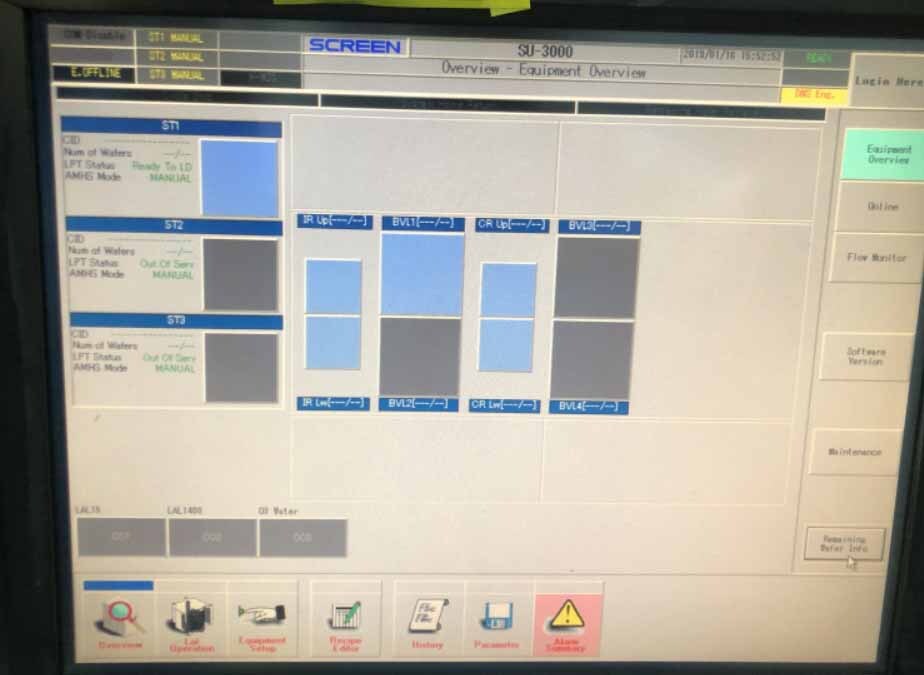

Used DNS / DAINIPPON SU-3000 #293657475 for sale

URL successfully copied!

Tap to zoom

ID: 293657475

Wafer Size: 12"

Vintage: 2006

Wafer cleaners, 12"

System-1:

Process: Poly

Gases: H2SO4, H2O2 and DHF (1:100)

System-2:

Process: Oxide

Gases: HF/DHF

Chemical Cabinet:

Chemical cabinet type: Low temperature control

Gasses: LAL 1400 / HF / DHF

Temperature range: RT- 50°C ± 0.5°C

Method of mixing chemical HF and DIW: Level sensor

CM-210-CE-HORIBA Concentration monitor

MYKROLIS QCDV ATX TH Filter, 10"

Does not include feedback control

(3) SHINKO DENKI SELOP3 Load ports

YASUKAWA XU-RC350D / XU-ACT153L Indexer robot

With OHT

YASUKAWA XU-RC615L Center robot

(4) Multi process chambers

Wafer chucked

With (6) movable pins

Power supply unit

2006 vintage.

DNS / DAINIPPON SU-3000 wet station is a state-of-the-art device used to quickly and cleanly remove excess solder from printed circuit boards. It offers fast, efficient, and precise solder removal without damaging the sensitive components and circuitry of the printed circuit boards. DNS SU-3000's design incorporates a combination of fluid injection via air pressure and the use of a rotating nozzle to create a pin-point stream of solder-dissolving liquid. The liquid is drawn up by a special pump, then pressurized and directed through the nozzle, which rotates at high speed to create a powerful, finely focused stream. The combination of high pressure and high velocity produces a kind of cavitation, a phenomenon which results in the disintegration of undesirable solder deposits. DAINIPPON SU 3000 features a digital controller, which allows users to accurately program their desired pressure level, rotational nozzle speed, and nozzle-pointing direction. The controller also features a processing monitor, which quickly and accurately determines the quantity of solder that needs to be cleared from the board. It is designed to eliminate mess due to drips and splashes of solder removal fluid and helps extend the solder nozzle life. To ensure that DNS SU 3000 remains safe to operate, it is equipped with a self-diagnosis equipment which can detect problems and relay the results via a graphic interface on the LCD screen. It also features an LED warning system that flashes when the unit is unsafe to use, thus helping protect users from potential exposure to hazardous levels of fluid. SU 3000 is designed for portability, as it requires no external power supply or ventilation machine. It also requires minimal maintenance, featuring a unique three-step cleaning process that helps keep it in pristine condition. Furthermore, the device is equipped with several protective features such as an electronic lock and tamper-proofing tool that prevents unauthorized access. In short, DAINIPPON SU-3000 wet station is a high-end device that is designed to offer users a fast, efficient, and precise way of clearing excess solder from printed circuit boards. It utilizes a combination of fluid injection and a rotating nozzle to create a powerful stream that instantly dissolves undesirable deposits. With its digital controller, processing monitor, and automated self-diagnosis asset, DNS / DAINIPPON SU 3000 is the perfect choice for anyone who needs a reliable and easy-to-use soldering solution.

There are no reviews yet