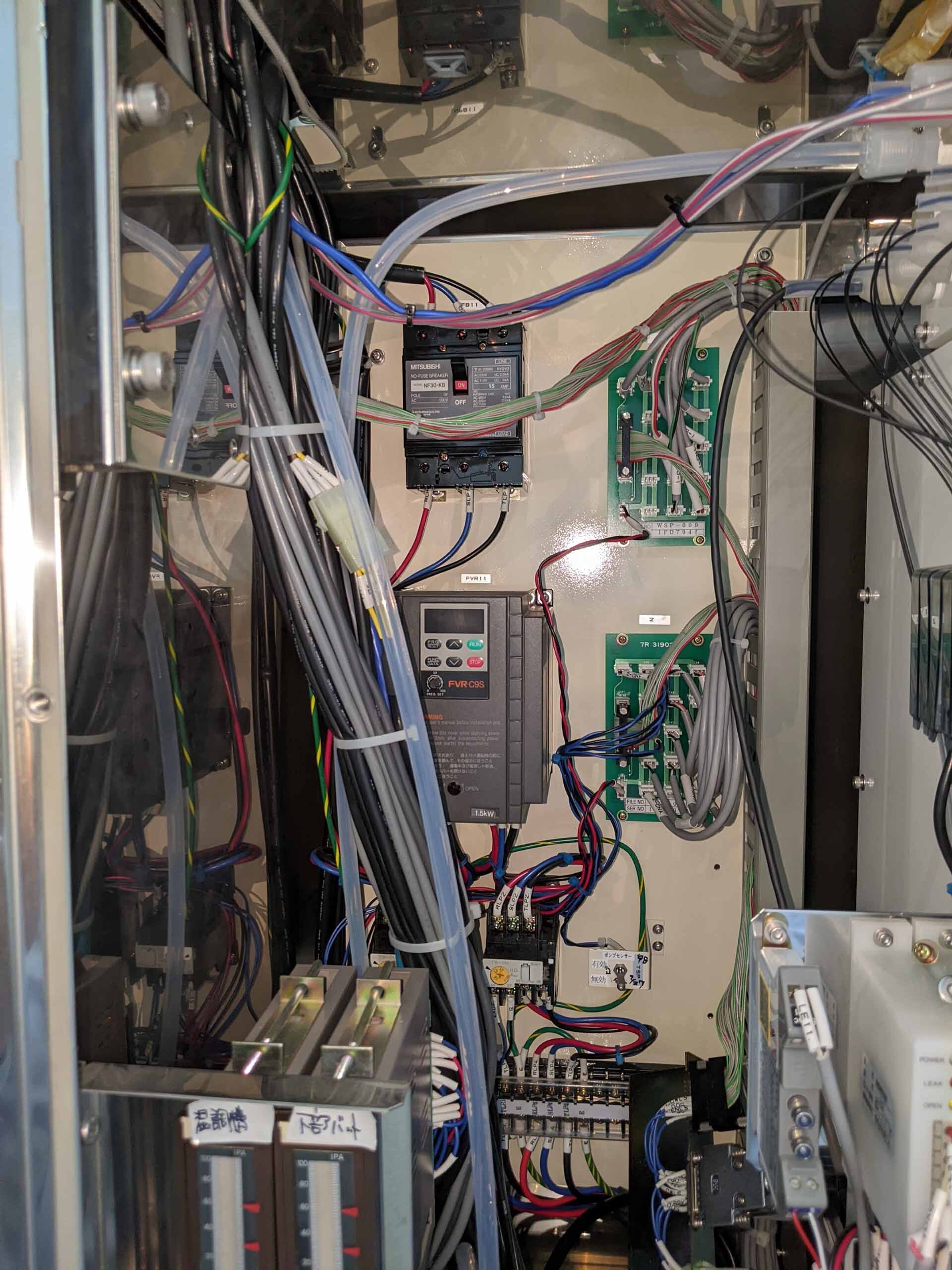

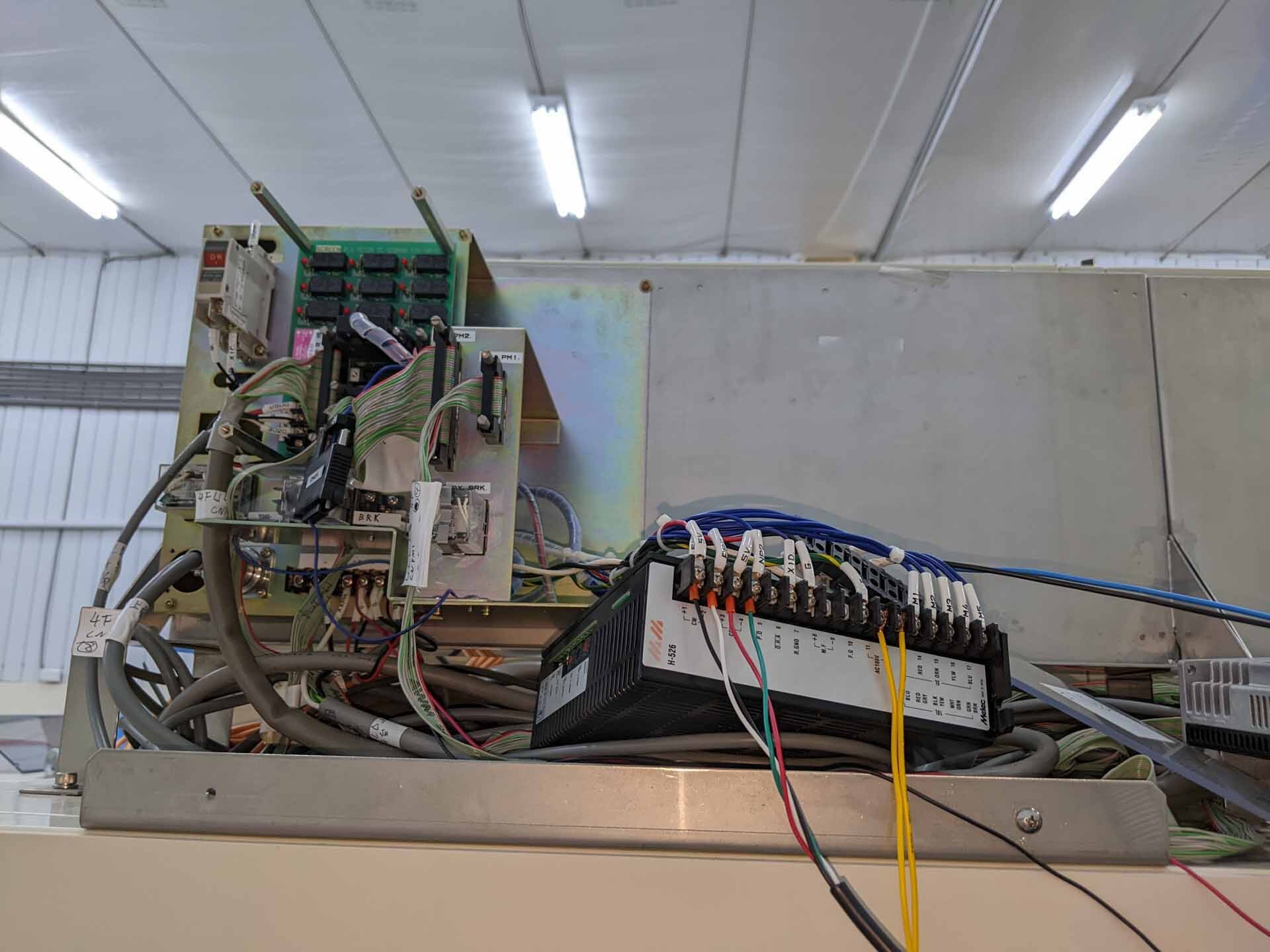

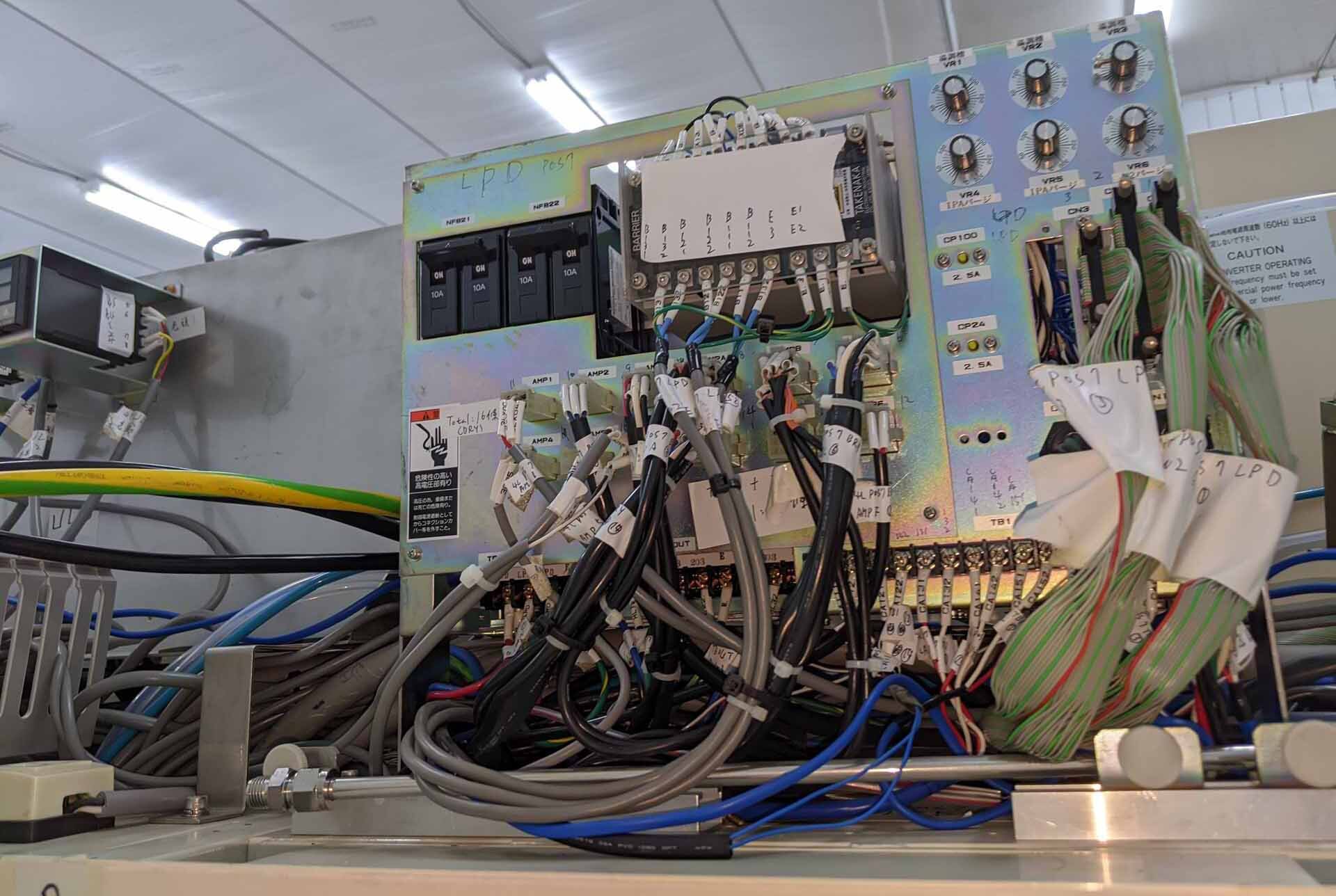

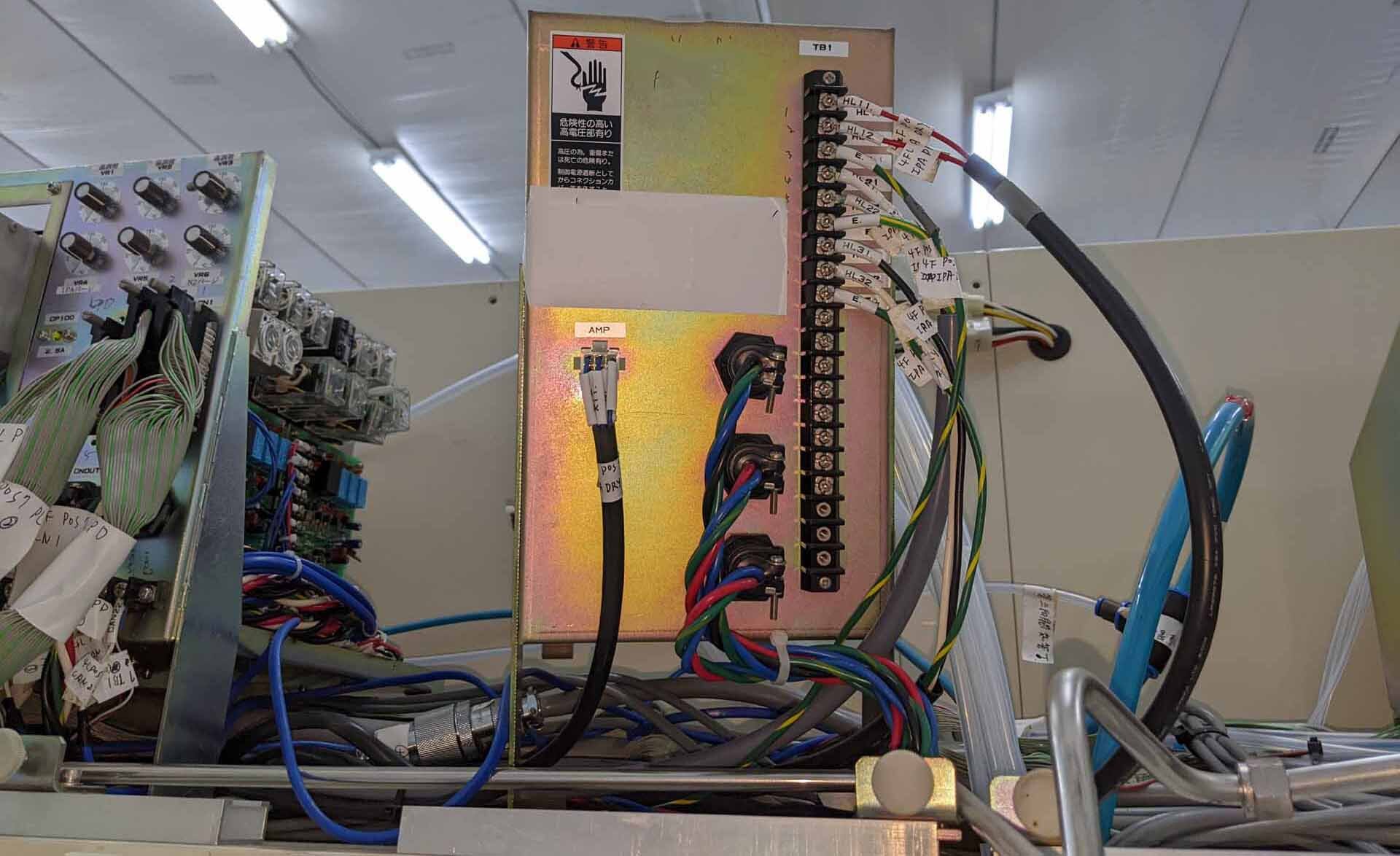

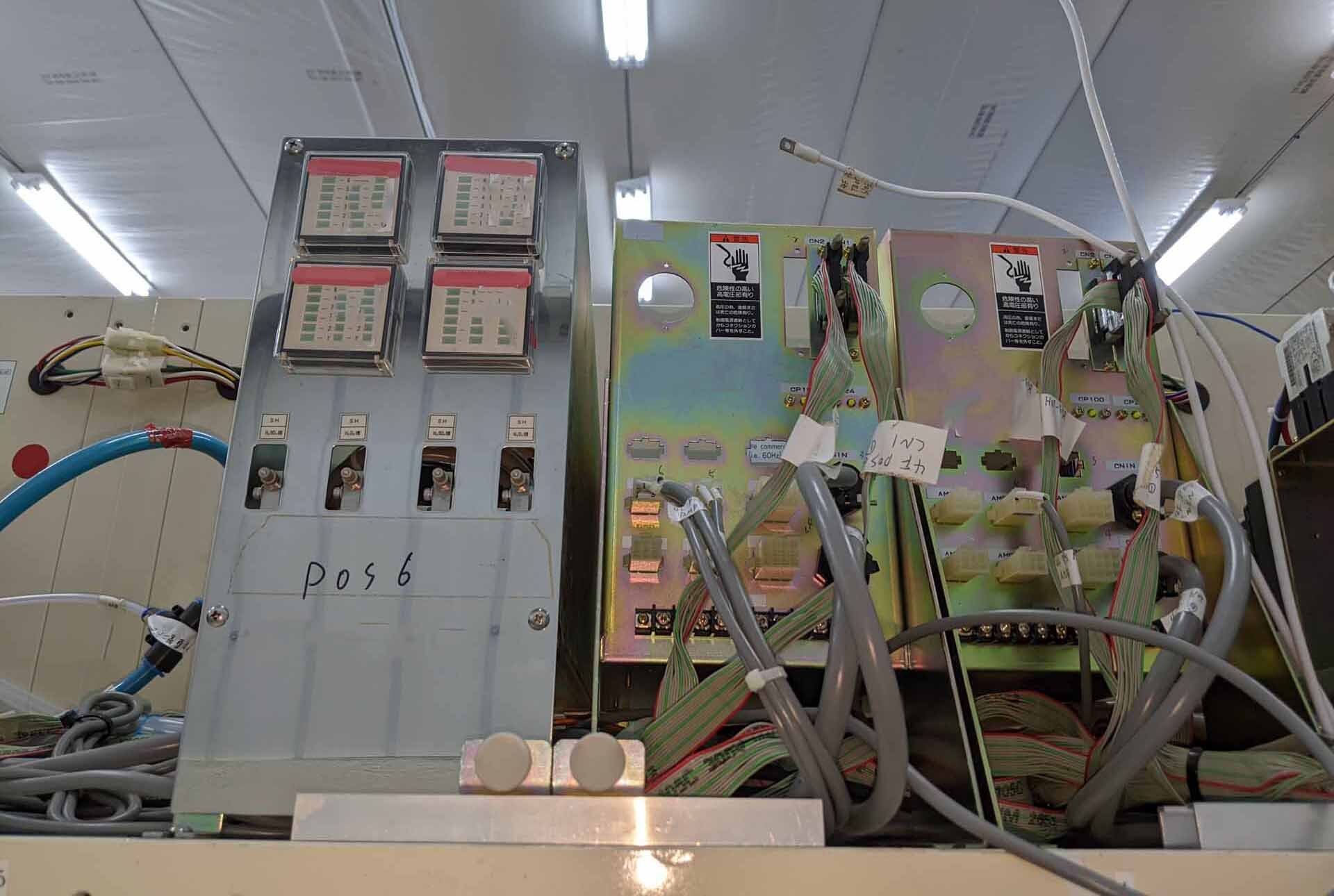

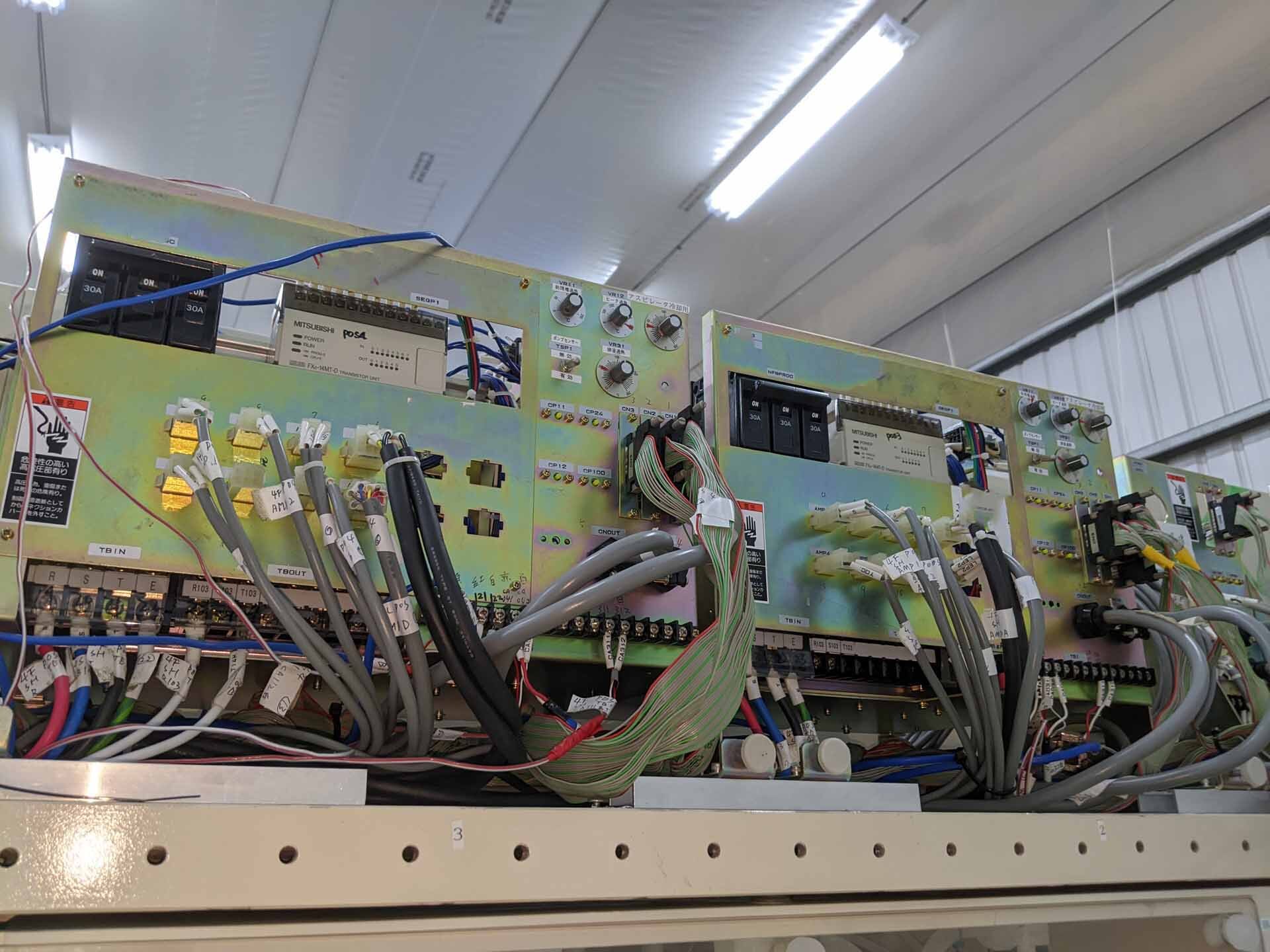

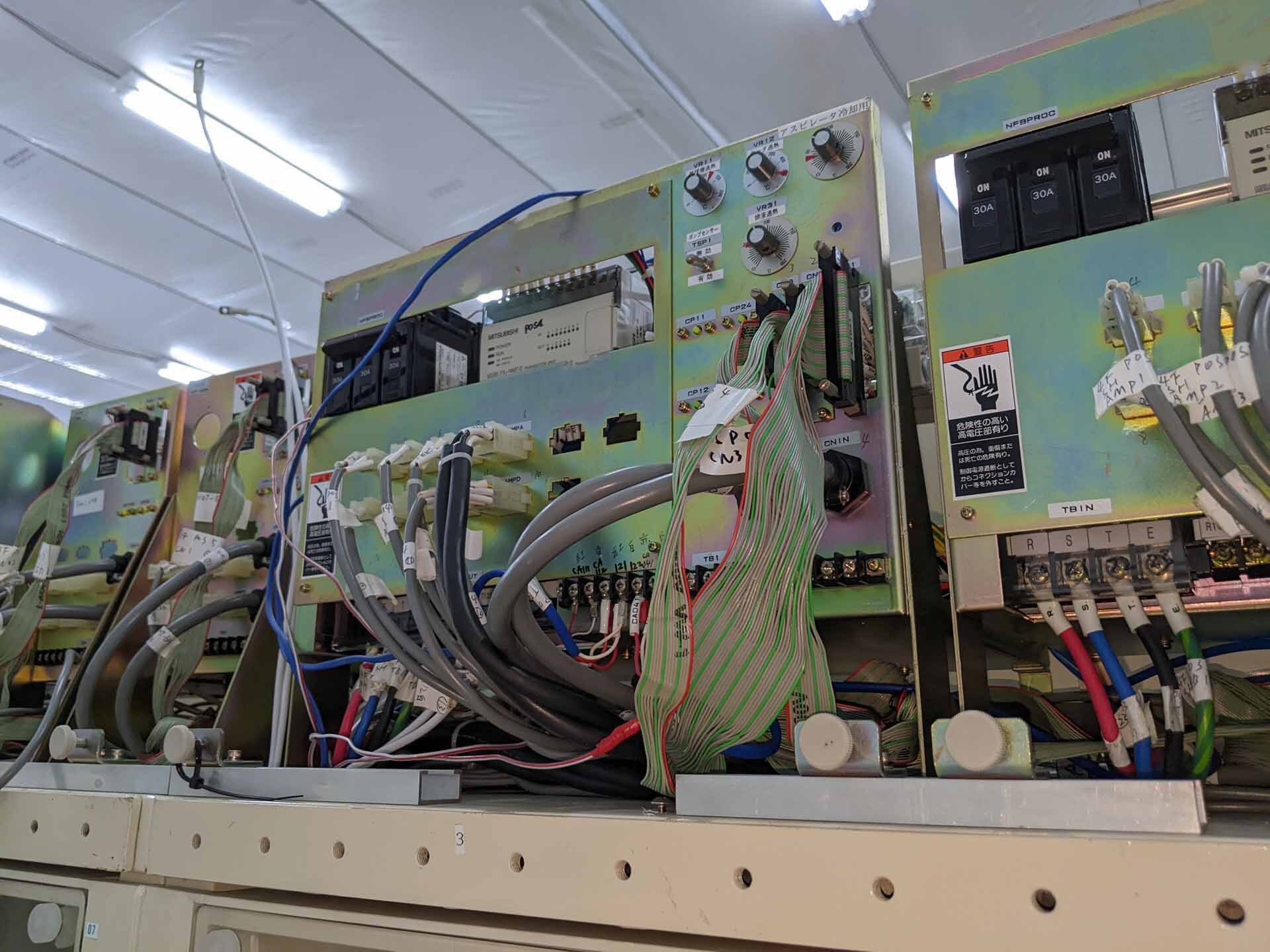

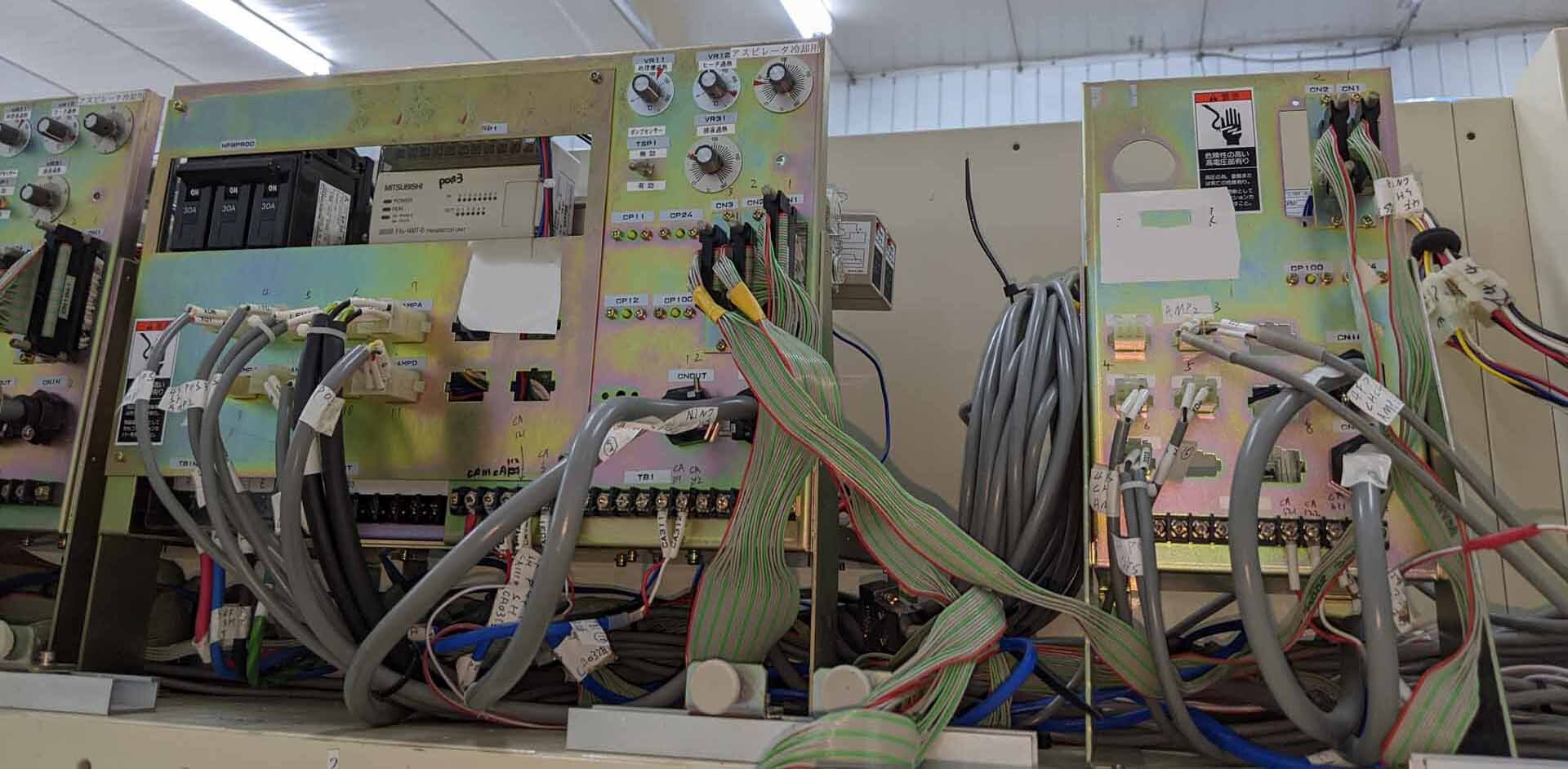

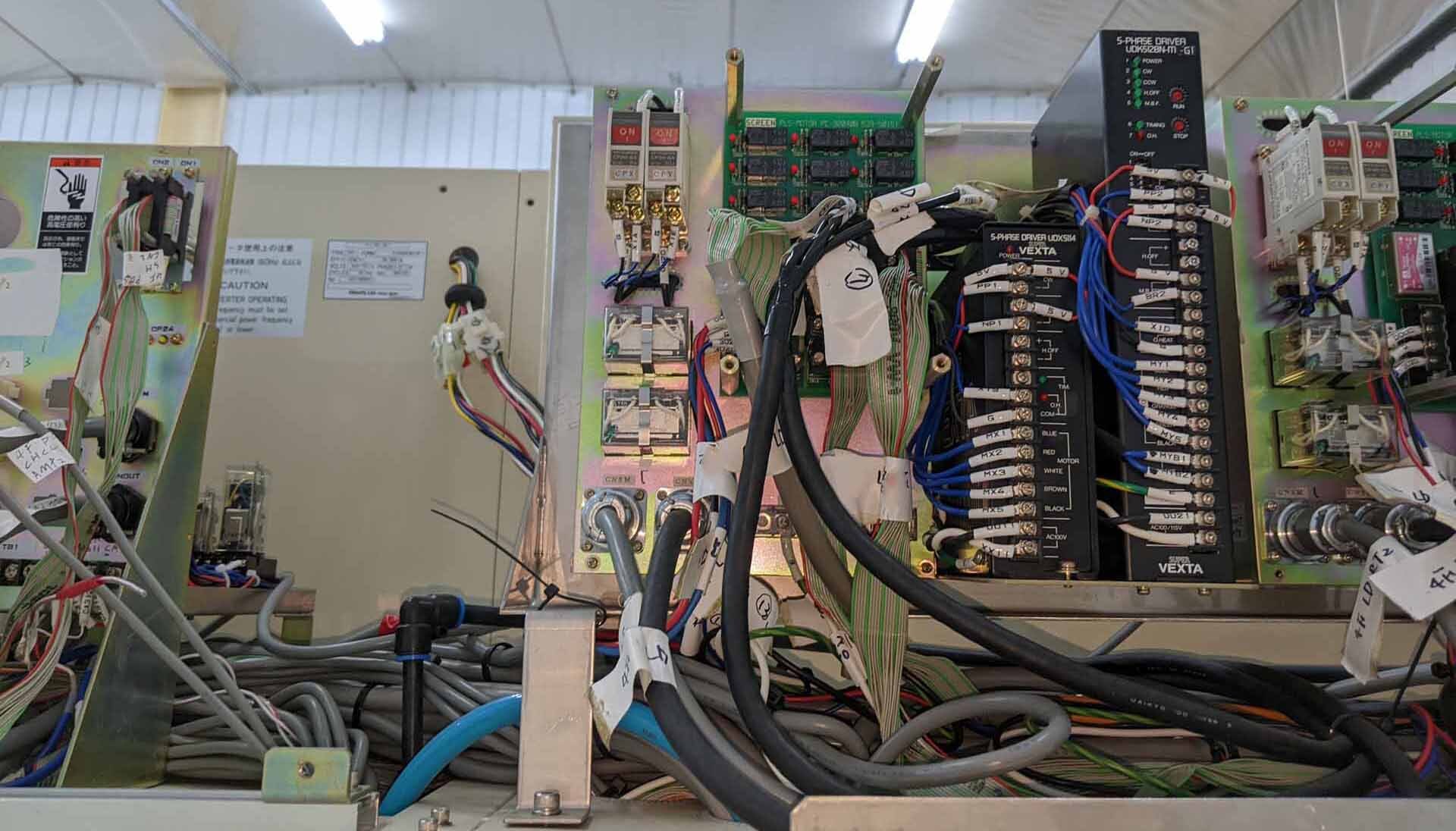

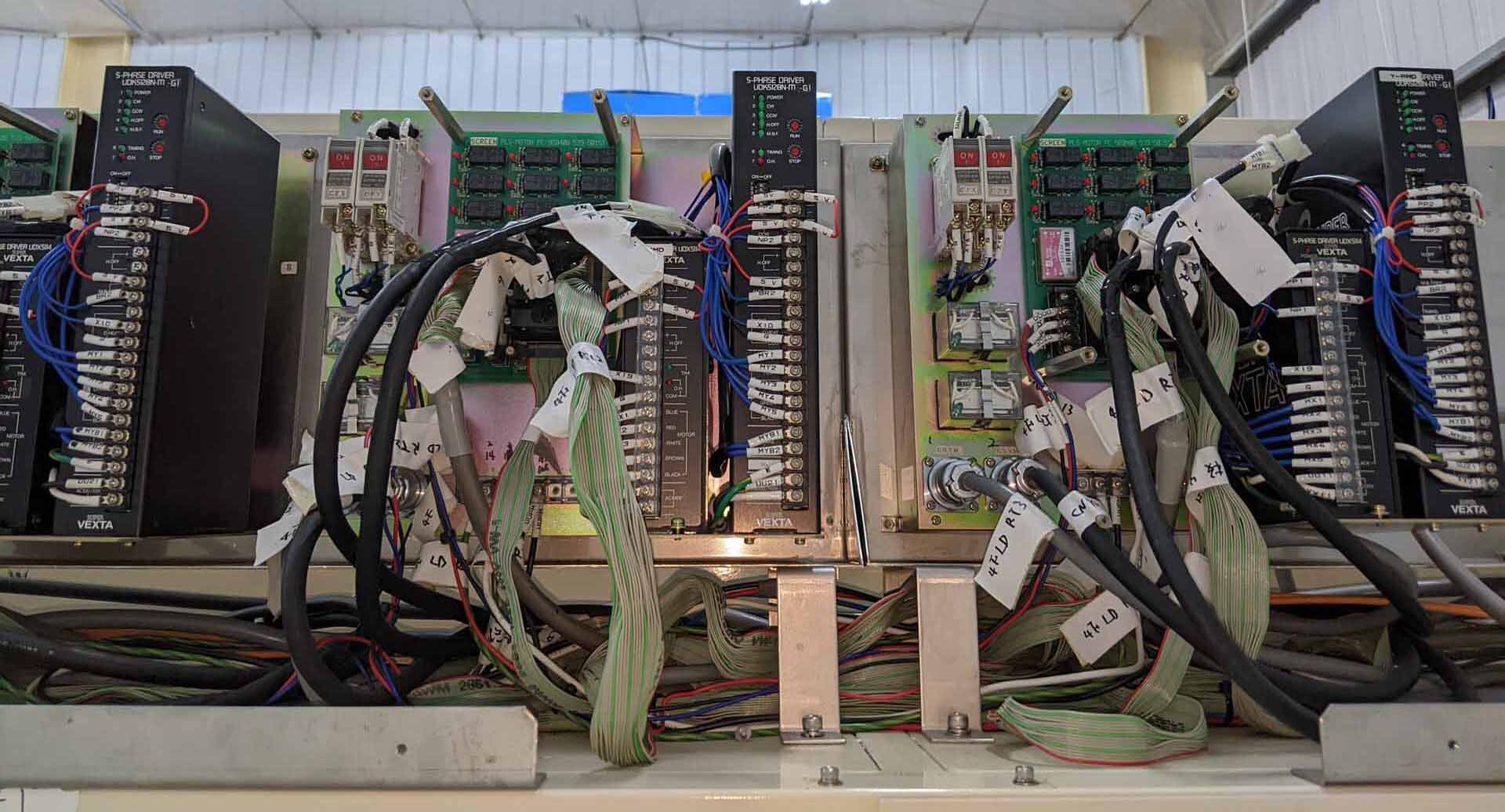

PLC Damaged

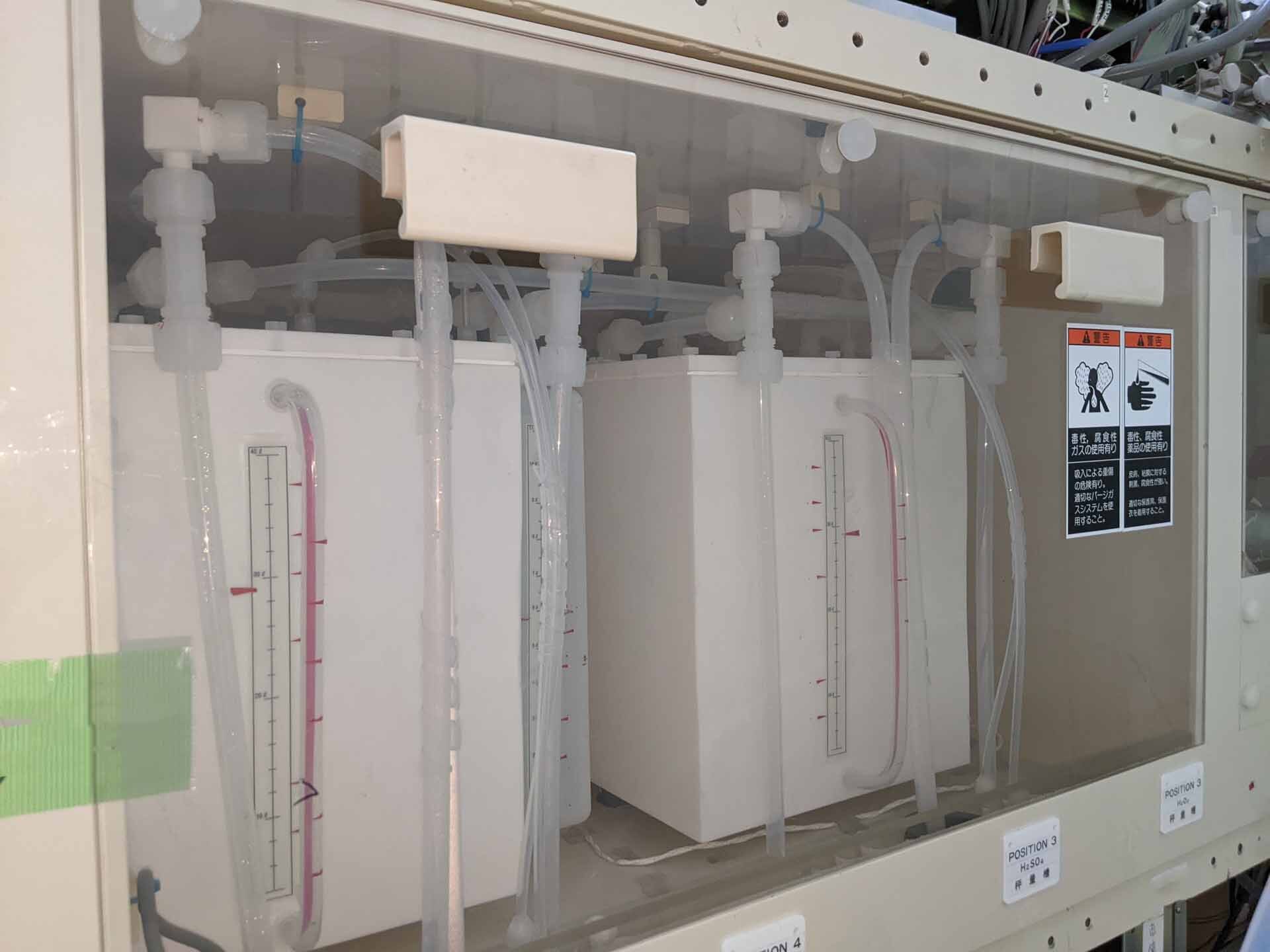

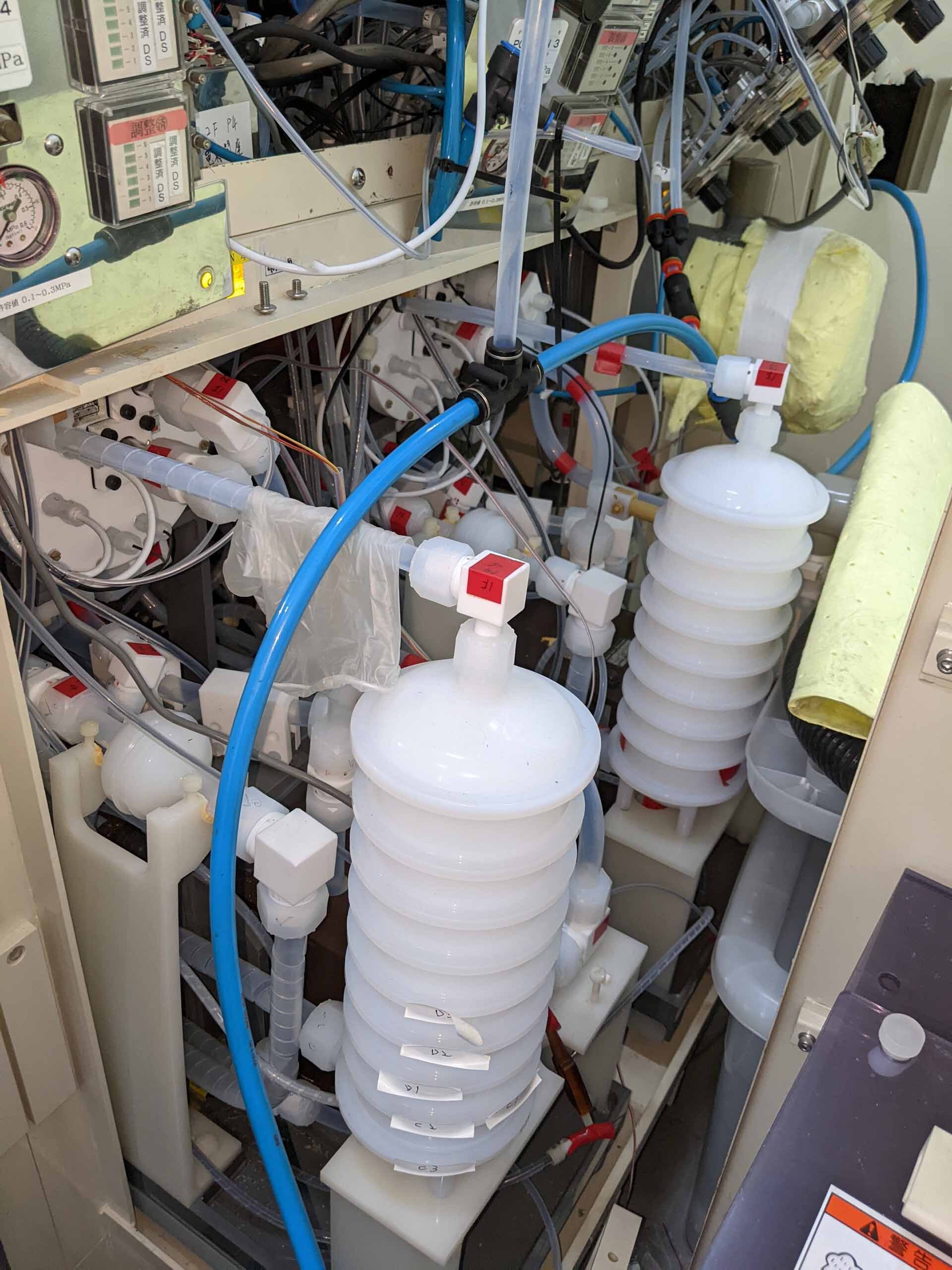

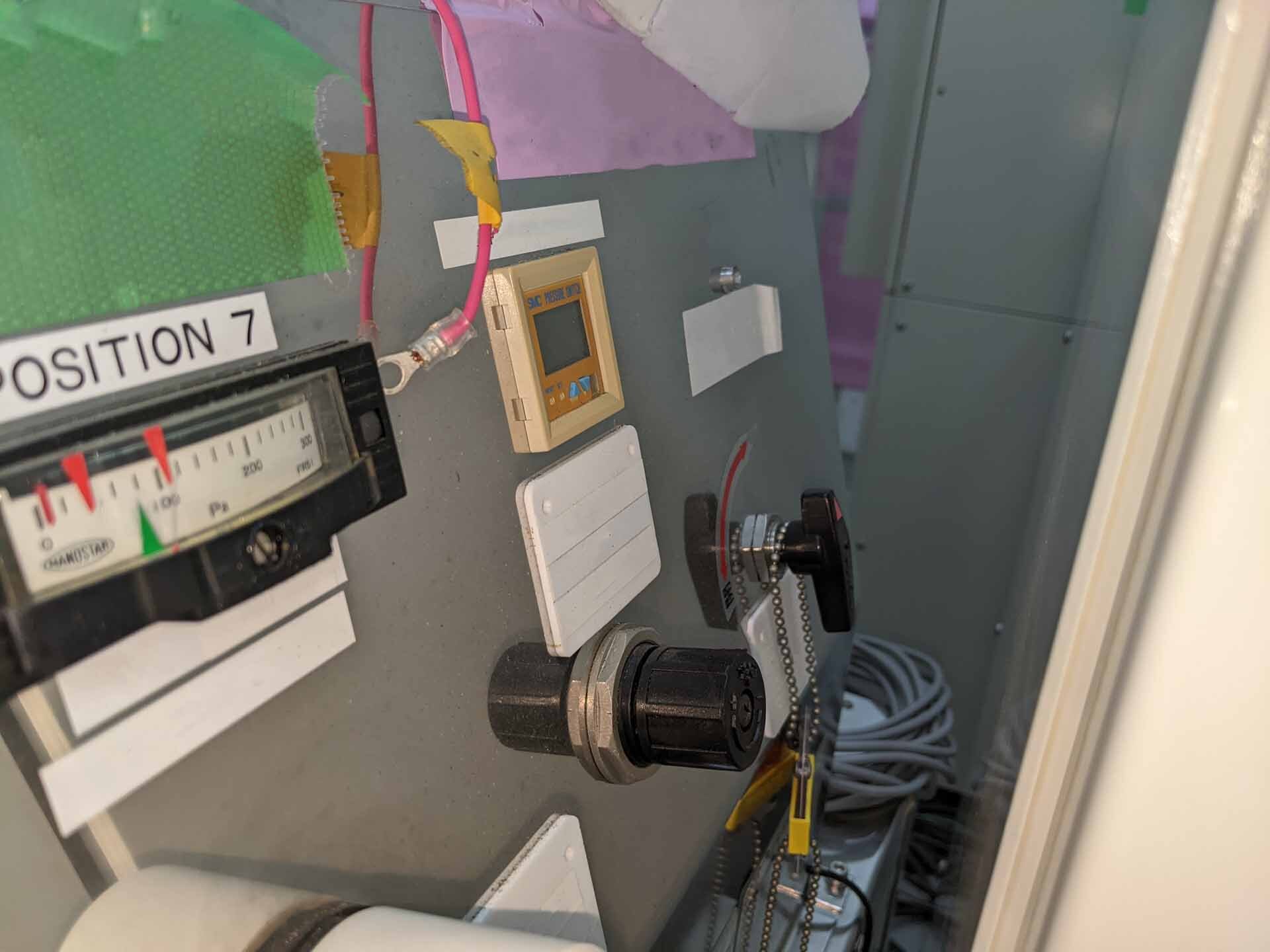

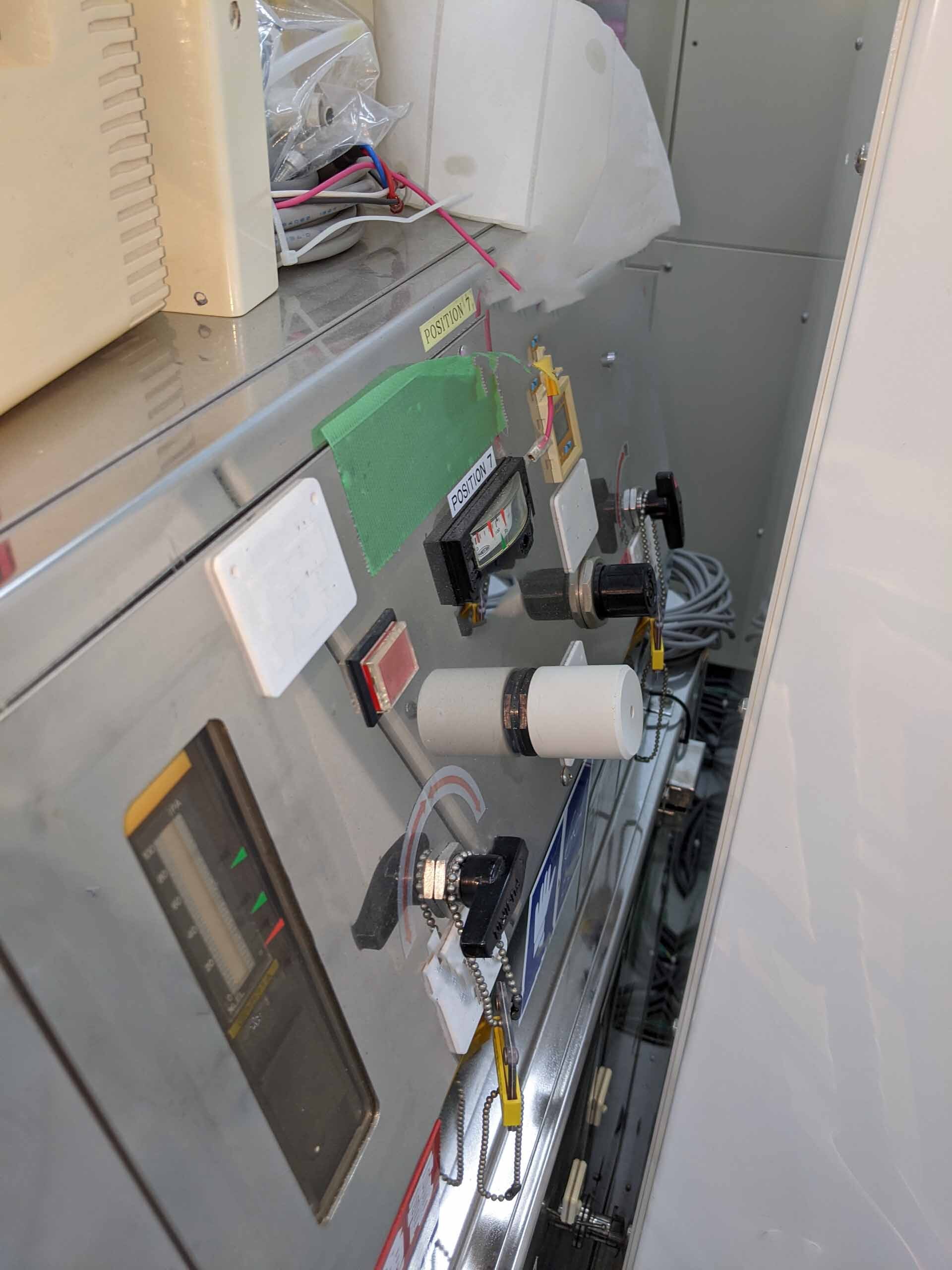

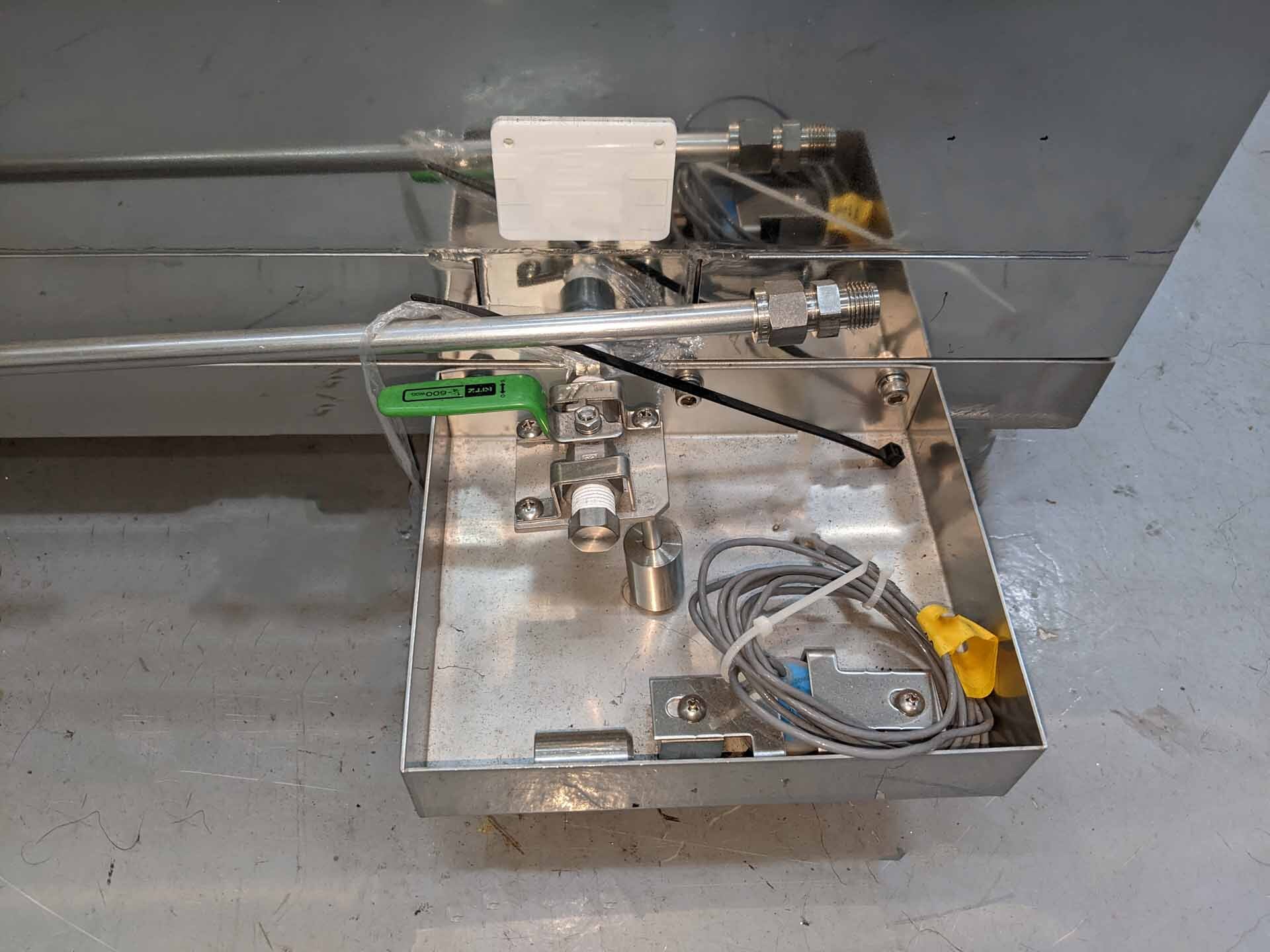

Acid tank

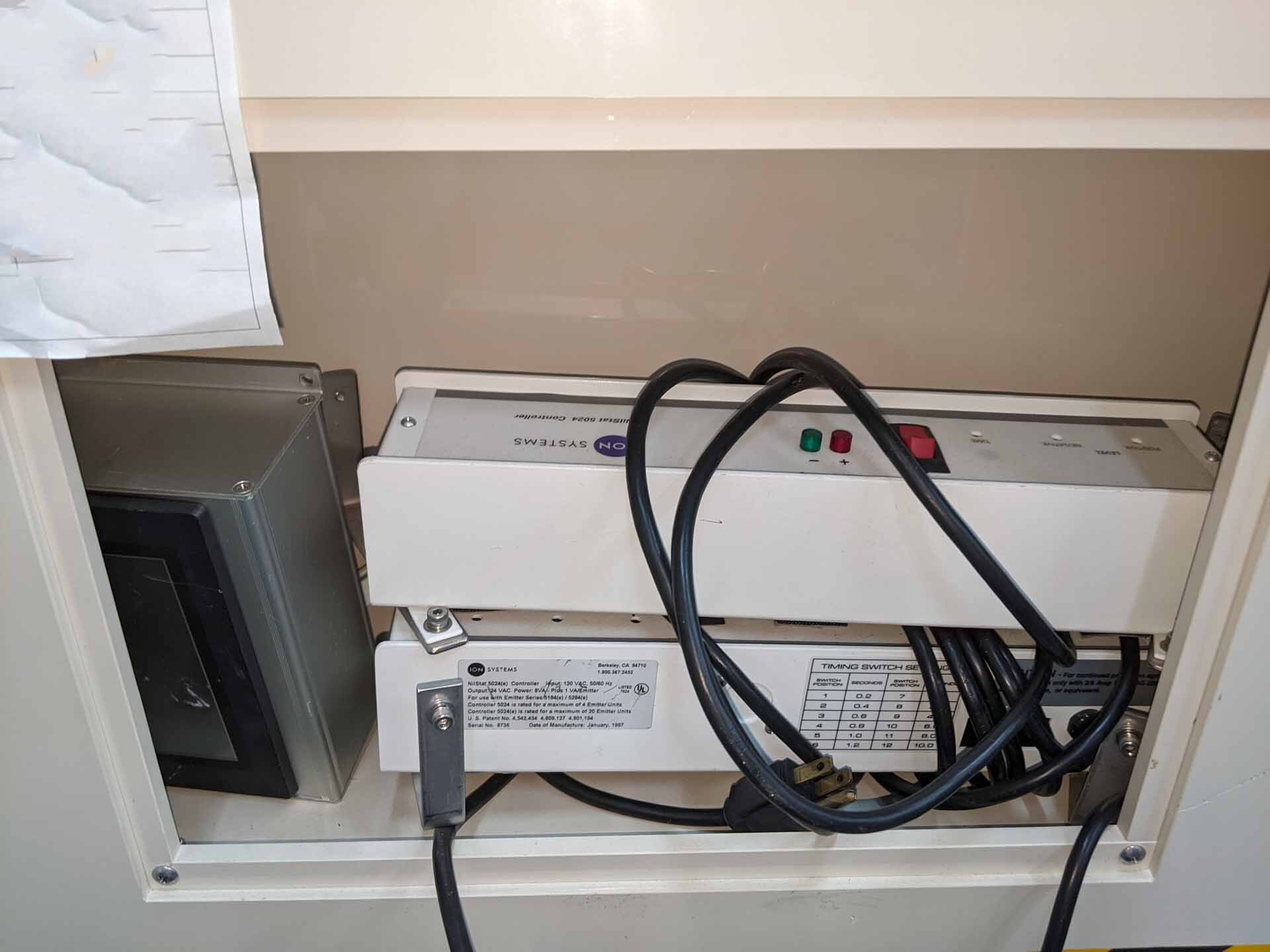

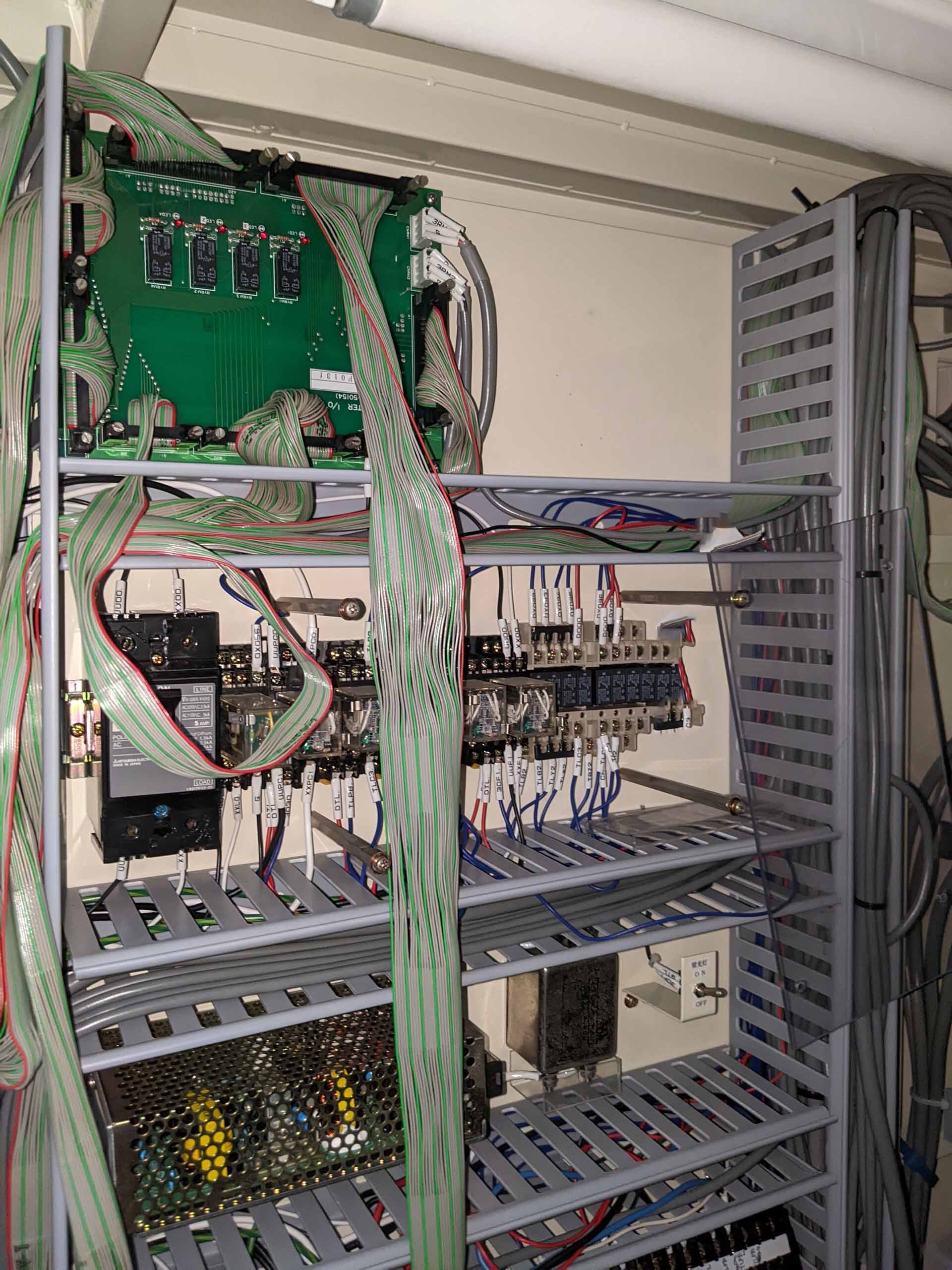

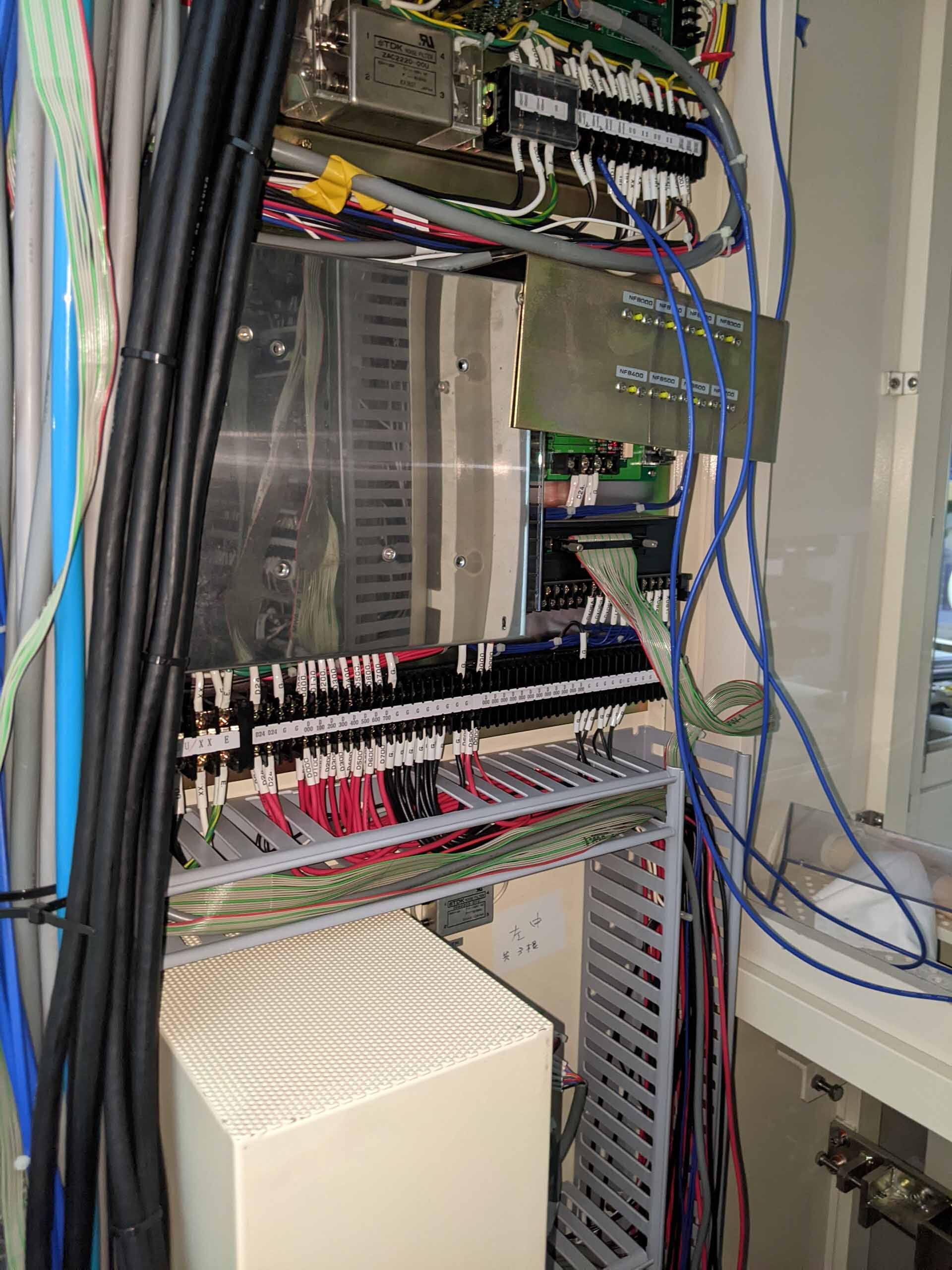

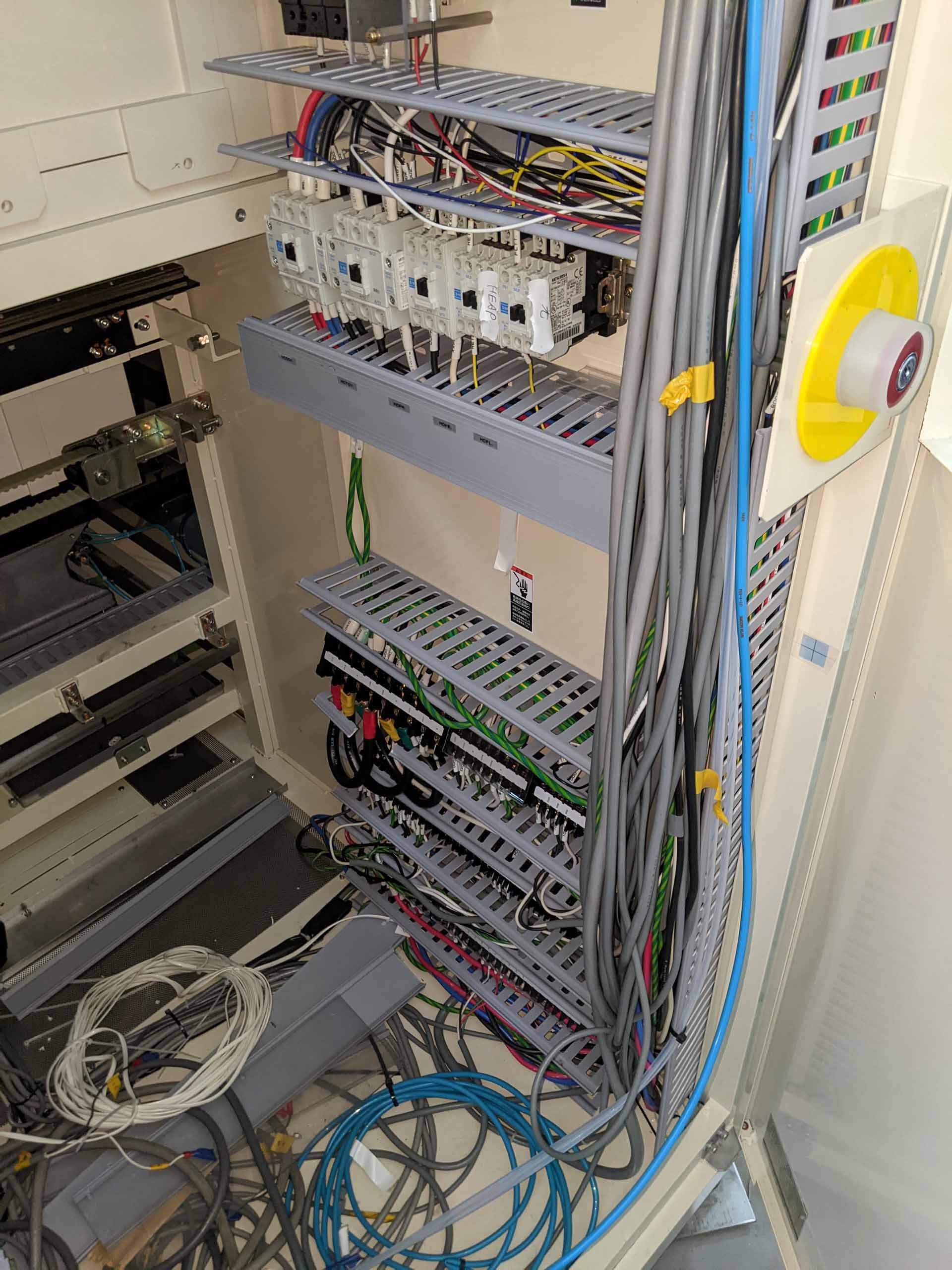

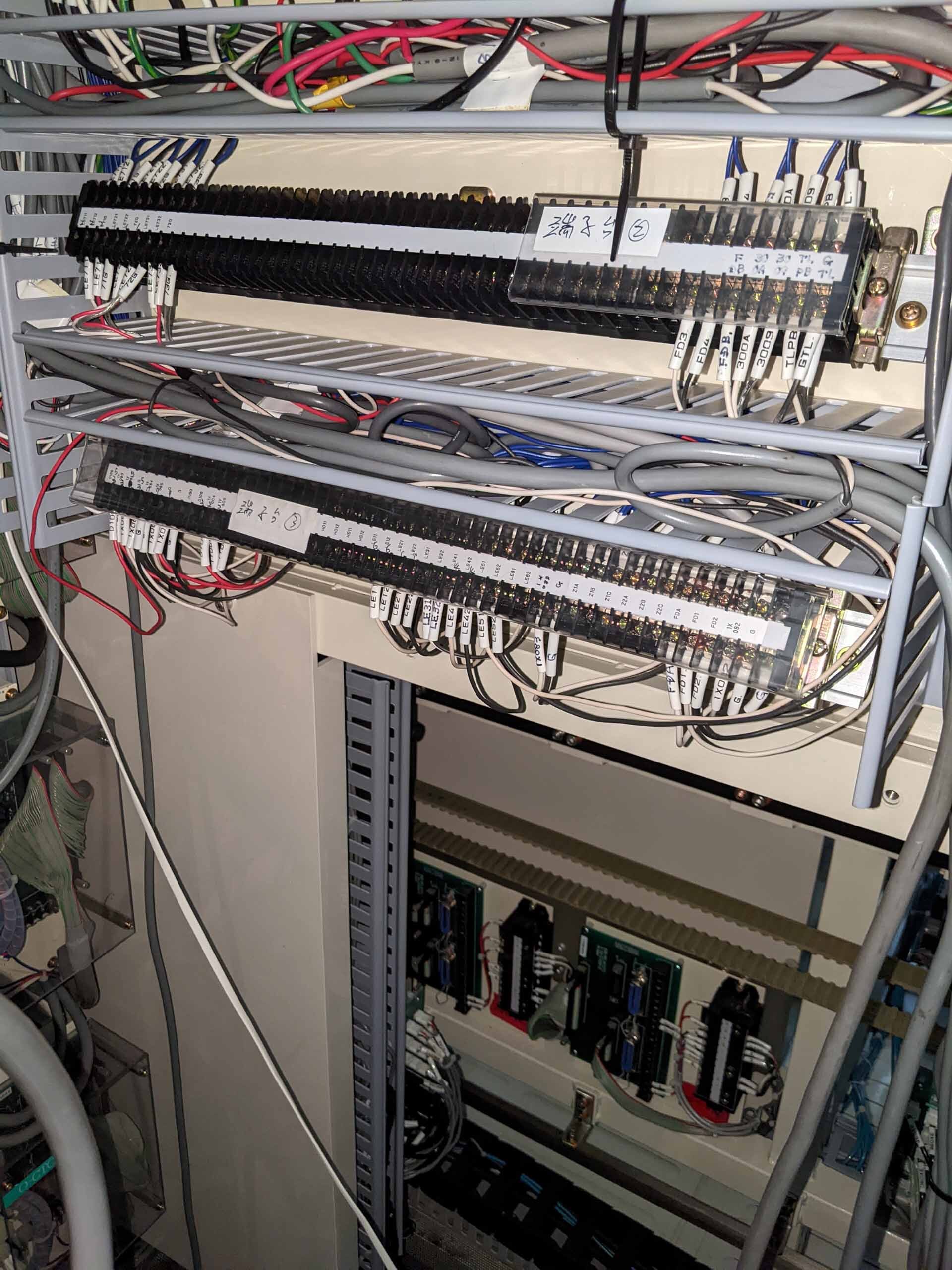

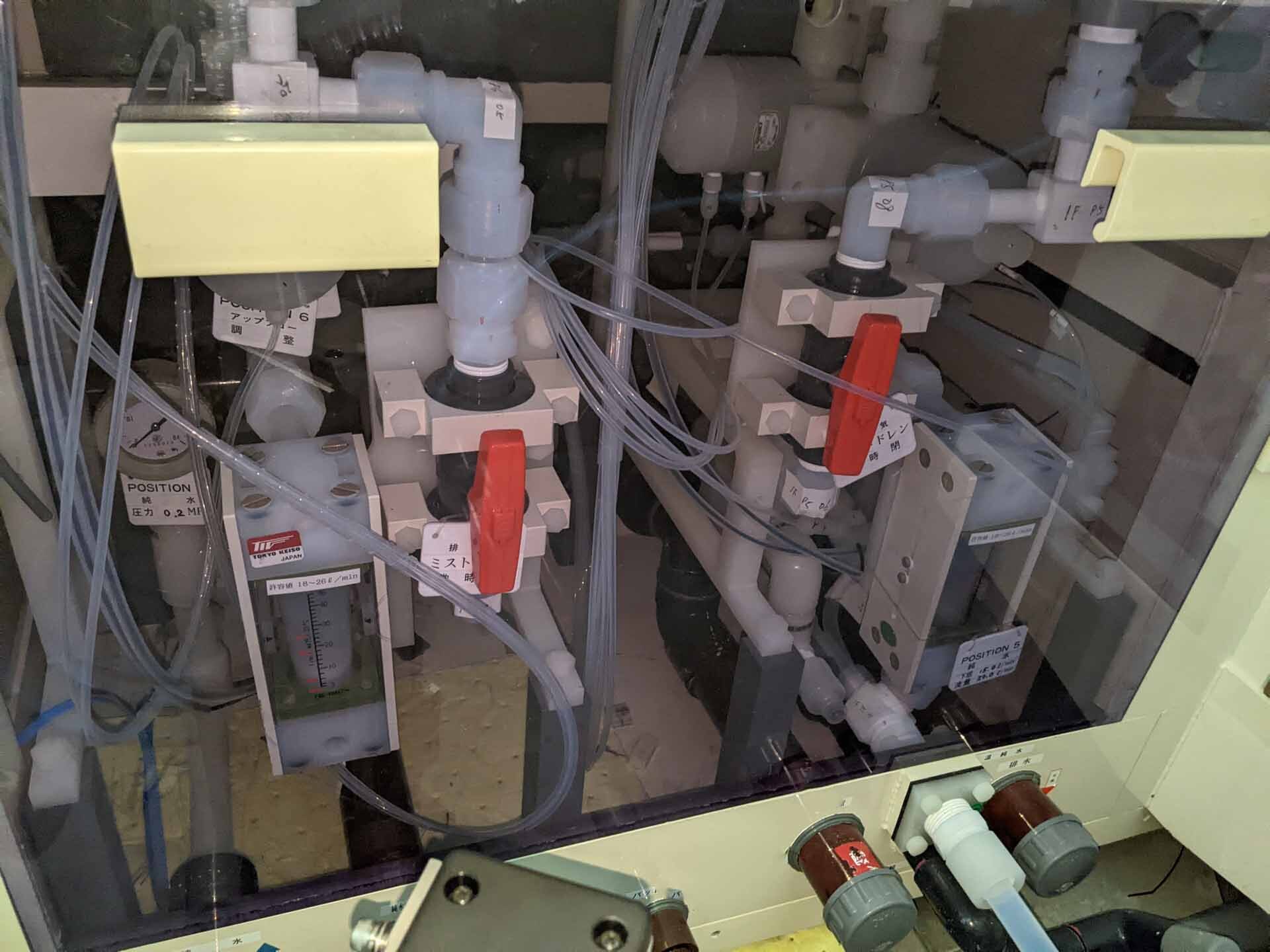

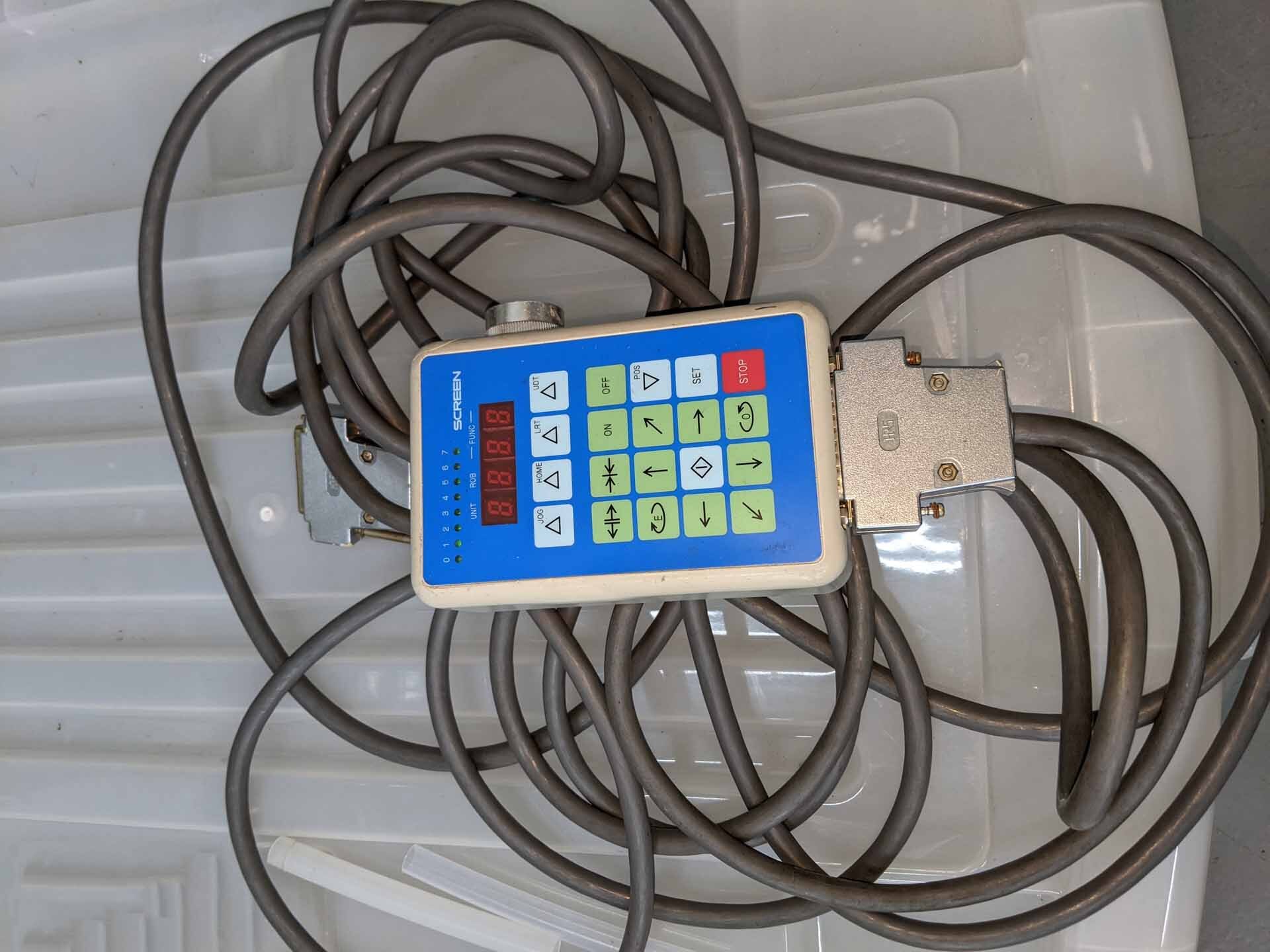

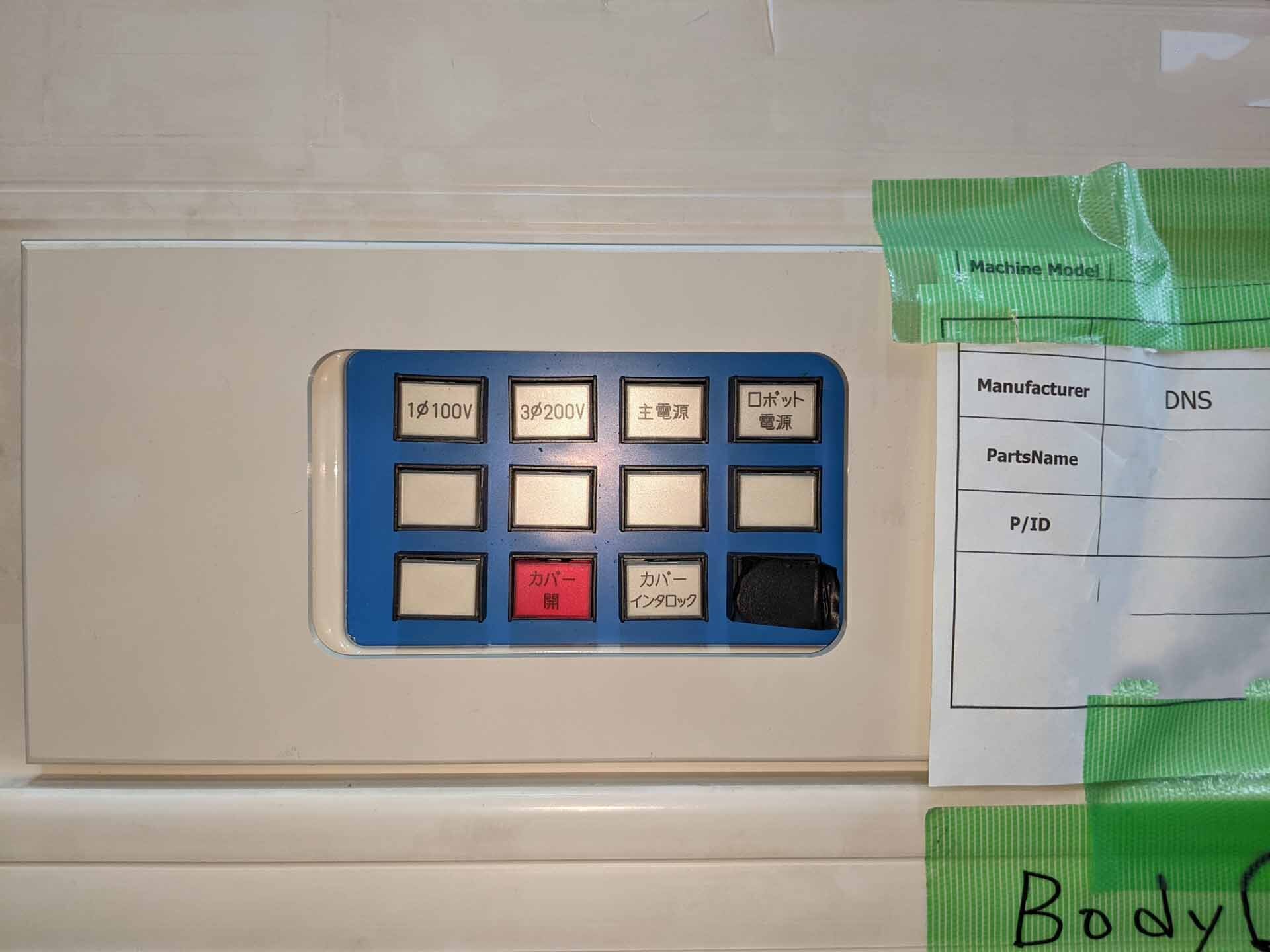

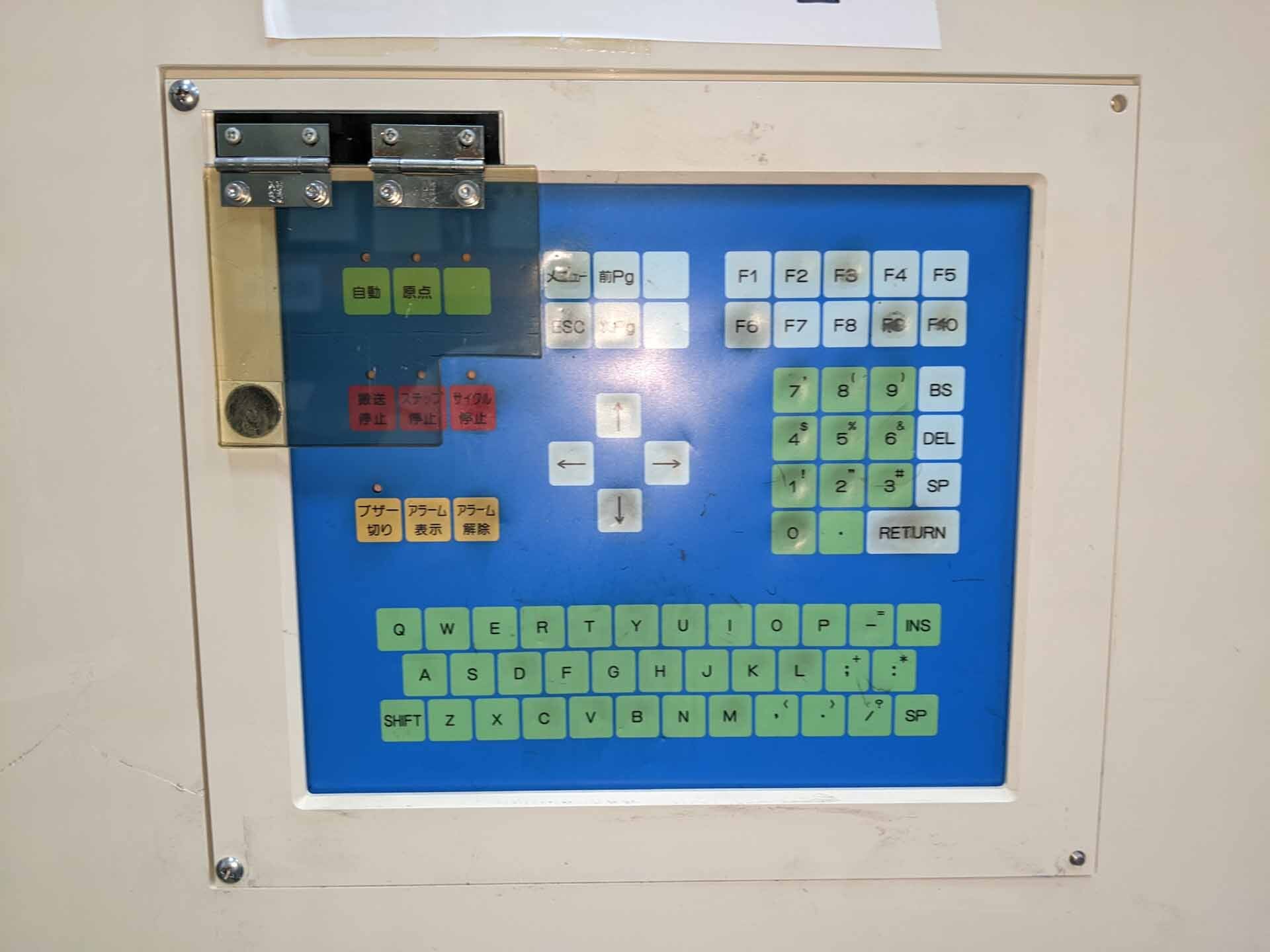

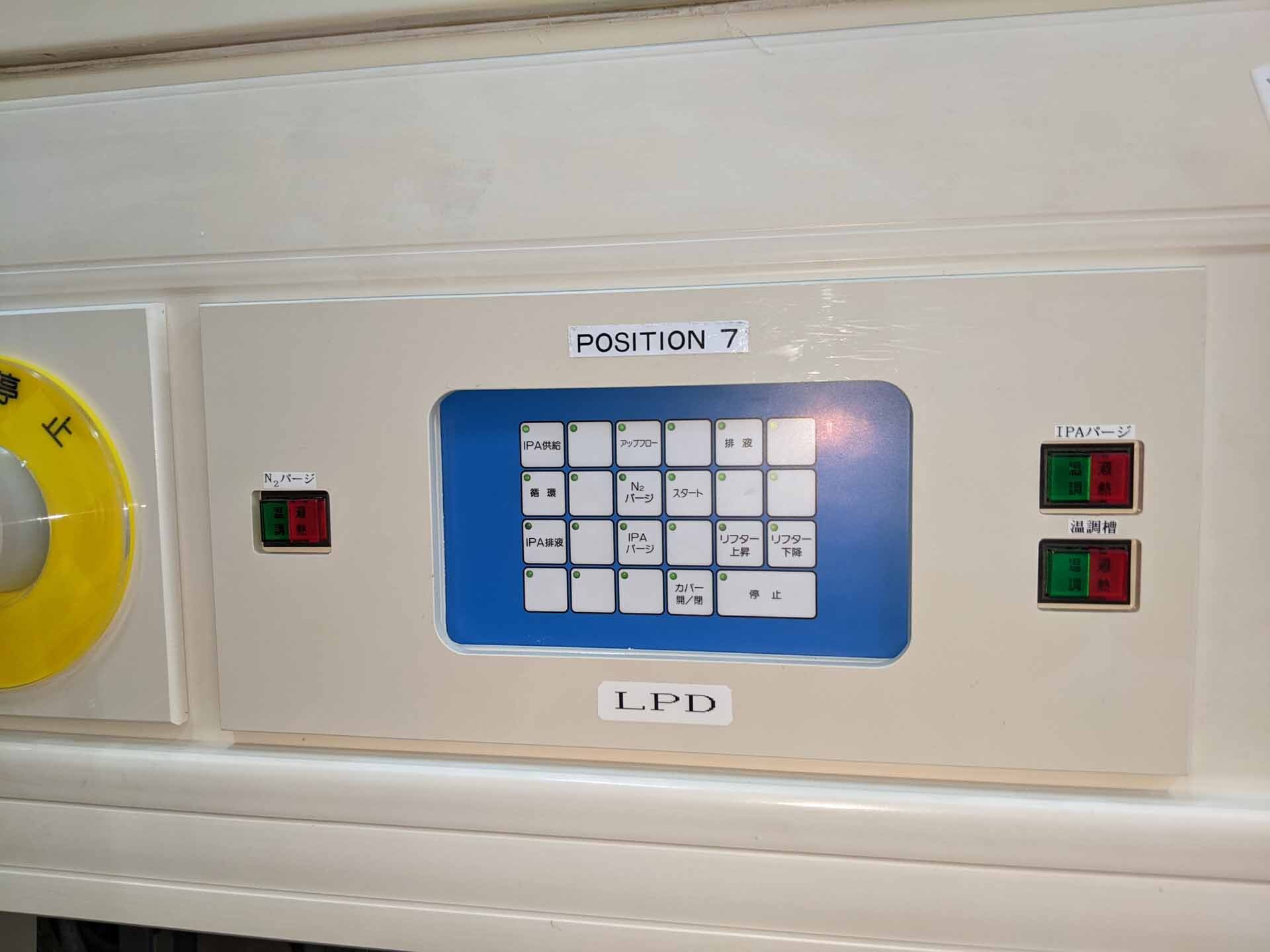

Controller

QUARTZ

1997 vintage.

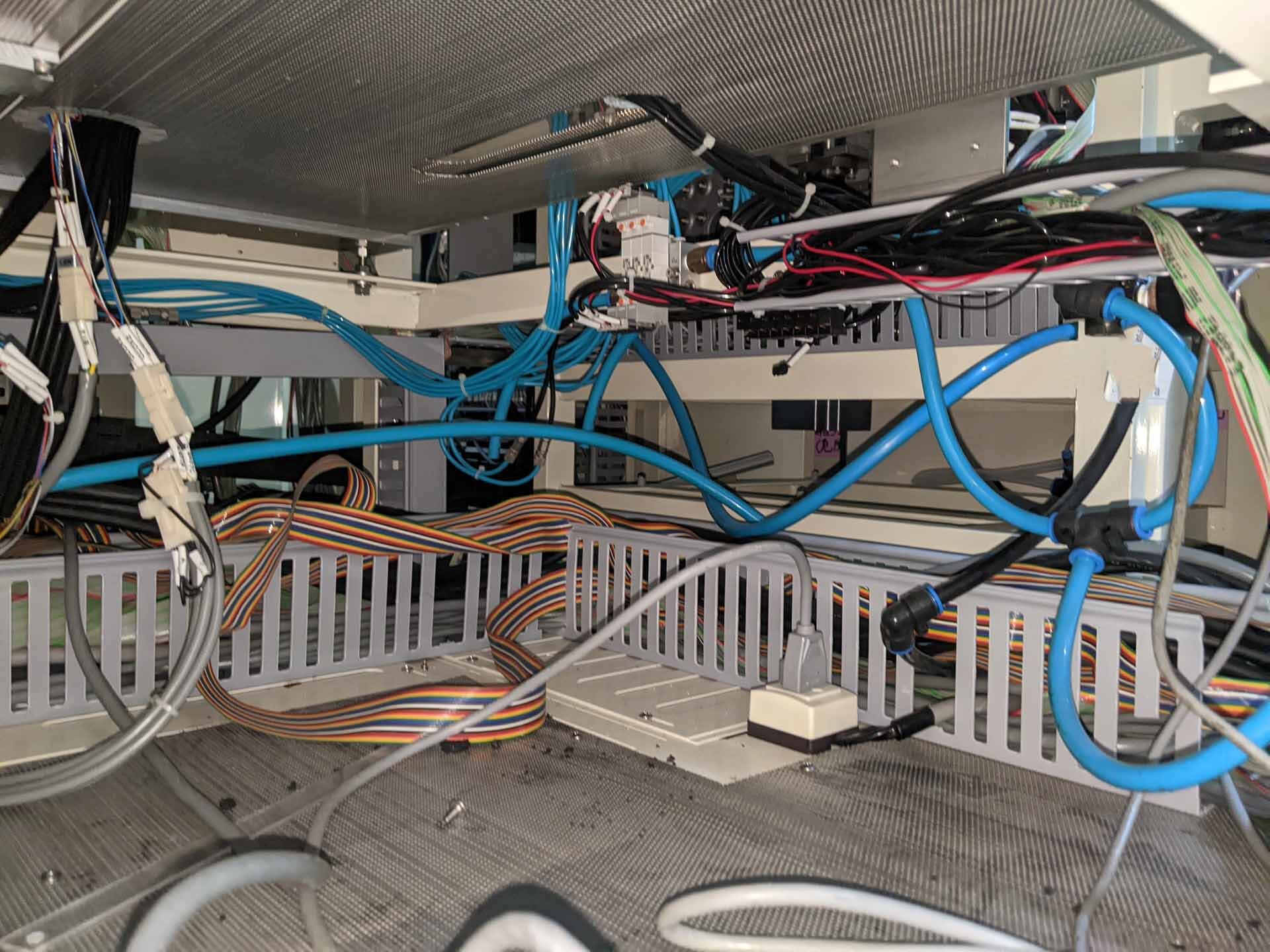

DNS / DAINIPPON / SCREEN WS-820L Wet Station is a multifunctional, high-precision automated wet-process box used in semiconductor photolithography and other processes. This equipment is designed to process semiconductor wafers through a range of different chemical treatments with precise accuracy. It is composed of a main cabinet unit and four attachment option cabinets. The main cabinet contains twelve independent chemical container/process systems, each configured with either a cassette system or an integrated chemical supply unit. These processes can include wet etching, ashing, and cleaning. Additionally, the machine includes a chemical reclaim tool, a unit for storing and managing chemical sludge, as well as a built-in control asset and a touch-panel display. DNS WS-820L also offers a wide range of functions to ensure efficient and accurate operation. It has the capacity to process up to eighteen 300 mm wafers simultaneously and can accommodate a variety of chemicals up to a liter in quantity. It has an alarm that warns about potential leakage and offers a variety of protection modes to prevent chemical exposure in case of a spill. Additionally, the touch-panel display allows for easy operation and visualization. Its safety features include interlocks and sensors that prevent accidental opening of the chemical container lid and the lid of the process bath. SCREEN WS-820L also has several control functions that ensure accuracy and stability. It offers analog and digital inputs and outputs for connection to IC testers, data collectors, and other devices. It also has the ability to support up to thirty concurrent processes with custom recipes. Additionally, it can be connected to other cameras and image analysis systems. Overall, WS-820L Wet Station is a high-precision automated wet-process box designed to efficiently and accurately process semiconductor wafers through etching, ashing, and cleaning processes. It features a variety of functions including a reclaim model, a control equipment, and a touch-panel display, as well as safety features. Additionally, it offers analog and digital inputs, outputs, and the ability to support thirty concurrent processes with custom recipes.

There are no reviews yet